Experimental Study on Load Sharing Characteristics of Fixed Axis Tri-Branching Gear Transmission System

-

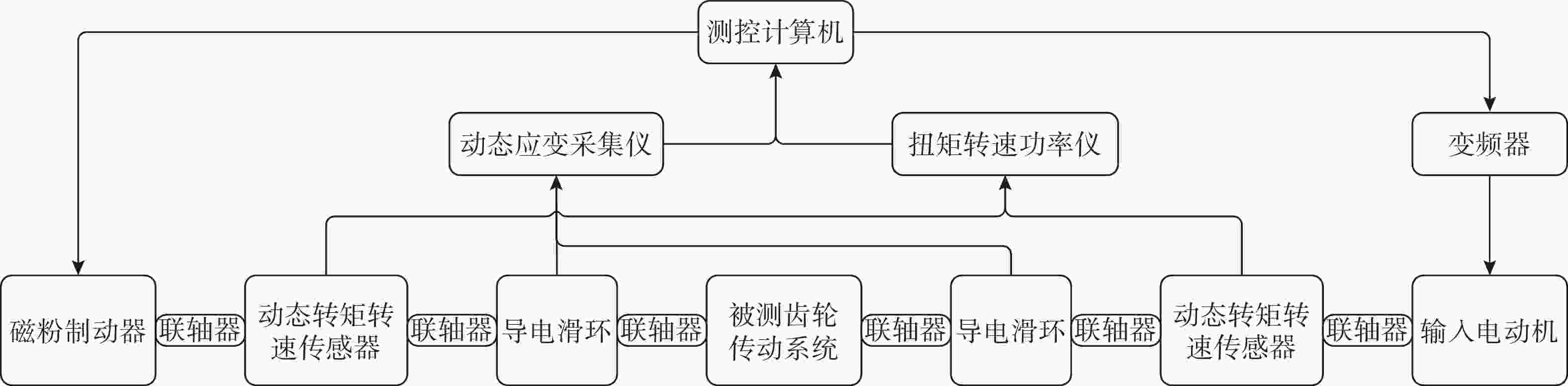

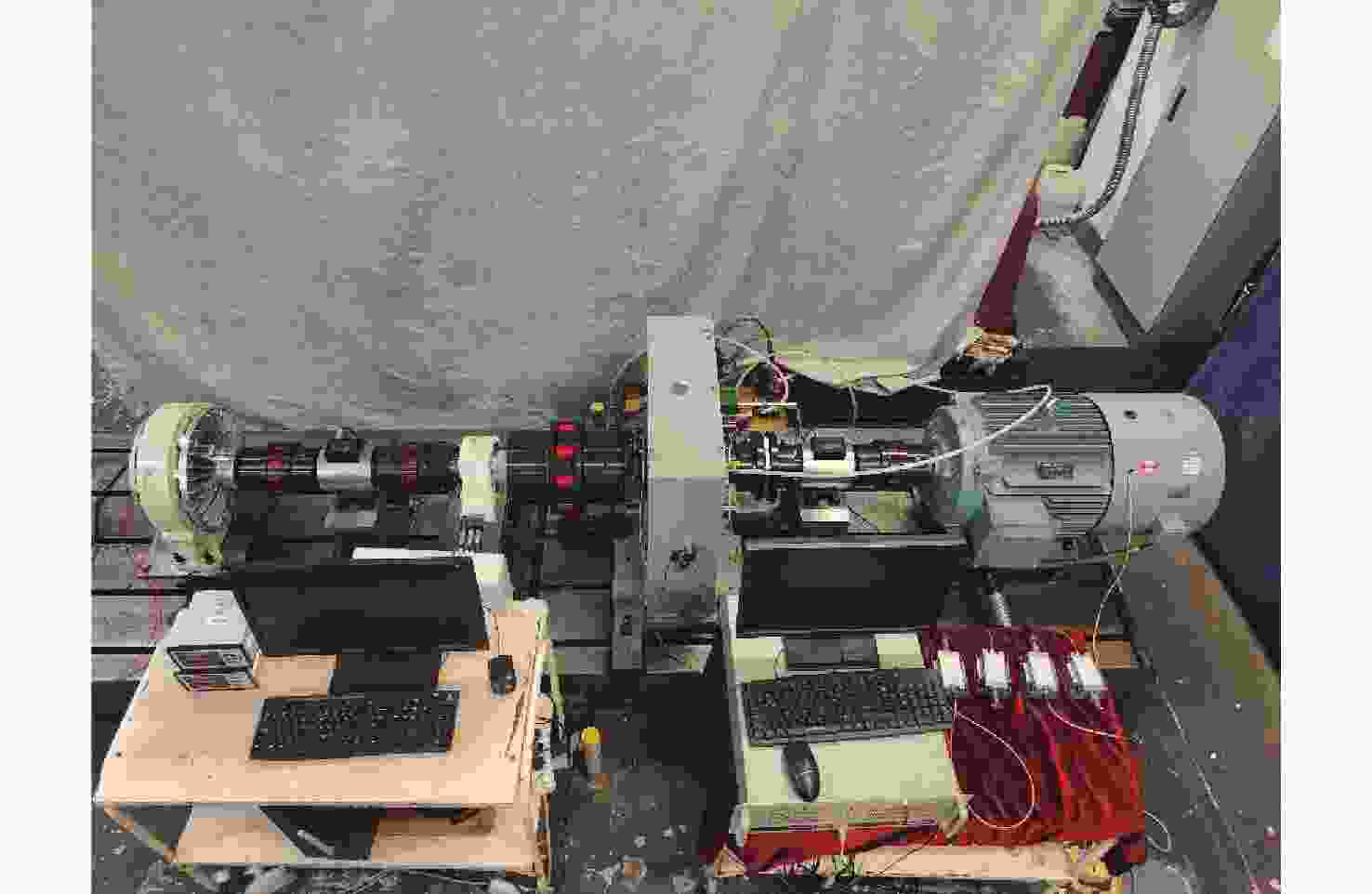

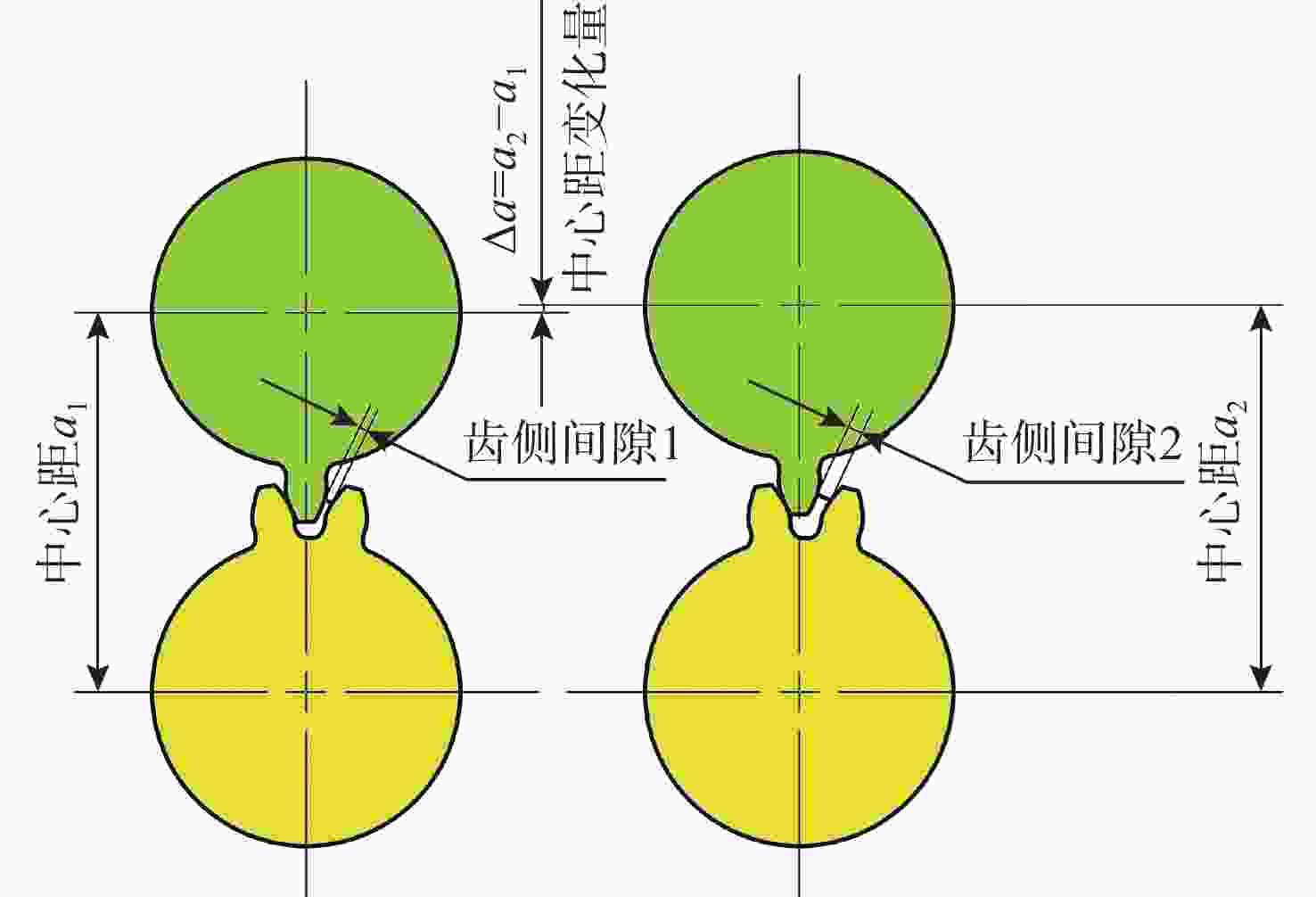

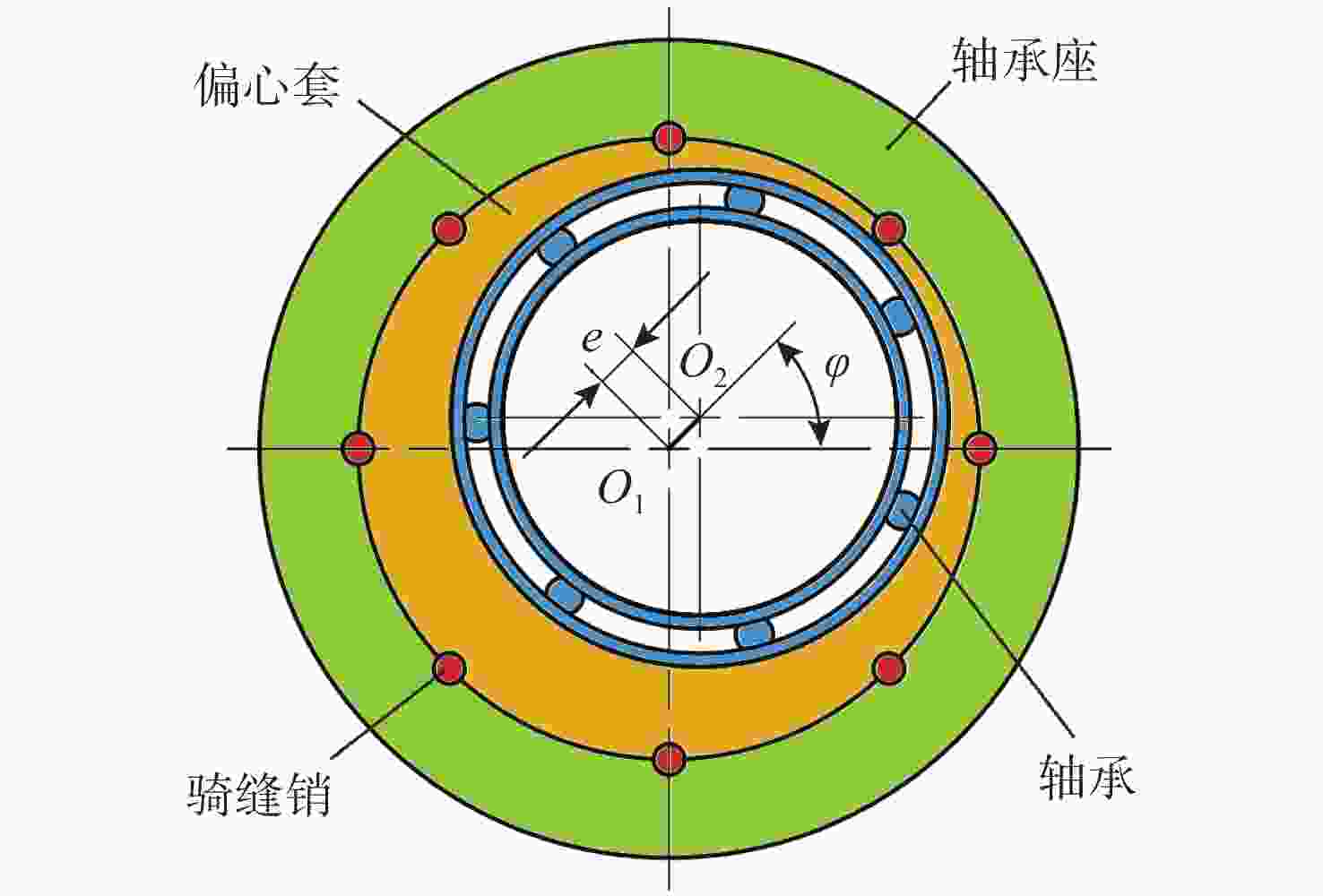

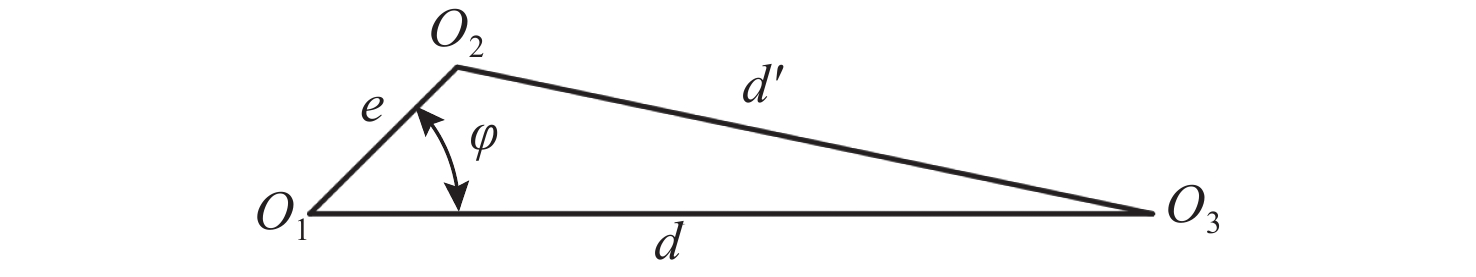

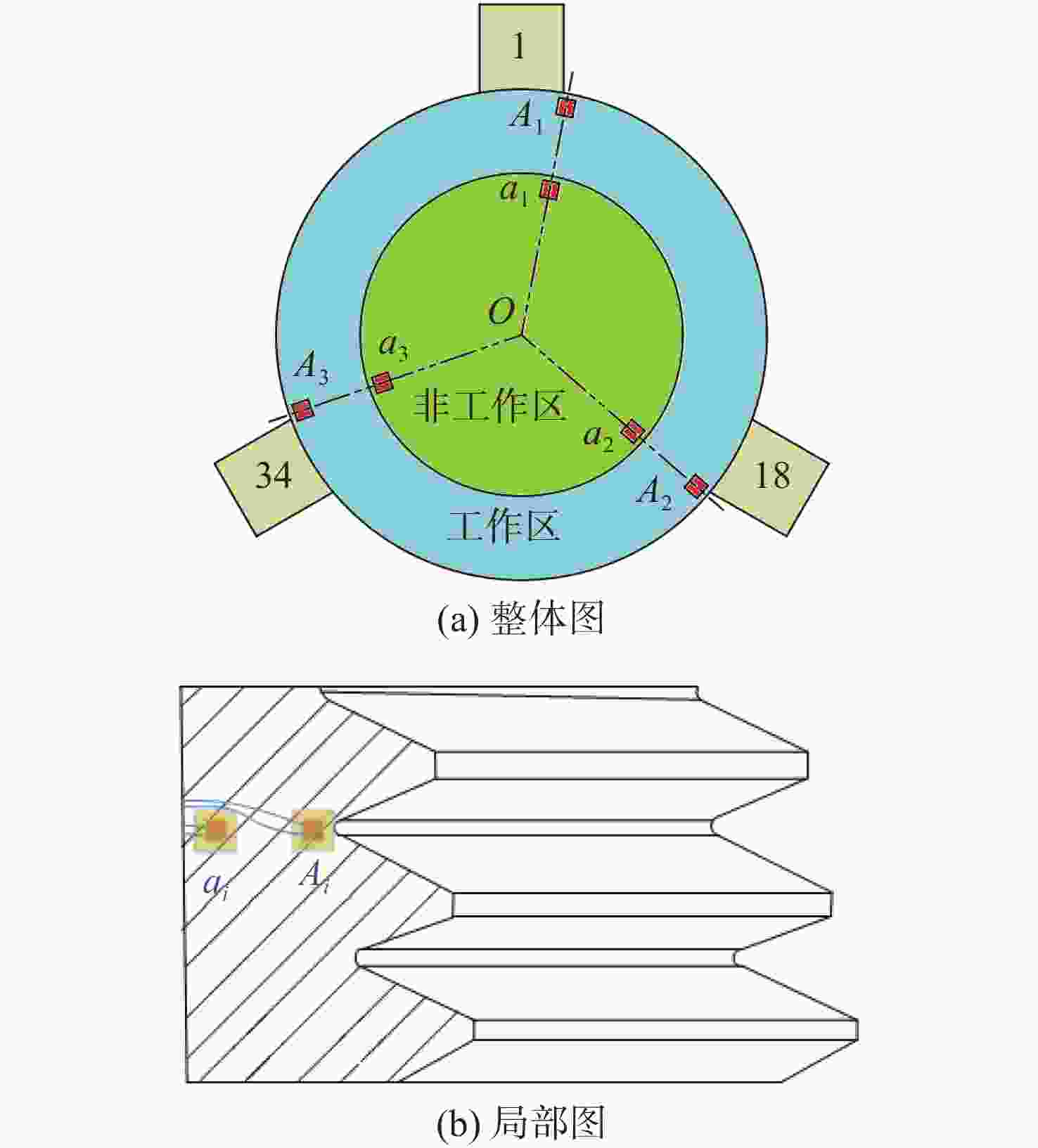

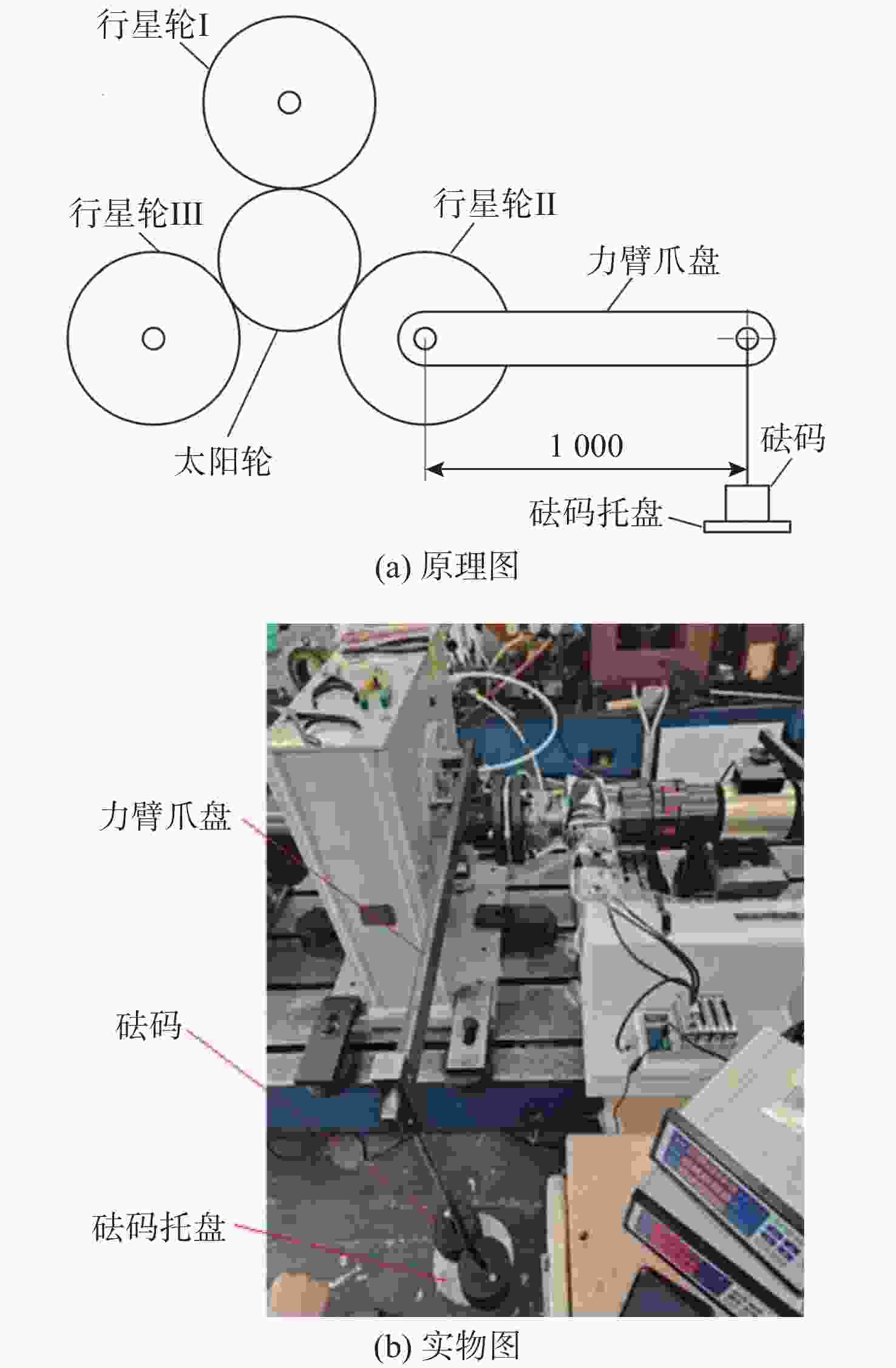

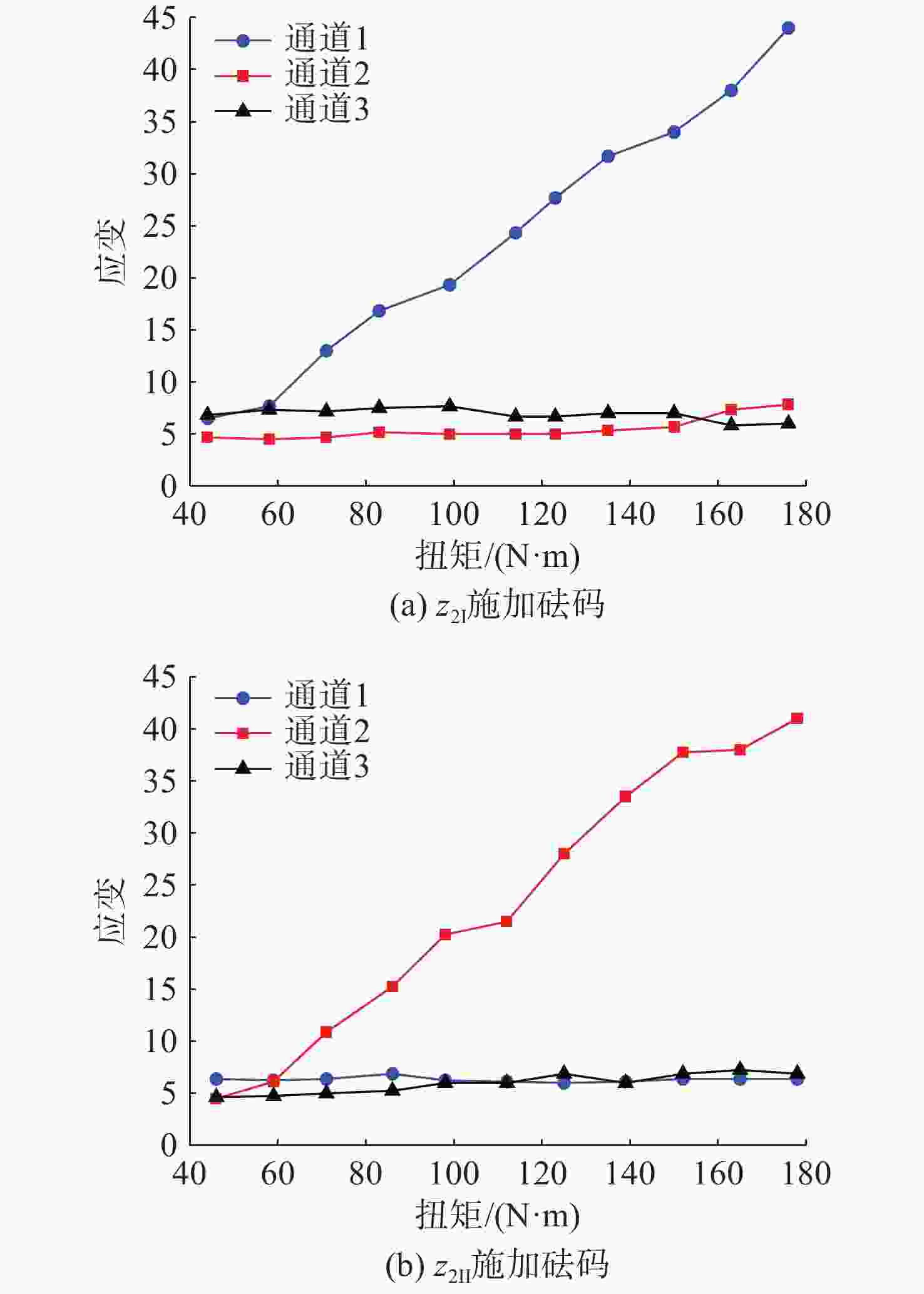

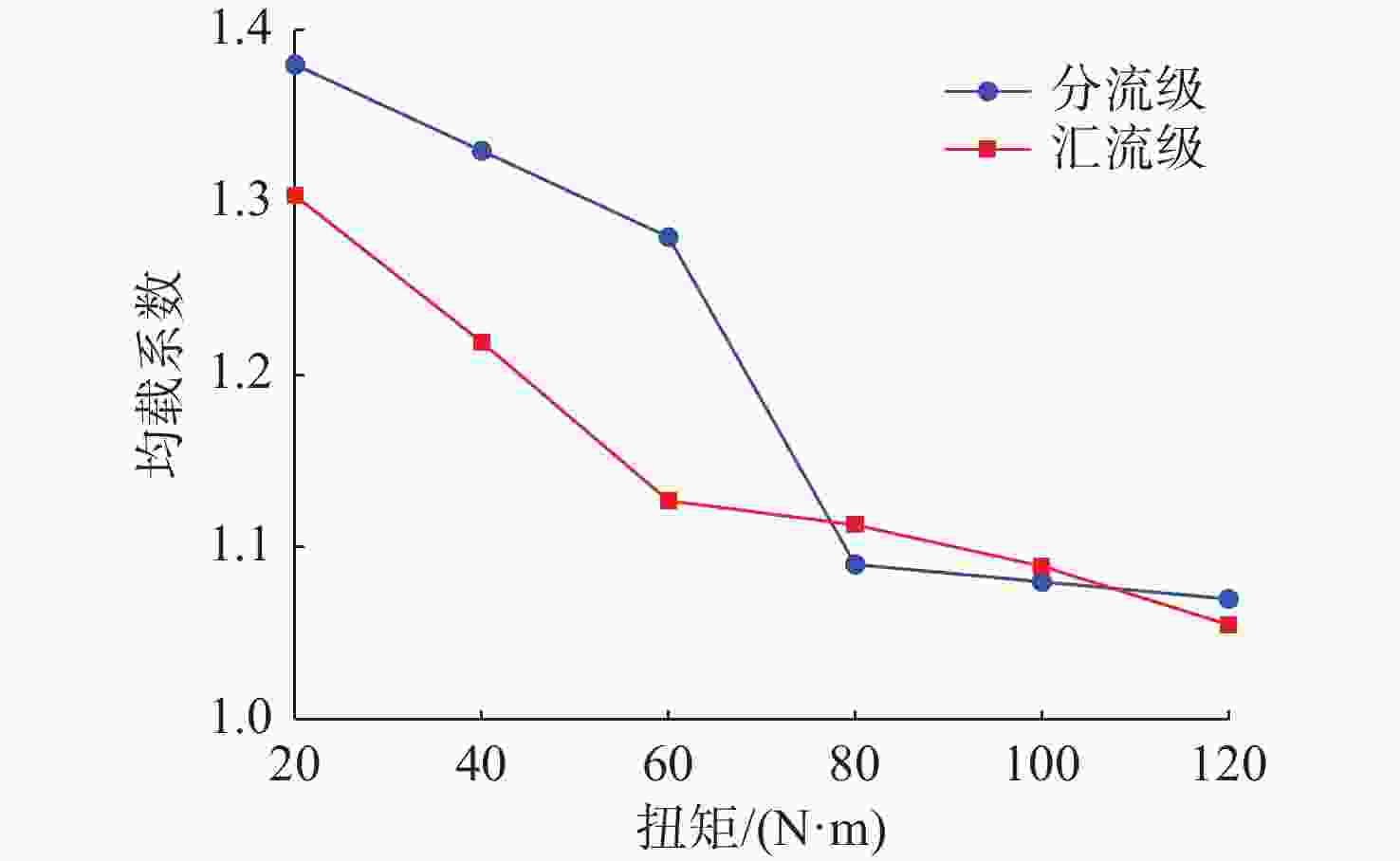

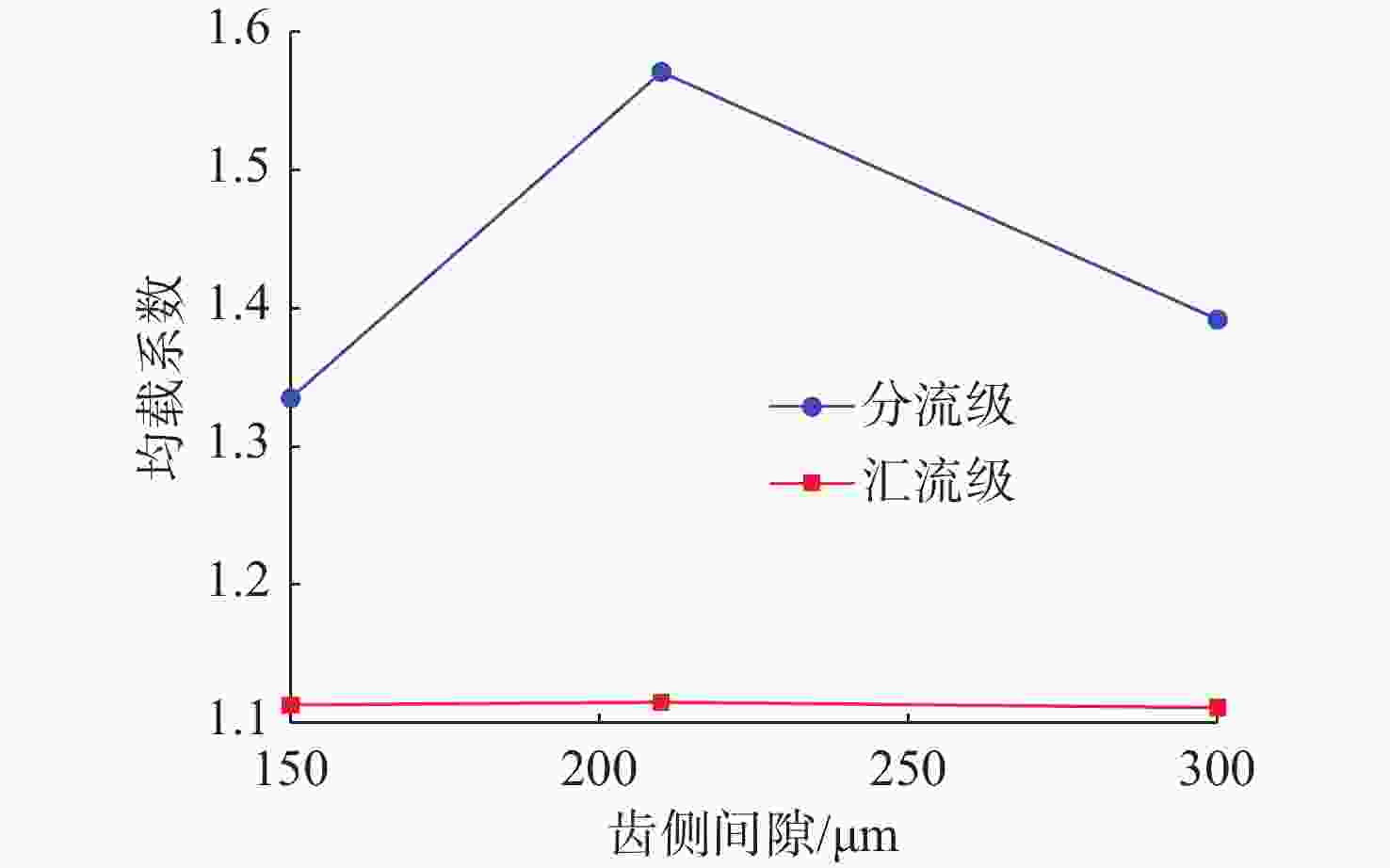

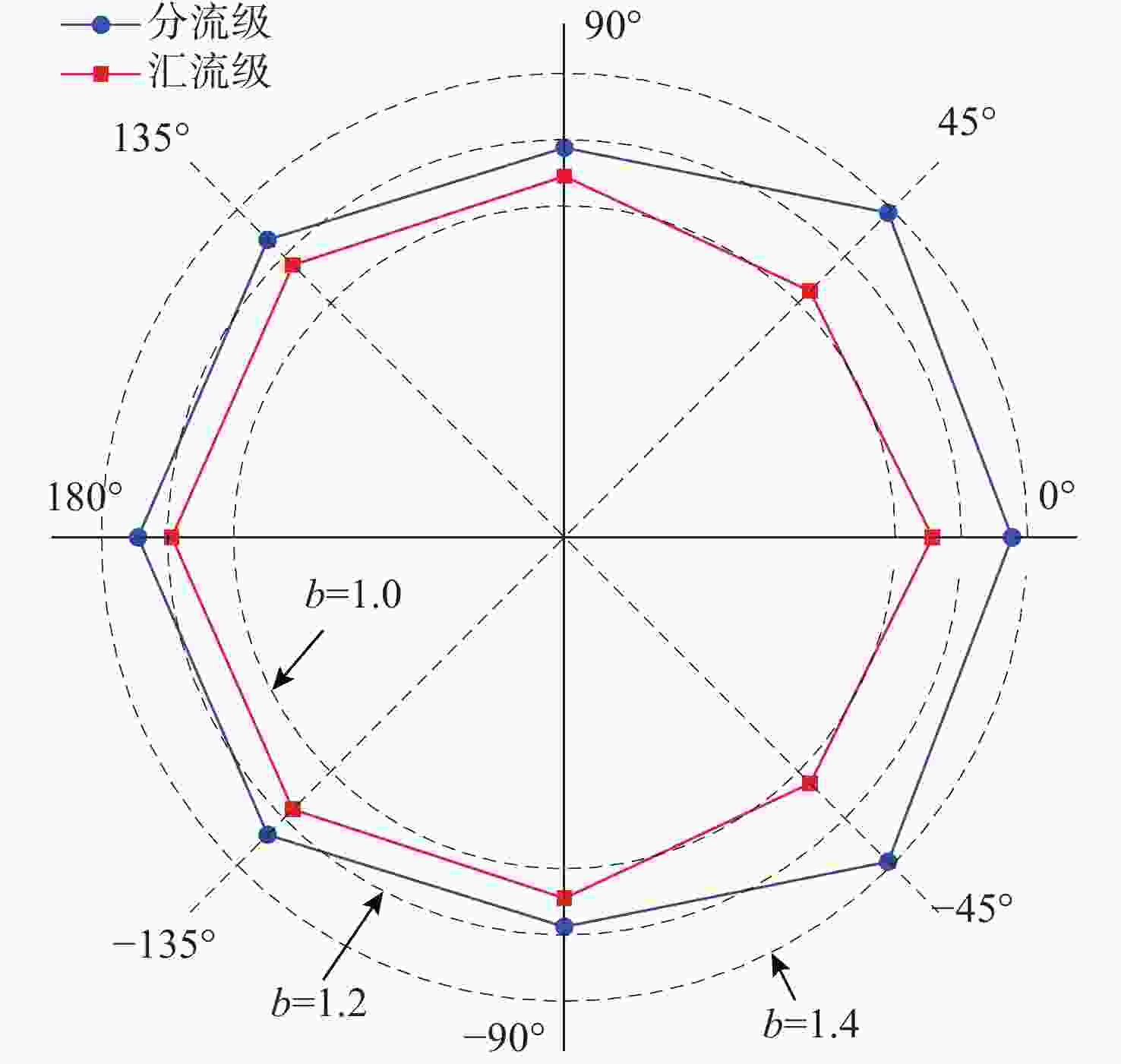

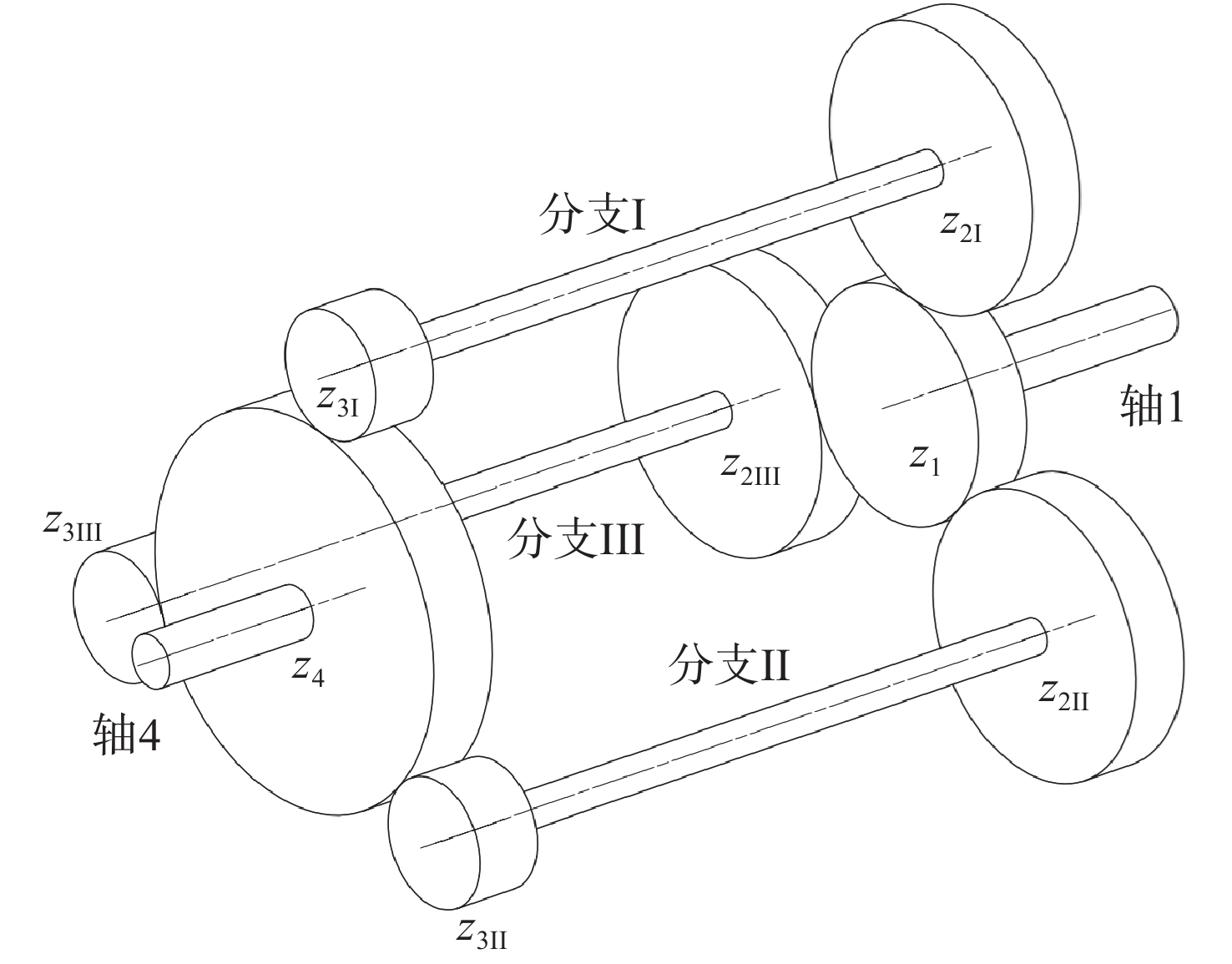

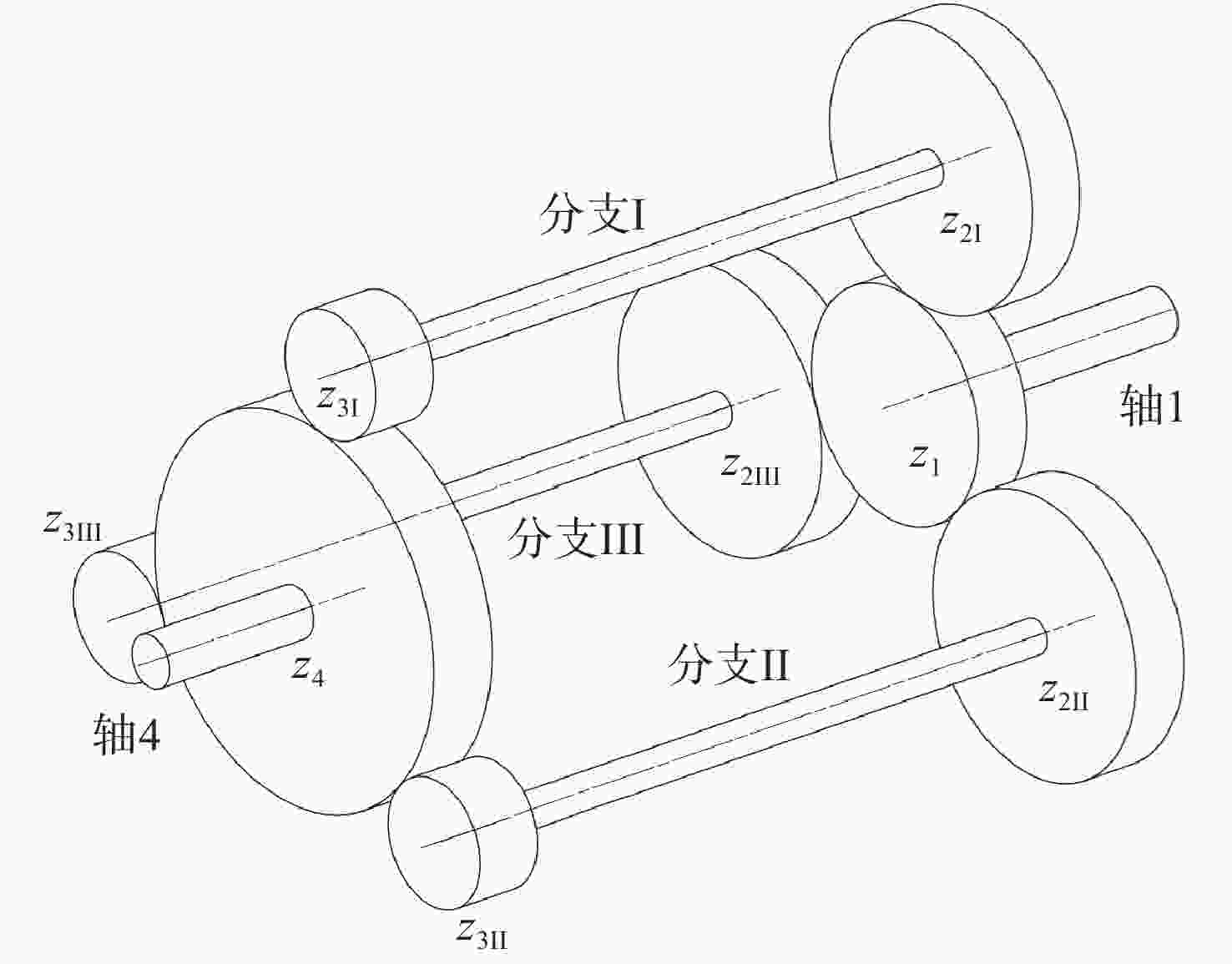

摘要: 针对目前齿轮传动系统均载特性试验未考虑齿侧间隙、轴偏心角等加工和安装误差等对均载特性的影响, 文中以定轴式功率三分支齿轮传动系统为研究对象, 搭建了齿轮传动系统均载特性试验台, 试验台设计中, 通过在轴承座处加装薄垫片实现齿侧间隙的精准调整, 通过定制偏心套结构实现轴偏心角度的可控调节。为探究均载特性的影响规律, 测试了不同工况下分流级与汇流级中心轮的齿根应力, 并采用温度补偿应变片消除温度干扰对测试精度的影响, 重点分析了负载、齿侧间隙及轴偏心角度与均载特性的关联关系。研究结果表明: 汇流级齿轮的均载特性优于分流级; 两级齿轮的均载效果均随载荷增大而提升; 轴偏心角度对齿轮均载特性的影响显著。Abstract: The current load sharing characteristic test of gear transmission systems does not consider the influence of processing and installation errors such as backlash and shaft eccentricity angle on load sharing characteristics. To address this issue, a load sharing characteristic test bench for a gear transmission system was built for a fixed axis power tri-branching gear transmission system. The backlash was accurately adjusted by adding a thin gasket at the bearing seat, and the shaft eccentricity angle was adjusted by designing the eccentric sleeve structure. The tooth root stress of the center gears of the split and combiner stages was tested under different operating conditions to explore the influence laws of the load sharing characteristics. Temperature compensation strain gauges were adopted to eliminate the influence of temperature interference on the test accuracy. The correlation between load, backlash, and shaft eccentricity angle and the load sharing characteristic was analyzed in detail. The results indicate that the load sharing characteristics of the combiner stage are superior to those of the split stage. The load sharing effect of the two-stage gears improves as the load increases; the shaft eccentricity angle has a significant impact on the load sharing characteristics of the gears.

-

表 1 齿轮参数表

Table 1. Parameters of gears

齿轮 模数/mm 齿数 螺旋角/ (°) 齿宽/mm 变位系数 z1 2.5 50 16 33 0.144 z2i 2.5 62 16 33 0 z3i 3.0 23 16 40 0 z4 3.0 71 16 40 −0.224 表 2 参试设备型号及参数表

Table 2. Model and parameters of test equipment

名称 型号 参数 动态应变测量仪 CT9316 16通道; 采样频率20 kHz 导电滑环 H75158-12-B0394 12通道; 额定电流5 A; 转速5 000 r/min 应变片 CHENGTEC120-2AA 灵敏度系数 2.0±1%; 动态响应频率范围 0~100 kHz 扭矩转速功率仪 CYT-30B 与转速扭矩传感器CYT-302配套使用 转速扭矩传感器 CYT-302 最大转速6 000 r/min; 最大扭矩3 000 N·m 电动机 YVF2-225M-2 电压380 V; 额定功率45 kW; 频率范围50~100 Hz 磁粉制动器 CZ-40 额定转矩400 N·m 变频器 V780 额定功率55 kW 梅花弹性联轴器 XL9-3/ XL13-1 转矩1 950 N·m, 转速4 750 r/min DJM09-1 转矩3 328 N·m, 转速9 000 r/min 表 3 太阳轮应变片布置位置表

Table 3. Layout on the strain gauges on the sun gear

通道编号 轮齿所属

太阳轮所在轮

齿编号应变

片组应变片

角度/(°)1 分流级太阳轮 1 [A1 a1] 0 2 分流级太阳轮 18 [A2 a2] 120 3 分流级太阳轮 34 [A3 a3] 240 4 汇流级太阳轮 1 [B1 b1] 0 5 汇流级太阳轮 25 [B2 b2] 120 6 汇流级太阳轮 49 [B3 b3] 240 -

[1] 余放, 王明为. 船舶减速装置的加工与设计[M]. 北京: 国防工业出版社, 2009. [2] HEATH G F, BOSSLER R B. Advanced rotor craft transmission(ART) program-final report: NASA CR-191057, ARL-CR-4[R]. Washington: NASA, 1993. [3] KISH J G. Sikorsky aircraft advanced rotor craft transmission(ART) program-final report: NASA CR-191079, ARL-CR-49[R]. Washington: NASA, 1993. [4] 张多丽, 周建星, 王海伟, 等. 偏心误差对分扭-并车齿轮传动系统均载性能的影响[J]. 机械传动, 2024, 48(11): 16-22. doi: 10.16578/j.issn.1004.2539.2024.11.003ZHANG D L, ZHOU J X, WANG H W, et al. Influence of eccentricity errors on load sharing performance of the split torque and the power confluence gear transmission system[J]. Journal of Mechanical Transmission, 2024, 48(11): 16-22. doi: 10.16578/j.issn.1004.2539.2024.11.003 [5] 李旺, 赵宁, 蔺彦虎, 等. 同轴面齿轮分扭传动的动态均载特性[J]. 西安交通大学学报, 2020, 54(9): 109-116. doi: 10.7652/xjtuxb202009012LI W, ZHAO N, LIN Y H, et al. Dynamic load sharing characteristics of the concentric torque split face gear transmission[J]. Journal of Xi’an Jiaotong University, 2020, 54(9): 109-116. doi: 10.7652/xjtuxb202009012 [6] 林何, 王三民. 参数对分扭-并车齿轮传动系统动载和均载特性的影响[J]. 机械传动, 2019, 43(5): 18-22. doi: 10.16578/j.issn.1004.2539.2019.05.004LIN H, WANG S M. Influence of parameter on dynamic load and load sharing characteristic of split torque-combine power gear transmission system[J]. Journal of Mechanical Transmission, 2019, 43(5): 18-22. doi: 10.16578/j.issn.1004.2539.2019.05.004 [7] 靳广虎, 高鹏, 周镇宇, 等. 两次载荷分流齿轮传动构型的静力学均载特性[J]. 航空动力学报, 2020, 35(10): 2104-2114.JIN G H, GAO P, ZHOU Z Y, et al. Static load sharing characteristic of twice load split gear transmission configuration[J]. Journal of Aerospace Power, 2020, 35(10): 2104-2114. [8] ZSCHIPPANG H A, LANZ N, KUCUK A K, et al. Face-gear drive: Assessment of load sharing, transmission characteristics and root stress based on a quasi-static analysis[J]. Mechanism and Machine Theory, 2020, 151: 103914. doi: 10.1016/j.mechmachtheory.2020.103914 [9] HU Z H, TANG J Y, WANG Q S, et al. Investigation of nonlinear dynamics and load sharing characteristics of a two-path split torque transmission system[J]. Mechanism and Machine Theory, 2020, 152: 103955. doi: 10.1016/j.mechmachtheory.2020.103955 [10] 姚澜, 赵兵, 徐景文, 等. 功率分流式齿轮系统均载特性影响因素分析[J]. 制造业自动化, 2016, 38(9): 50-53. doi: 10.3969/j.issn.1009-0134.2016.09.014YAO L, ZHAO B, XU J W, et al. Influence factor analysis of load sharing characteristic of power split gear system[J]. Manufacturing Automation, 2016, 38(9): 50-53. doi: 10.3969/j.issn.1009-0134.2016.09.014 [11] DONG H, ZHANG H Q, ZHAO X L, et al. Study on the load sharing characteristics of face-gear four-branching split torque transmission system[J]. Advances in Mechanical Engineering, 2021, 13(4): 1-15. [12] 周建星, 董海军. 基于非线性动力学的行星传动均载性能分析[J]. 机械科学与技术, 2008, 27(6): 808-811. doi: 10.13433/j.cnki.1003-8728.2011.04.026ZHOU J X, DONG H J. On load sharing characteristic of planetary gear system based on nonlinear dynamics[J]. Mechanical Science and Technology for Aerospace Engineering, 2008, 27(6): 808-811. doi: 10.13433/j.cnki.1003-8728.2011.04.026 [13] AYDOĞAN M Ö, SARIBAY Z B, ÖZGUVEN H N. Non-linear dynamic modeling and analysis of split-torque face gear drive systems[J]. Journal of Vibration and Acoustics, 2023, 145(3): 031003. doi: 10.1115/1.4056632 [14] GONG F, ZHU R P, WANG Q B. Dynamics modeling and load sharing performance optimization of concentric face gear split torque transmission systems[J]. Applied Sciences, 2023: 13(7): 4352. [15] KRANTZ T L, Delgado I R. Experimental study of split-path transmission load sharing: NASA TM-107202[R]. Washington: NASA, 1996. [16] 谭援强, 胡聪芳, 张跃春, 等. 封闭差动行星齿轮箱动态均载性能试验研究[J]. 机械工程学报, 2016, 52(9): 28-35. [17] 靳朝举. 风电齿轮箱行星结构动态均载测试方法研究[D]. 大连: 大连理工大学, 2014. [18] 吴样洋. 多级斜齿行星齿轮传动系统动力学研究[D]. 大连: 大连理工大学, 2016. [19] 王怀宾. 大功率风电组行星均载特性的试验研究[D]. 大连: 大连理工大学, 2017. [20] 杨望. 多柔性支撑行星齿轮传动系统动态均载研究[D]. 重庆: 重庆交通大学, 2018. [21] 黎康康, 张保松, 靳国忠, 等. 行星传动齿轮箱均载特性影响试验研究[J]. 现代制造工程, 2019(2): 87-94. doi: 10.16731/j.cnki.1671-3133.2019.02.016 [22] 陈振. 单级人字齿轮行星传动系统动力学特性试验研究[D]. 哈尔滨: 哈尔滨工业大学, 2017. [23] 胡升阳, 沈刚, 方宗德, 等. 行星传动系统均载与动载系数试验测量改进设计[J]. 哈尔滨工程大学学报, 2024, 45(2): 359-366. [24] 靳广虎, 高鹏, 严岳胜, 等. 刚度和齿隙对功率分流传动系统均载特性影响的敏感度分析[J]. 中南交通大学(自然科学版), 2021, 5(4): 1149-1159. doi: 10.11817/j.issn.1672-7207.2021.04.012 -

下载:

下载: