CFD Simulation for the Propulsion Performance in Cross-Medium Robot

-

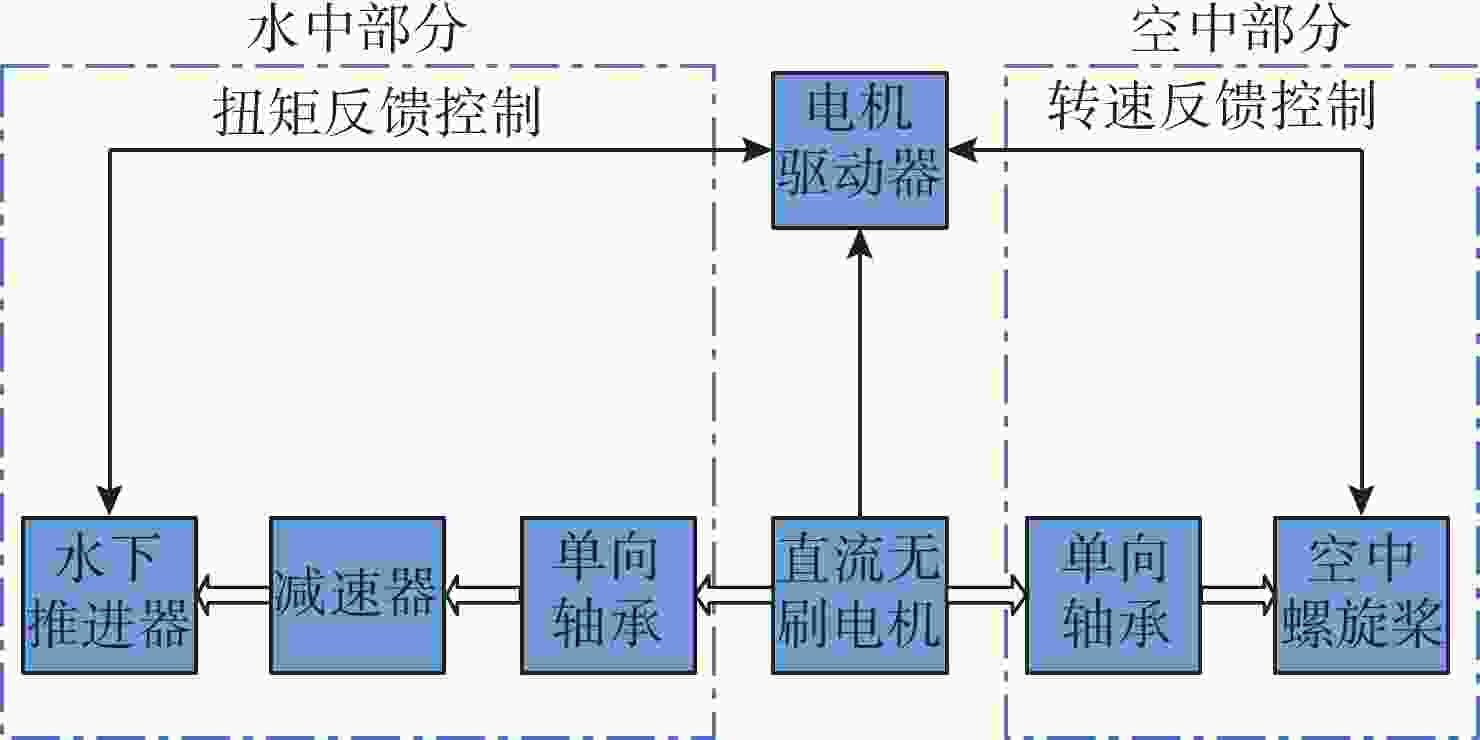

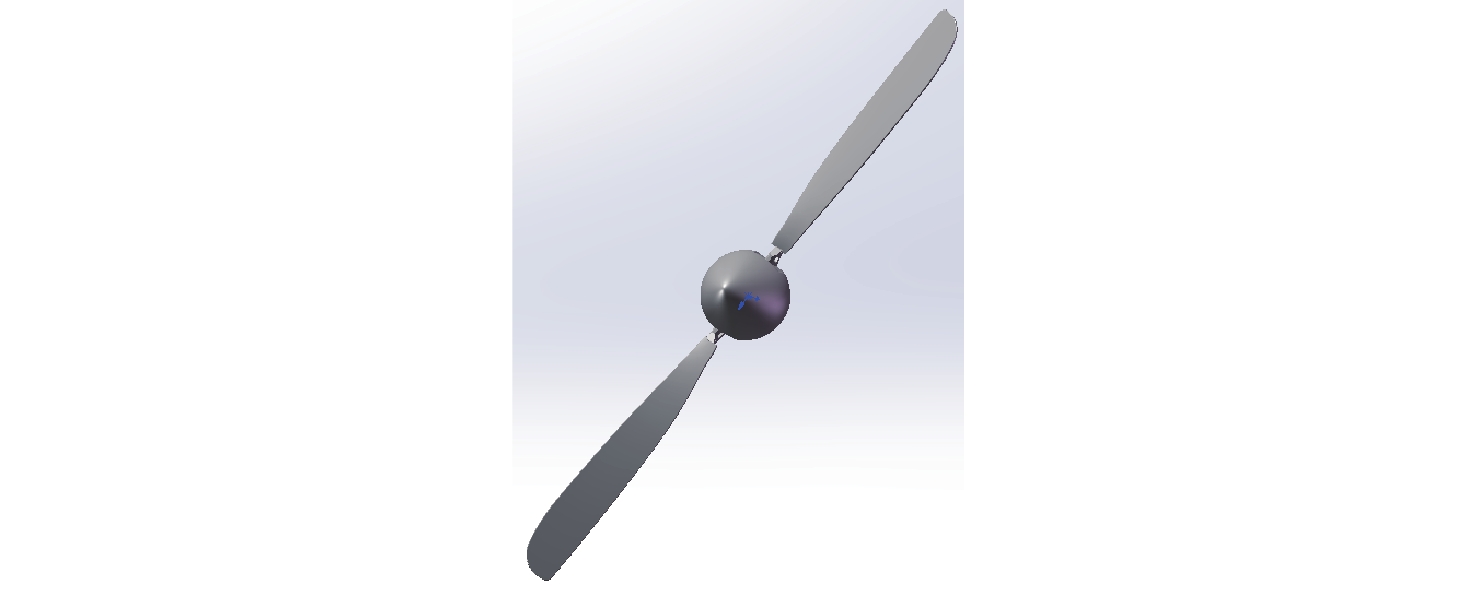

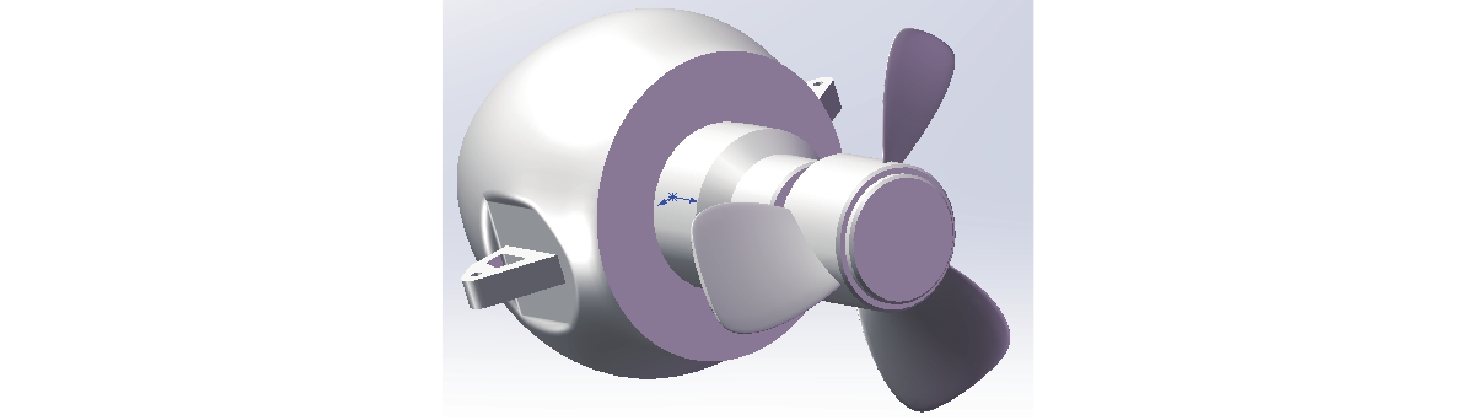

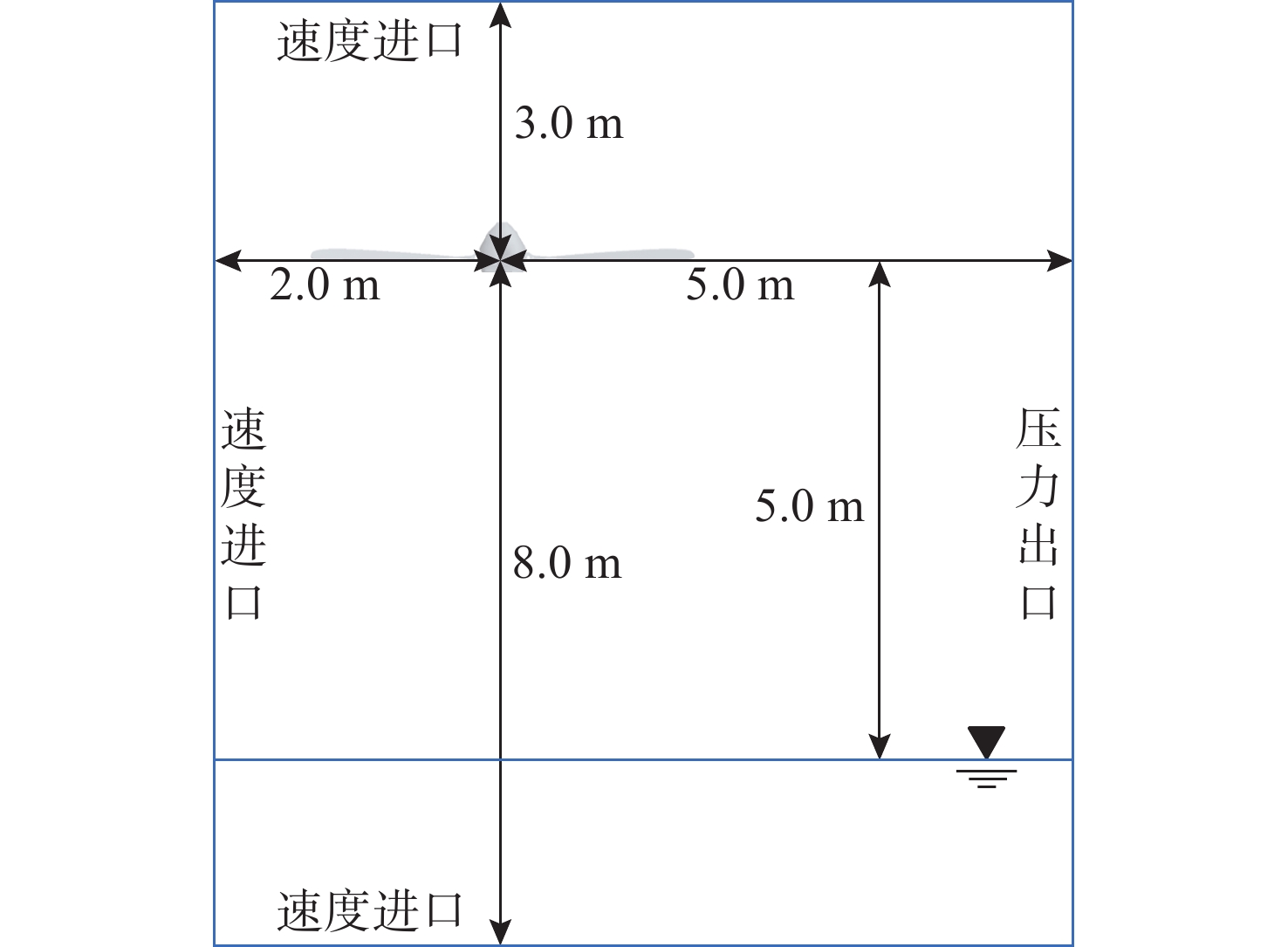

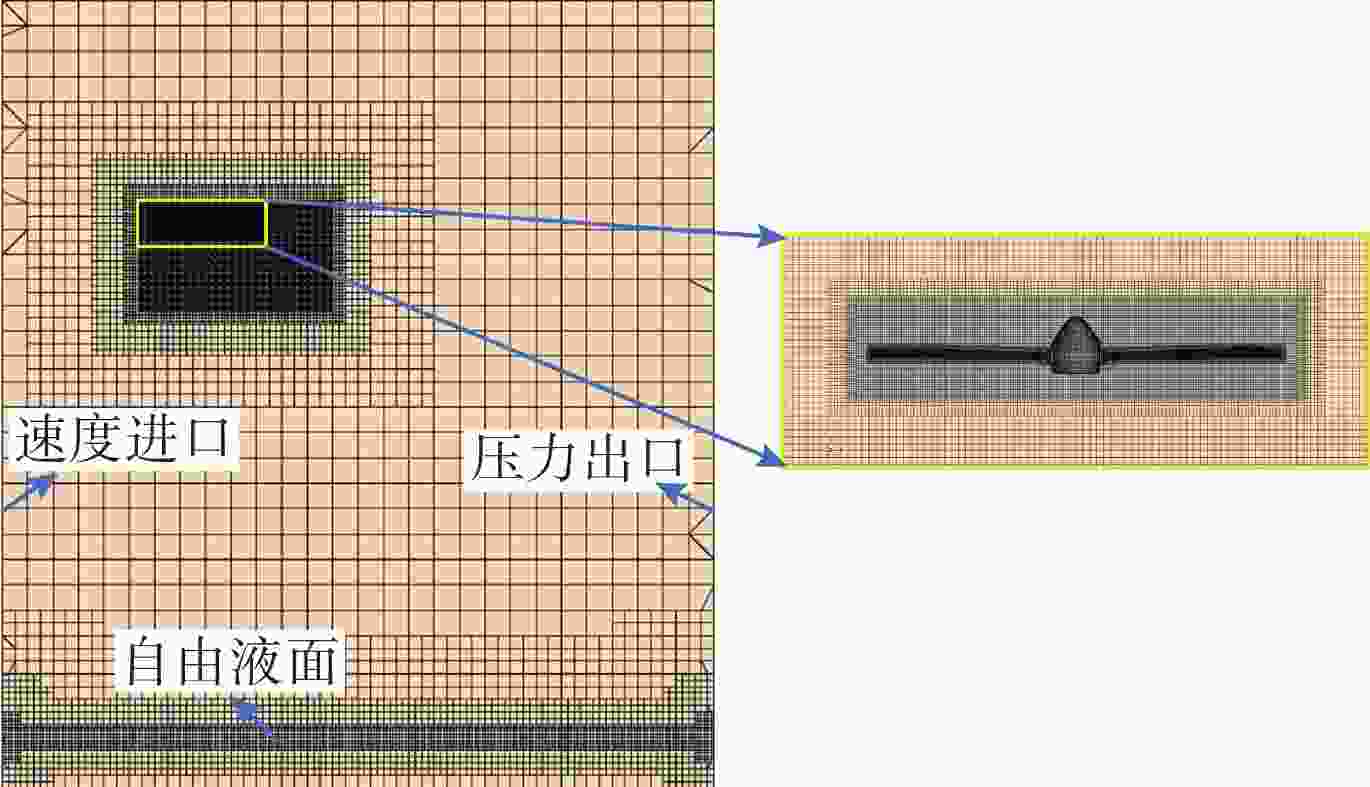

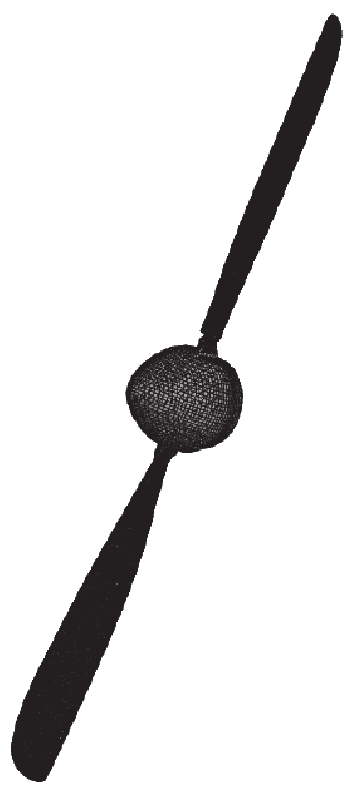

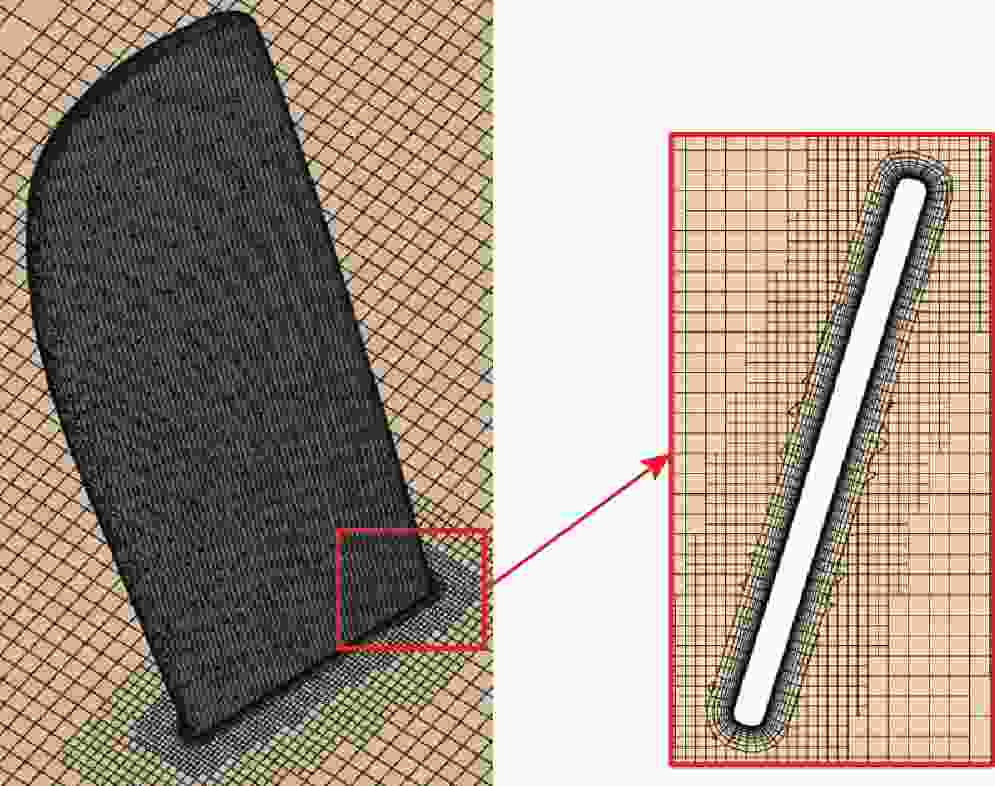

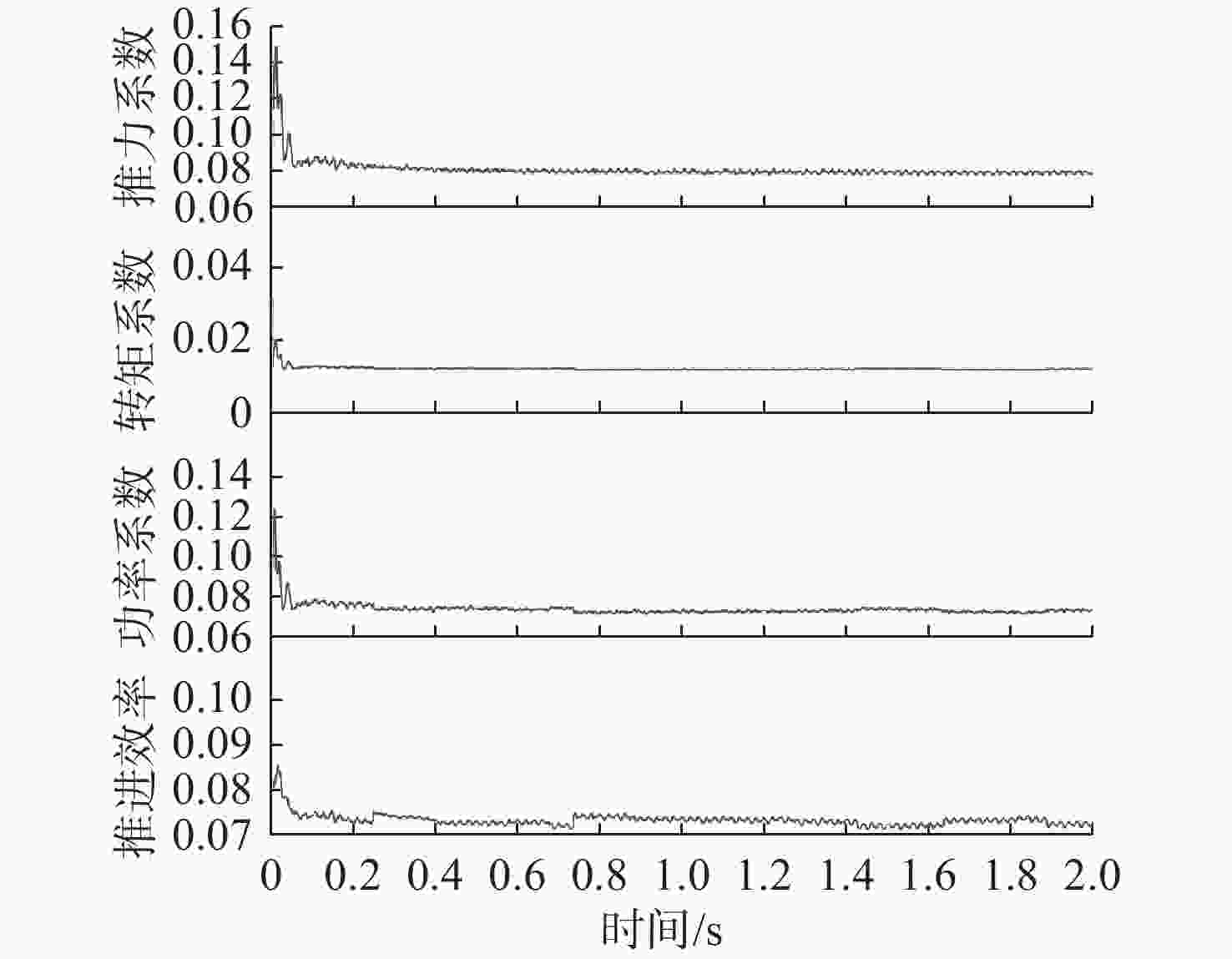

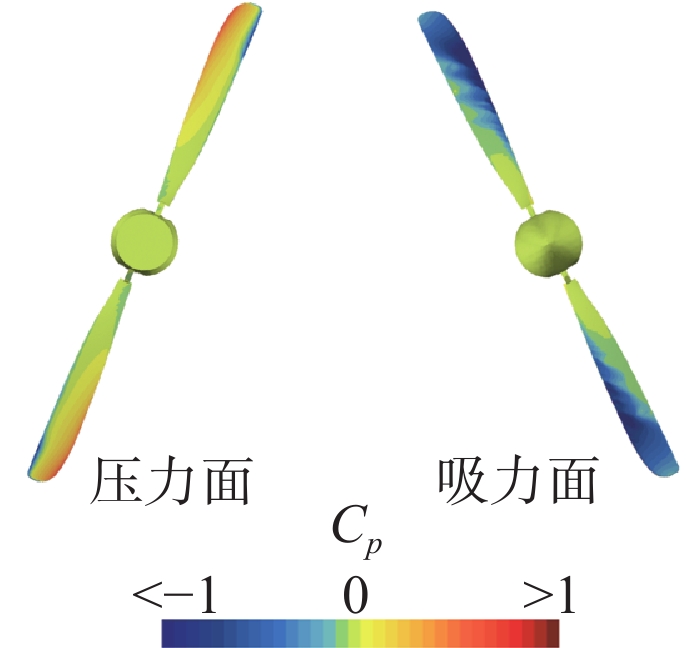

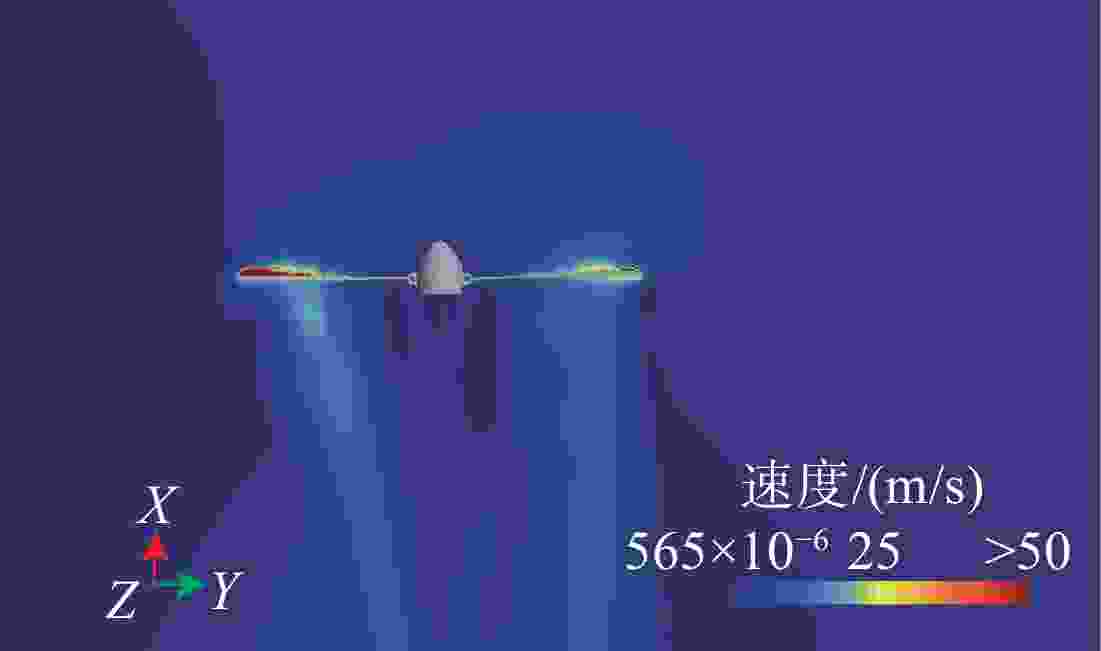

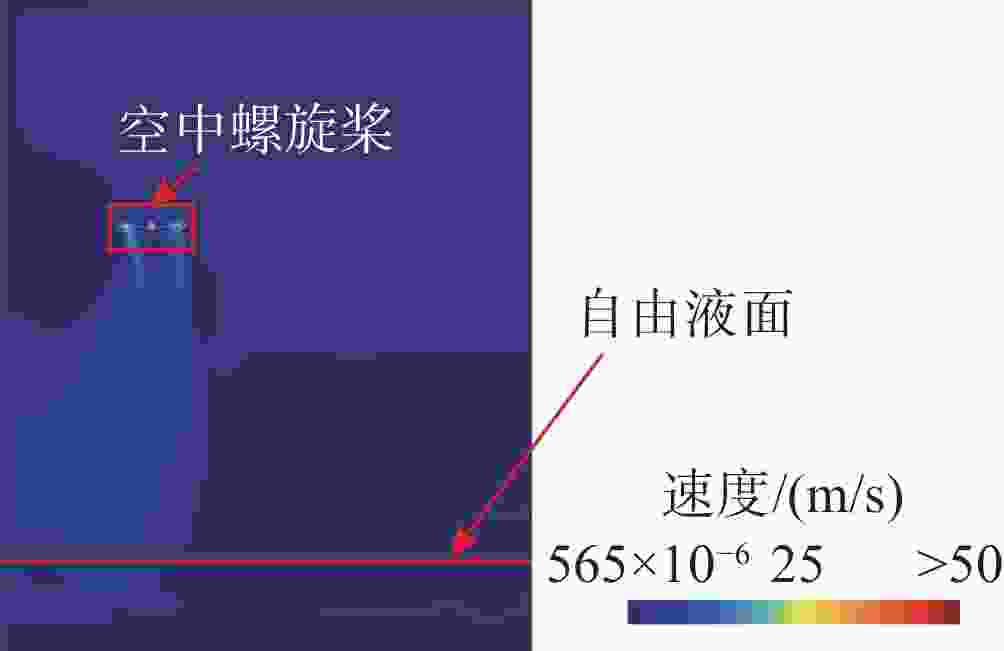

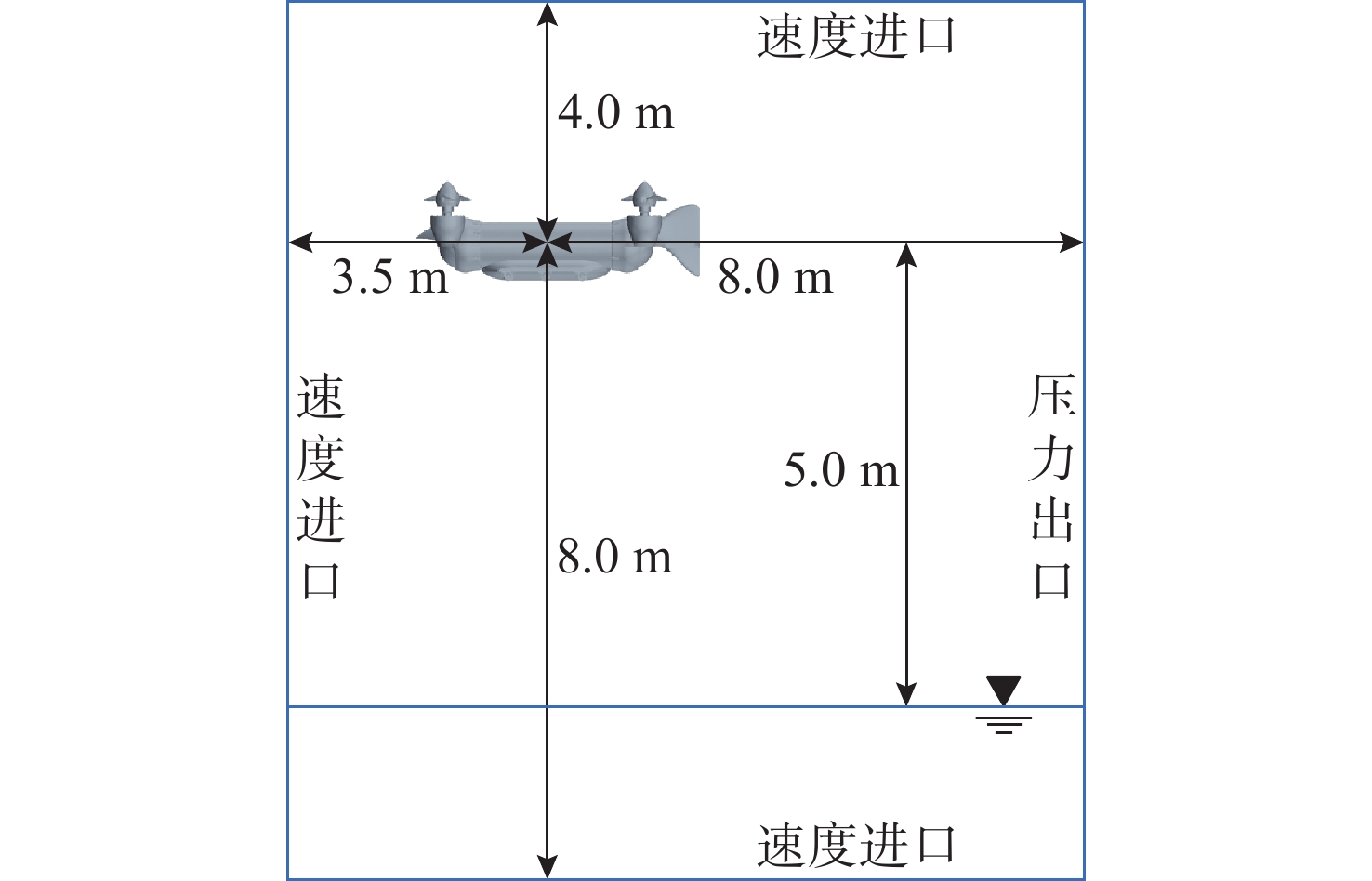

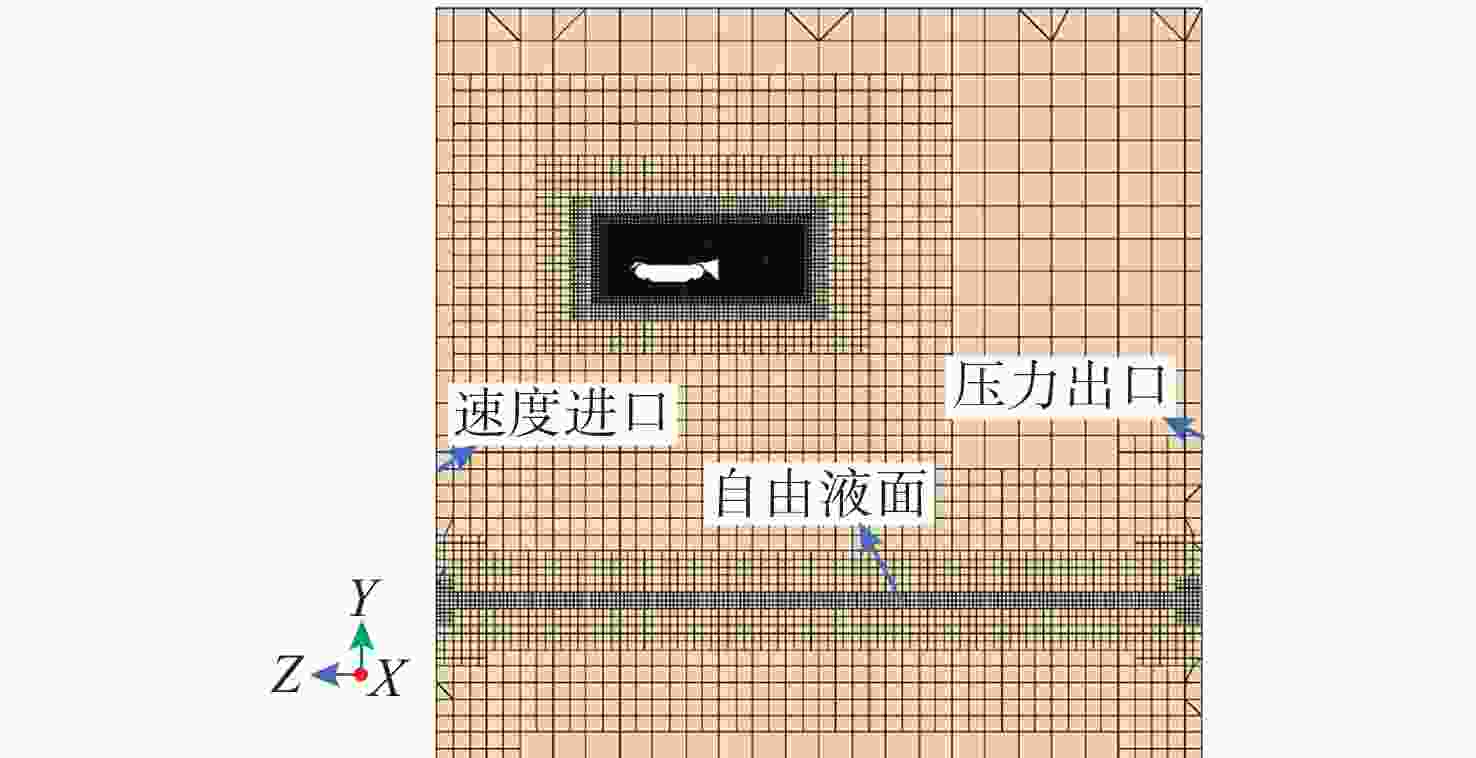

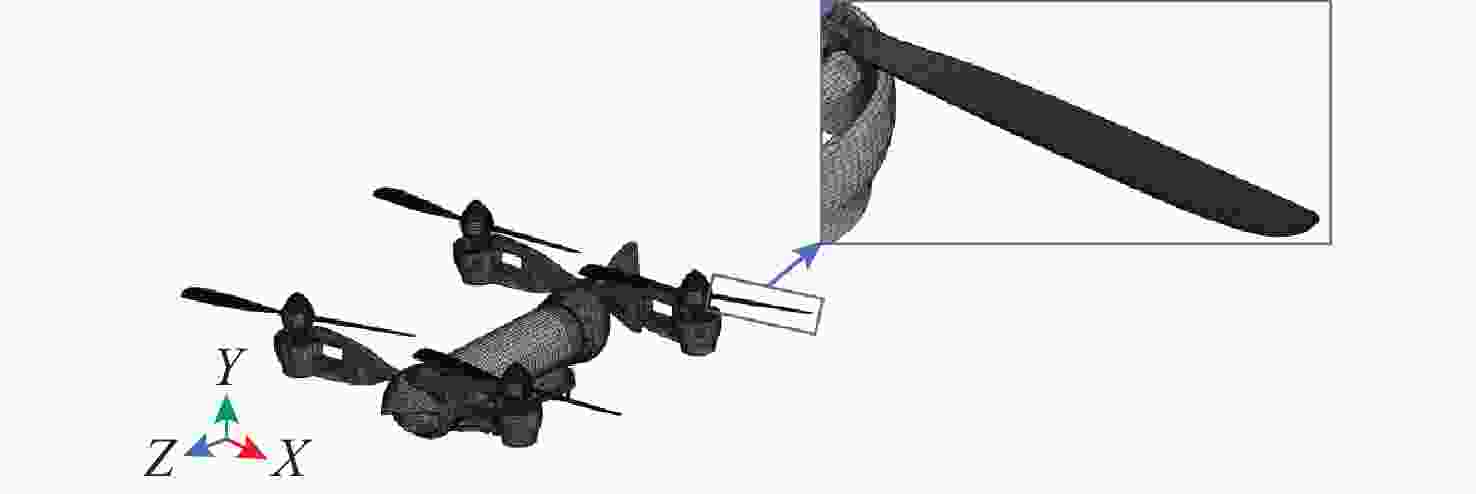

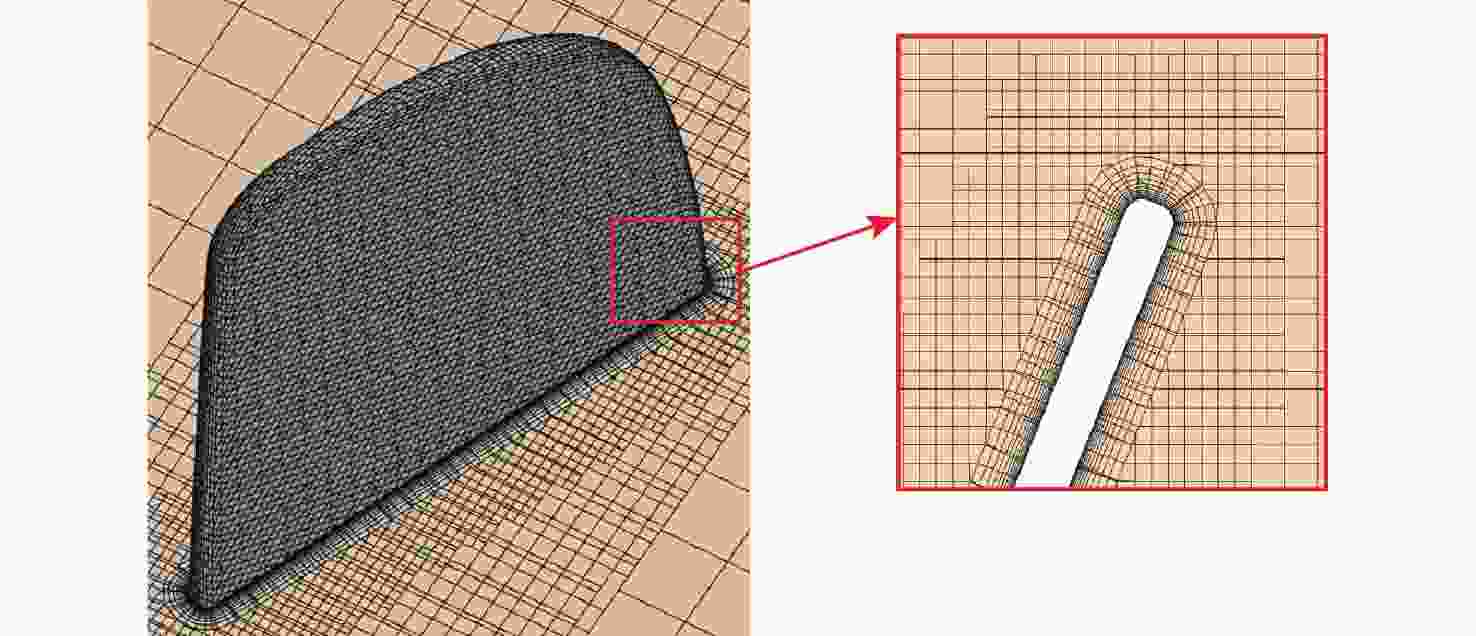

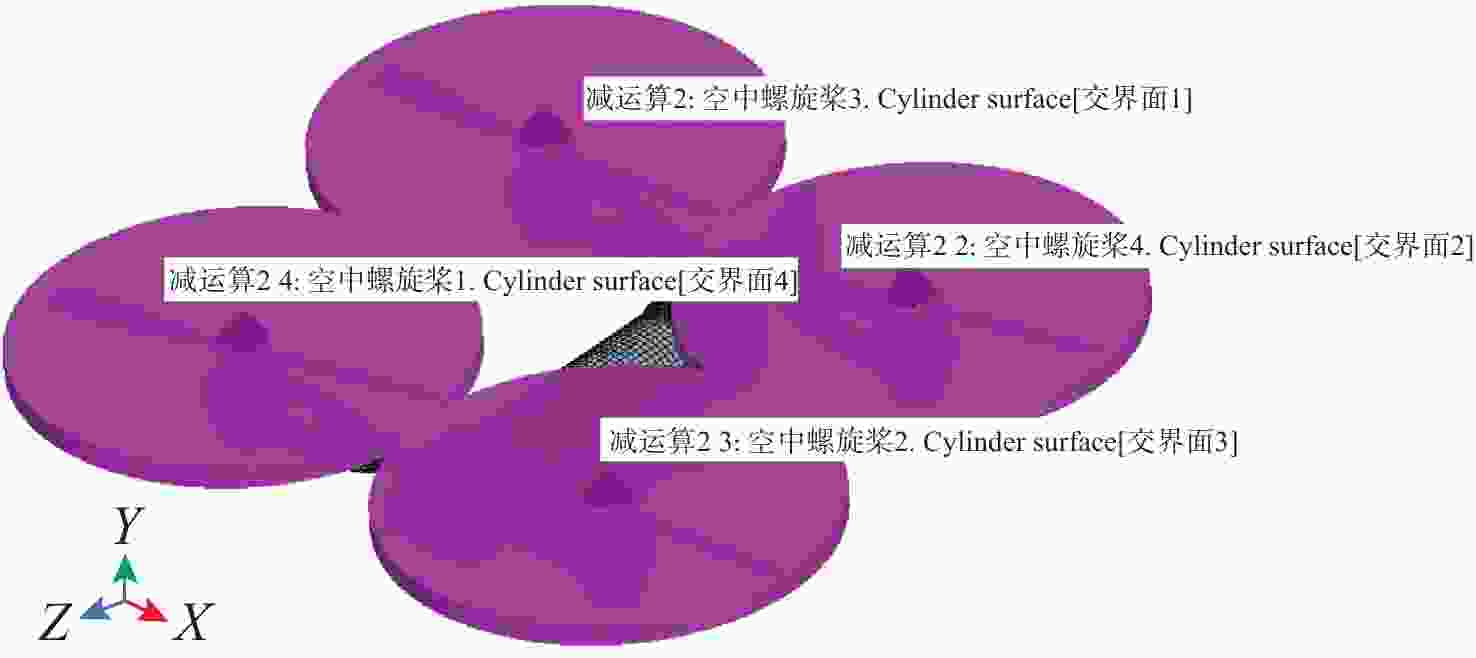

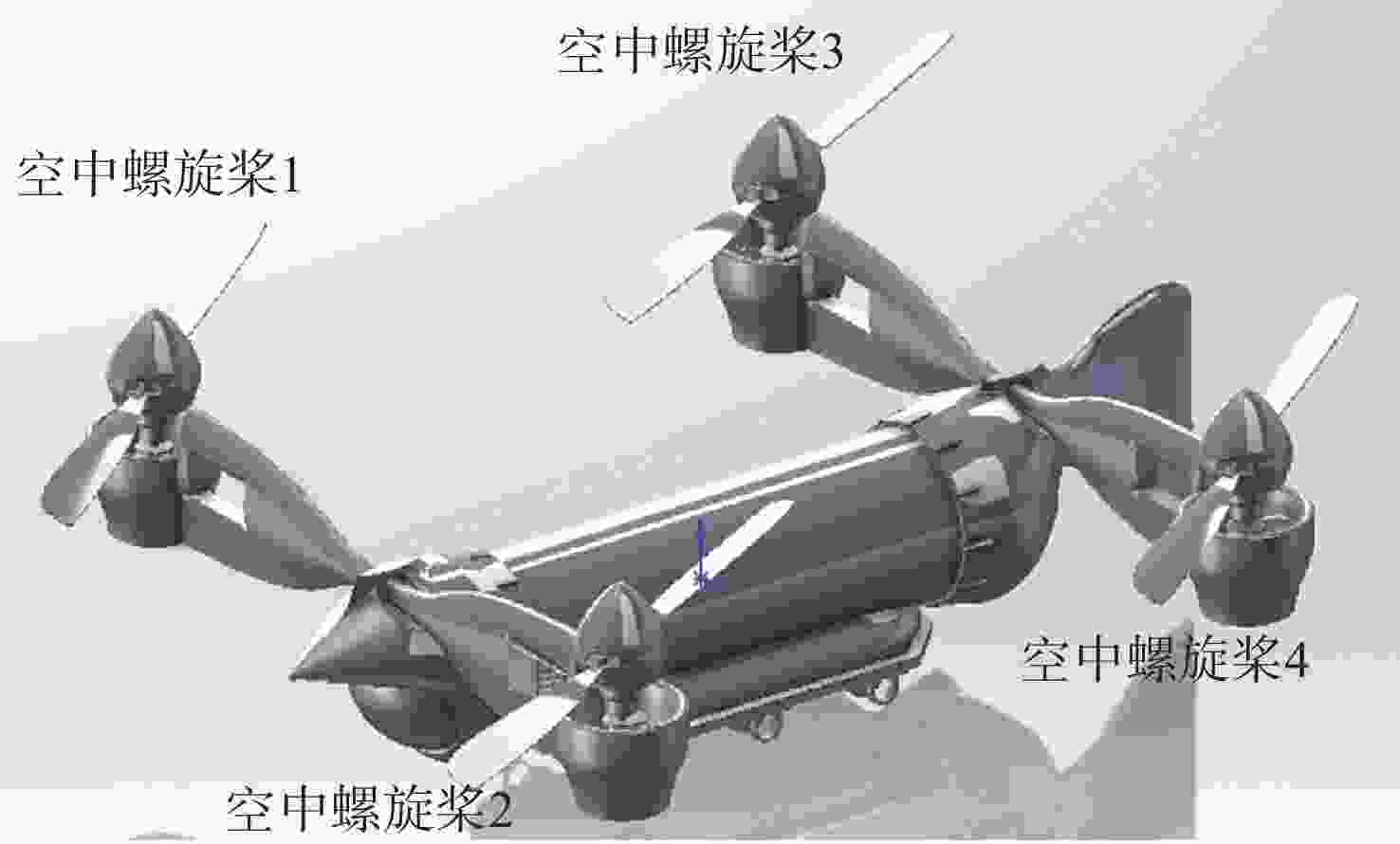

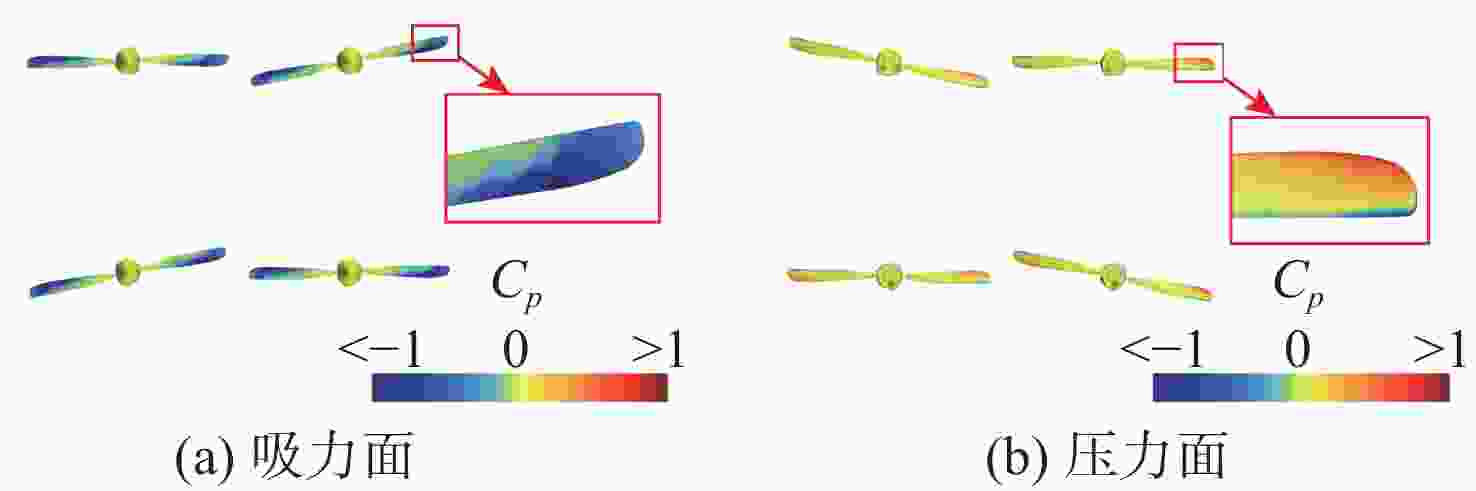

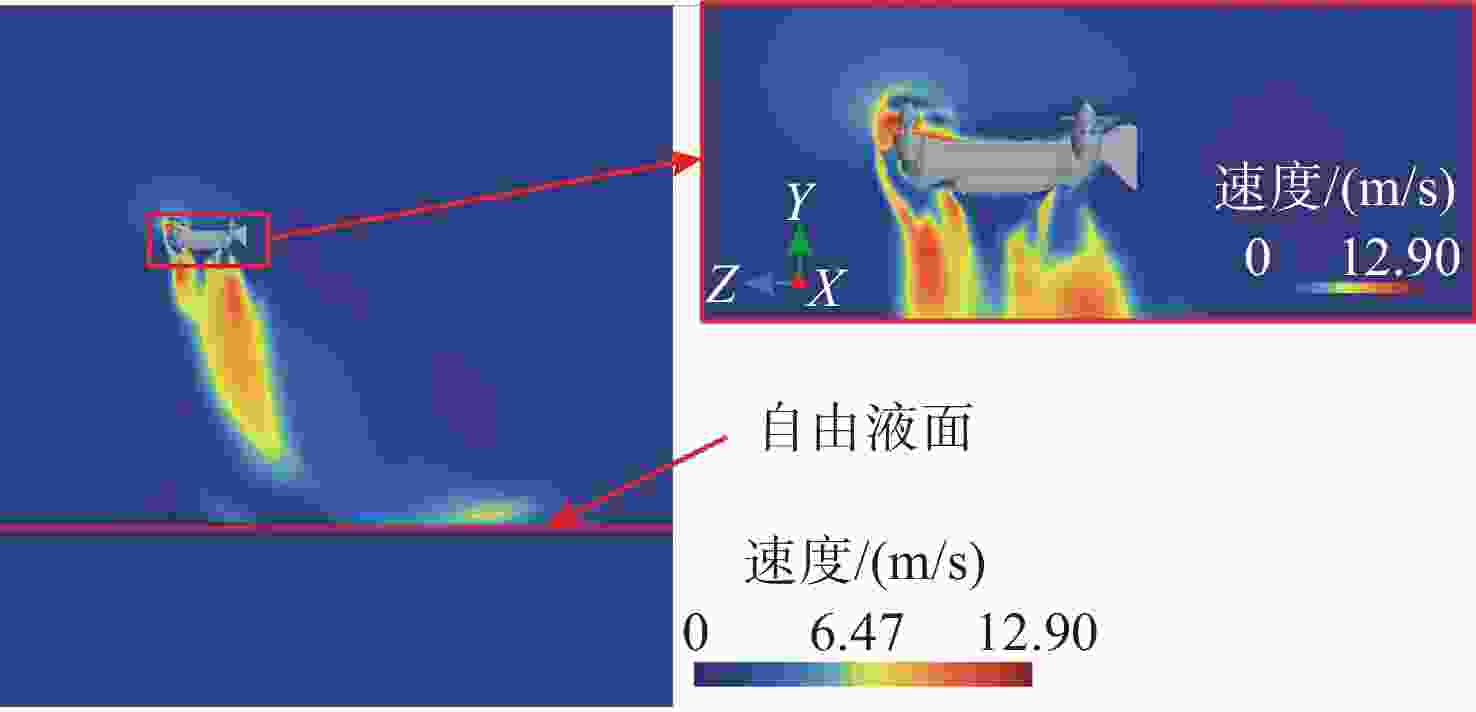

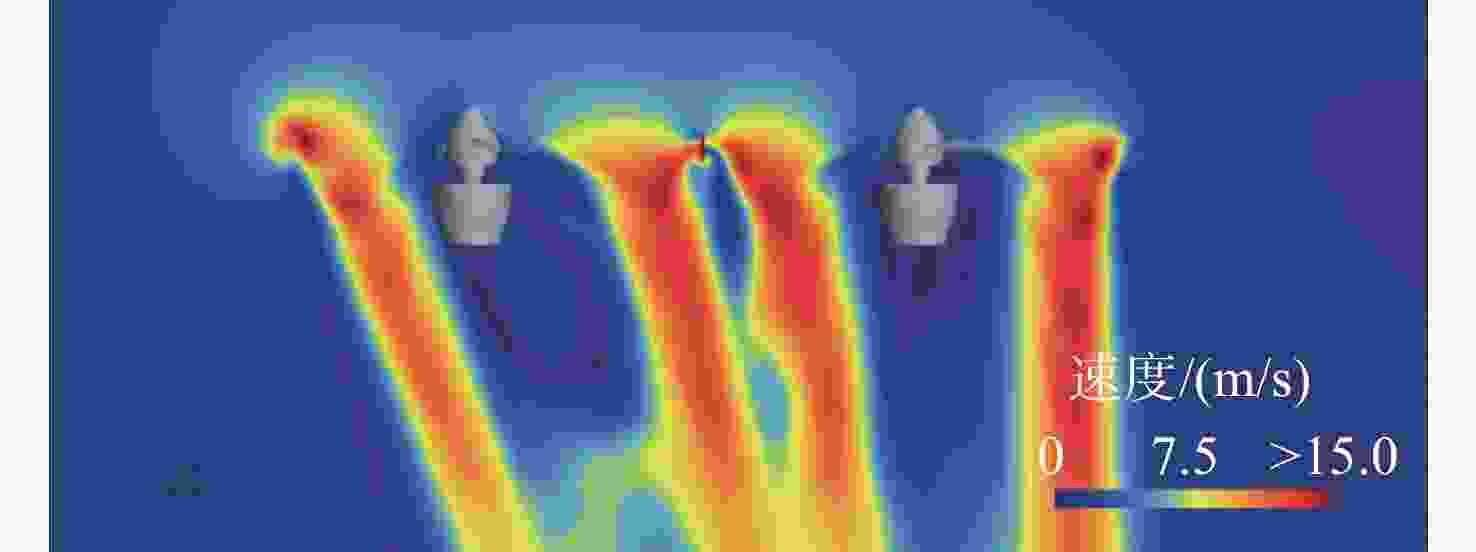

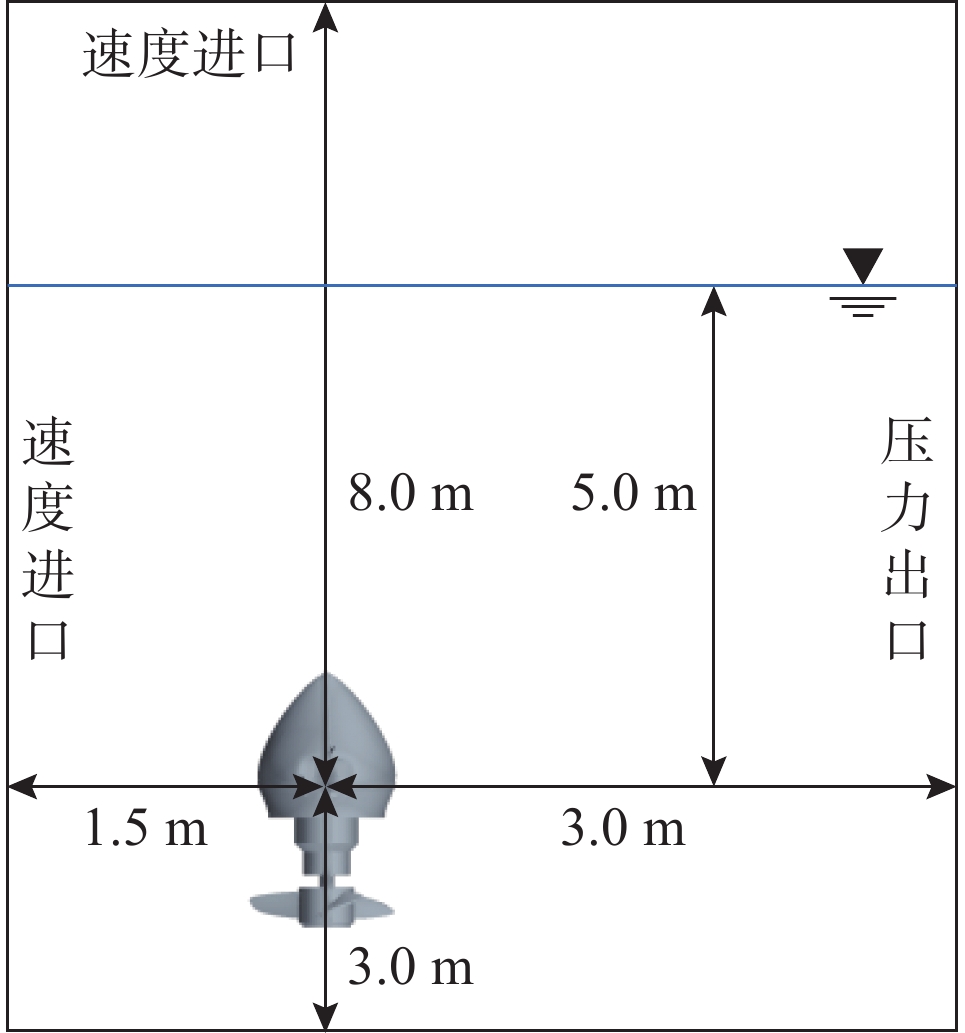

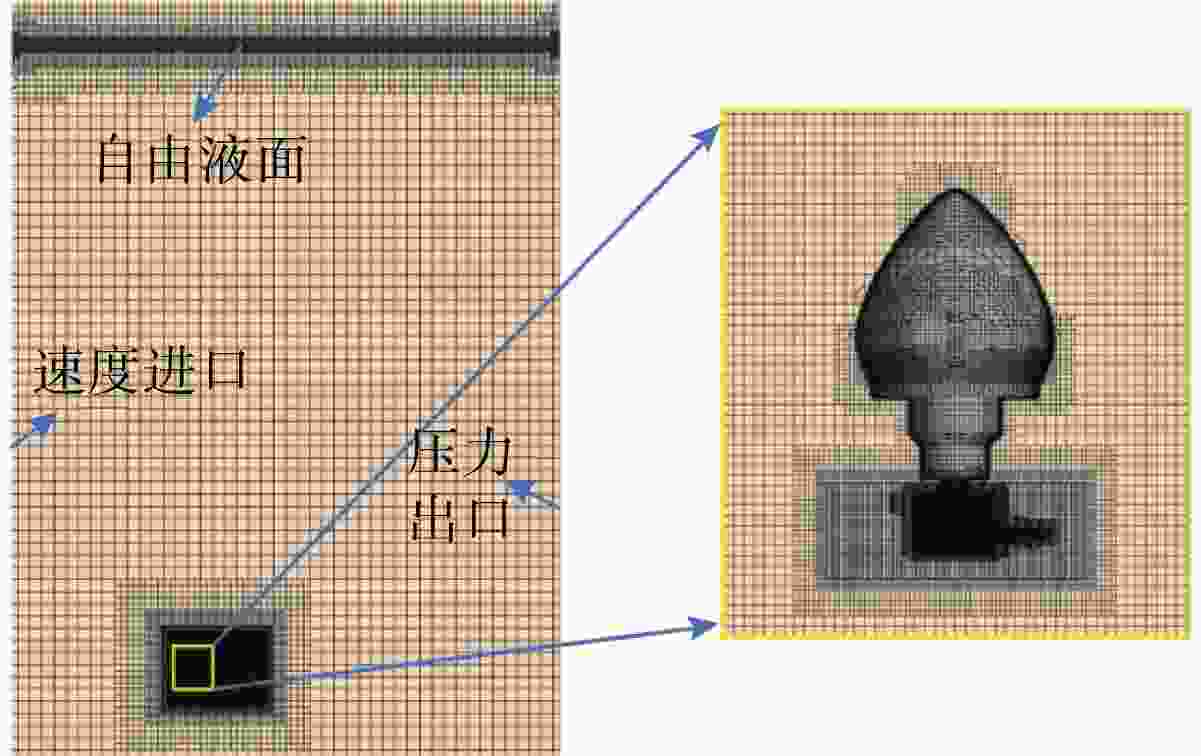

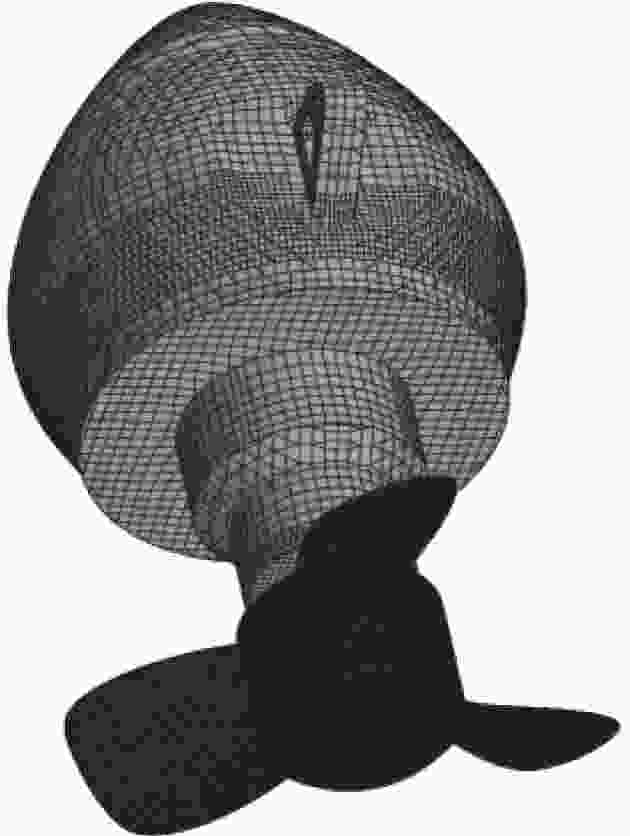

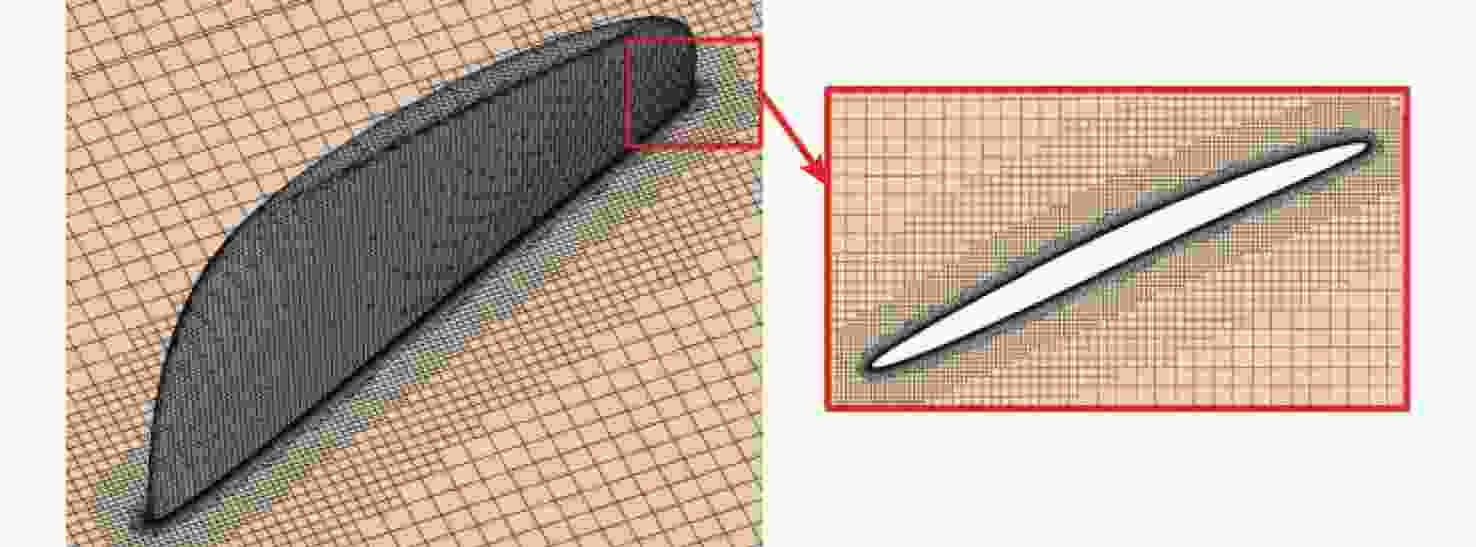

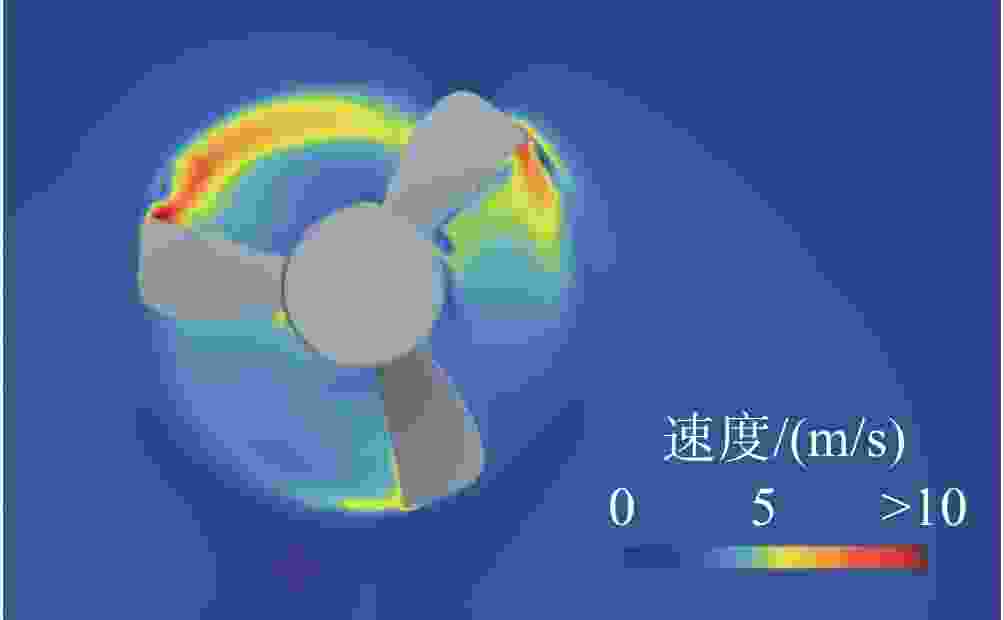

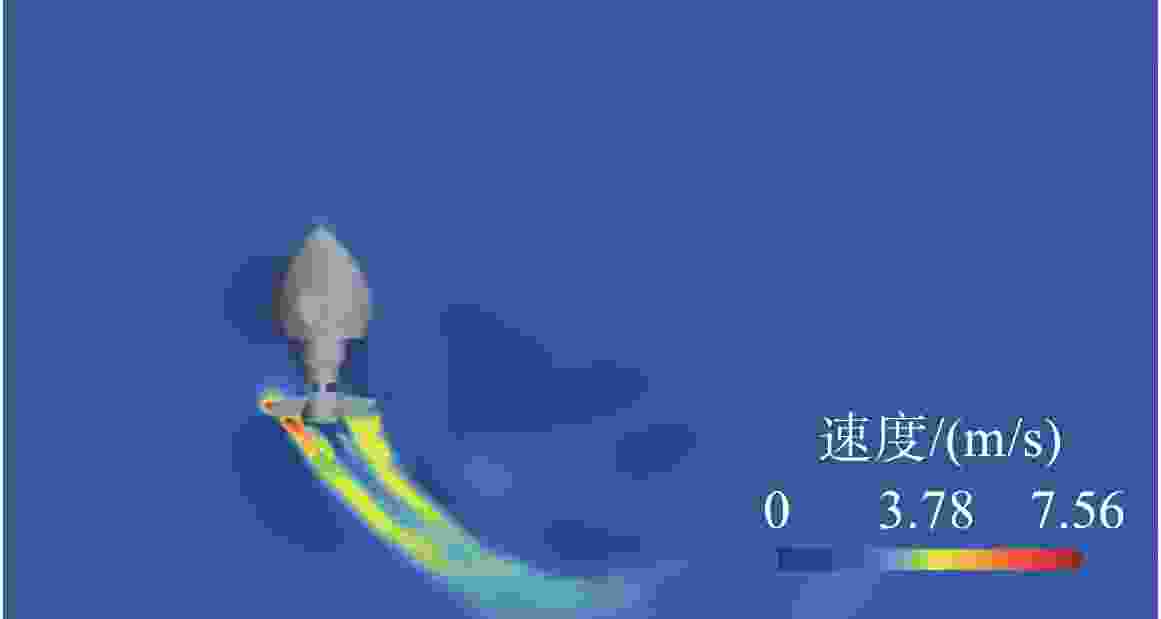

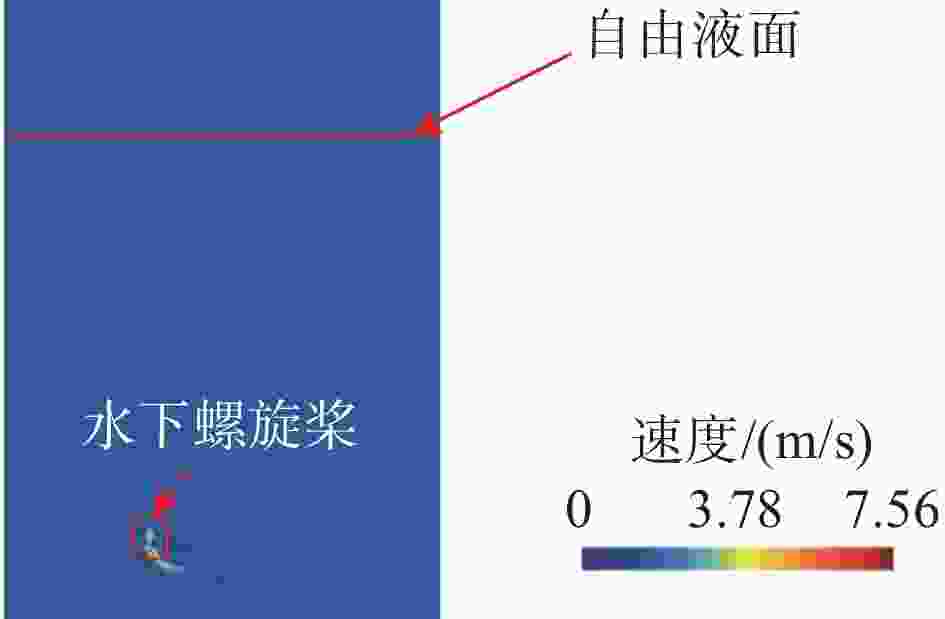

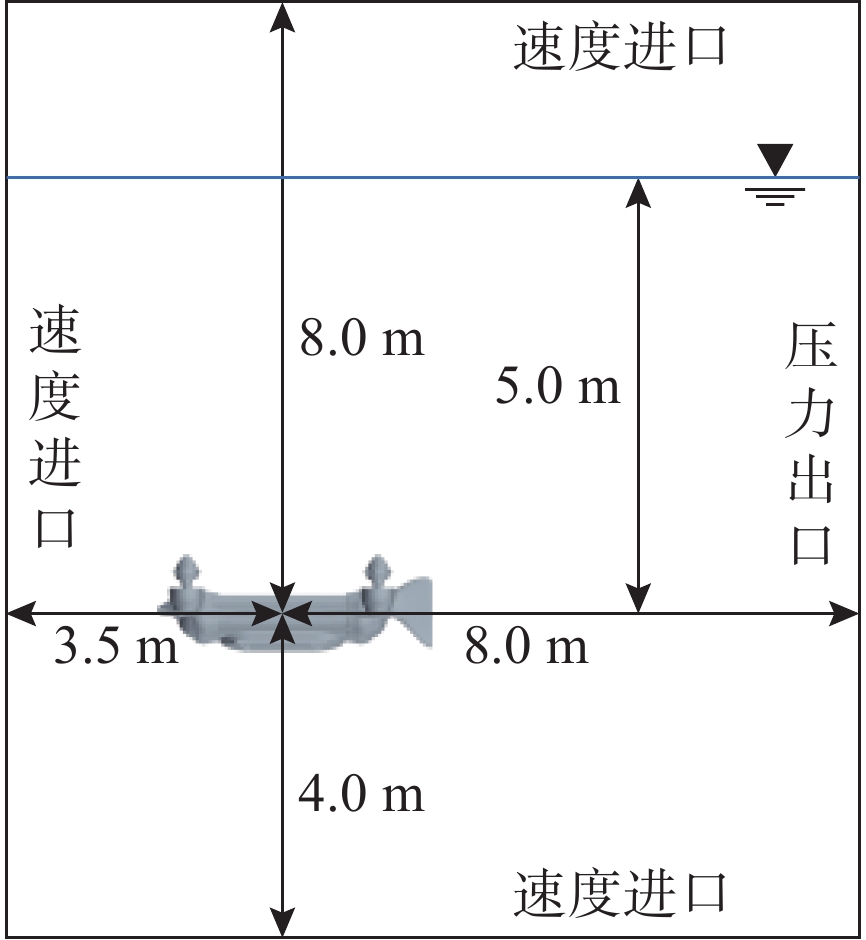

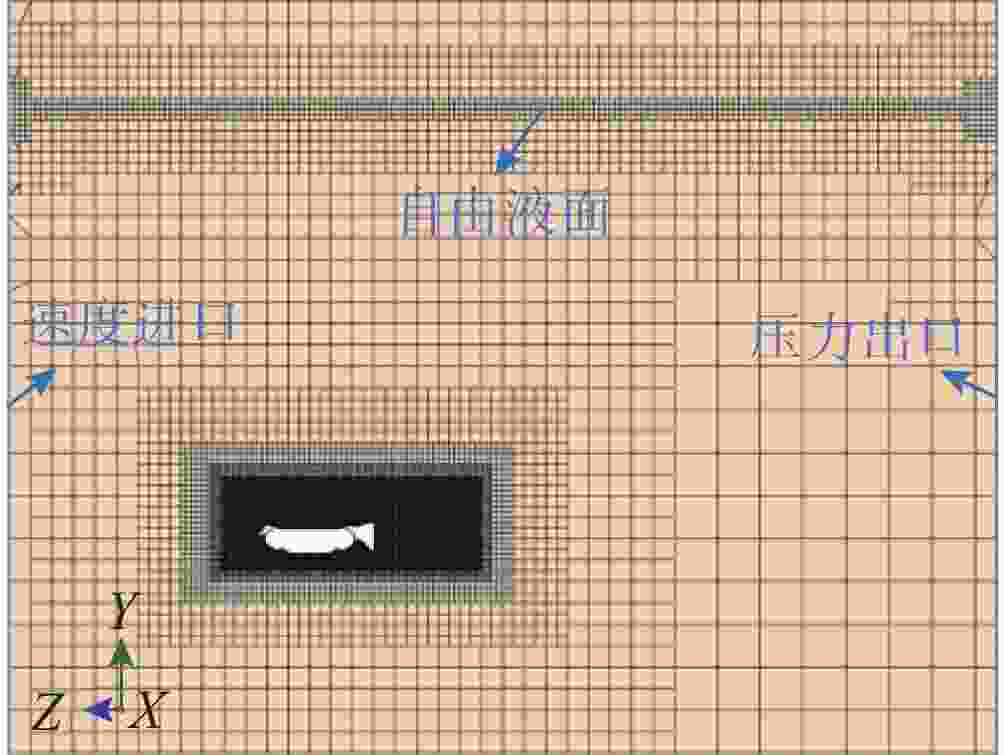

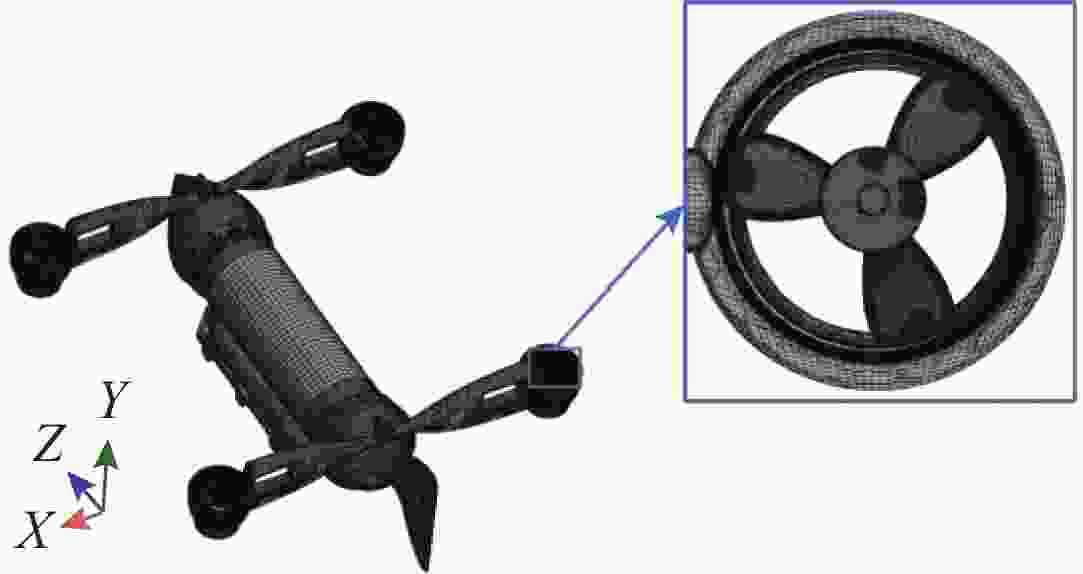

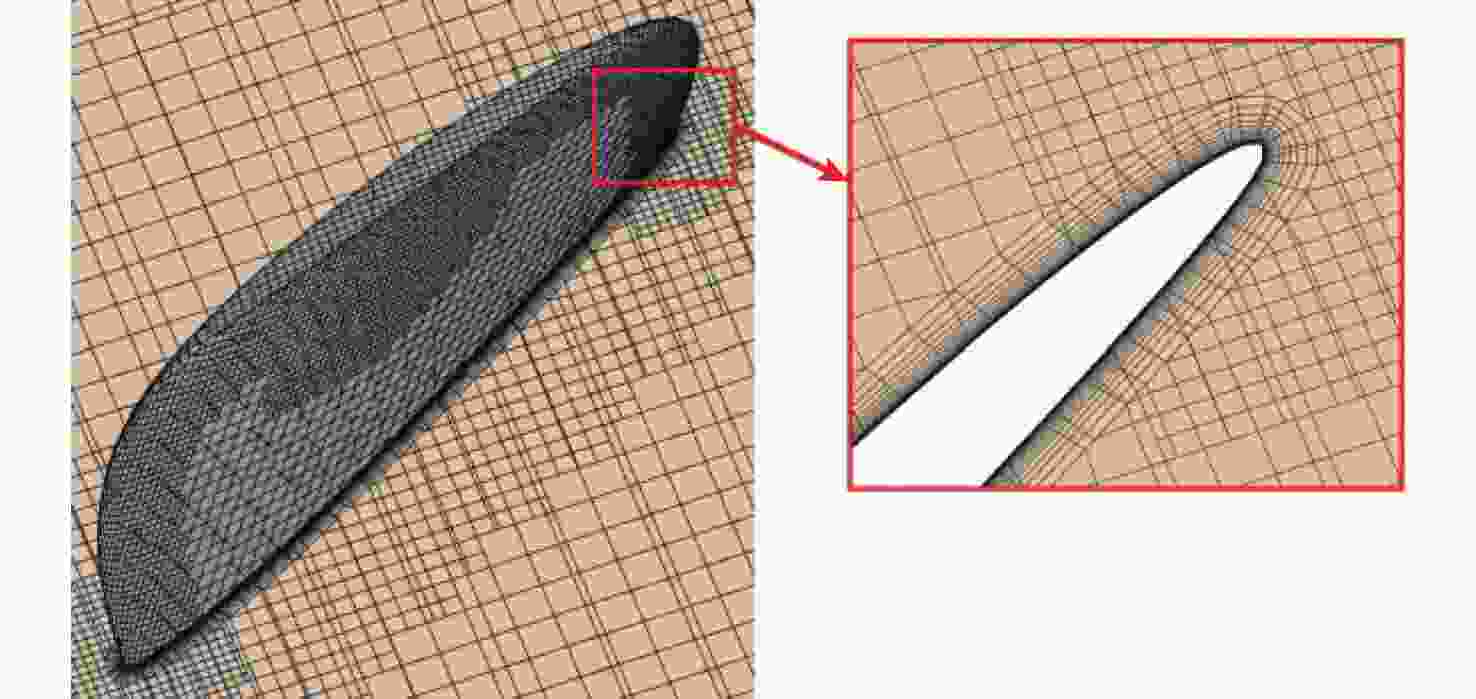

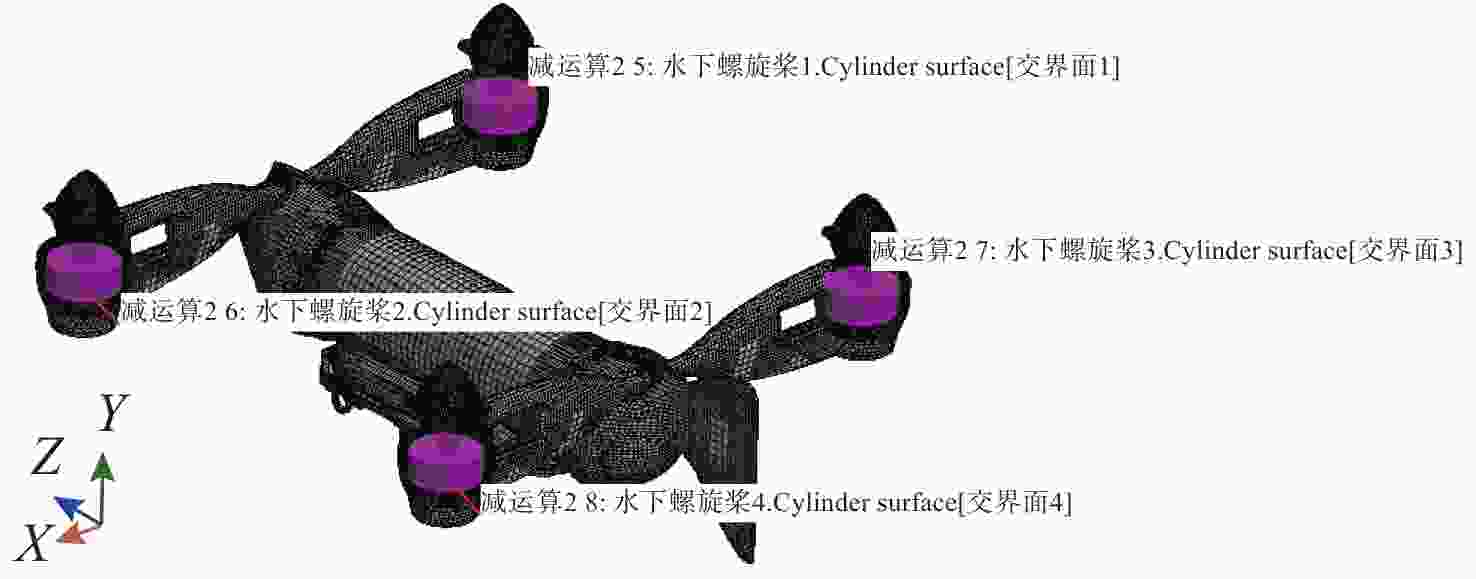

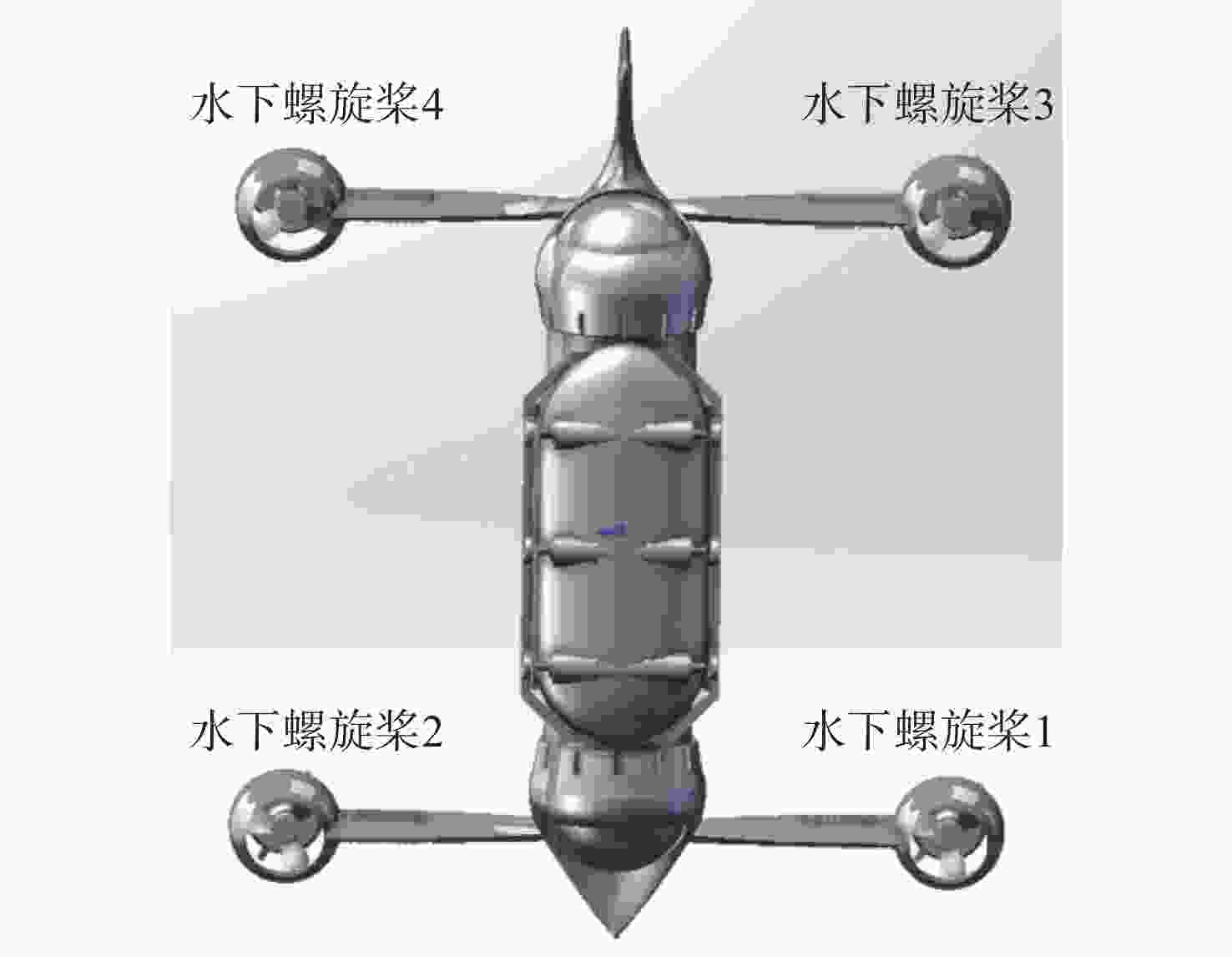

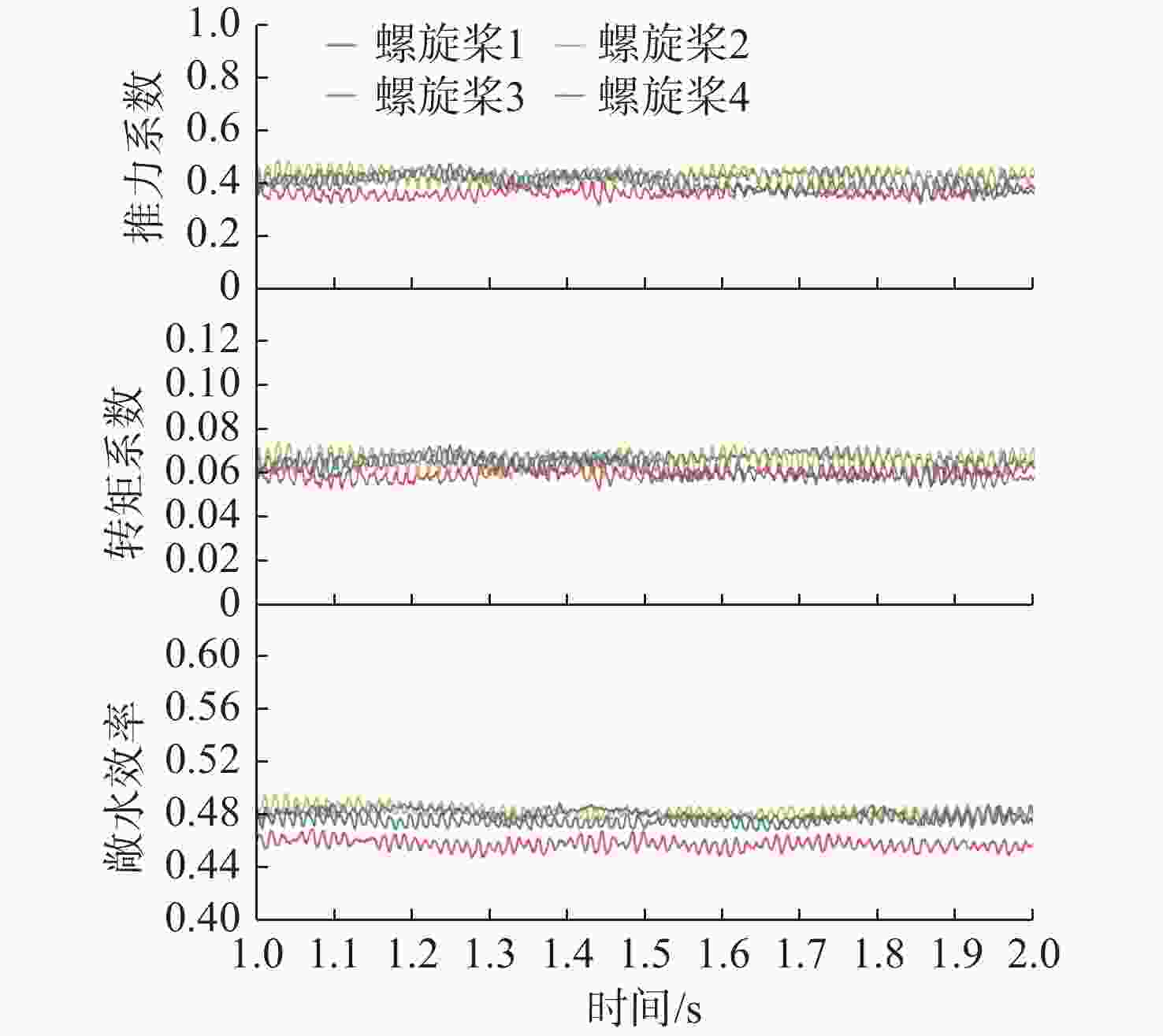

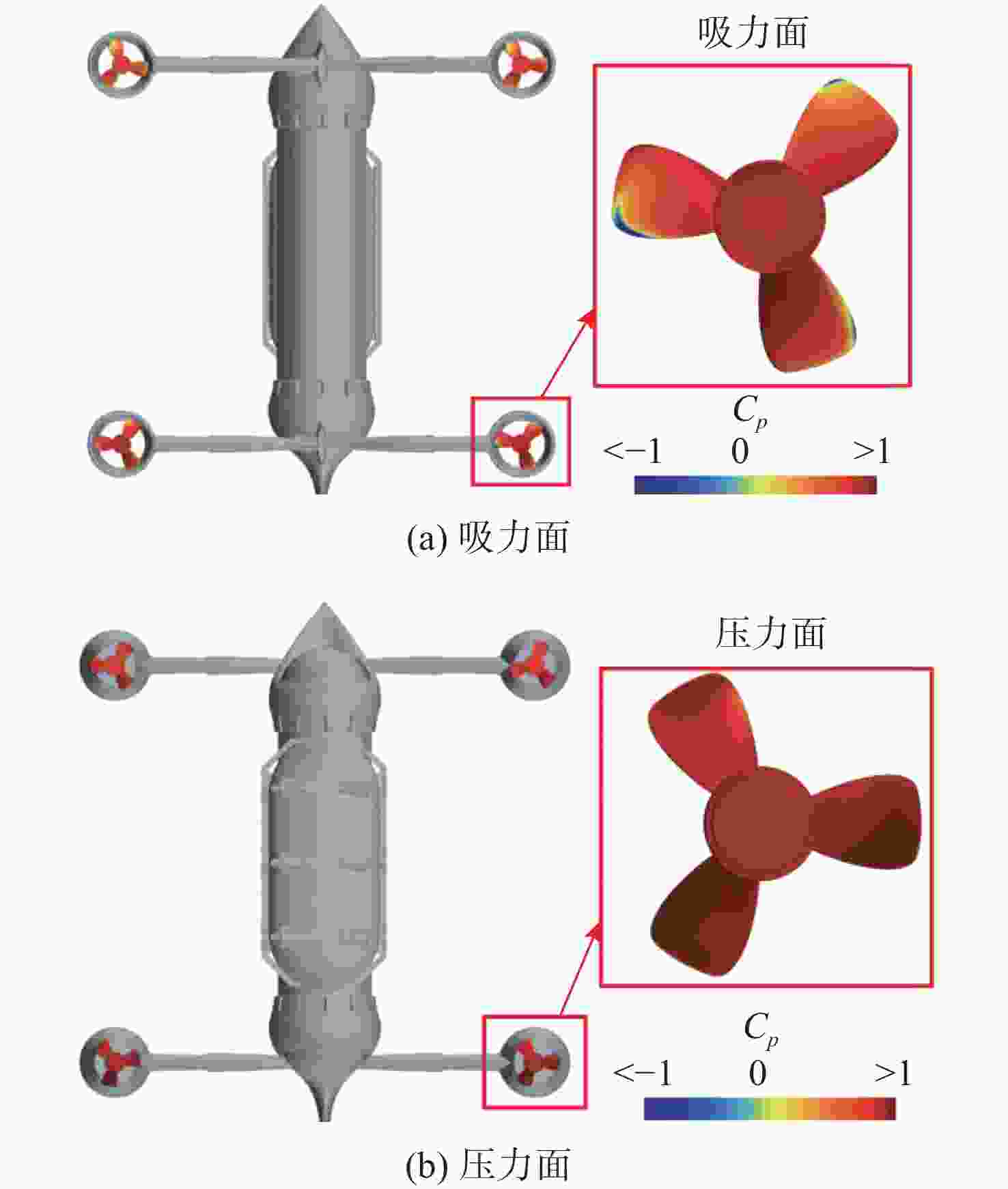

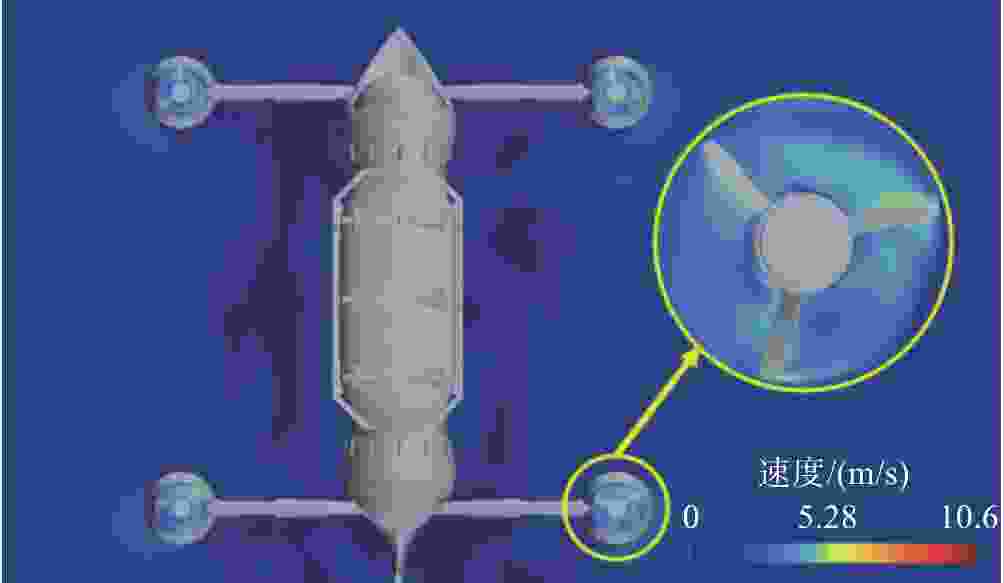

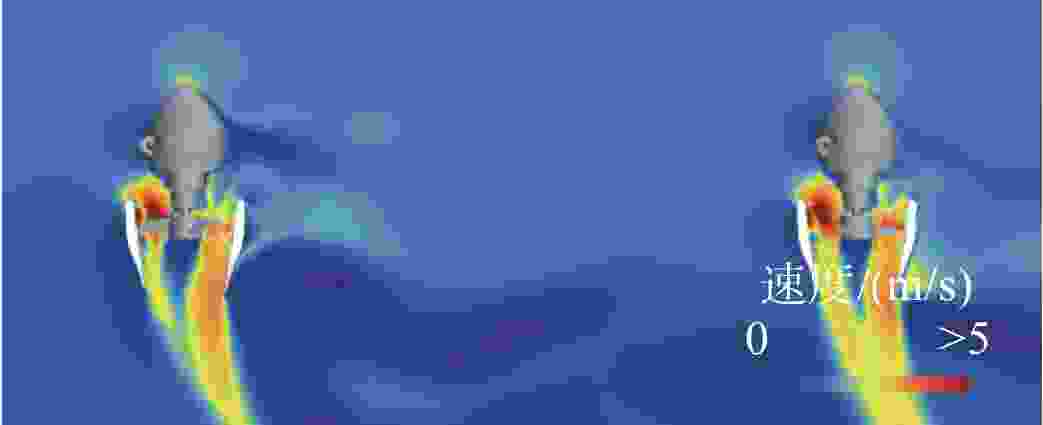

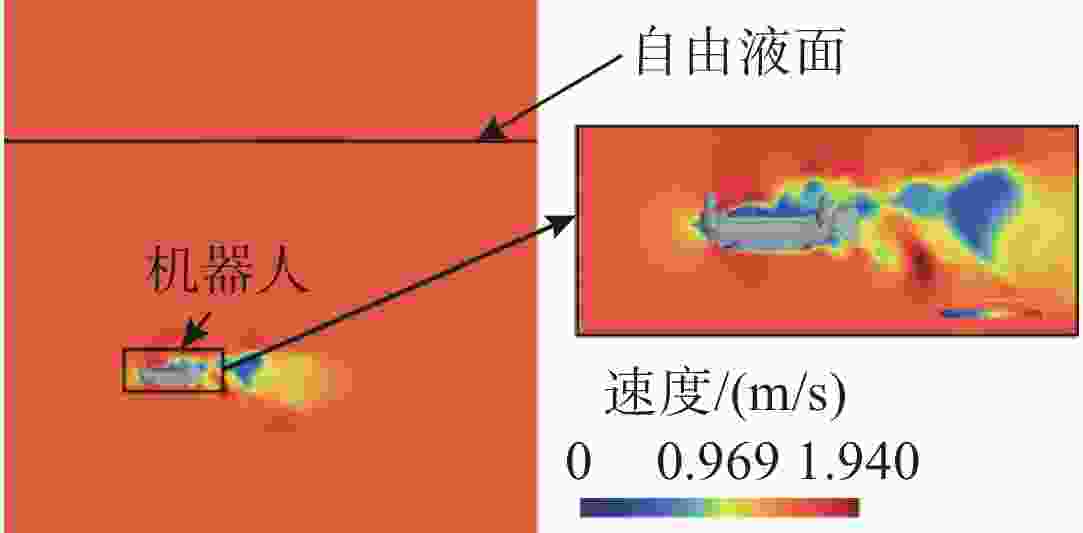

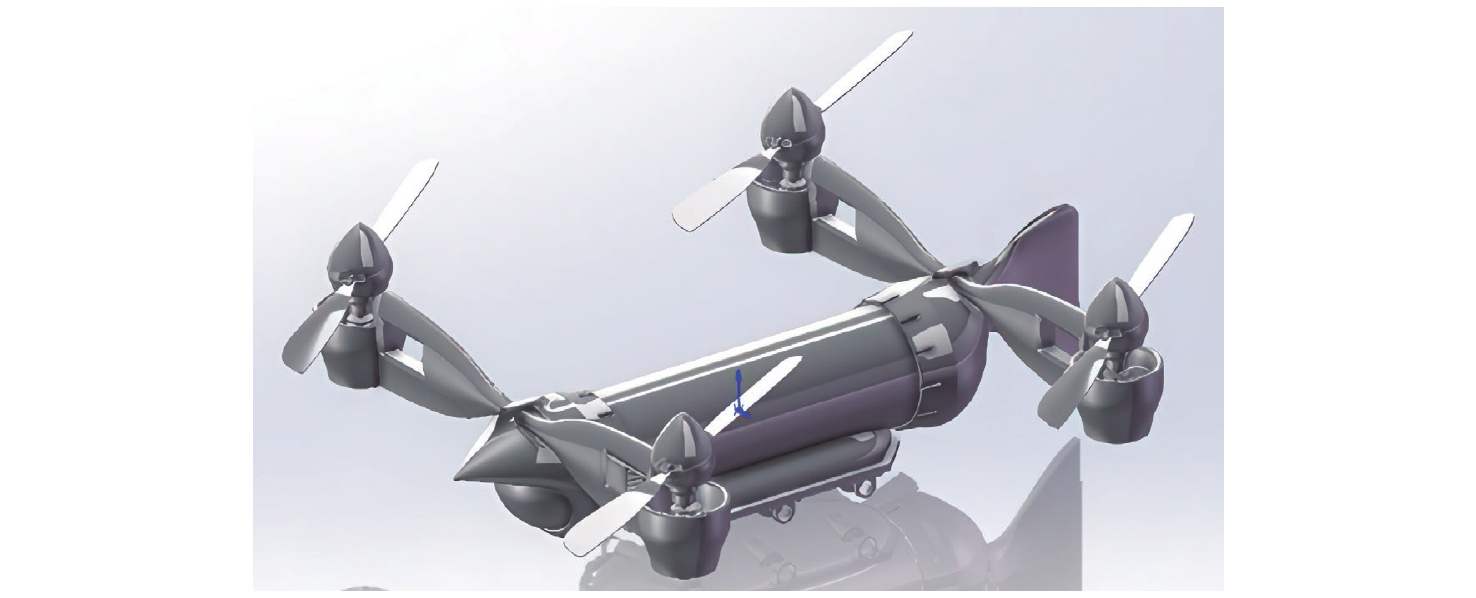

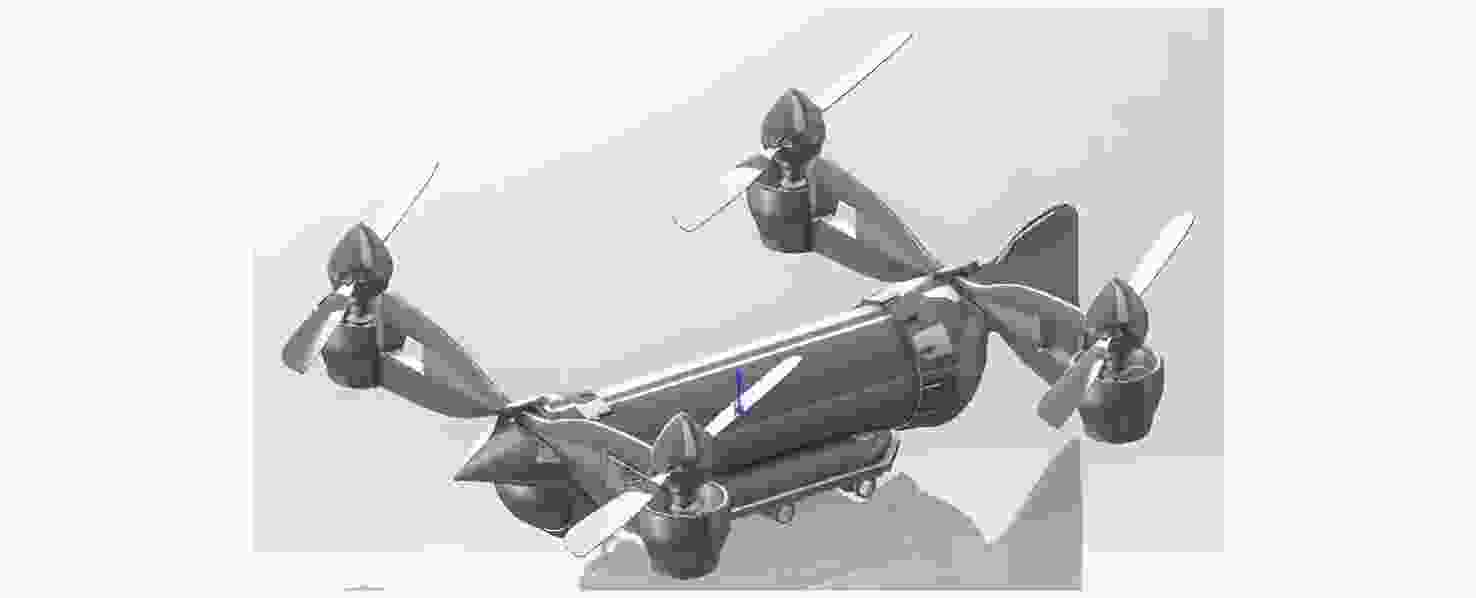

摘要: 为应对复杂海洋环境中跨介质作业的需求, 针对一款具备空中与水下双模态运动能力的跨介质机器人, 开展了推进系统的计算流体动力学(CFD)研究。由于空气与水在密度、黏性等物理性质上存在显著差异, 传统单环境推进器难以兼顾空、水2种介质的高效推进。文中建立了涵盖空中与水下2种典型工况的三维瞬态CFD模型, 采用滑移网格与流体体积(VOF)方法, 对单螺旋桨与多推进器耦合系统进行对比仿真分析。研究揭示了跨介质推进系统在推力系数、推进效率与尾流干扰等方面的差异性及规律。结果表明, 在3 kn航速下, 水下推进系统效率最高可达48.48%, 显著高于空中推进系统(7.43%); 多推进器协同运行会引起尾流耦合干扰, 但在合理布局下可提升整体效率。文中构建了统一的空-水推进CFD分析框架, 提出了一种跨介质推进性能定量评估方法, 为跨介质机器人推进系统的布局优化与多模态协同设计提供理论参考。Abstract: To meet the operational demands of cross-medium missions in complex ocean environments, this study conducts a computational fluid dynamics(CFD) analysis on the propulsion system of a cross-medium robot capable of both aerial and underwater motion. Owing to the significant differences in physical properties such as density and viscosity between air and water, traditional single-environment propellers cannot achieve high propulsion efficiency in both media. A three-dimensional transient CFD model covering typical aerial and underwater conditions was established. The Sliding Mesh and Volume of Fluid (VOF) methods were applied to perform comparative simulations of single-propeller and multi-propeller coupled systems. The study reveals the differences and patterns of thrust coefficient, propulsion efficiency, and wake interference under cross-medium conditions. Results show that at a speed of 3 knots, the underwater propulsion system achieves an efficiency of up to 48.48%, significantly higher than the aerial propulsion system (7.43%). Although multi-propeller operation induces wake coupling effects, an optimized layout can improve overall efficiency. This work establishes a unified CFD analysis framework for air-water propulsion and proposes a quantitative evaluation method for cross-medium propulsion performance, providing theoretical support for propulsion layout optimization and multimodal coordination design in cross-medium robots.

-

Key words:

- cross-medium robot /

- air-water /

- computational fluid dynamics simulation /

- propulsion /

- wake /

- multimodal coordination

-

表 1 计算工况

Table 1. Computational conditions

名称 空中 水下 空中驱动转速/(r/min) 1 500 0 水下驱动转速/(r/min) 0 1 500 进速/kn 3 3 表 2 空中螺旋桨3套网格的尺寸和数量(单组)

Table 2. Sizes and numbers of three mesh sets of the aerial propeller(single)

网格编号 网格质量 最小网格尺寸/m 网格总数 1 精细 4.75×10−4 13 863 440 2 中等 6.25×10−4 7 143 909 3 粗糙 7.50×10−4 4 676 327 表 3 空中螺旋桨网格收敛性分析结果(单组)

Table 3. Results of grid convergence analysis for aerial propeller(single)

物理量 $ \phi_{1} $ $ \phi_{2} $ $ \phi_{3} $ $ \phi_{\mathrm{ext}}^{21} $ $ e_{a}^{21} $ $ e_{\mathrm{ext}}^{21} $ $ GCI^{21}/{\text{%}} $ 推力系数 0.078 3 0.079 8 0.081 9 0.077 9 0.016 6 0.007 5 0.94 转矩系数 0.011 4 0.011 8 0.013 0 0.011 3 0.035 1 0.005 5 0.69 表 4 气动性能的统计结果

Table 4. Statistical results of aerodynamic performance

变量 数值 航速/kn 3 驱动转速/(r/min) 1 500 推力系数 0.079 8 转矩系数 0.011 8 功率系数 0.073 8 推进效率 0.072 9 表 5 空中螺旋桨三套网格的尺寸和数量(多组)

Table 5. Sizes and numbers of three mesh sets for aerial propellers(multiple)

网格编号 网格质量 最小网格尺寸/m 网格总数 1 精细 3.8×10−4 25 345 372 2 中等 5.0×10−4 14 519 320 3 粗糙 7.0×10−4 7 804 743 表 6 空中螺旋桨网格收敛性分析结果(多组)

Table 6. Results of grid convergence analysis for aerial propellers(multiple)

物理量 ${\phi}_{1} $ $ \phi_{2} $ $ \phi_{3} $ $ \phi^{21}_{\mathrm{ext }}$ $ e_{a}^{21} $ $e^{21}_{\mathrm{ext}} $ $ GC I^{21}/{\text{%}} $ 推力/N 173.13 173.87 175.21 171.85 0.004 3 0.007 4 0.77 转矩/$ \mathrm{N} \cdot \mathrm{~m} $ 22.76 23.15 23.24 23.67 0.017 1 0.003 8 0.38 表 7 气动性能的统计结果

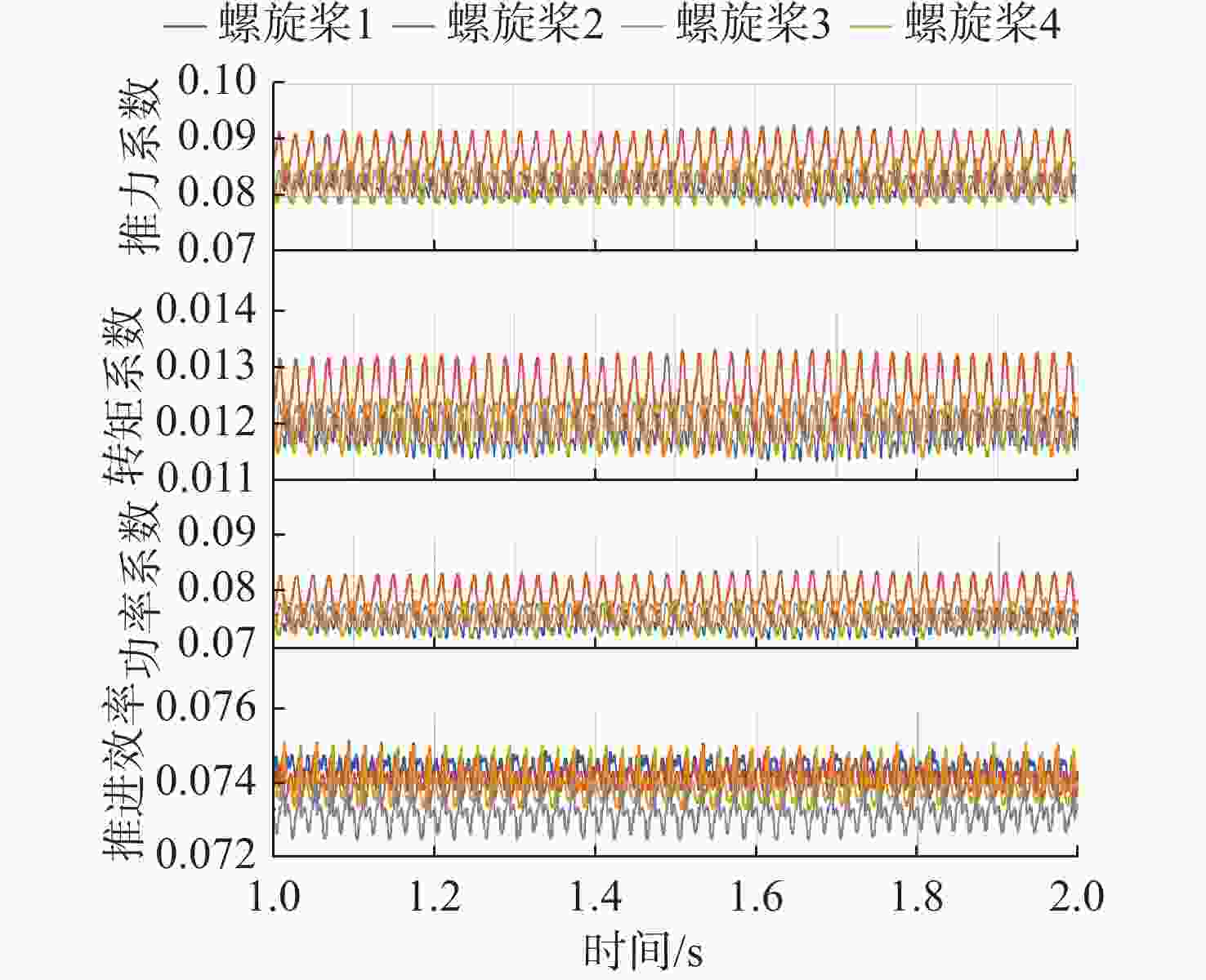

Table 7. Statistical results of aerodynamic performance

螺旋桨编号 推力系数 转矩系数 功率系数 推进效率 1 0.081 6 0.011 8 0.074 0 0.074 3 2 0.086 9 0.012 6 0.079 0 0.074 2 3 0.082 0 0.012 0 0.075 5 0.073 2 4 0.083 2 0.012 1 0.075 7 0.074 0 表 8 跨介质机器人航行时的升阻力

Table 8. Lift and drag forces during the navigation of the amphibious robot

变量 数值 航速/kn 3 转速/(r/min) 1 500 升力/N 173.87 阻力/N 5.98 表 9 水下螺旋桨3套网格的尺寸和数量(单组)

Table 9. Sizes and numbers of three mesh sets of the underwater propeller(single)

网格编号 网格质量 最小网格尺寸/m 网格总数 1 精细 1.31×10−4 10 984 385 2 中等 1.75×10−4 6 028 379 3 粗糙 2.45×10−4 3 101 420 表 10 水下螺旋桨网格收敛性分析结果(单组)

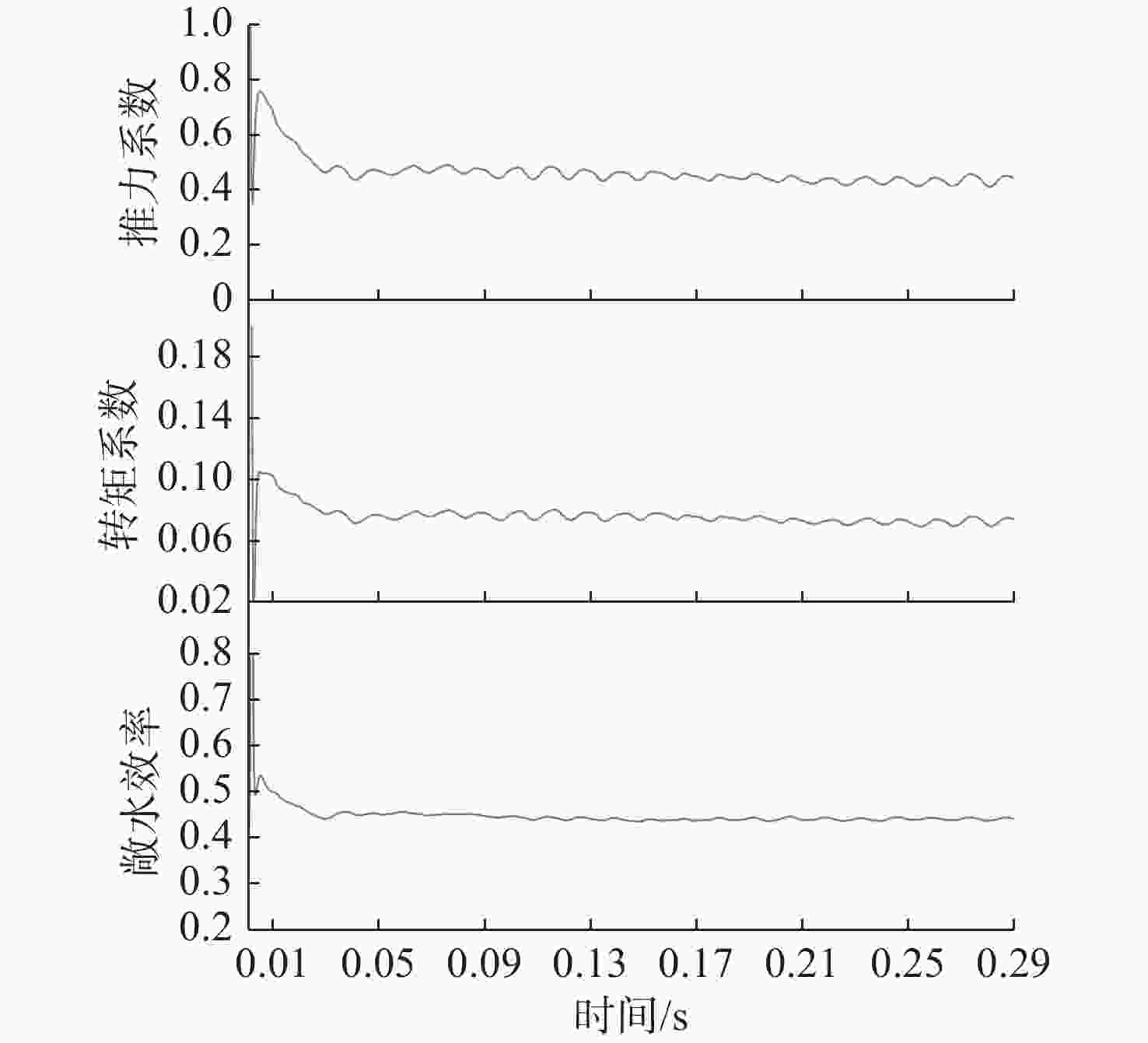

Table 10. Results of grid convergence analysis for the underwater propeller(single)

物理量 $ {\phi}_{1} $ $ \phi_{2} $ $ \phi_{3} $ $ \phi^{21} $ $ e_{a}^{21} $ $ {e_{{\mathrm{ext}}}}^{21} $ $ G C I^{21}/{\text{%}} $ 推力系数 0.443 2 0.440 6 0.432 1 0.444 7 0.005 9 0.003 3 0.41 转矩系数 0.073 8 0.073 1 0.071 6 0.074 6 0.009 5 0.010 9 1.37 表 11 水动力性能的统计结果

Table 11. Statistical results of hydrodynamic performance

变量 数值 航速/kn 3 驱动转速/(r/min) 1 500 推力系数 0.440 6 转矩系数 0.073 1 敞水效率 0.441 7 表 12 水下螺旋桨3套网格的尺寸和数量(多组)

Table 12. Sizes and numbers of three mesh sets of underwater propellers(multiple)

网格编号 网格质量 最小网格尺寸/m 网格总数 1 精细 2.250×10−4 18 041 700 2 中等 3.125×10−4 9 121 663 3 粗糙 4.125×10−4 5 522 231 表 13 水下螺旋桨网格收敛性分析结果(多组)

Table 13. Results of grid convergence analysis for underwater propellers(multiple)

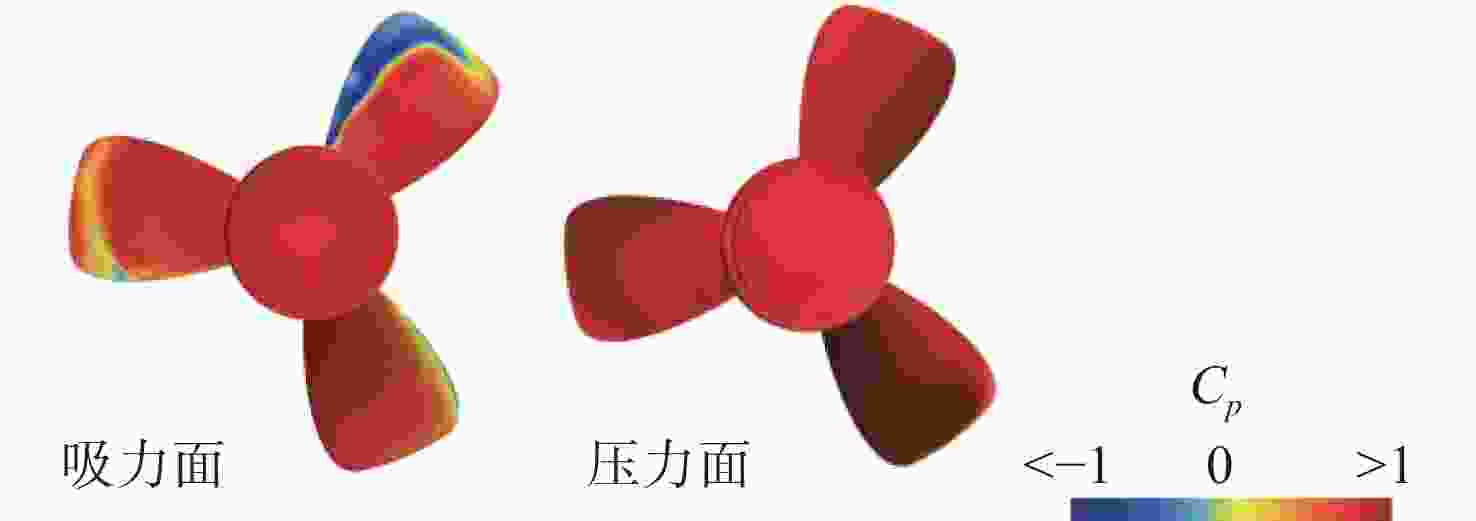

物理量 $ {\phi}_{1} $ $ \phi_{2} $ $ \phi_{3} $ $ \phi_{{\mathrm{ext}}}^{21} $ $ e_{a}^{21} $ $ e_{{\mathrm{ext}}}^{21} $ $ G C I^{21} /{\text{%}}$ 推力/N 327.73 326.82 324.97 328.12 0.0012 0.0028 0.15 转矩/$ \mathrm{N} \cdot \mathrm{~m} $ 6.85 6.77 6.61 6.89 0.0117 0.0051 0.65 表 14 水动力性能的统计结果

Table 14. Statistical results of hydrodynamic performance

螺旋桨编号 推力系数 转矩系数 敞水效率 1 0.427 2 0.065 9 0.476 8 2 0.438 6 0.066 3 0.484 8 3 0.372 6 0.059 6 0.458 6 4 0.387 4 0.059 6 0.476 5 表 15 跨介质机器人航行时的升阻力

Table 15. Lift and drag forces during the navigation of the amphibious robot

变量 数值 航速/kn 3 转速/(r/min) 1 500 升力/N 326.82 阻力/N 636.24 -

[1] 兰二斌, 杨登杰, 覃继灿, 等. 陆空两栖机器人的结构设计与运动控制研究[J]. 工业控制计算机, 2019, 32(6): 58-60.LAN E B, YANG D J, QIN J C, et al. Structural design and motion control of land-air amphibious robot[J]. Industrial Control Computer, 2019, 32(6): 58-60. [2] IZRAELEVITZ J S, TRIANTAFYLLOU M S. A novel degree of freedom in flapping wings shows promise for a dual aerial/aquatic vehicle propulsor[C]//2015 IEEE International Conference on Robotics and Automation (ICRA). Seattle, WA, USA: IEEE, 2015: 5830-5837. [3] 刘福伟. 一种水空两栖无人艇的概念设计及其航行稳定性分析[D]. 镇江: 江苏科技大学, 2014. [4] MAIA M M, MERCADO D A, DIEZ F J. Design and implementation of multirotor aerial-underwater vehicles with experimental results[C]//2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). Vancouver, British Columbia(CA): IEEE, 2017: 961-966. [5] MAIA M M, MERCADO D A, DIEZ F J. Demonstration of an aerial and submersible vehicle capable of flight and underwater navigation with seamless air-water transition[C]//XPONENTIAL 2016: An AUVSI Experience. New Orleans, USA: Curran Associates, 2016: 700-706. [6] CARUCCIO D, RUSH M, SMITH P, et al. Design, fabrication, and testing of the fixed-wing air and underwater drone[C]//17th AIAA Aviation Technology, Integration, and Operations Conference. Denver, Colorado, USA: AIAA, 2017: 4447. [7] SALUMÄE T, CHEMORI A, KRUUSMAA M. Motion control of a hovering biomimetic four-fin underwater robot[J]. IEEE Journal of Oceanic Engineering, 2017, 44(1): 54-71. doi: 10.1109/joe.2017.2774318 [8] WANG T M, YANG X B, LIANG J H, et al. CFD based investigation on the impact acceleration when a gannet impacts with water during plunge diving[J]. Bioinspiration & Biomimetics, 2013, 8(3): 036006. doi: 10.1088/1748-3182/8/3/036006 [9] LU D, XIONG C, ZENG Z, et al. A multimodal aerial underwater vehicle with extended endurance and capabilities[C]//2019 International Conference on Robotics and Automation(ICRA). Montreal, QC, Canada: IEEE, 2019: 4674-4680. [10] LU D, XIONG C, LYU B, ET al. Multi-mode hybrid aerial underwater vehicle with extended endurance[C]//2018 OCEANS-MTS/IEEE Kobe Techno-Oceans (OTO). Kobe, Japan: IEEE, 2018: 1-7. [11] BAI Y, JIN Y, LIU C, et al. Nezha-F: Design and analysis of a foldable and self-deployable HAUV[J]. IEEE Robotics and Automation Letters, 2023, 8(4): 2309-2316. [12] 王展智, 熊鹰, 齐万江, 等. 船后桨的布局对螺旋桨水动力性能的影响[J]. 哈尔滨工程大学学报, 2012, 33(4): 427-431. doi: 10.3969/j.issn.1006-7043.201105013WANG Z Z, XIONG Y, QI W J, et al. The effect of propeller arrangement behind the hull on propeller hydrodynamic performance[J]. Journal of Harbin Engineering University, 2012, 33(4): 427-431. doi: 10.3969/j.issn.1006-7043.201105013 [13] CHEN Q, YANG J, MAO J, et al. A path following controller for deep-sea mining vehicles considering slip control and random resistance based on improved deep deterministic policy gradient[J]. Ocean Engineering, 2023, 278: 114069. doi: 10.1016/j.oceaneng.2023.114069 [14] SUURNÄKKI P, TIIHONEN M, JOKELA T. UAV icing: Low reynolds number drone propeller performance during dynamic icing process[C]//AIAA AVIATION 2021 FORUM. Washington DC, USA: AIAA, 2021: 2672. [15] 卿黎. 高空长航时无人机总体设计与气动优化研究[D]. 成都: 电子科技大学, 2025. [16] 王晓璐, 陈昌宁, 刘英禹, 等. 无人机动力布局与桨机气动耦合效应研究综述[J]. 航空工程进展, 2025, 16(6): 1-16. doi: 10.16615/j.cnki.1674-8190.2025.06.01 [17] 何朝晖.非均匀流中不同侧斜螺旋桨空化涡流演变及压力脉动数值分析[D].武汉:武汉大学,2022. [18] 王倩倩, 辛公正, 周伟新, 等. 环形螺旋桨几何构型与水动力性能计算及验证[J]. 船海工程, 2025, 54(04): 1-8.Wang Qianqian, Xin Gongzheng, Zhou Weixin, et al. Calcu-lation and Verification of Geometric Configuration and Hy-drodynamic Performance of Toroidal Propeller[J]. Ship & Ocean Engineering, 2025, 54(04): 1-8. [19] Celik I B, Ghia U, Roache P J, et al. Procedure forestimation and reporting of uncertainty due to discre-tization in CFD applications[J]. Journal of fluids En-gineering-Transactions of the ASME, 2008, 130(7): 078001-1-078001-4-0. -

下载:

下载: