Research and Implementation of Aperture Measurement Method for Irregular Broken Hole on Target Plate

-

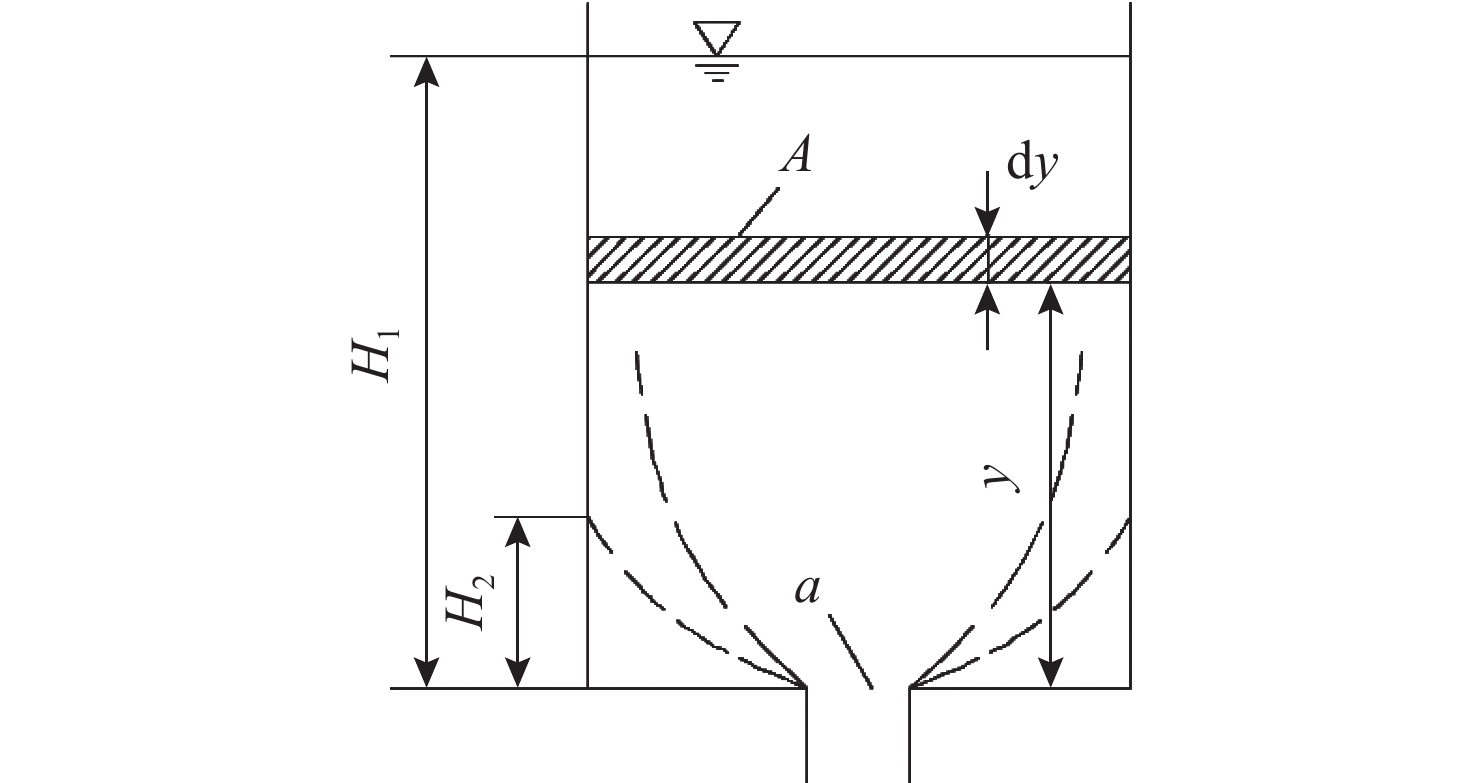

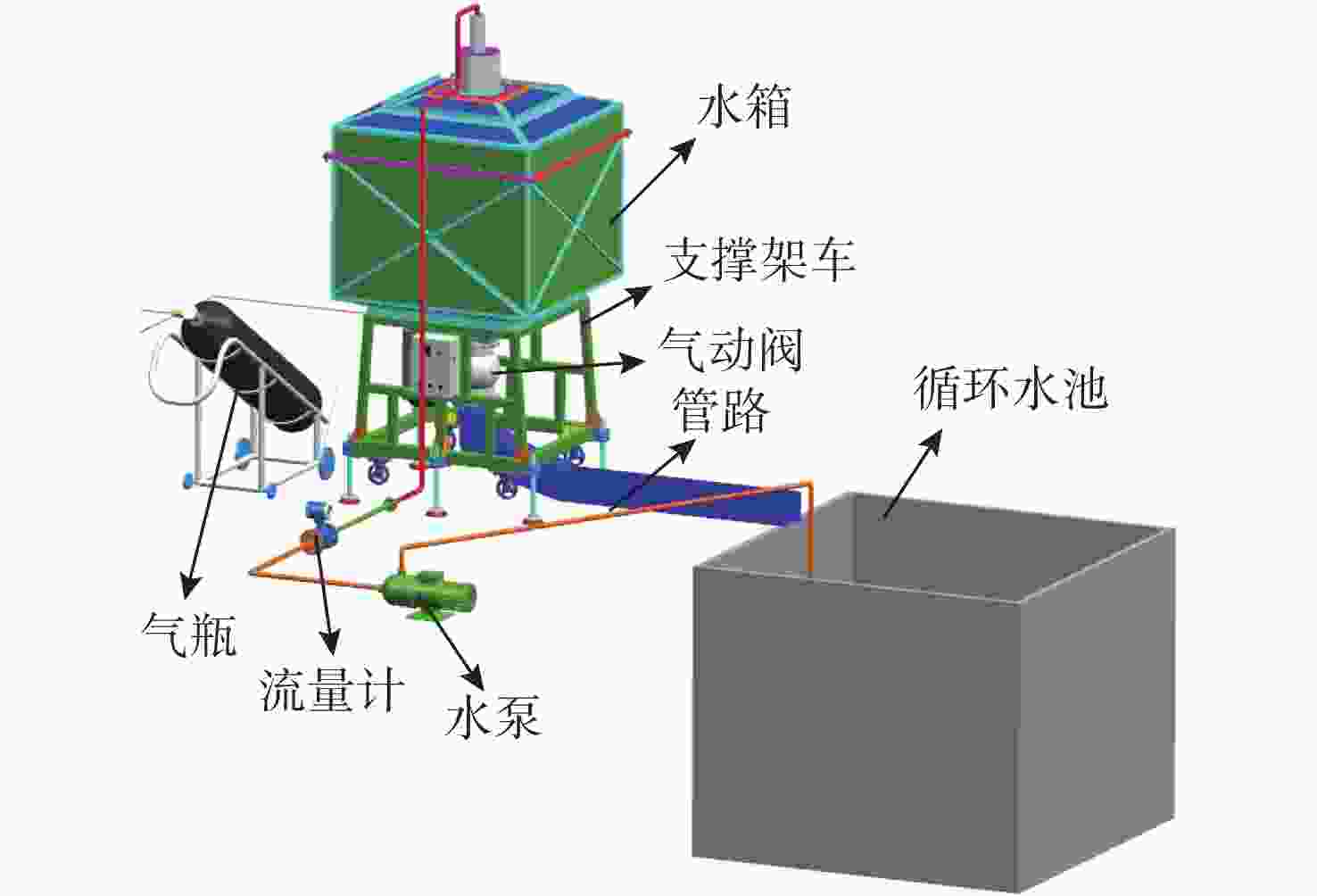

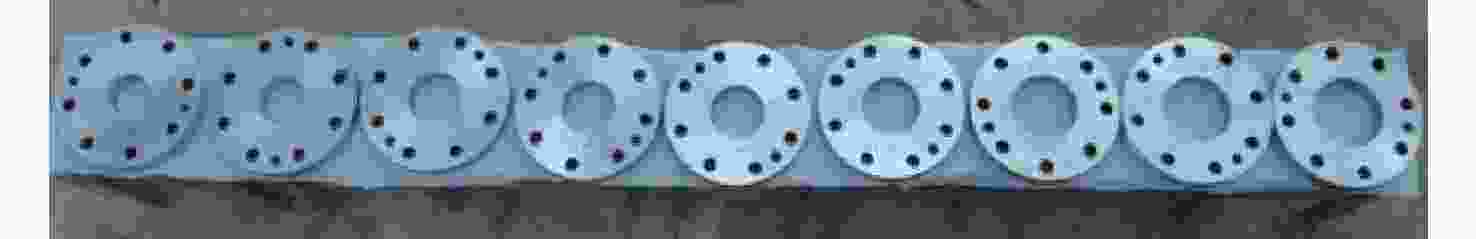

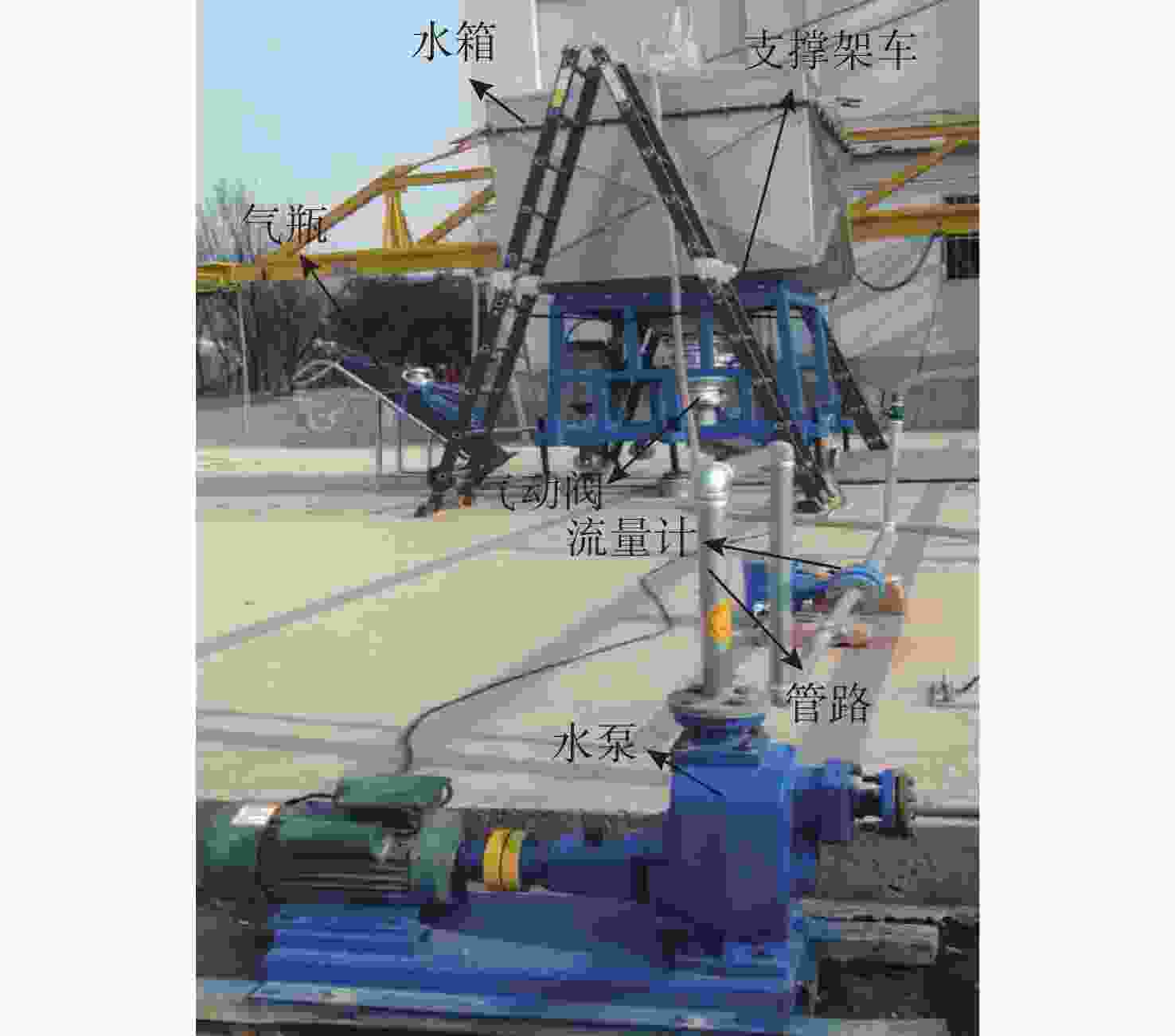

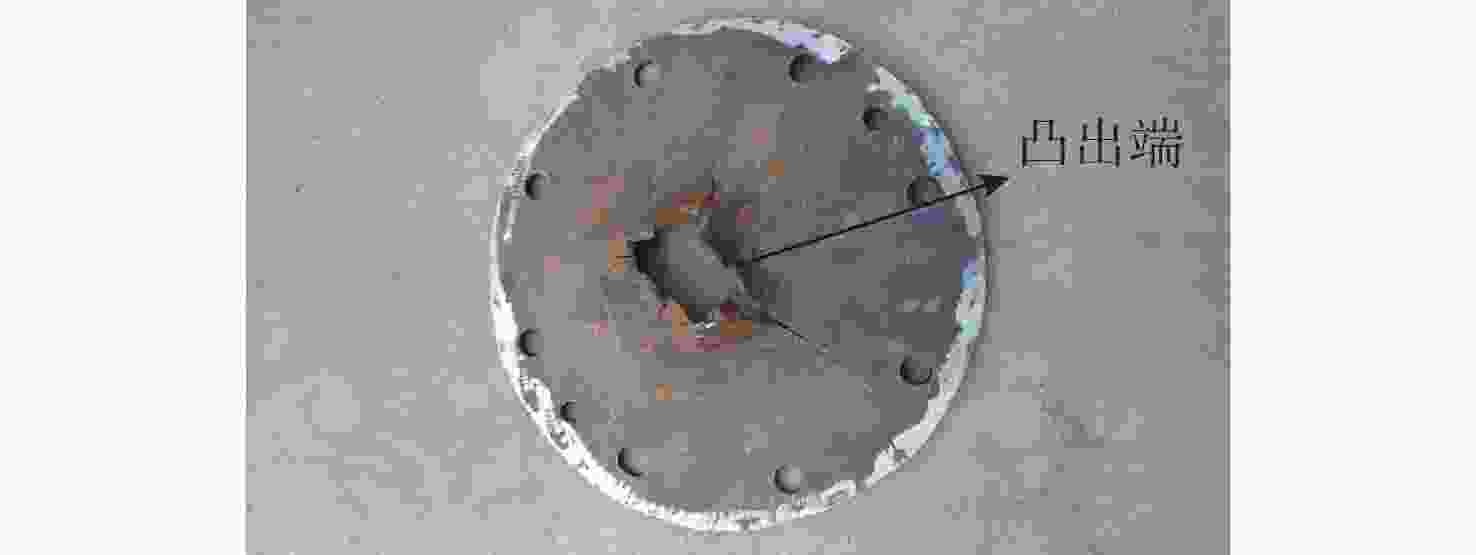

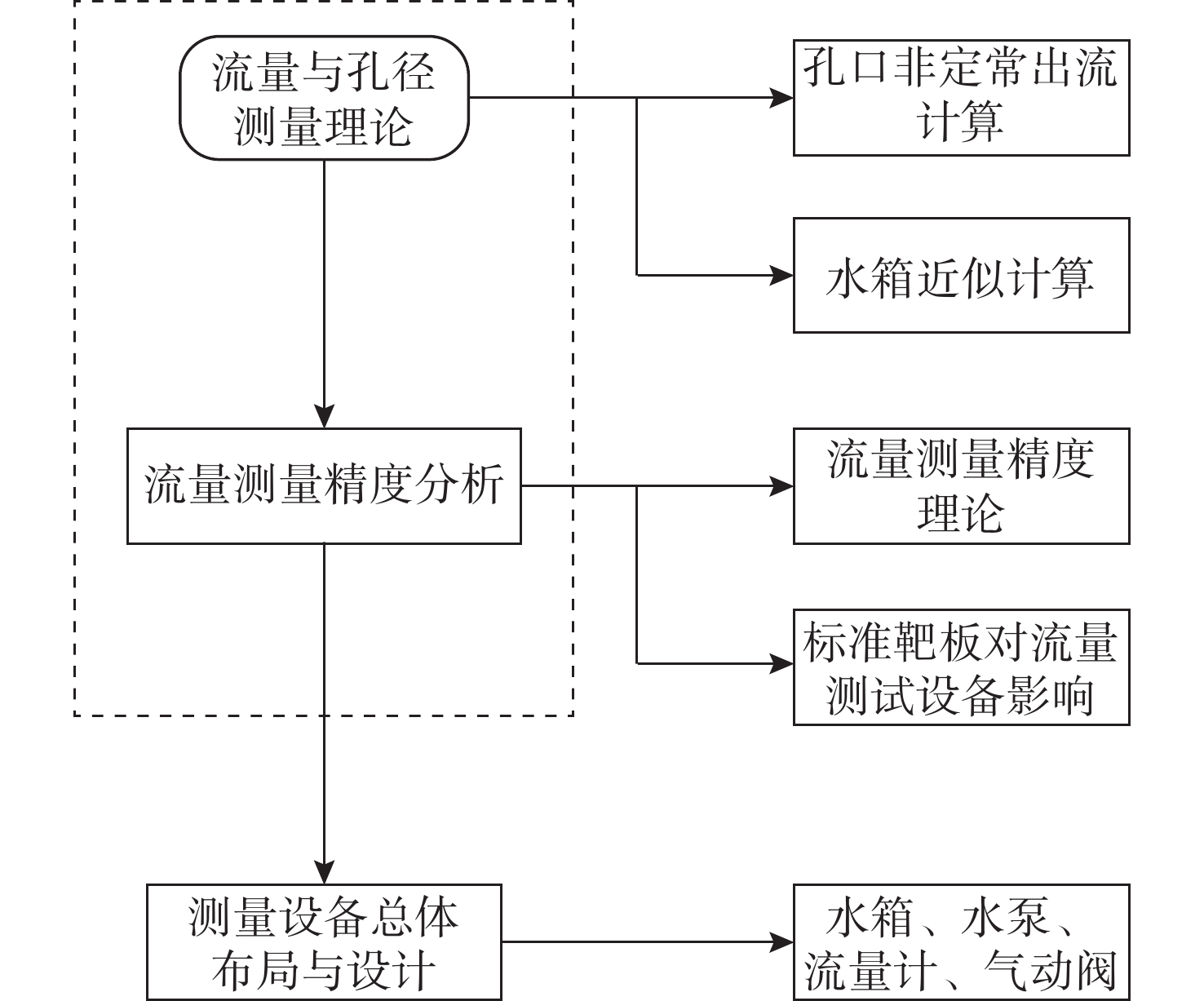

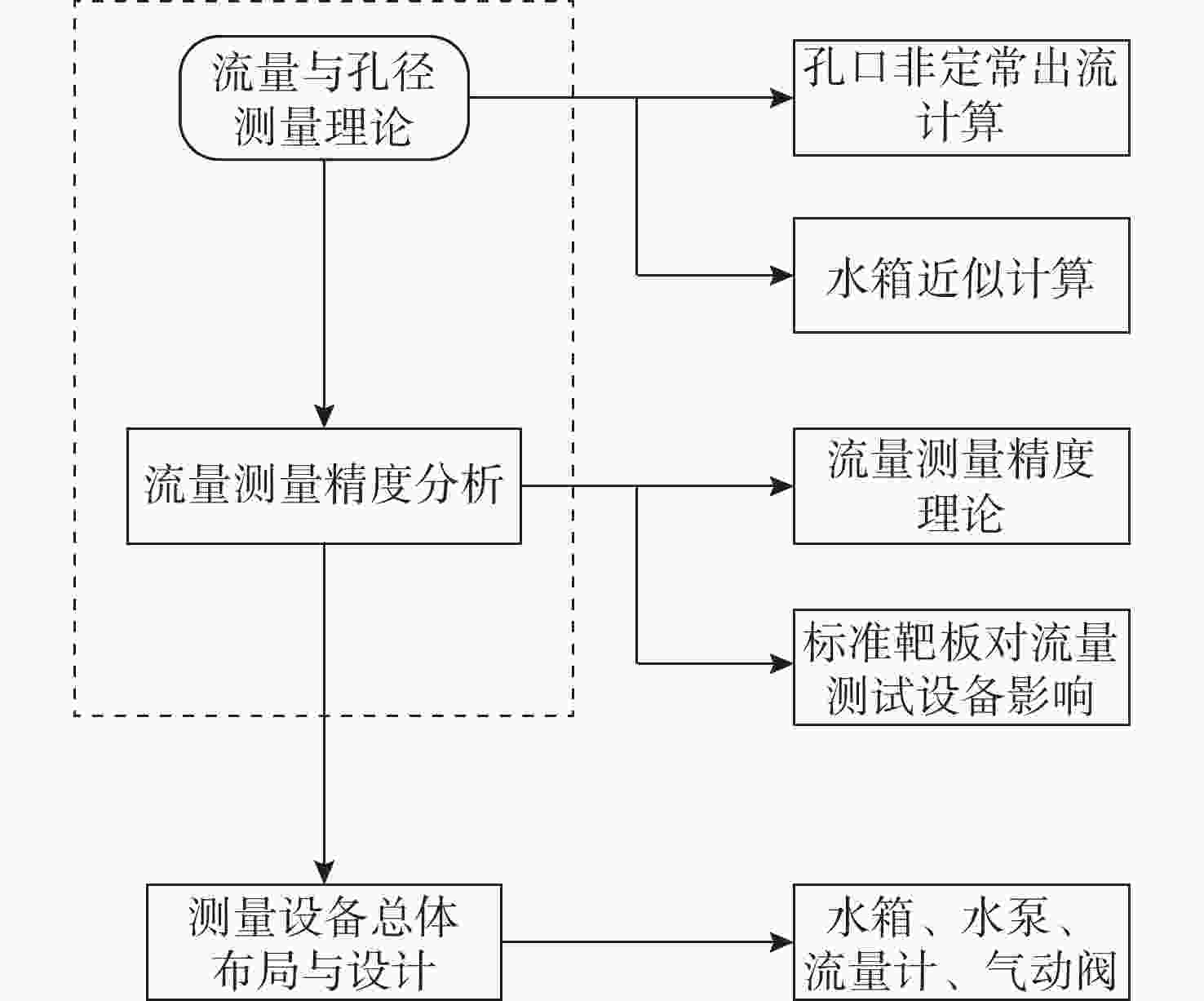

摘要: 针对靶板不规则破孔孔径难以准确测量的技术难题, 文中提出一种采用流量比对法的测量设备方案。该方案将不规则破孔等效为规则孔进行孔径大小准确测量, 具有贴近实际工况、简单易实施、工作可靠以及使用成本较低等显著优势, 对水下毁伤效能评估具有特殊表征意义。其核心原理亦可为其他行业解决类似不规则孔径测量需求提供重要参考。Abstract: Aiming at the technical problems of accurately measuring the aperture of irregular broken holes on target plates, this paper proposed a measurement device scheme based on the flow comparison method. The scheme equated irregular broken holes to regular holes for aperture characterization, which was close to the actual working condition, and it was simple and easy to implement, reliable, and low-cost. It has special characterization significance for underwater damage effectiveness evaluation. The core principle can also provide important reference for other industries to address similar irregular aperture measurement requirements.

-

Key words:

- target plate /

- broken hole /

- aperture measurement /

- flow comparison method

-

表 1 Φ100 mm靶板倒角和未倒角流场参数计算结果

Table 1. Calculation results of flow field parameters of chamfered and unchamfered Φ100 mm target plate

流场参数 未倒角 0.5 mm、45°倒角 入口静压/Pa 116 882.76 115682.66 出口静压/Pa 101 325 101325 静压压差/Pa 15 557.76 14357.66 入口总压/Pa 116 882.93 115682.82 出口总压/Pa 102 937.08 103051.46 总压压差/Pa 13 945.85 12631.36 表 2 箱体容积试验数据

Table 2. Test data of chamber volume

次数 气瓶压力

/MPa气瓶减压阀

压力/MPa执行机构压力

/MPa容积

/L1 5.8 0.9 0.45 3 185 2 3.8 0.9 0.45 3 181 3 3.0 0.9 0.45 3 181 4 8.7 0.9 0.45 3 183 5 6.5 0.9 0.45 3 184 6 11.5 0.9 0.45 3 181 7 8.5 0.9 0.45 3 180 表 3 不同孔径标准靶板流量测量数据

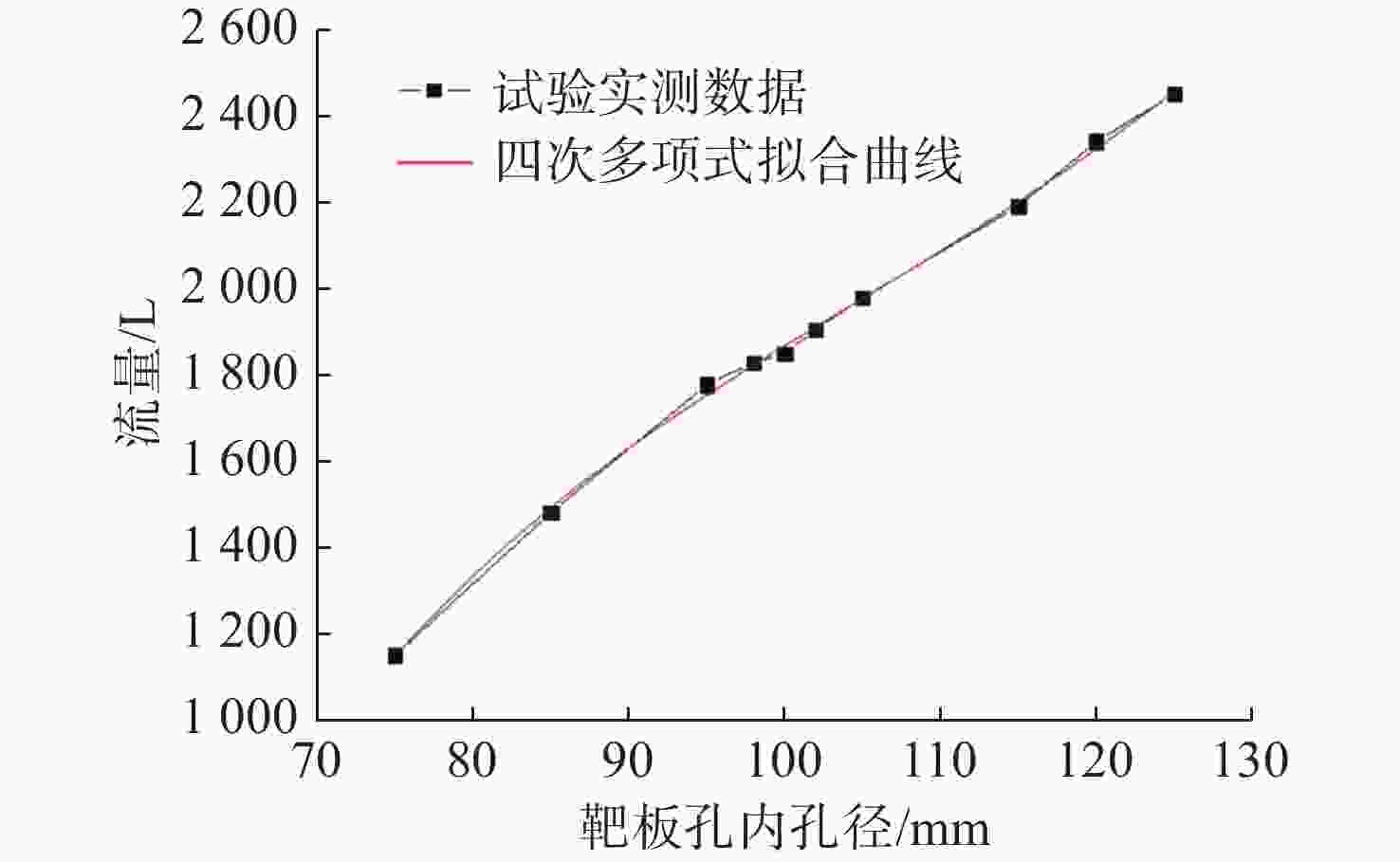

Table 3. Flow measurement data of standard target plates with different apertures

序号 内孔径/mm 流量/L 1 95 1 779.0 2 99 1 830.3 3 100 1 851.0 4 101 1 907.3 5 105 1 980.7 -

[1] DAVID F, IAN C, PAUL H. A fast and accurate model for the creation of explosion fragments with improved fragment shape and dimensions[J]. Defence Technology, 2022, 18: 159-169. doi: 10.1016/j.dt.2020.12.004 [2] 王冬生. 基于光纤光栅系统的流量测量研究[D]. 秦皇岛: 燕山大学, 2014. [3] 罗守南. 基于超声多普勒方法的管道流量测量研究[D]. 北京: 清华大学, 2004. [4] 肖骁. 基于亥姆霍兹线圈励磁的电容式电磁流量测量技术研究[D]. 成都: 电子科技大学, 2014. [5] 陶晓磊. 基于调节阀的流量测量方法研究[D]. 杭州: 中国计量大学, 2014. [6] 沈昱明. 流量测量中若干问题的计量学基本原则[J]. 计量学报, 2008, 29(5): 472-474.SHEN Y M, Principles of metrology for problems in the flow measurement[J]. Acta Metrologica Sinica, 2008, 29(5): 472-474. [7] 金珍珍, 梅武军, 周卫华, 等. 基于FPGA和单片机的孔径测量系统[J]. 轻工机械, 2022, 40(1): 71-77.JIN Z Z, MEI W J, ZHOU W H, et al. Aperture measurement system based on FPGA and MCU[J]. Light Industry Machinery, 2022, 40(1): 71-77. [8] 李治国, 马峰, 朱炜, 等. 基于深度学习神经网络的水中爆炸靶板变形响应预测研究[J]. 水下无人系统学报, 2024, 32(6): 1045-1052, 1062.LI Z G, MA F, ZHU W, et al. Prediction of deformation response of target plate in underwater explosion based on deep learning neural network[J]. Journal of Unmanned Undersea Systems, 2024, 32(6): 1045-1052, 1062. [9] 邵建军. 一种爆破型鱼雷战斗部对舰船毁伤效能评估方法[J]. 水下无人系统学报, 2017, 25(4): 272-277.SHAO J J, An evaluation method for damaging efficiency of blasting torpedo warhead to warship[J]. Journal of Unmanned Undersea Systems, 2017, 25(4): 272-277. [10] 谢振华, 宋存义. 工程流体力学[M]. 北京: 冶金工业出版社, 106-107. [11] 于洪仕, 张涛, 葛利俊. 多孔孔板流出系数和压力损失的影响因素[J]. 化工自动化及仪表, 2016, 43(1): 20-22, 88.YU H S, ZHANG T, GE L J. Influencing factors for discharge coefficient and pressure loss of multi-hole orifice plate[J]. Control and Instruments in Chemical Industry, 2016, 43(1): 20-22, 88. -

下载:

下载: