Study on Full-Size Drop Impact Response Characteristics and Safety of Marine Equipment

-

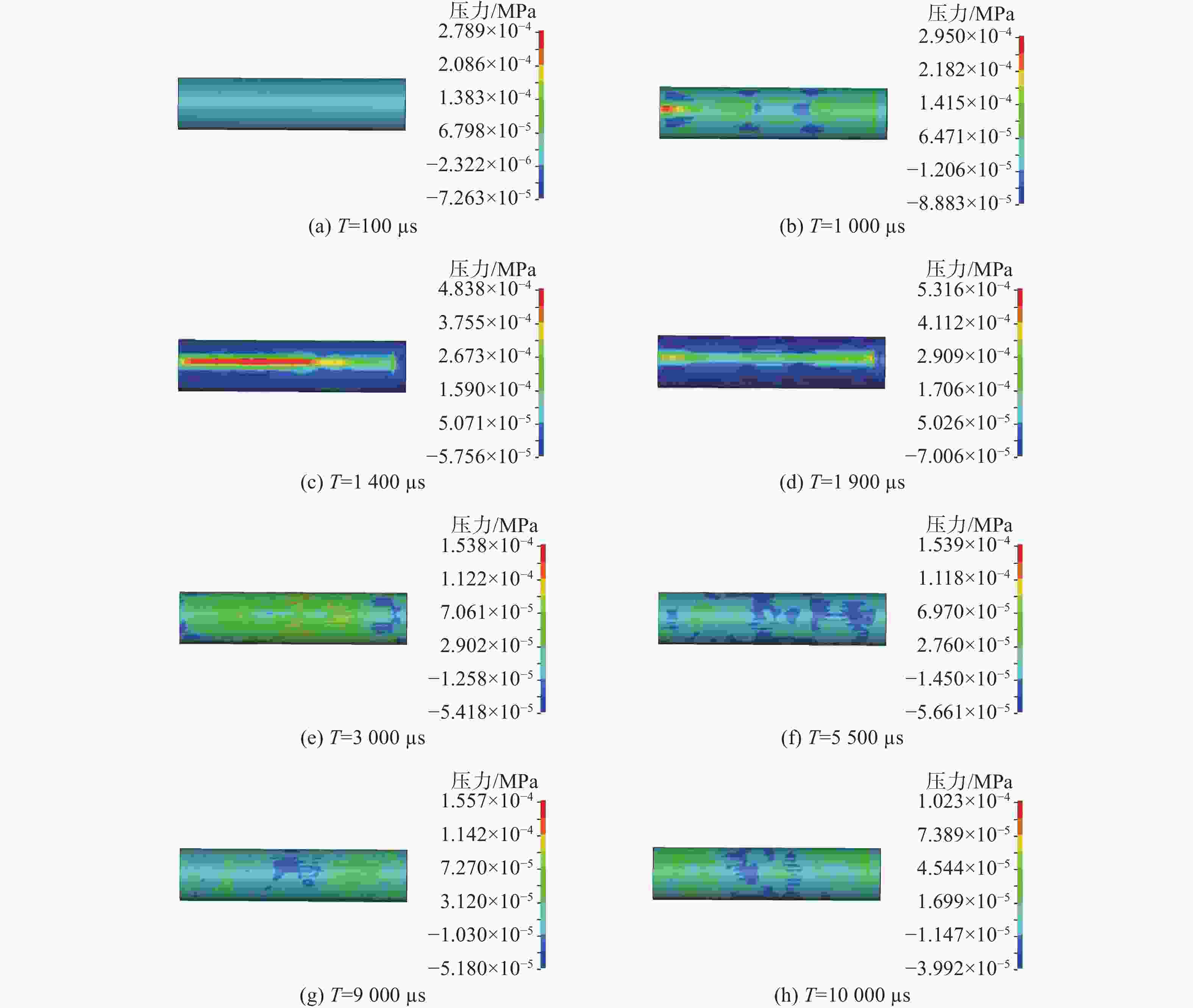

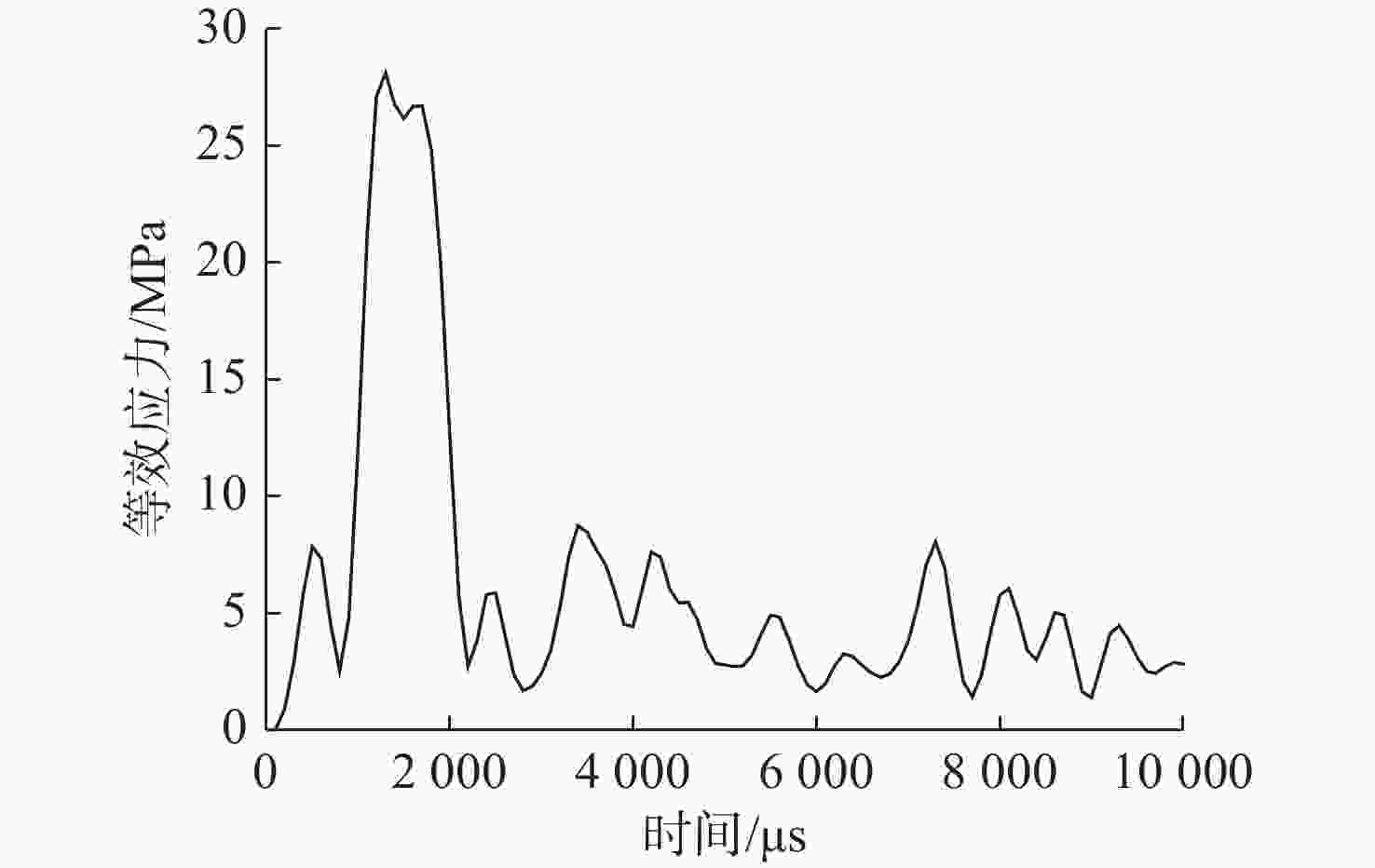

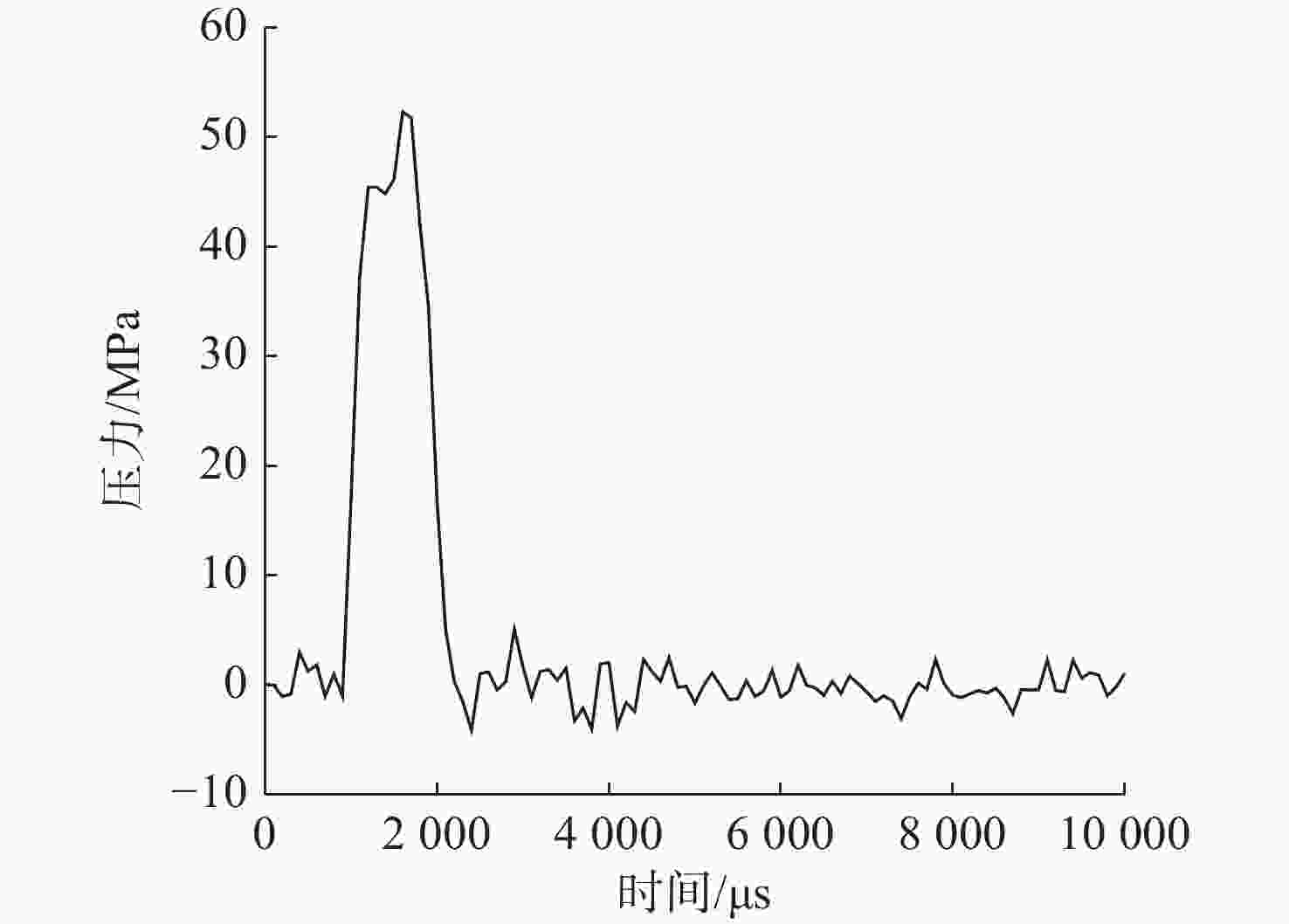

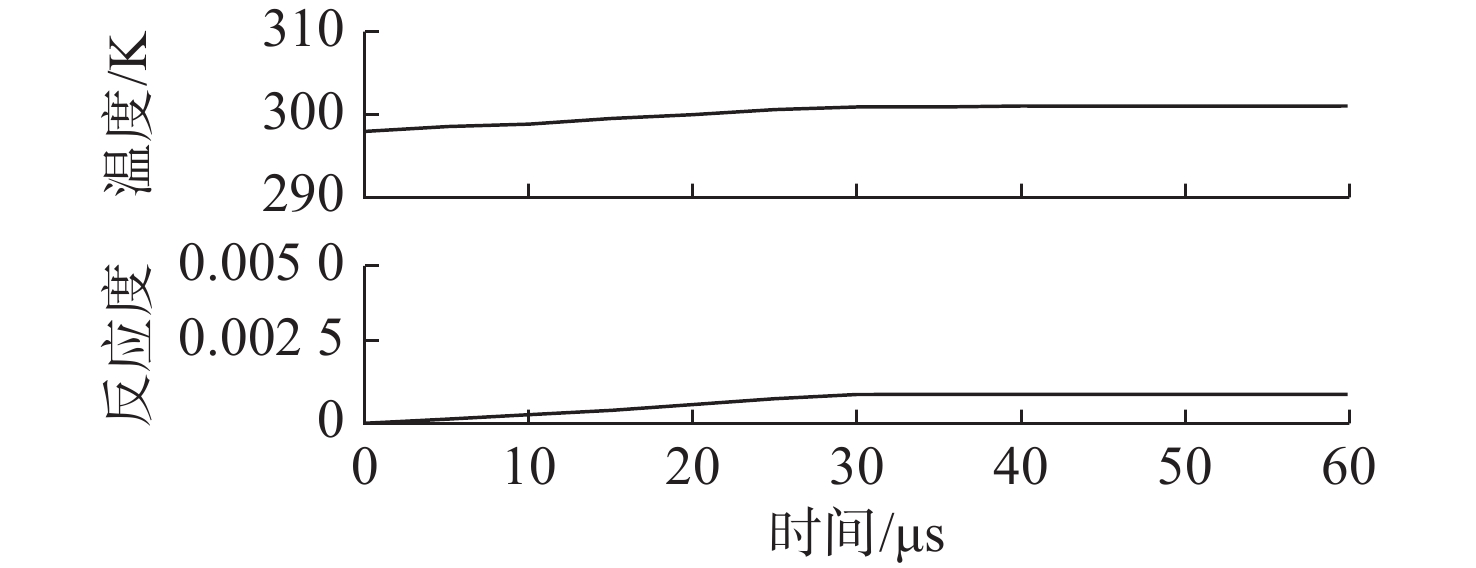

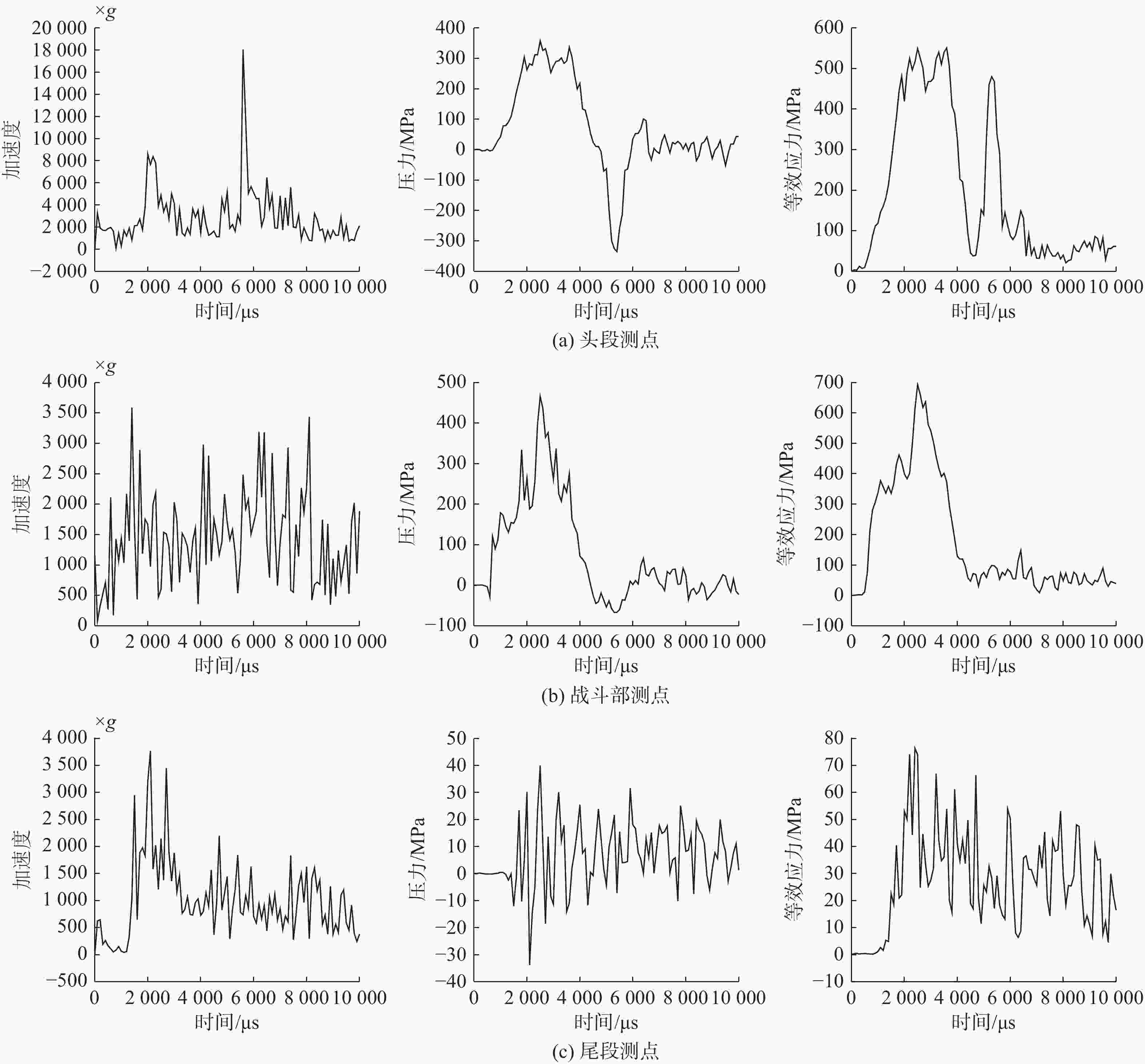

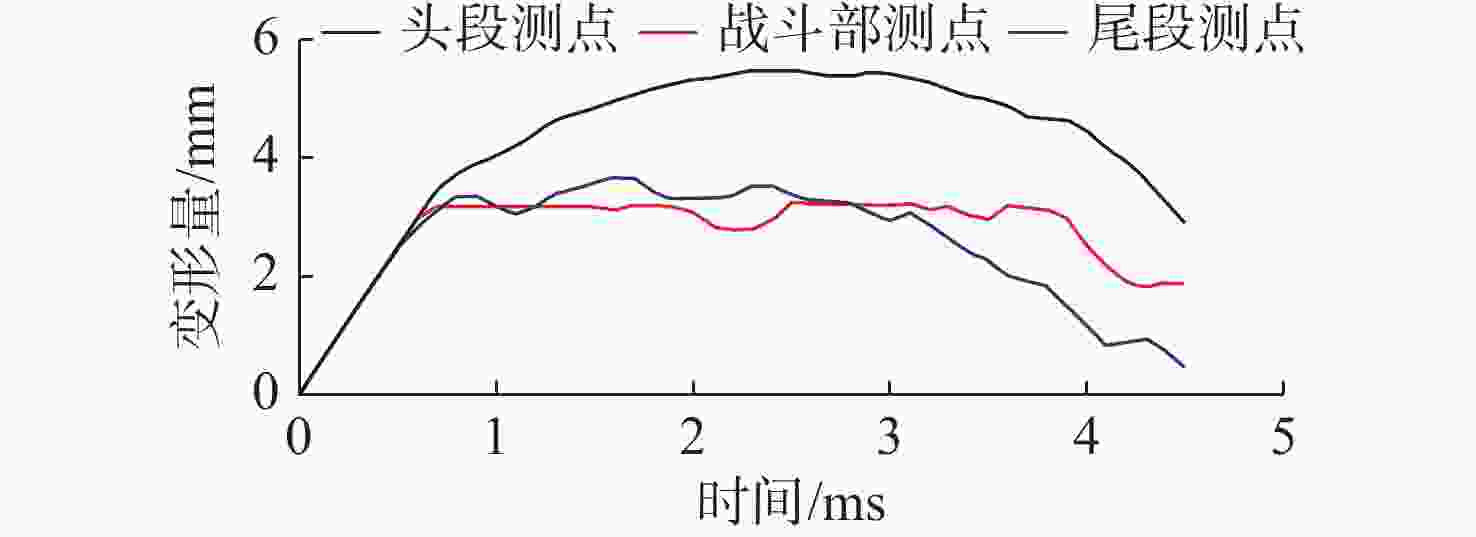

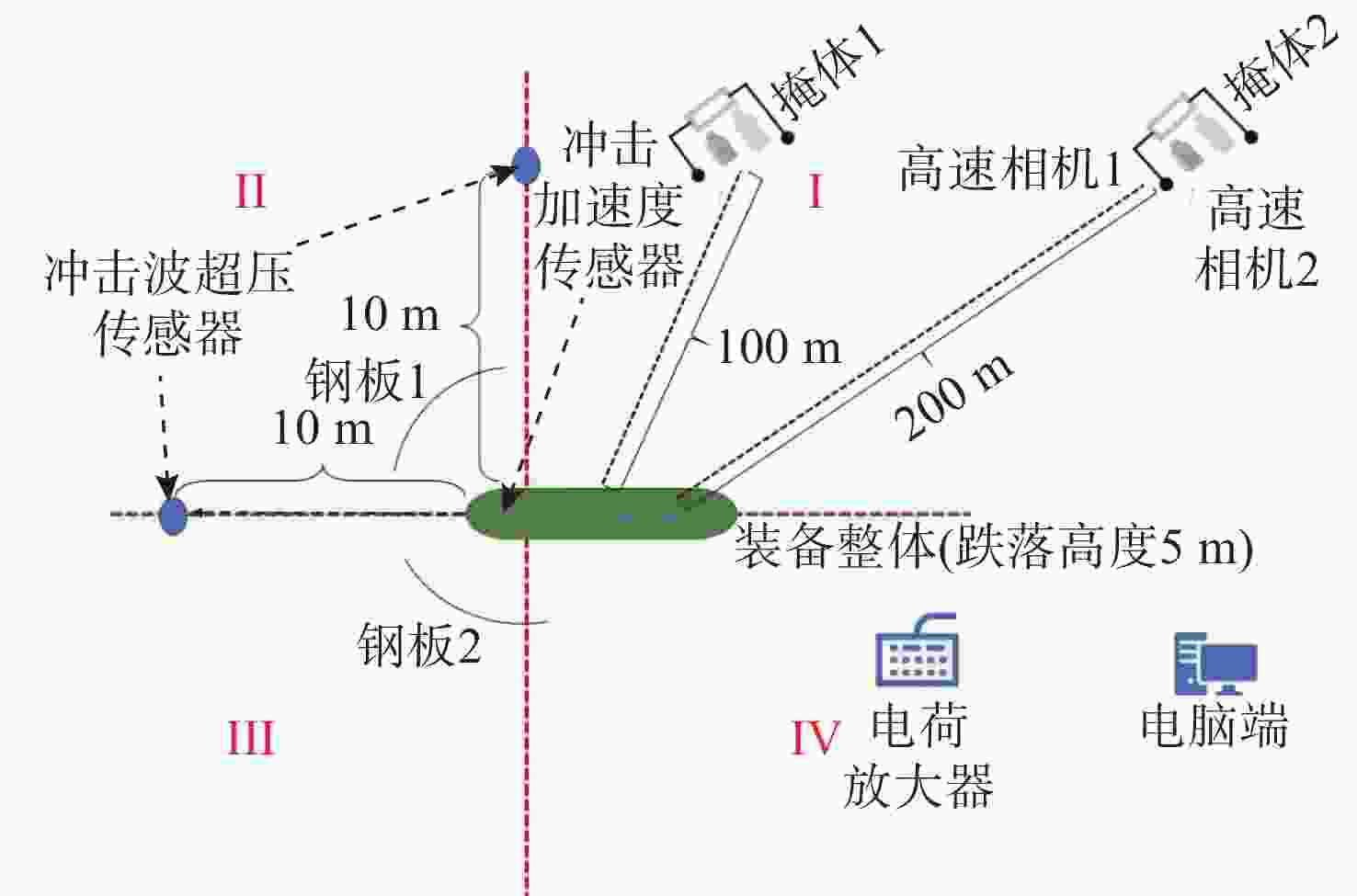

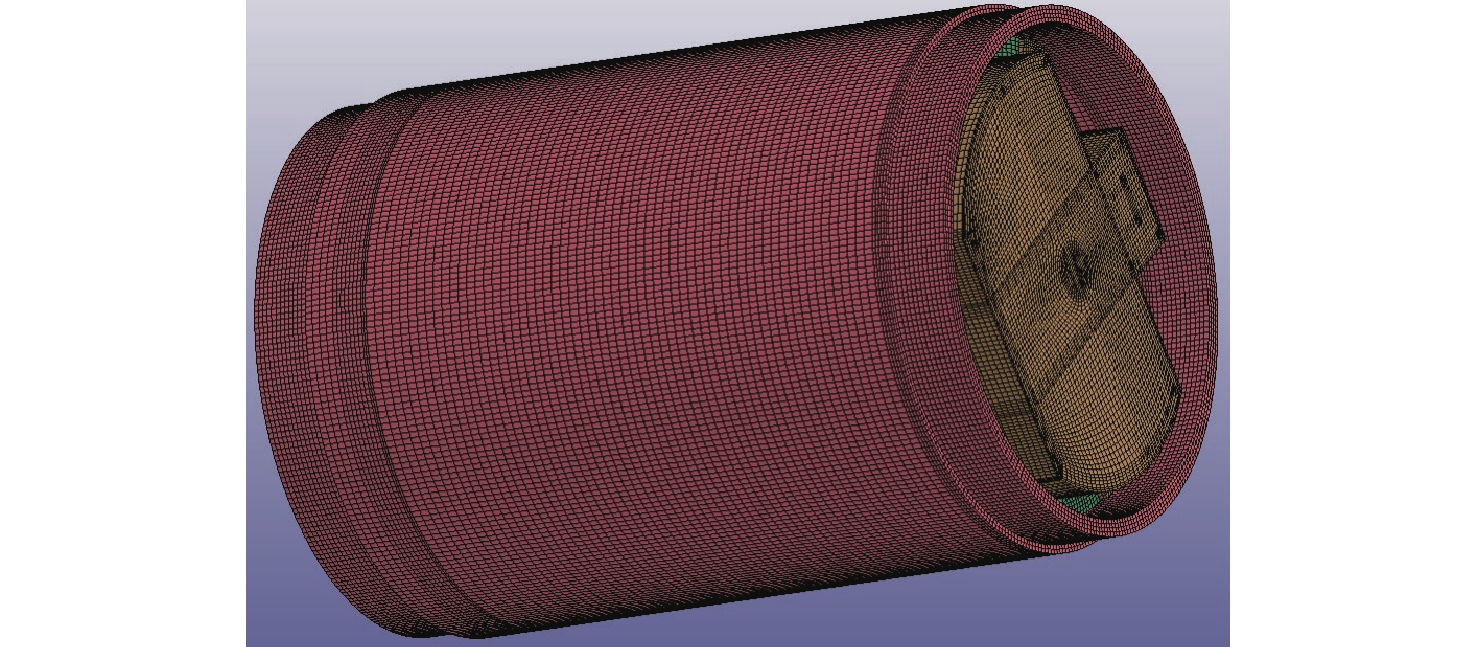

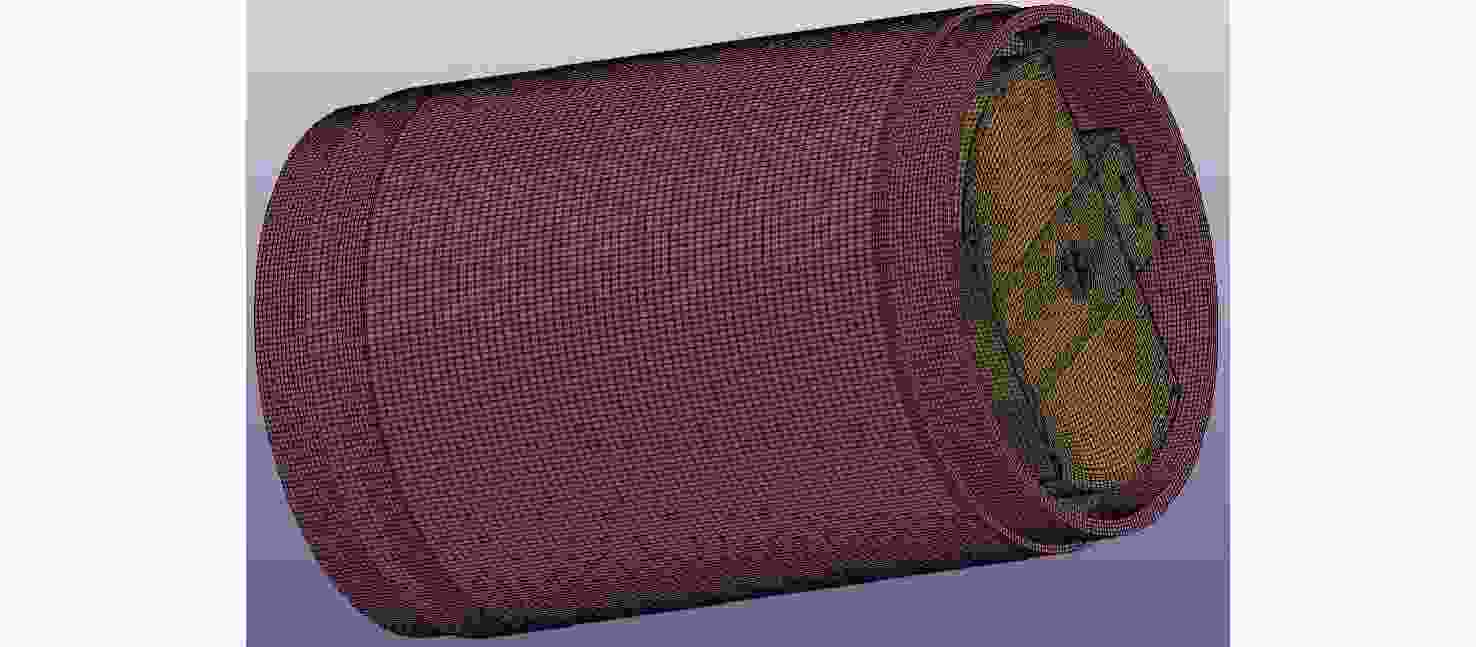

摘要: 海洋装备的跌落安全在日常勤务操作中至关重要。针对某装备全尺寸跌落的安全性, 采用LS-DYNA软件, 建立了整体结构的有限元仿真计算模型, 对整体结构从5 m高度水平跌落过程进行数值仿真分析, 获取含能材料和各舱段的冲击响应规律。结果表明, 整体结构在5 m水平跌落条件下, 经多次反弹后各舱段材料内部产生塑性变形; 含能材料在整体结构和地面碰撞点内腔对应位置处应力最大, 含能材料内局部压力超过屈服强度产生变形, 在整个碰撞过程中虽没有发生点火反应, 但含能材料内部应力、温度和反应度数值有低幅变化, 局部发生轻微化学反应。结合整体结构5 m水平跌落试验进行验证, 试验结果与仿真结果趋于一致, 不燃不爆。文中研究可有效指导海洋装备的安全性设计和工程研制。Abstract: The drop safety of marine equipment is of paramount importance in daily operational tasks. To assess the safety of a full-size drop of a certain type of equipment, a finite element simulation model of the overall structure was established using LS-DYNA software. The numerical simulation and analysis of the horizontal drop from a height of 5 meters were conducted to obtain the impact response characteristics of the energetic material and each compartment. The results show that under 5-meter drop conditions, after multiple rebounds, plastic deformation occurs within the materials of each compartment. The maximum stress of the energetic material is located at the corresponding position in the cavity at the collision point between the structure and the ground. When the local pressure inside the energetic material exceeds its yield strength, deformation occurs. Although no ignition reaction happens during the entire collision process, the internal stress, temperature, and reactivity values of the energetic material show slight fluctuations, and minor local chemical reactions occur. A verification test of the 5-meter horizontal drop using a full-size structure is conducted. The experimental results are consistent with the simulation results, confirming that the structure does not ignite or explode. This study can be applied to the safety analysis and assessment of full-size drops for other marine equipment and can effectively guide the safety design and engineering development of such systems.

-

Key words:

- marine equipment /

- safety /

- drop /

- full-size /

- impact response /

- energetic material

-

表 1 含能材料点火增长模型参数

Table 1. Parameters of ignition growth model for energetic materials

参数 符号 数值 初始反应速率系数/μs−1 Ⅰ 7.43×104 压力指数 b 0.667 压缩度指数 a 0 压缩度指数修正项 x 20 低压阶段反应增长因子/(GPa−2·μs−1) G1 3.1 高压指数 c 0.667 高压阶段压缩度指数 d 0.111 高压阶段压缩度修正项 y 1 高压阶段反应增长因子/( GPa−2·μs−1) G2 400 反应完成度指数 e 0.333 反应完成度修正系数 g 1 反应完成度指数修正项 z 2 表 2 相关材料参数

Table 2. Related material parameters

材料 弹性模量

/MPa泊松比 密度

/(t·mm−3)屈服强度

/MPa头部PU橡胶 0.491 1.05×10−9 壳体铝合

金材料72 000 0.300 2.7×10−9 340 炸药 8 230 0.300 1.8×10−9 31 钢 210 000 0.300 7.9×10−9 235 混凝土 40 000 0.300 2.65×10−9 100 -

[1] 范士锋, 董平, 李鑫, 等. 国外海军弹药安全性研究进展[J]. 火炸药学报, 2017, 40(2): 101-104.FAN S F, DONG P, LI X, et al. Research progress in the safety of foreign naval ammunition[J]. Chinese Journal of Explosives & Propellants, 2017, 40(2): 101-104. [2] Department of Defense. Hazard assessment tests for non-unclear munitions: DOD-STD-2105[S]. Washington, DC, USA: DOD, 1982. [3] Department of Defense. Hazard assessment tests for non-unclear munitions: MIL-STD-2105A[S]. Washington, DC, USA: DOD, 1991. [4] Department of Defense. Hazard assessment tests for non-unclear munitions: DOD-STD-2105B[S]. Washington, DC, USA: DOD, 1994. [5] Department of Defense. Hazard assessment tests for non-unclear munitions: DOD-STD-2105C[S]. Washington, DC, USA: DOD, 2003. [6] Department of Defense. Hazard assessment tests for non-unclear munitions: DOD-STD-2105D[S]. Washington, DC, USA: DOD, 2011. [7] 航空工业部零一四中心. 空-空导弹最低安全要求: GJB 357-1987[S]. 北京: 国防科学技术工业委员会, 1987. [8] 黄凤军, 苏晓璐. 关于水中兵器全雷跌落试验的讨论[J]. 水下无人系统学报, 2017, 25(3): 282-287. doi: 10.11993/j.issn.2096-3920.2017.03.012HUANG F J, SU X L. Discussion on drop test of undersea weapons[J]. Journal of Unmanned Undersea Systems, 2017, 25(3): 282-287. doi: 10.11993/j.issn.2096-3920.2017.03.012 [9] 卢熹, 康松逸, 贾曦雨, 等. 战斗部跌落安全性研究及对水雷战斗部的启示[J]. 水下无人系统学报, 2024, 32(5): 948-961.LU X, KANG S Y, JIA X Y, et al. Research on warhead drop safety and its implications for mine warheads[J]. Journal of Unmanned Undersea Systems, 2024, 32(5): 948-961. [10] 张迪, 闫锐兵, 贾宏春. 水中兵器跌落安全性试验研究现状分析[J]. 舰船电子工程, 2023, 43(1): 23-27. doi: 10.3969/j.issn.1672-9730.2023.01.006 [11] 代晓淦, 申春迎, 文玉史. 模拟跌落撞击下PBX-2炸药的响应[J]. 含能材料, 2011, 19(2): 209-212.DAI X G, SHEN C Y, WEN Y S. Reaction of PBX-2 explosive under simulated drop impact[J]. Chinese Journal of Energetic Materials, 2011, 19(2): 209-212. [12] 王晨, 陈朗, 鲁峰, 等. 炸药跌落响应数值模拟分析[J]. 含能材料, 2012, 20(6): 748-753. doi: 10.3969/j.issn.1006-9941.2012.06.019WANG C, CHEN L, LU F, et al. Numerical Simulation for Spigot Tests[J]. Chinese Journal of energetic materials, 2012, 20(6): 748-753. doi: 10.3969/j.issn.1006-9941.2012.06.019 [13] 王新颖, 王树山, 王绍慧, 等. 典型水中战斗部炸药装药跌落撞击响应特性[J]. 兵工学报, 2021, 41(增刊1): 33-39. doi: 10.3969/j.issn.1000-1093.2021.S1.004 [14] 周金波, 赖建云, 叶枫桦. 战斗部跌落响应数值分析[J]. 数字海洋与水下攻防, 2022, 5(1): 44-49. [15] 李广嘉, 周涛, 曹玉武, 等. 带舱大型战斗部跌落响应数值分析[J]. 高压物理学报, 2018, 32(4): 045106-1-045106-5. doi: 10.11858/gywlxb.20170584 [16] 倪庆乐, 王雨时, 闻泉, 等. 基于有限元的裸态弹丸底向下跌落冲击特性[J]. 探测与控制学报, 2016, 38(6): 51-56. -

下载:

下载: