Design and Verification of End Face Bidirectional Self-Sealing Structure

-

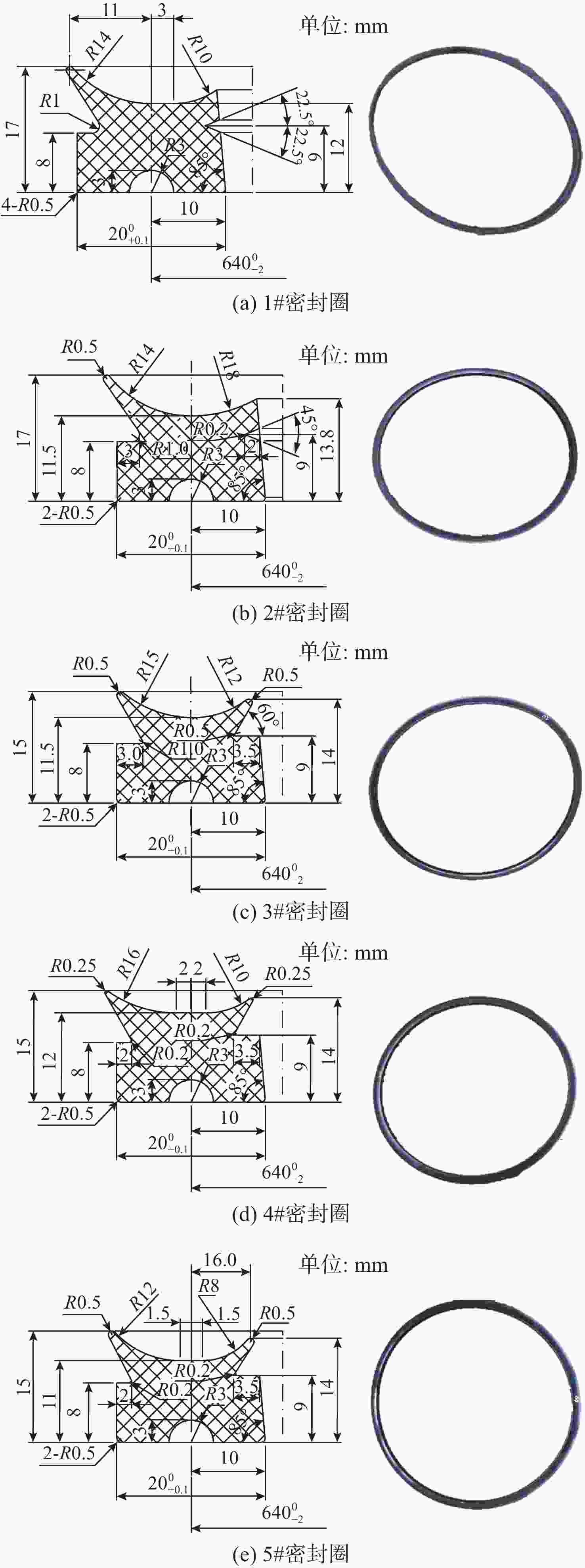

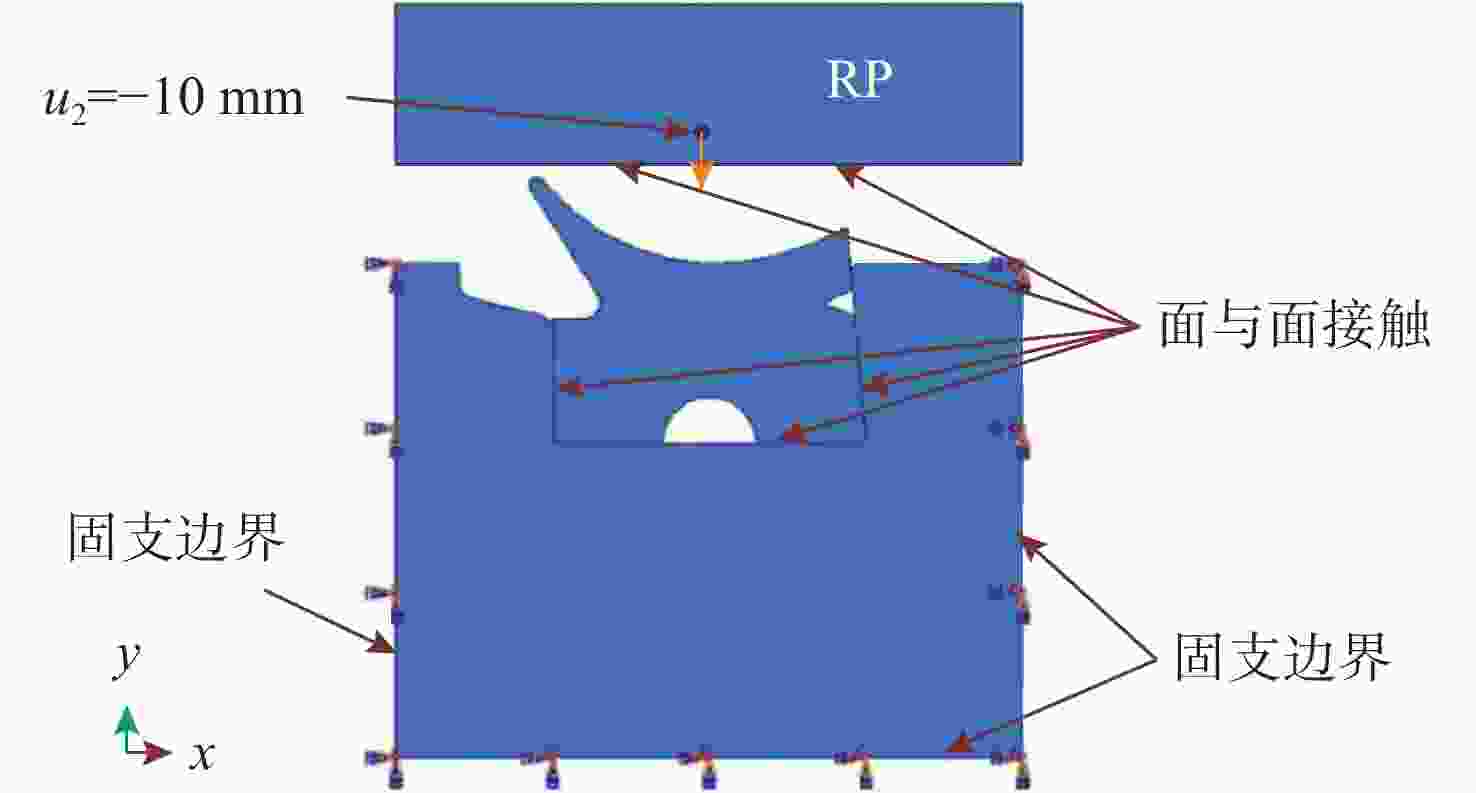

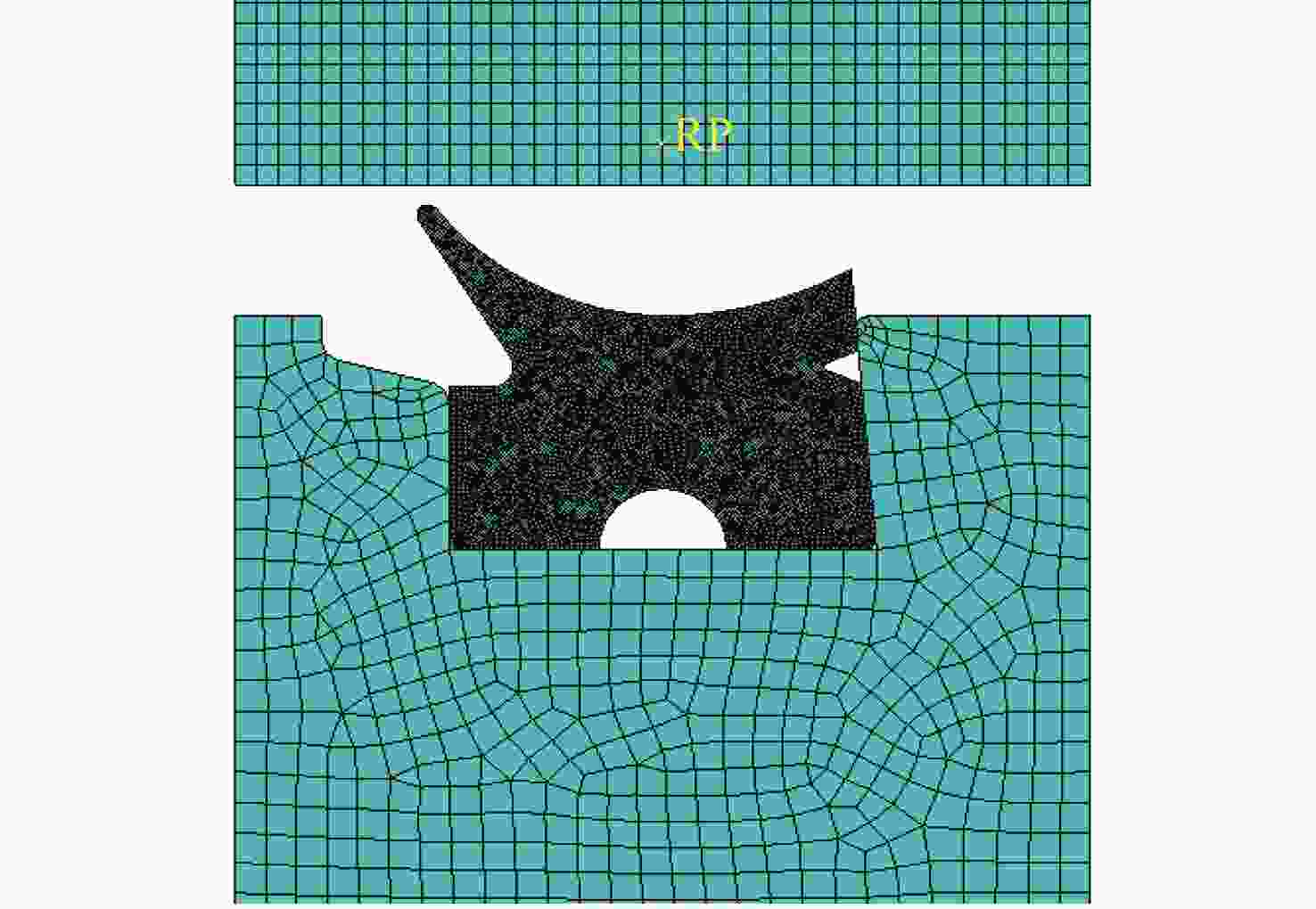

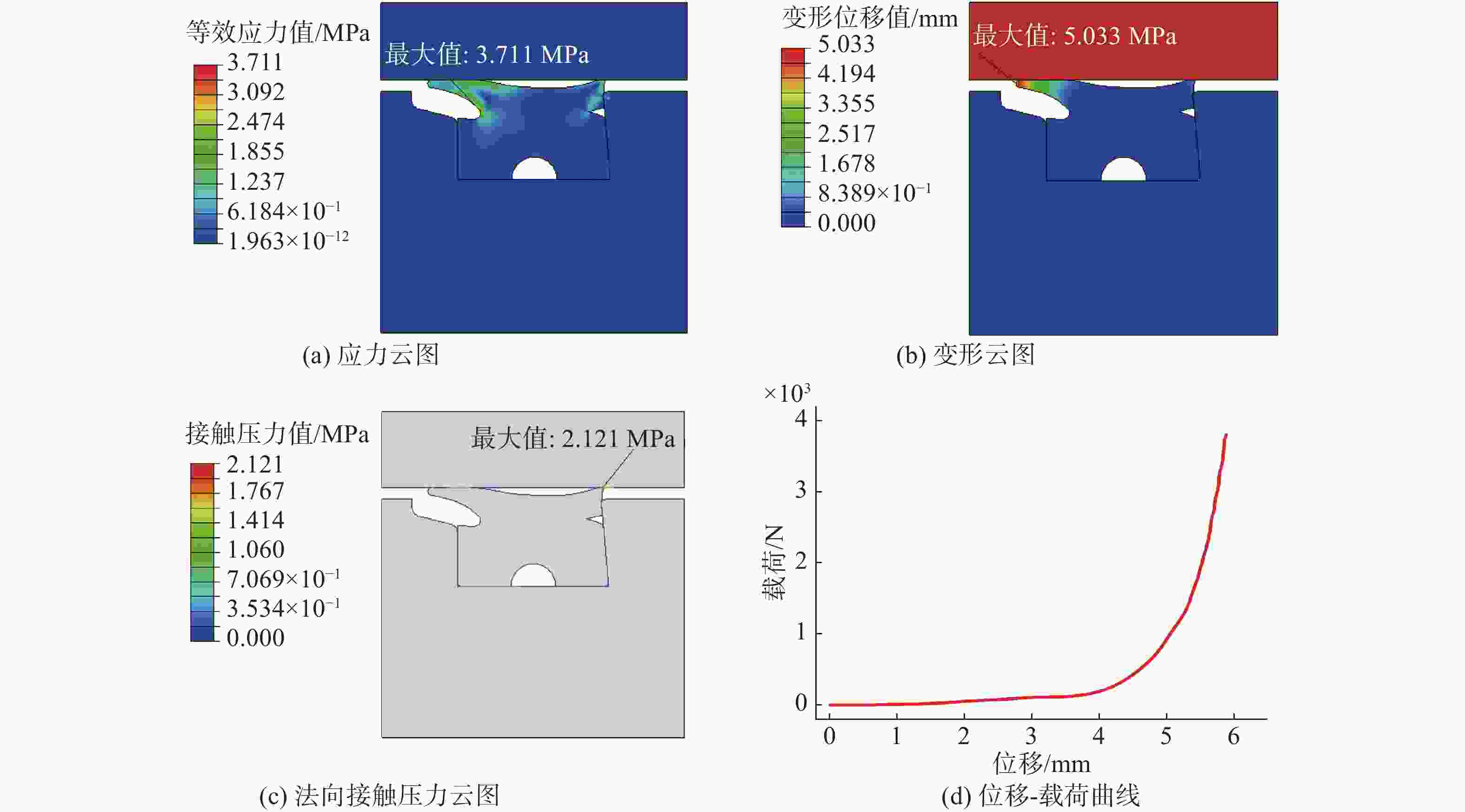

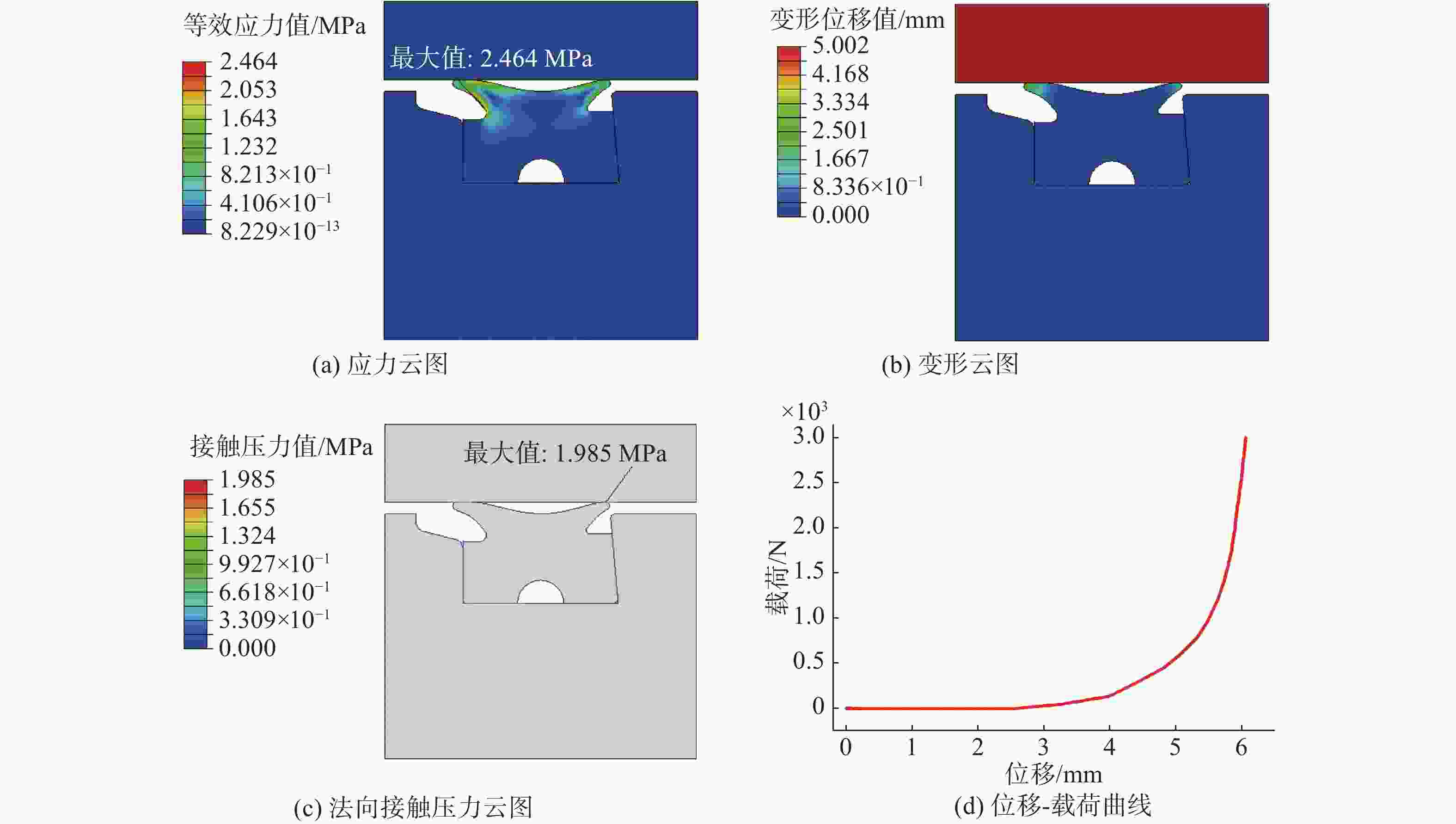

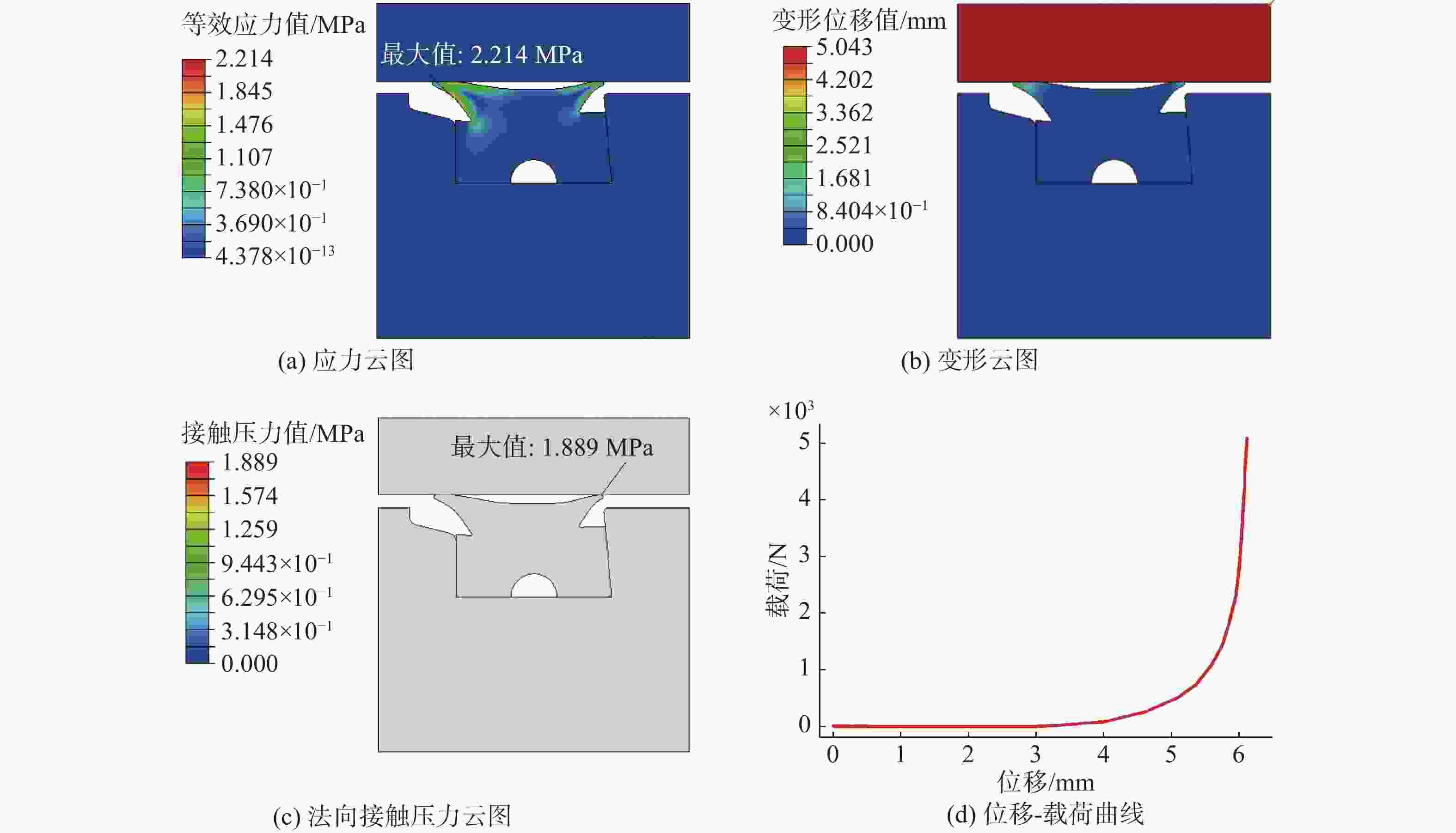

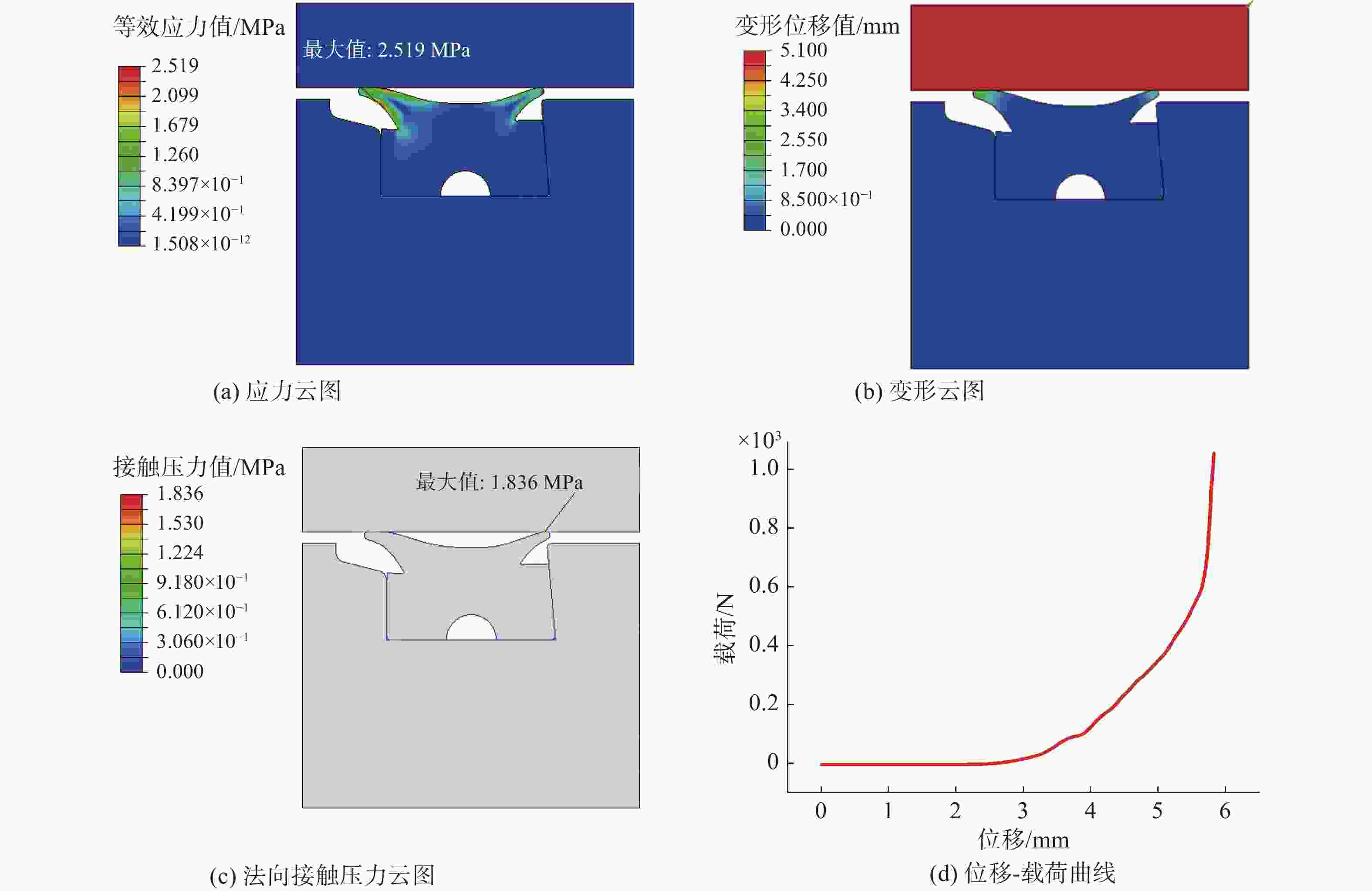

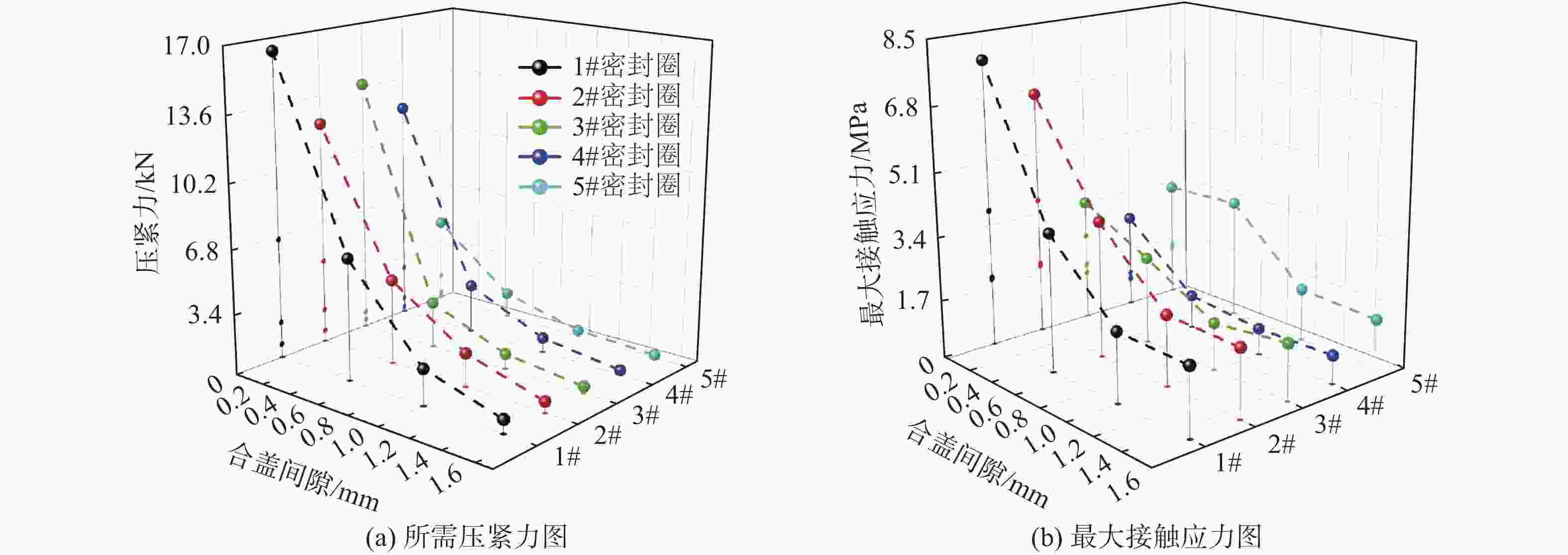

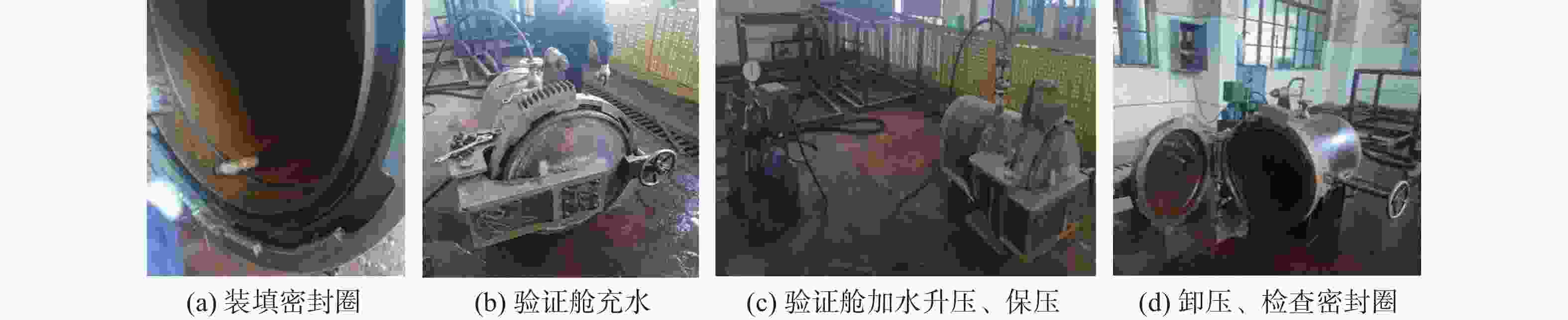

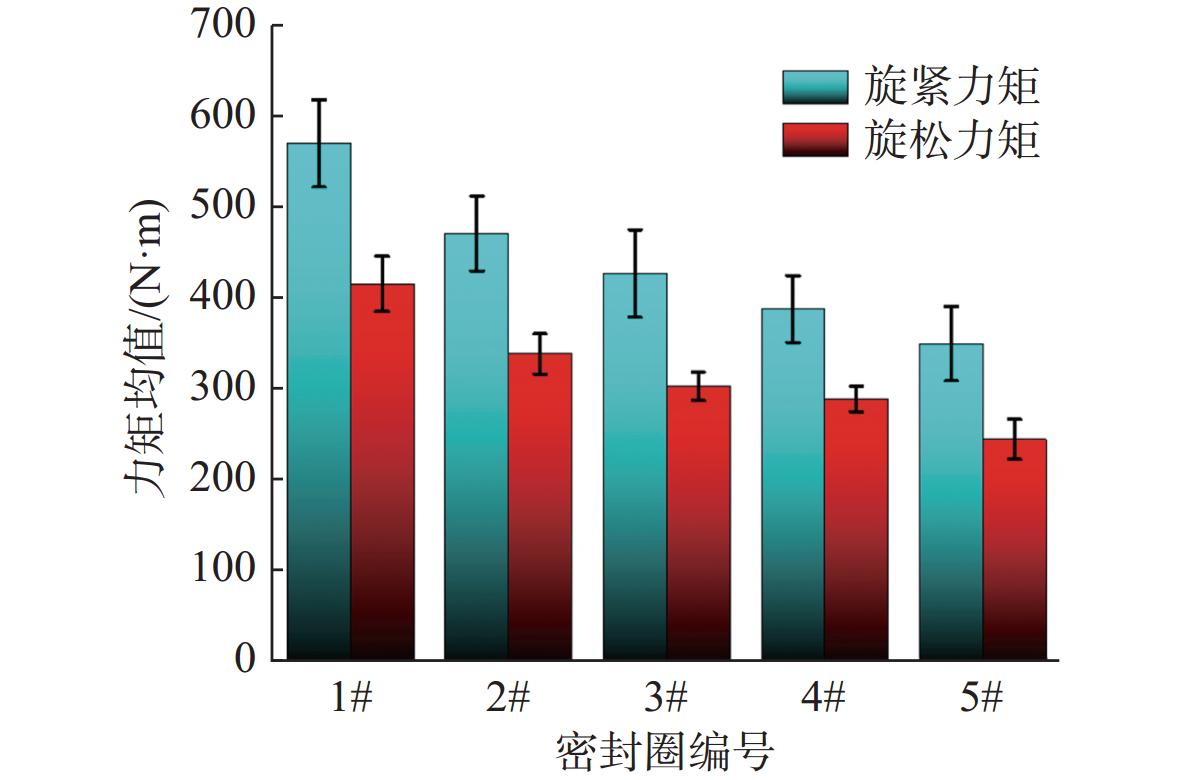

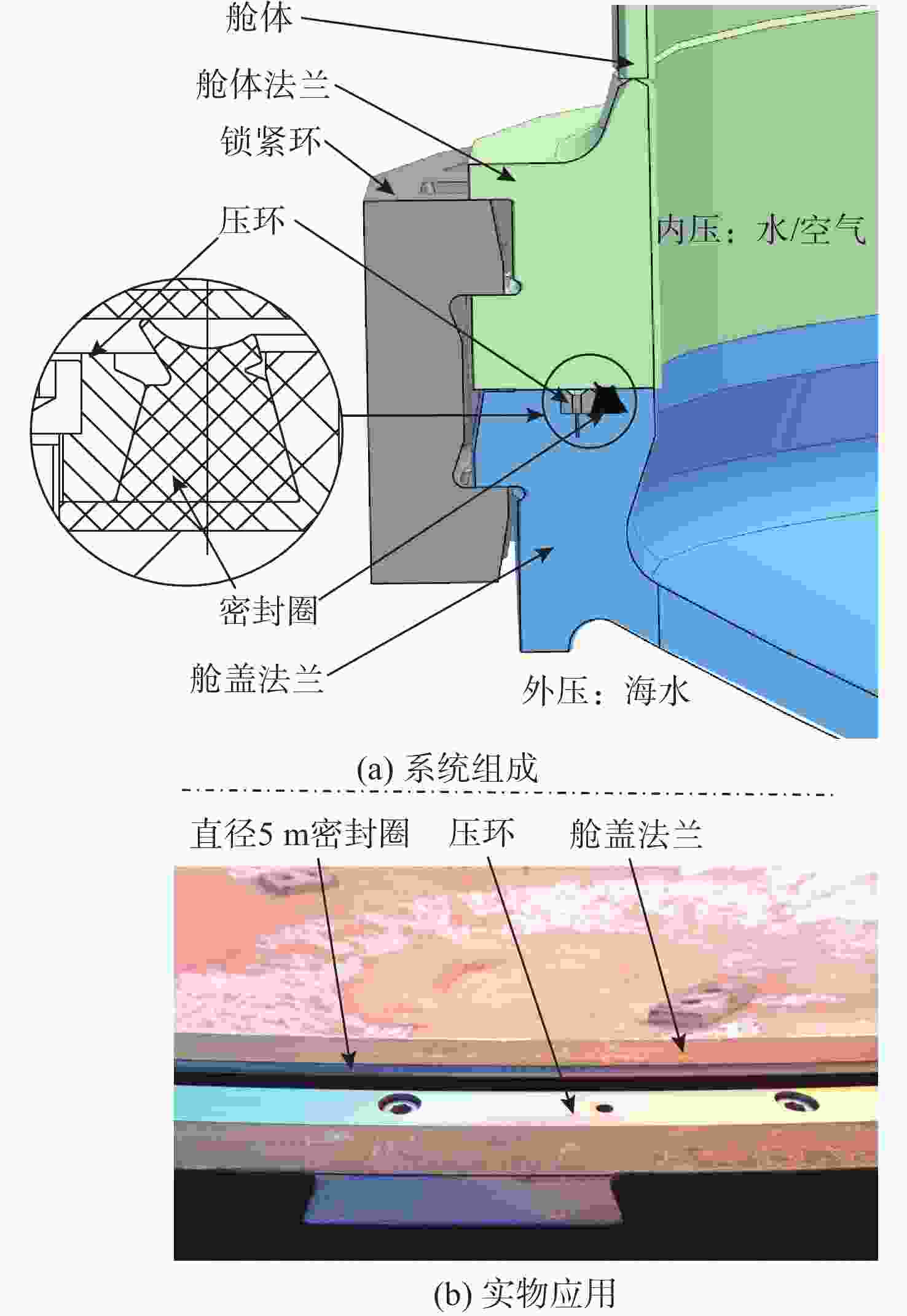

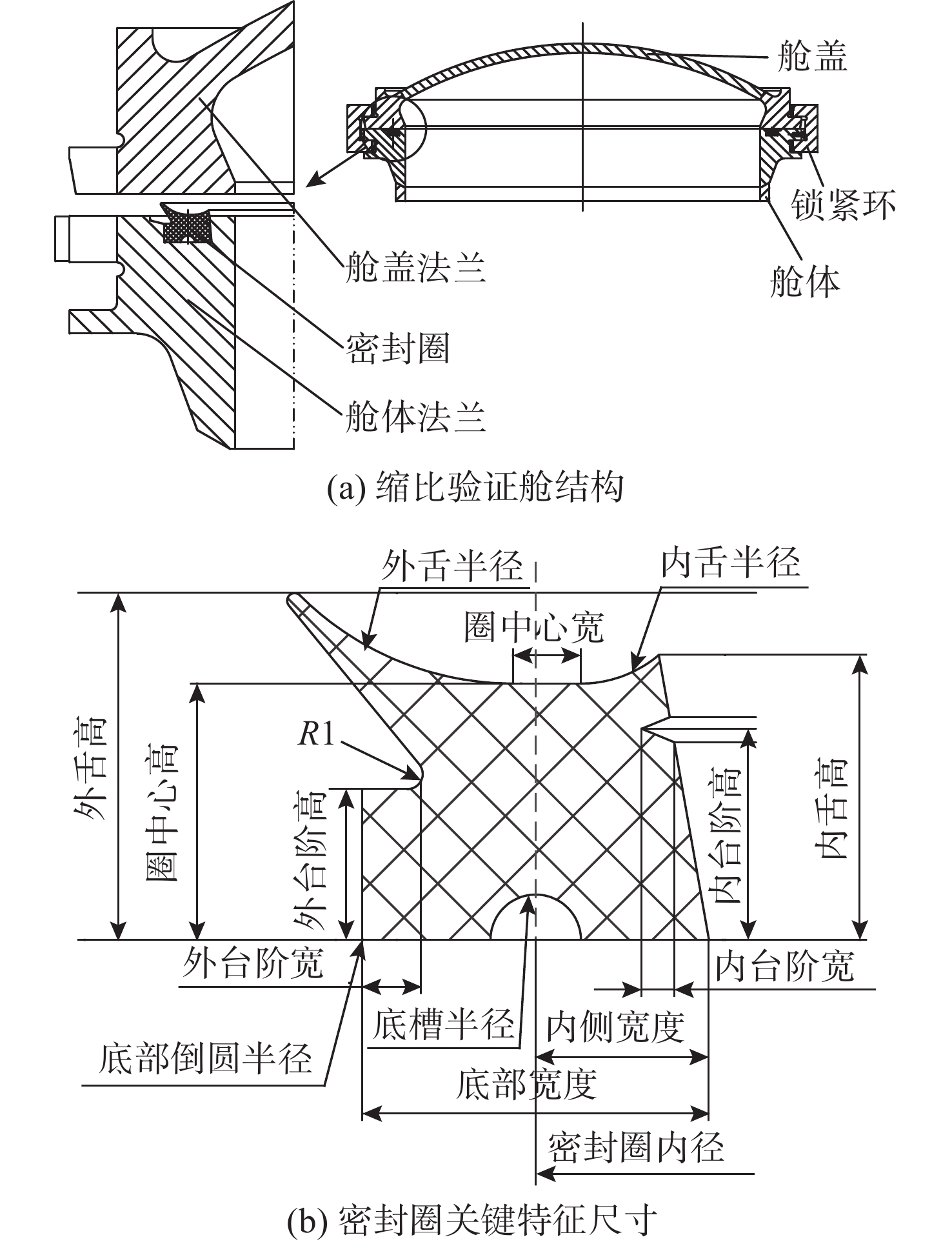

摘要: 为实现水下大口径舱盖的端面双向密封, 并解决合盖过程密封圈反力大的问题, 创新地结合舌形截面良好的自密封优势和燕尾防脱出结构, 设计了5种规格的高低舌双向自密封圈, 采用Abaqus软件对密封圈进行了应力、变形及接触压力等仿真分析, 并试制样机开展了内外压密封试验与旋松、旋紧力矩测试。试验结果与有限元分析结果一致, 高低舌形密封圈能在低反力下实现端面双向自密封, 舌形结构倒角越大, 密封圈与密封面之间的接触应力值越高, 密封效果越好; 密封圈两侧舌高相差越小, 中间平台高度越低, 密封圈越容易被吸出; 降低密封圈的最大高度和中间平台高度能有效降低密封反力, 延长密封圈使用寿命。基于试验结果对密封圈进行改进优化并试制大口径密封圈, 合盖压紧千余次后仍能实现内气压、内水压和外水压的自密封。研究成果可为水下大型承压设备端面密封设计应用提供参考。Abstract: In order to achieve the bidirectional sealing of the end face of underwater large-caliber hatch covers and solve the problem of the large reaction force of the sealing ring during the closing process, this paper innovatively combined the good self-sealing advantage of the tongue-shaped cross-section and the anti-ejection structure of the dovetail structure and designed five specifications of “high-low tongue” bidirectional self-sealing rings. The stress, deformation, contact pressure, and other simulation analyses of the sealing rings were carried out using Abaqus, and a prototype was trial-produced to conduct internal and external pressure sealing tests, as well as loosening and tightening torque tests. The test results were consistent with the results of finite element analysis. The “high-low tongue” sealing ring could achieve bidirectional self-sealing of the end face under low reaction force. A larger chamfer of the tongue-shaped structure means a higher contact stress value between the sealing ring and the sealing surface and better sealing effect; a smaller difference in the height of the tongue on both sides of the sealing ring indicates a lower height of the middle platform and makes the sealing ring easier to be sucked out. Reducing the maximum height and the middle platform height of the sealing ring can effectively reduce the sealing reaction force and extend the service life of the sealing ring. Based on the test results, the sealing ring is improved and optimized, and a large-caliber sealing ring is trial-produced. After closing and pressing the cover more than a thousand times, it can still achieve self-sealing of internal air pressure, internal water pressure, and external water pressure. The research results provide a reference for the design and application of end face sealing of large underwater pressure-bearing equipment.

-

表 1 密封圈关键特征尺寸

Table 1. Key characteristics of sealing ring

mm 特征参数 1# 2# 3# 4# 5# 圈中心高 12.0 11.5 11.5 12.0 11.0 外舌高 17.0 17.0 15.0 15.0 15.0 内舌高 13.8 13.8 14.0 14.0 14.0 外舌半径 14.0 14.0 15.0 16.0 12.0 内舌半径 10.0 18.0 12.0 10.0 8.0 圈中心宽 3.0 0.0 0.0 4.0 3.0 外台阶宽 3.0 3.0 3.0 2.0 2.0 内台阶宽 2.0 2.0 3.5 3.5 3.5 表 2 不同间隙下舱盖法兰和舱体法兰合盖所需压紧力

Table 2. Pressure of the hatch and barrel flange cover under different clearances

kN 密封圈编号 间隙值/mm 1.5 1.0 0.5 0 1# 0.92 2.12 6.62 16.32 2# 0.79 1.98 4.70 12.12 3# 0.56 1.01 2.64 13.73 4# 0.45 0.97 2.79 11.94 5# 0.35 0.52 1.52 4.73 表 3 不同间隙下舱盖法兰和舱体法兰合盖的最大接触应力

Table 3. Maximum contact stress of hatch cover and barrel flange cover under different clearances

MPa 密封圈编号 间隙值/mm 1.5 1.0 0.5 0 1# 1.92 1.97 3.80 7.77 2# 1.93 1.99 3.77 6.66 3# 1.61 1.37 2.44 3.39 4# 0.86 0.81 1.01 2.62 5# 1.40 1.51 3.32 3.22 表 4 5种密封圈的内压试验结果

Table 4. The results of the inner pressure seal test of five sealing rings

编号 状态 内水压变化 损失状态 0~6.0 MPa 0~0.3 MPa 1# 无泄漏 无压降 无压降 无损伤 2# 无泄漏 无压降 无压降 无损伤 3# 无泄漏 无压降 无压降 无损伤 4# 有泄漏 无压降 无压降 吸出脱落 5# 无泄漏 无压降 无压降 吸出脱落 表 5 5种密封圈外水压密封试验结果

Table 5. The results of the outer water pressure seal test of five sealing rings

编号 外水压变化 损失状态 备注 0 MPa升压

至6.0 MPa6.0 MPa降压

至0 MPa1# 无压降 无压降 无损伤 难合盖 2# 无压降 无压降 无损伤 3# 无压降 无压降 无损伤 4# 无明显压降 无明显压降 吸出脱落 积水少 5# 无压降 无压降 吸出脱落 表 6 合盖旋紧、旋松力矩测试结果

Table 6. The test results of the close and spinning torque

N·m 编号 旋紧 旋松 最小值 最大值 均值 标准差 最小值 最大值 均值 标准差 1# 535.0 603.0 569.0 48.1 393.0 436.0 414.5 30.4 2# 441.0 499.0 470.0 41.0 322.0 353.0 337.5 21.9 3# 392.0 460.0 426.0 48.1 291.0 313.0 302.0 15.6 4# 361.0 413.0 387.0 36.8 278.0 298.0 288.0 14.1 5# 320.0 378.0 349.0 41.0 228.0 259.0 243.5 21.9 -

[1] 邱志明, 马焱, 孟祥尧, 等. 水下无人装备前沿发展趋势与关键技术分析[J]. 水下无人系统学报, 2023, 31(1): 1-9. doi: 10.11993/j.issn.2096-3920.2023-0018QIU Z M, MA Y, MENG X Y, et al. Analysis on the development trend and key technologies of unmanned underwater equipment[J]. Journal of Unmanned Undersea Systems, 2023, 31(1): 1-9. doi: 10.11993/j.issn.2096-3920.2023-0018 [2] 陈旭光, 寇海磊, 牛小东, 等. 深海水下技术装备发展研究[J]. 中国工程科学, 2024, 26(2): 1-14. doi: 10.15302/J-SSCAE-2024.02.002CHEN X G, KOU H L, NIU X D, et al. Development of deep-sea underwater technology and equipment[J]. Strategic Study of CAE, 2024, 26(2): 1-14. doi: 10.15302/J-SSCAE-2024.02.002 [3] 孙彭涛. 接触式机械密封摩擦磨损特性及性能分析[D]. 青岛: 中国石油大学(华东), 2021. [4] 梁宇翔. 螺栓法兰接头垫片安全密封性能分析[D]. 兰州: 兰州理工大学, 2017. [5] 陈凤官, 明友, 钱俊峰, 等. 阀杆填料密封系统性能分析与试验研究进展[J]. 流体机械, 2022, 50(8): 59-66.CHEN F G, MING Y, QIAN J F, et al. Progress in performance analysis and experimental research of valve stem packing seal system[J]. Fluid Machinery. 2022, 50(8): 59-66. [6] 王永茂, 申展. 基于ANSYS的不同截面密封圈密封性能仿真分析[J]. 包装工程, 2017, 38(19): 158-163.WANG Y M, SHEN Z. Simulation and analysis of sealing performance of different cross-section sealing ring based on ANSYS[J]. Packing Engineering. 2017, 38(19): 158-163. [7] 叶子波, 黄兴. 新型双向密封件的接触变形及应力分析[J]. 润滑与密封, 2007, 32(11): 142-145. doi: 10.3969/j.issn.0254-0150.2007.11.040YE Z B, HUANG X. The contact deformation and stress analysis of new type of bidirectional seal ring[J]. Lubrication Engineering, 2007, 32(11): 142-145. doi: 10.3969/j.issn.0254-0150.2007.11.040 [8] 韩传军, 张瀚, 张杰. 星形橡胶密封圈的密封特性分析及截面改进[J]. 机械设计与研究, 2015, 31(4): 90-94.HAN C J, ZHANG H, ZHANG J. Sealing performance analysis and cross section melioration of X-ring[J]. Machine Design and Research, 2015, 31(4): 90-94. [9] 方艳峰, 罗凯. 动静环双抛物线型机械密封性能理论研究[J]. 流体机械, 2024, 52(7): 98-104. doi: 10.3969/j.issn.1005-0329.2024.07.014FANG Y F, LUO K. Theoretical study on performance of mechanical seals with double parabolic rotating and stationary rings[J]. Fluid Machinery, 2024, 52(7): 98-104. doi: 10.3969/j.issn.1005-0329.2024.07.014 [10] 陈飞, 李拓, 麻晓丹, 等. 基于数值模拟的矩形密封圈参数化分析[J]. 机械设计, 2020, 37(8): 91-96.CHEN F, LI T, MA X D, et al. Parametric analysis on the rectangular sealing ring based on numerical simulation[J]. Journal of Machine Design, 2020, 37(8): 91-96. [11] 陈鑫, 吴福迪, 王立峰, 等. 大缝隙密封的几种异型截面橡胶密封结构的有限元分析[J]. 强度与环境, 2009, 36(4): 1-5. doi: 10.3969/j.issn.1006-3919.2009.04.001CHEN X, WU F D, WANG L F, et al. FEM analysis on several hetero-shaped cross-section seal structures for large gaps sealing[J]. Structure and Environment Engineering, 2009, 36(4): 1-5. doi: 10.3969/j.issn.1006-3919.2009.04.001 [12] 田有良, 刘庆荣, 陈立军, 等. T-Bolt O型圈快开封头泄漏失效分析及改善措施[J]. 现代制造技术与装备, 2022, 58(1): 169-172. doi: 10.3969/j.issn.1673-5587.2022.01.054TIAN Y L, LIU Q R, CHEN L J, et al. Analysis and improvement for the leak failure of the T-Bolt O-ring closure[J]. Modern Manufacturing Technology and Equipment, 2022, 58(1): 169-172. doi: 10.3969/j.issn.1673-5587.2022.01.054 [13] 李斌, 卢大伟, 张作鹏. 压缩式封隔器波浪形胶筒力学性能分析[J]. 应用力学学报, 2018, 35(4): 828-833.LI B, LU D W, ZHANG Z P. Analysis of mechanical properties of wave packer rubber[J]. Chinese Journal of Applied Mechanics, 2018, 35(4): 828-833. [14] 张良, 李忠华, 马新强. 橡胶Mooney-Rivlin超弹性本构模型的参数特性研究[J]. 噪声与振动控制, 2018, 38(S2): 427-430. doi: 10.3969/j.issn.1006-1355.2018.Z1.091ZHANG L, LI Z H, MA X Q. Study on parameter characteristics of rubber Mooney-Rivlin model[J]. Noise and Vibration Control, 2018, 38(S2): 427-430. doi: 10.3969/j.issn.1006-1355.2018.Z1.091 -

下载:

下载: