Design and Simulation Analysis of Sound Absorption Structure for Acoustic Detection-Based Underwater Gliders

-

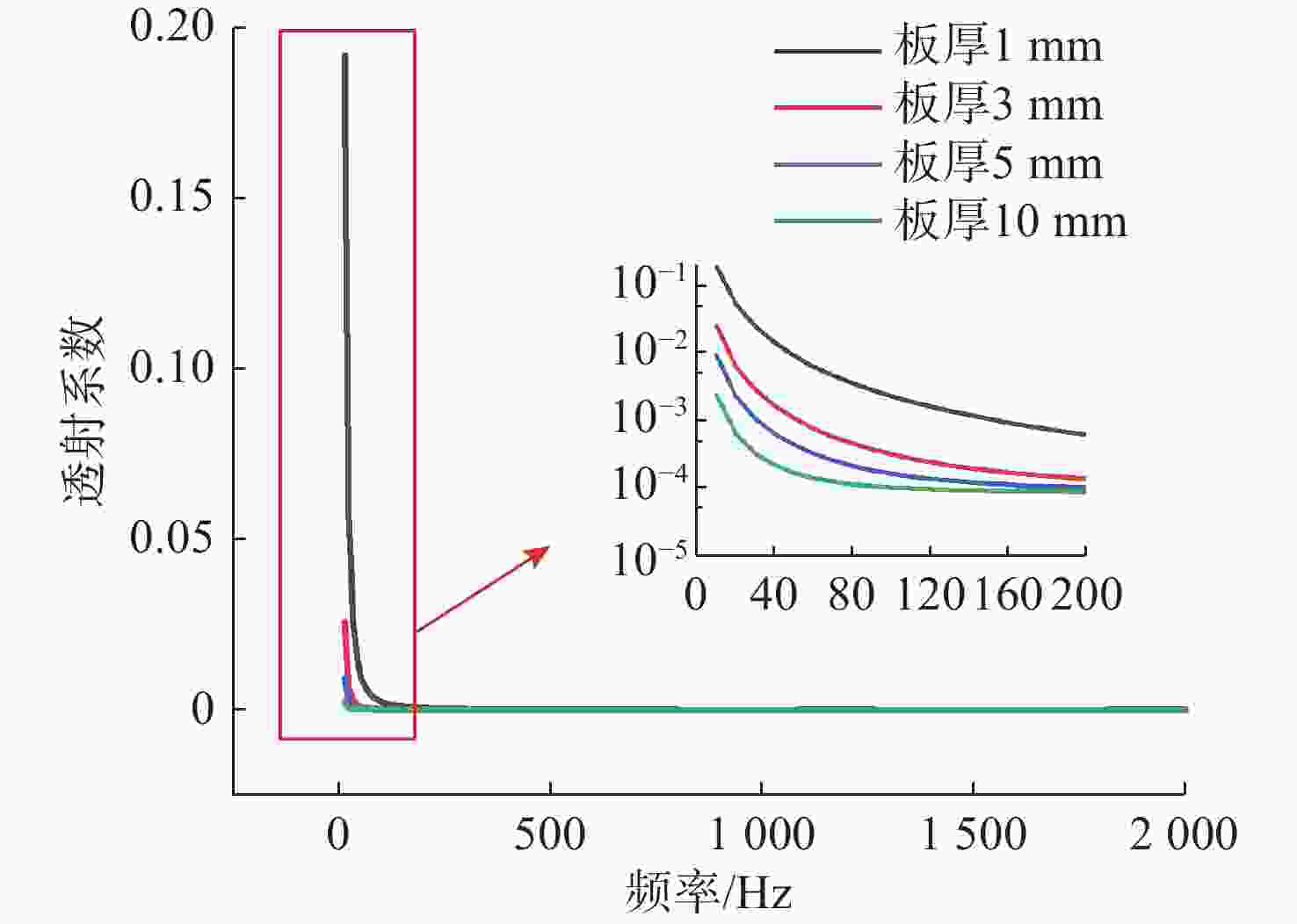

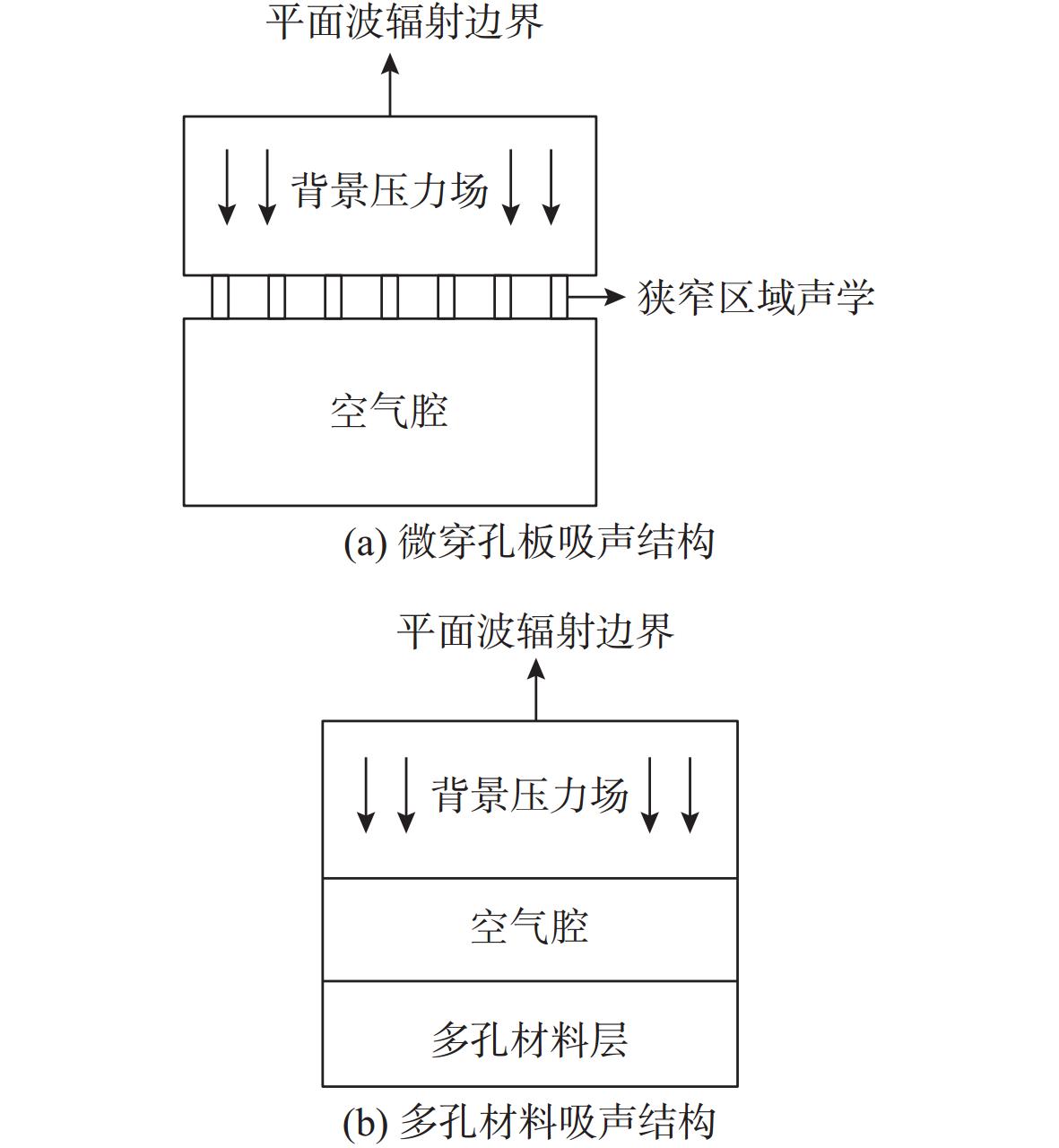

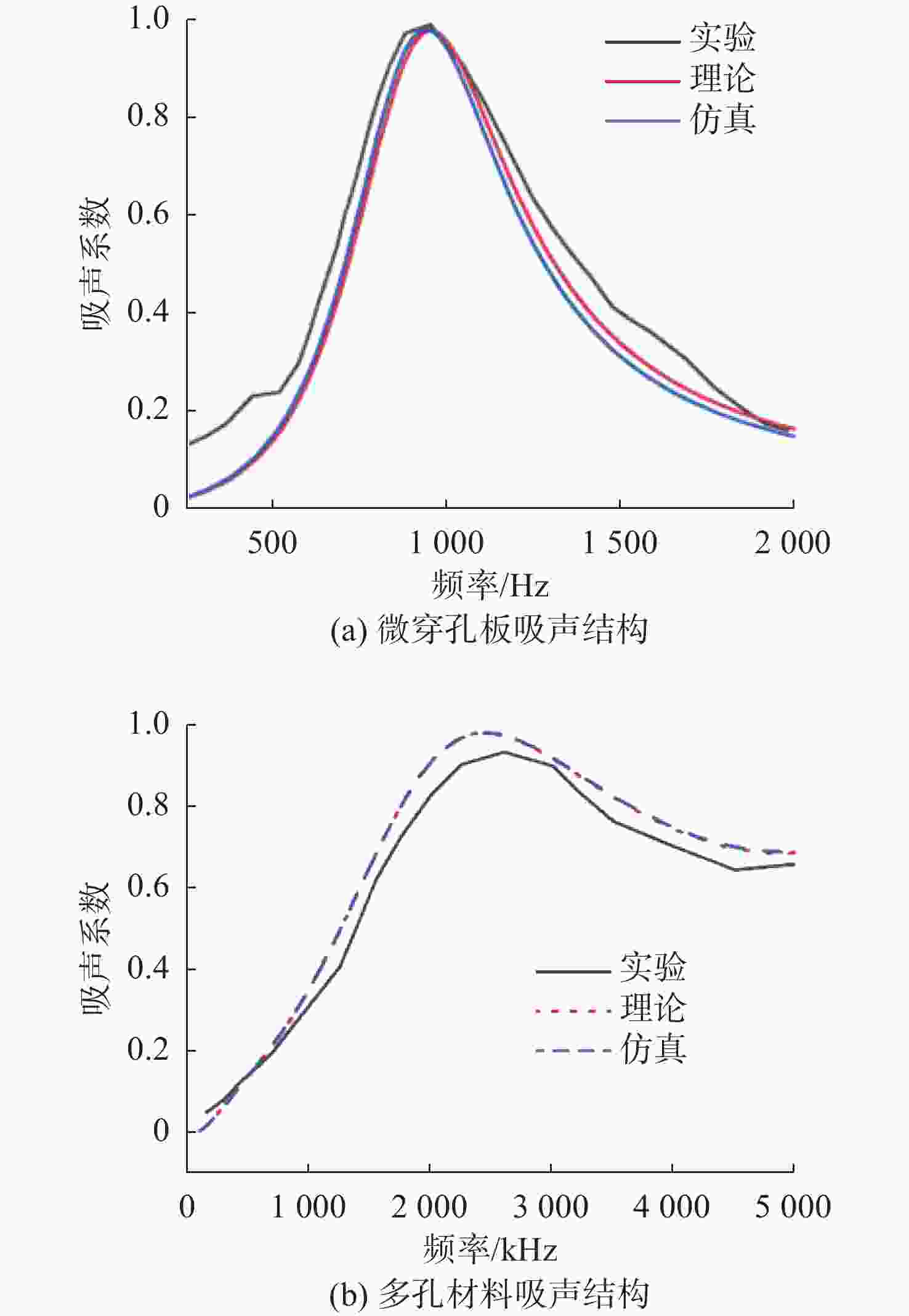

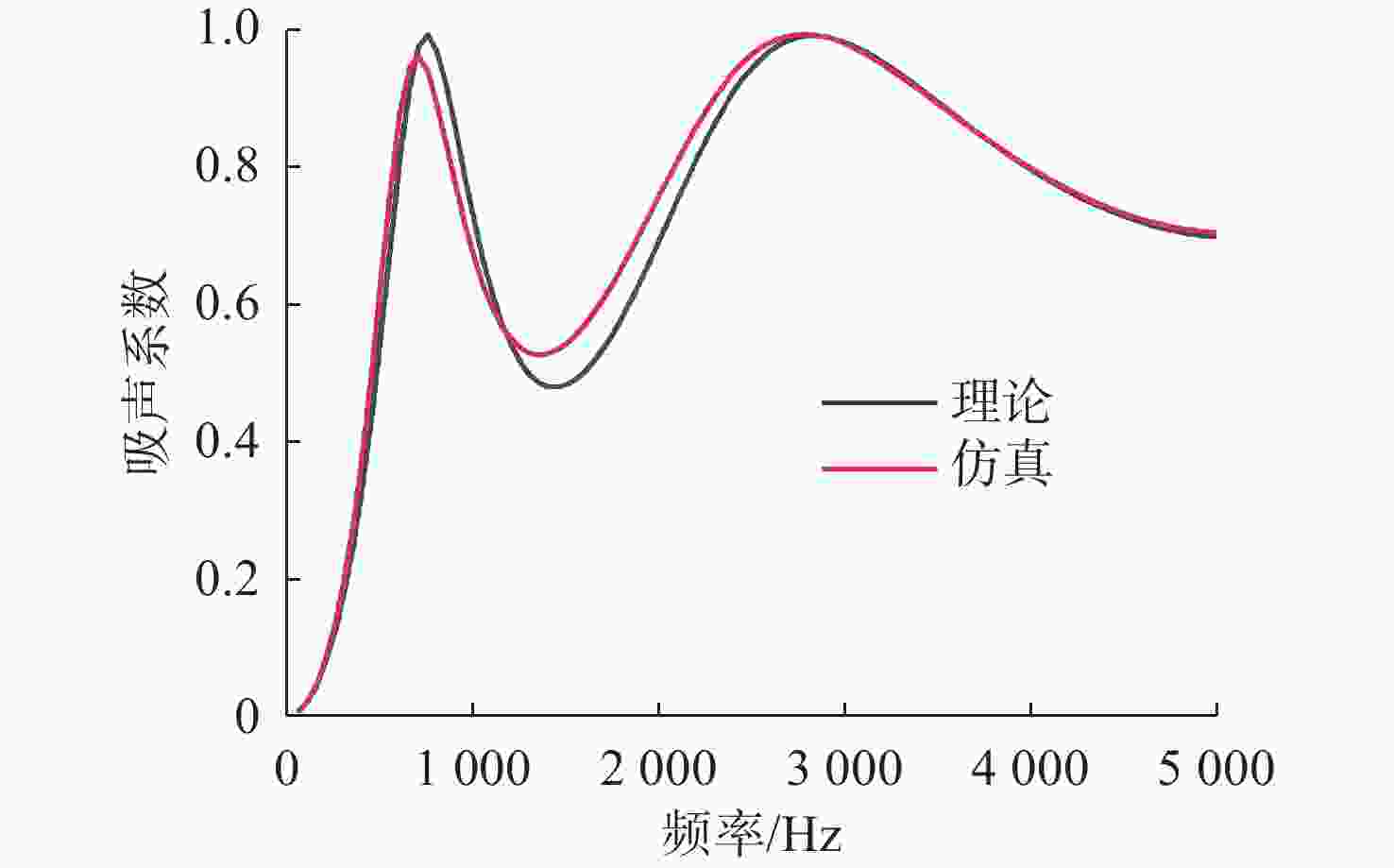

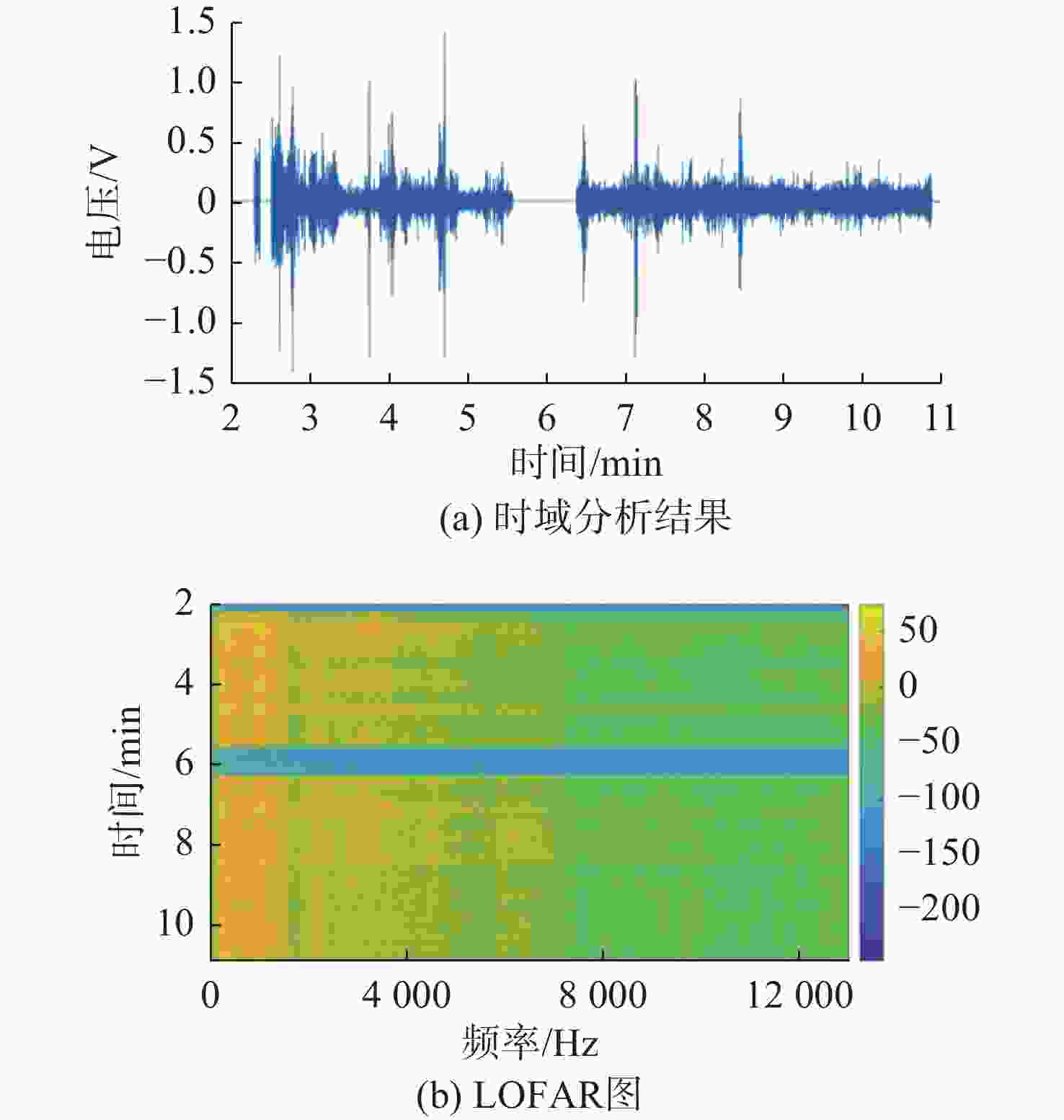

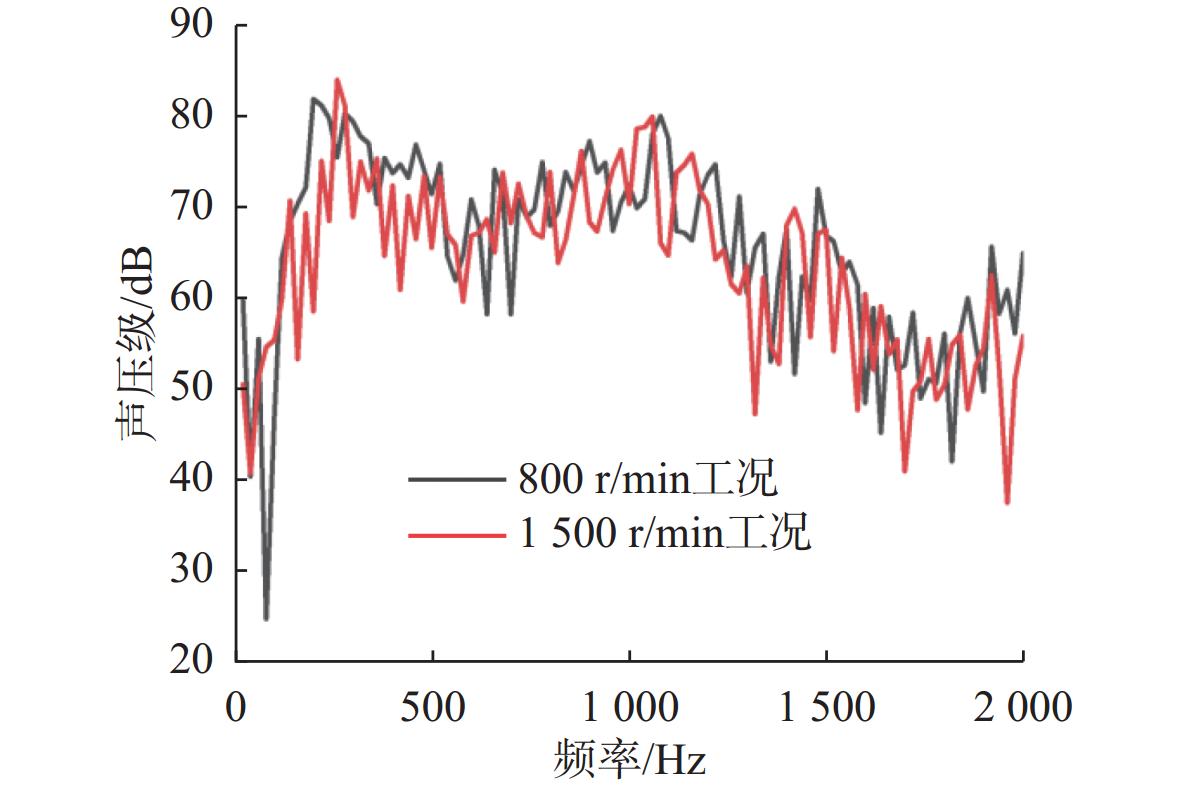

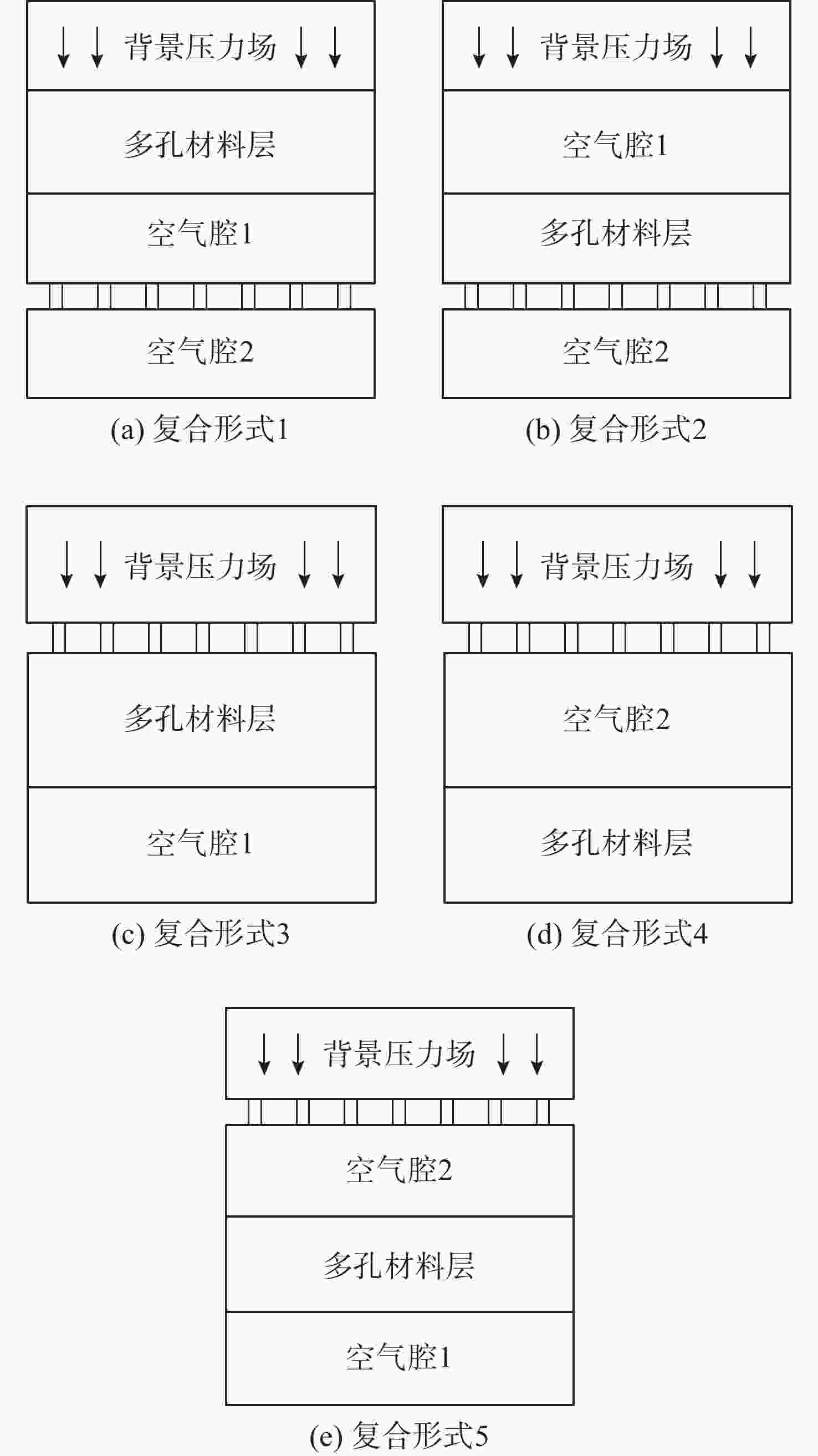

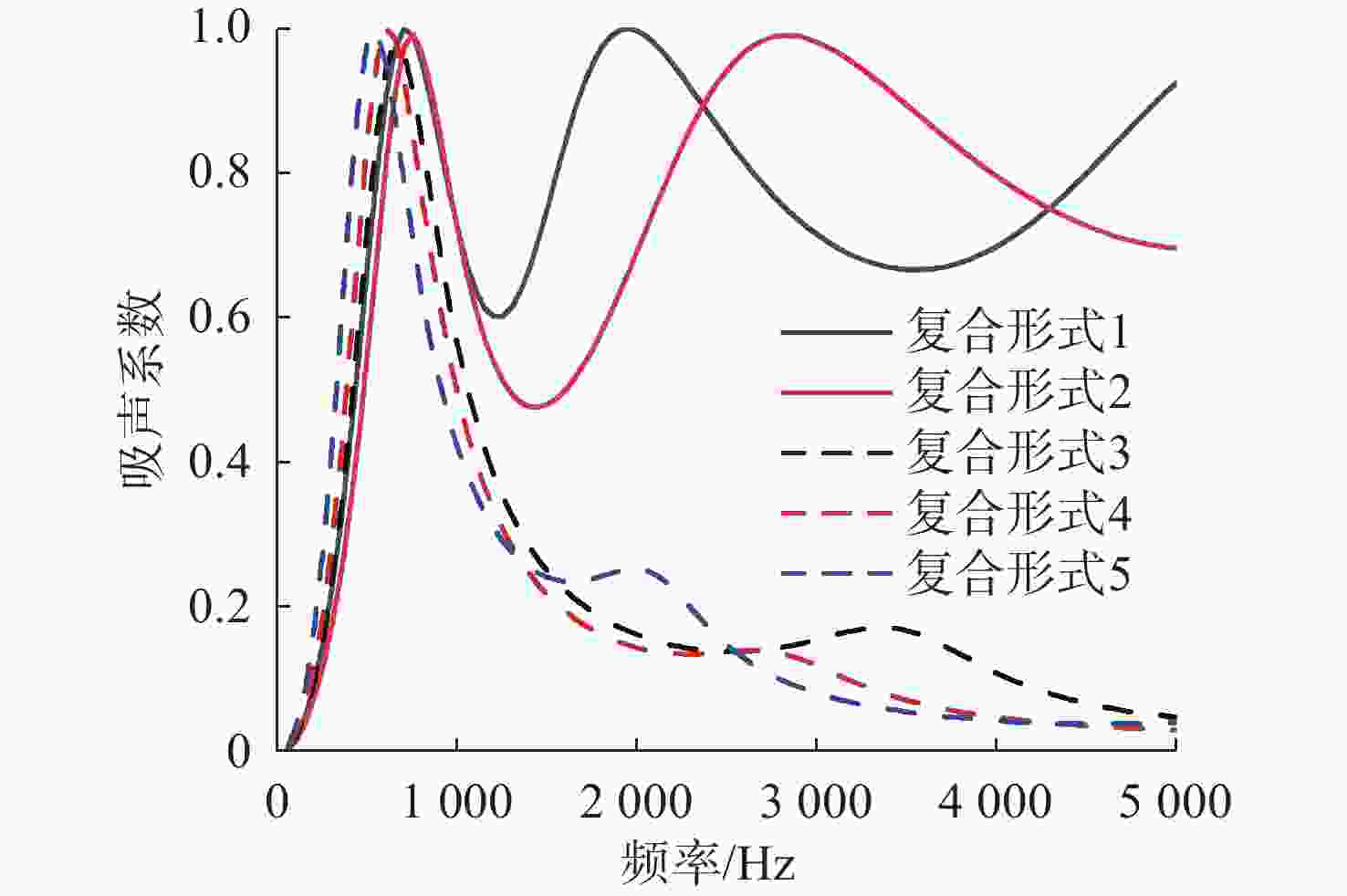

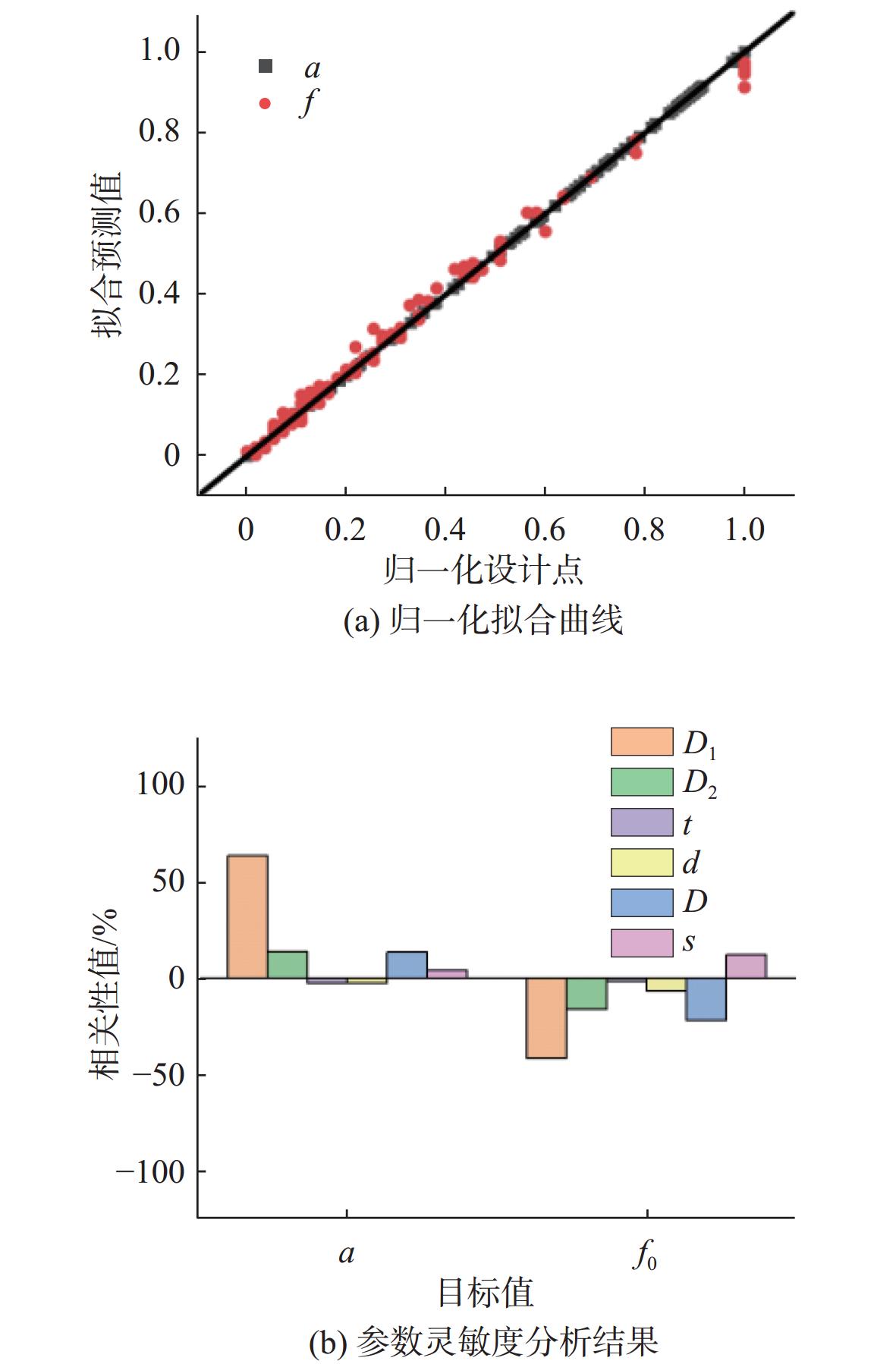

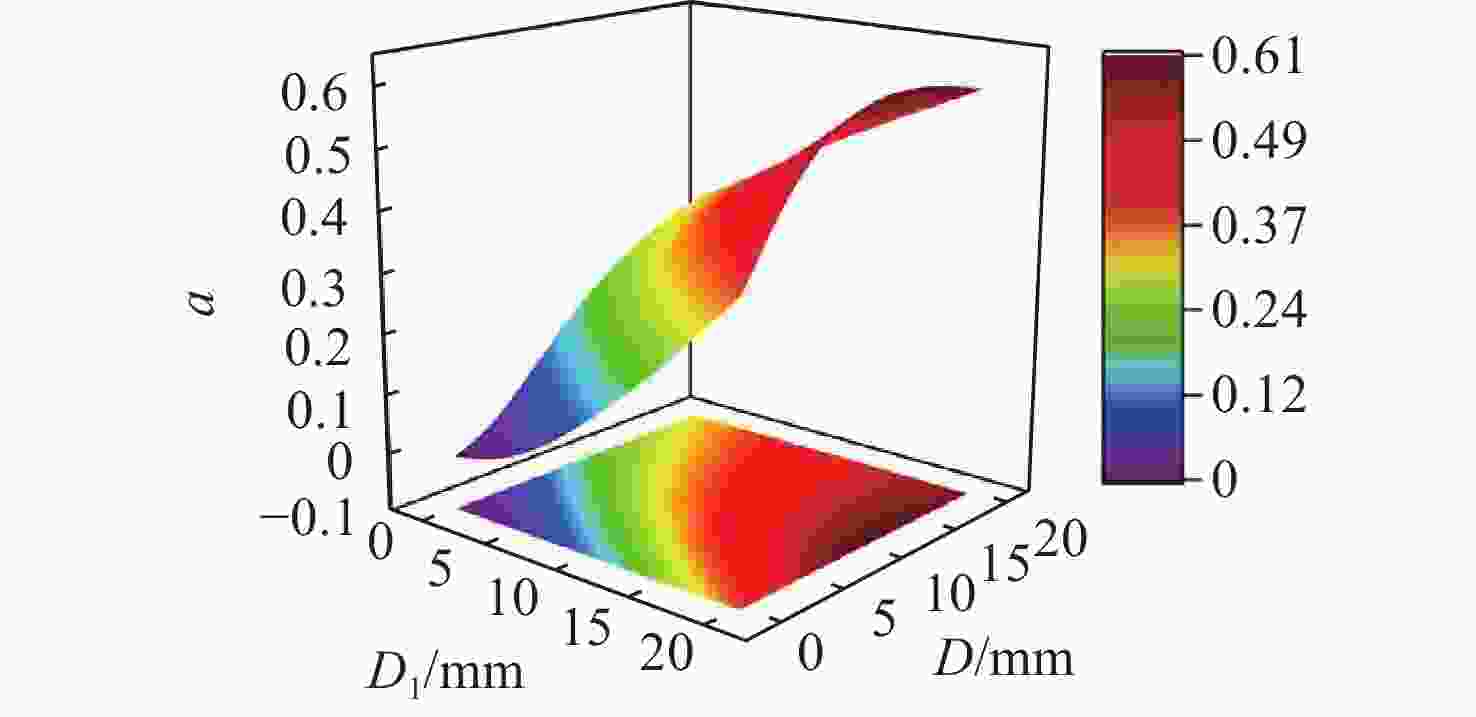

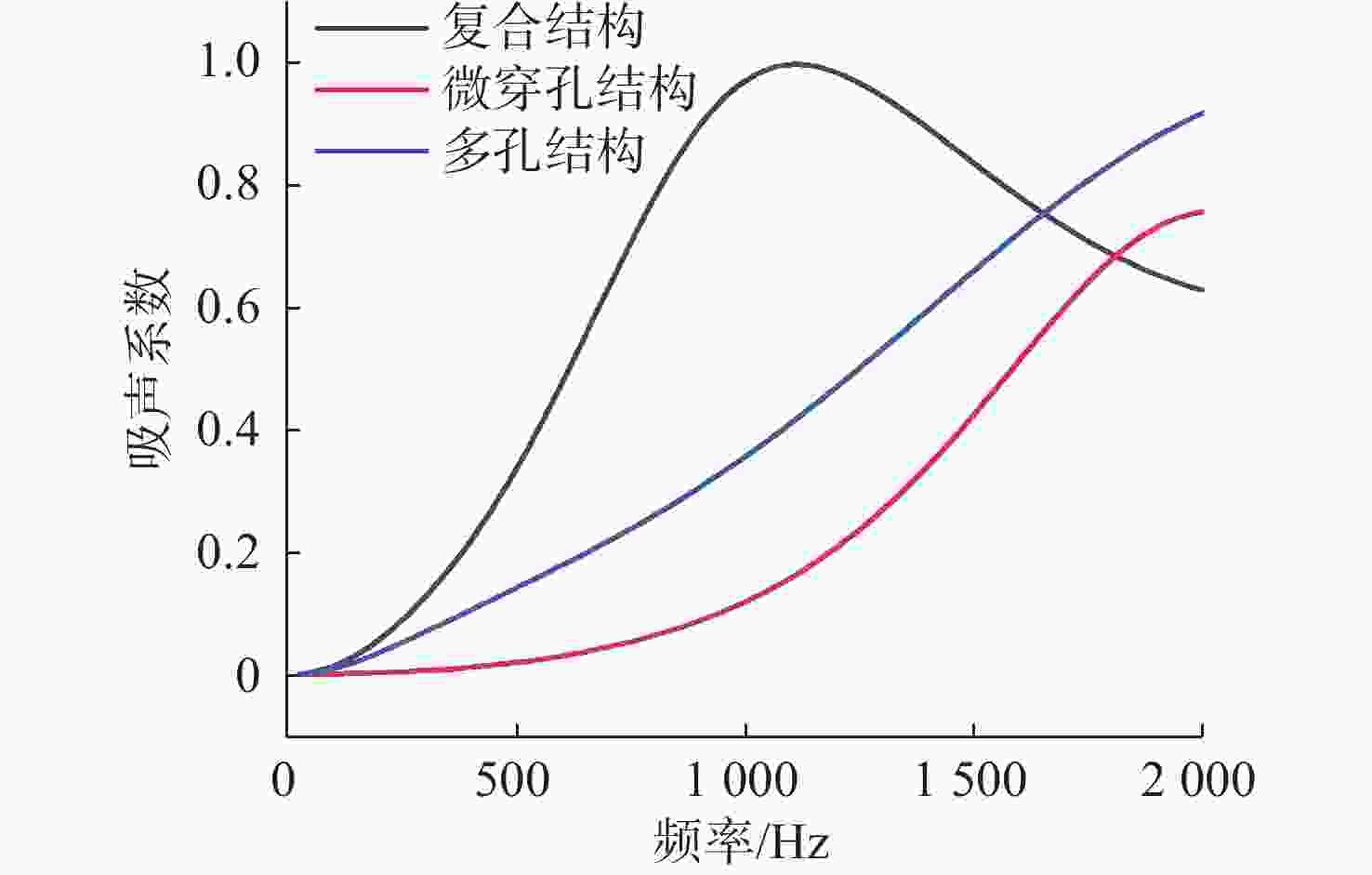

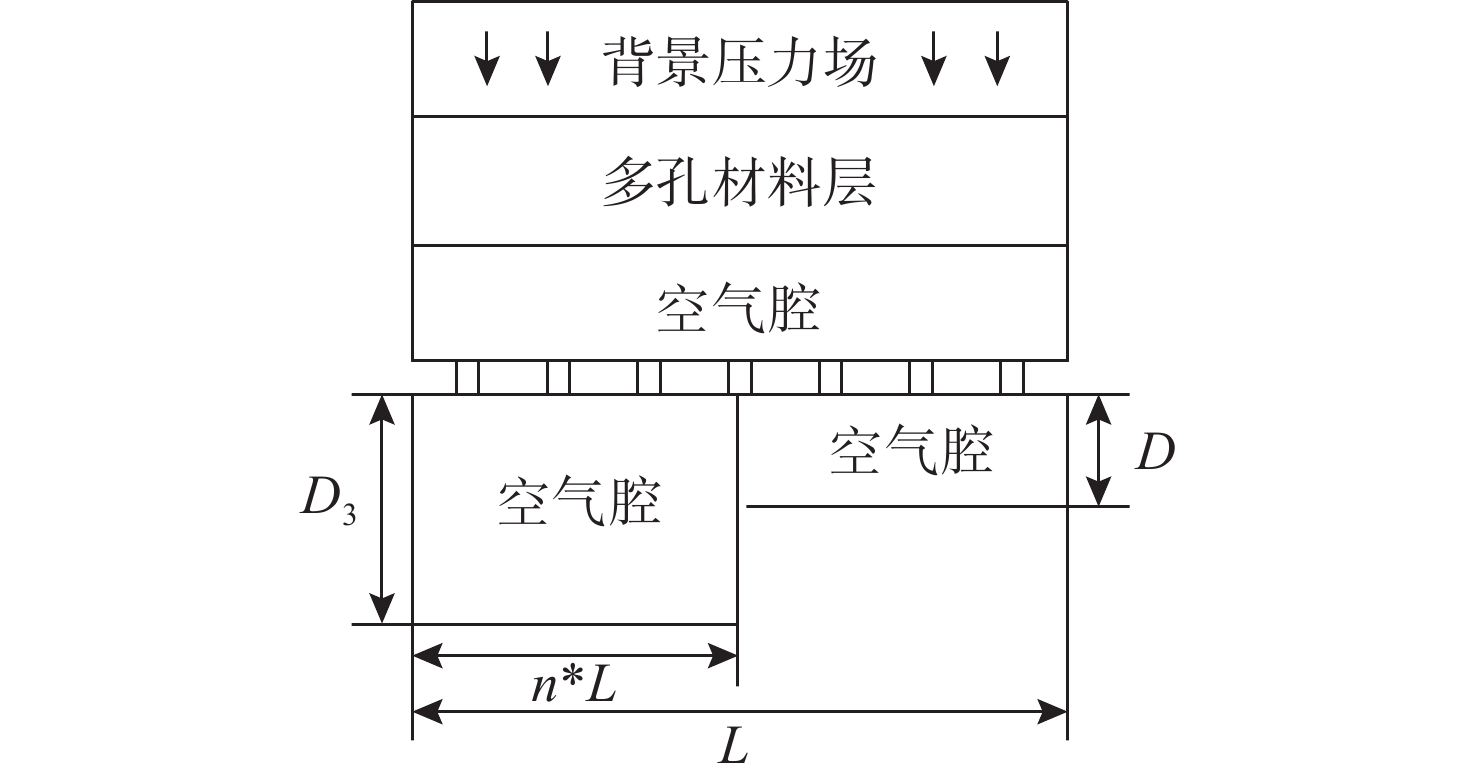

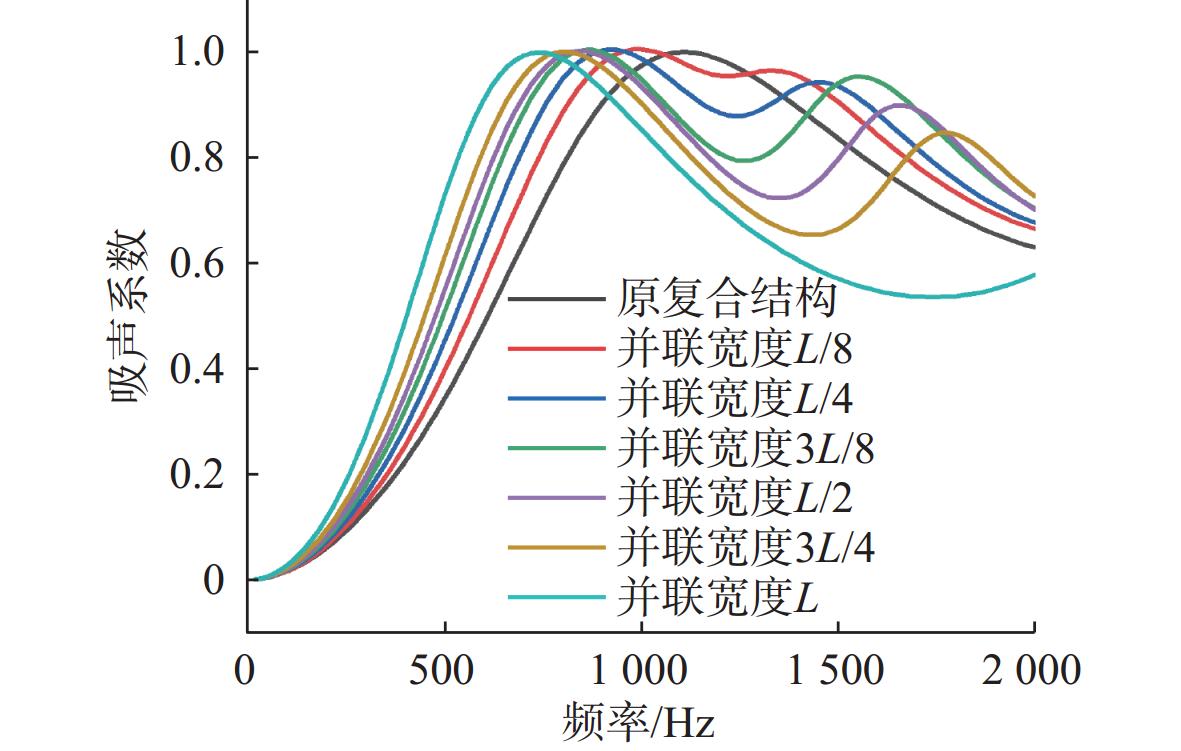

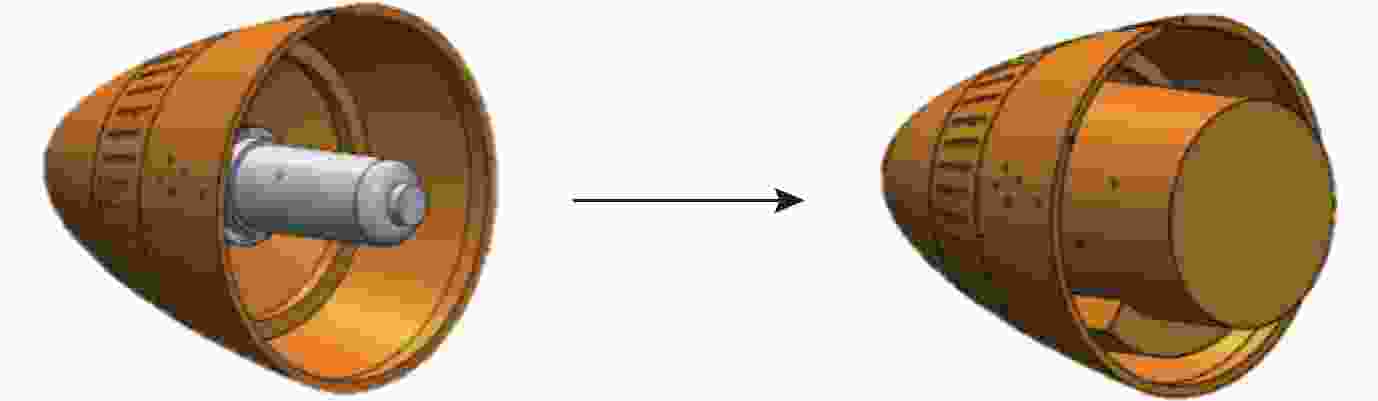

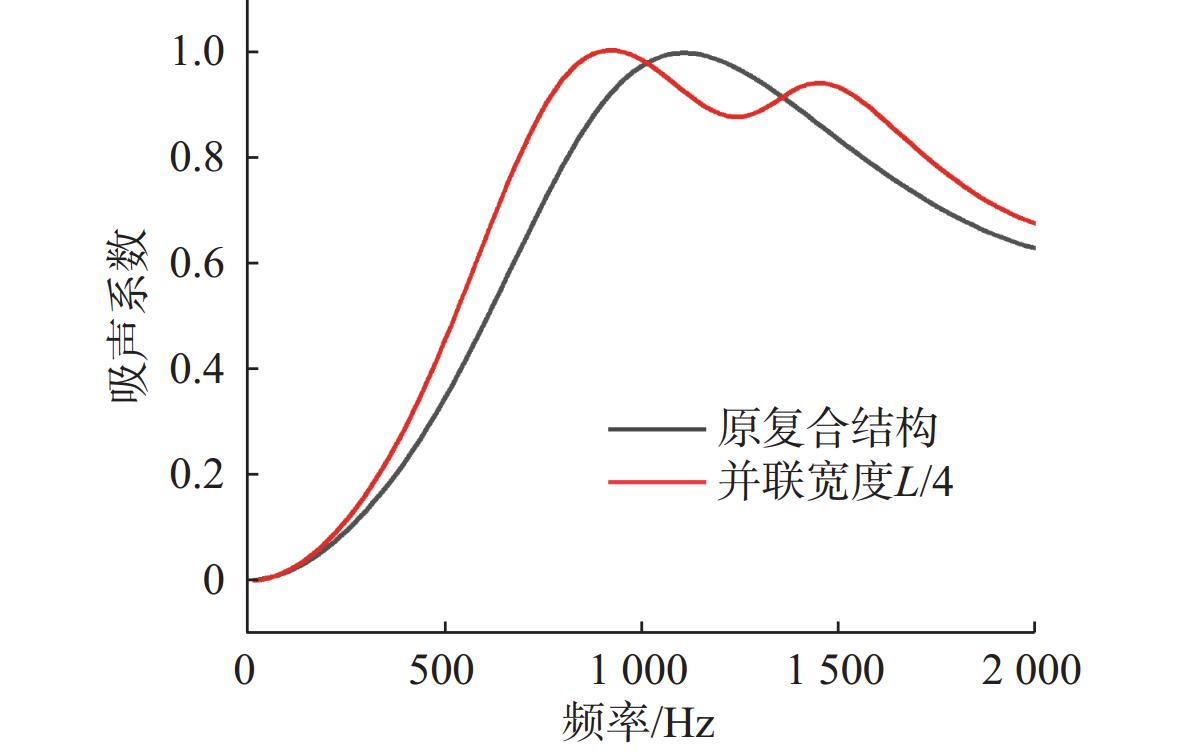

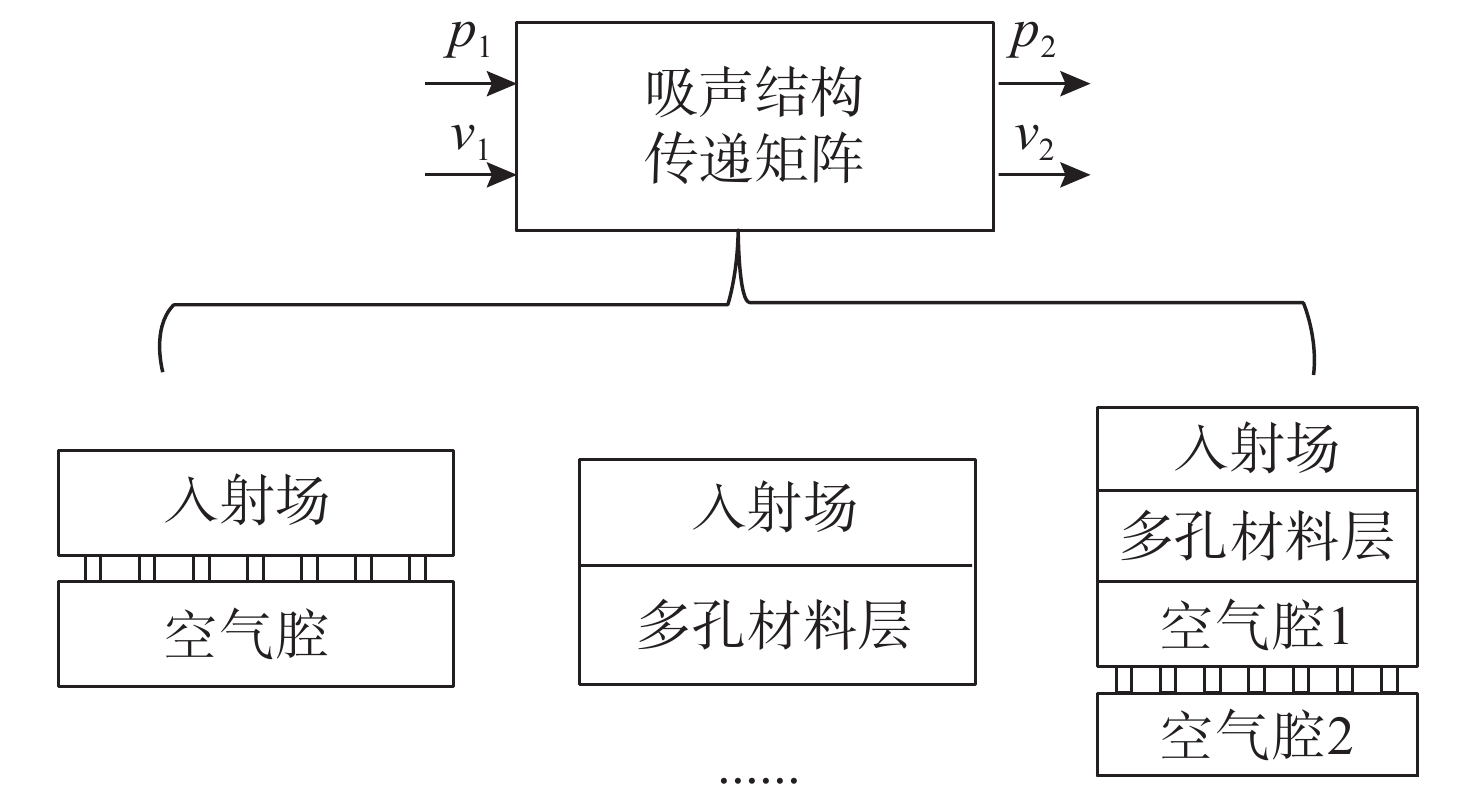

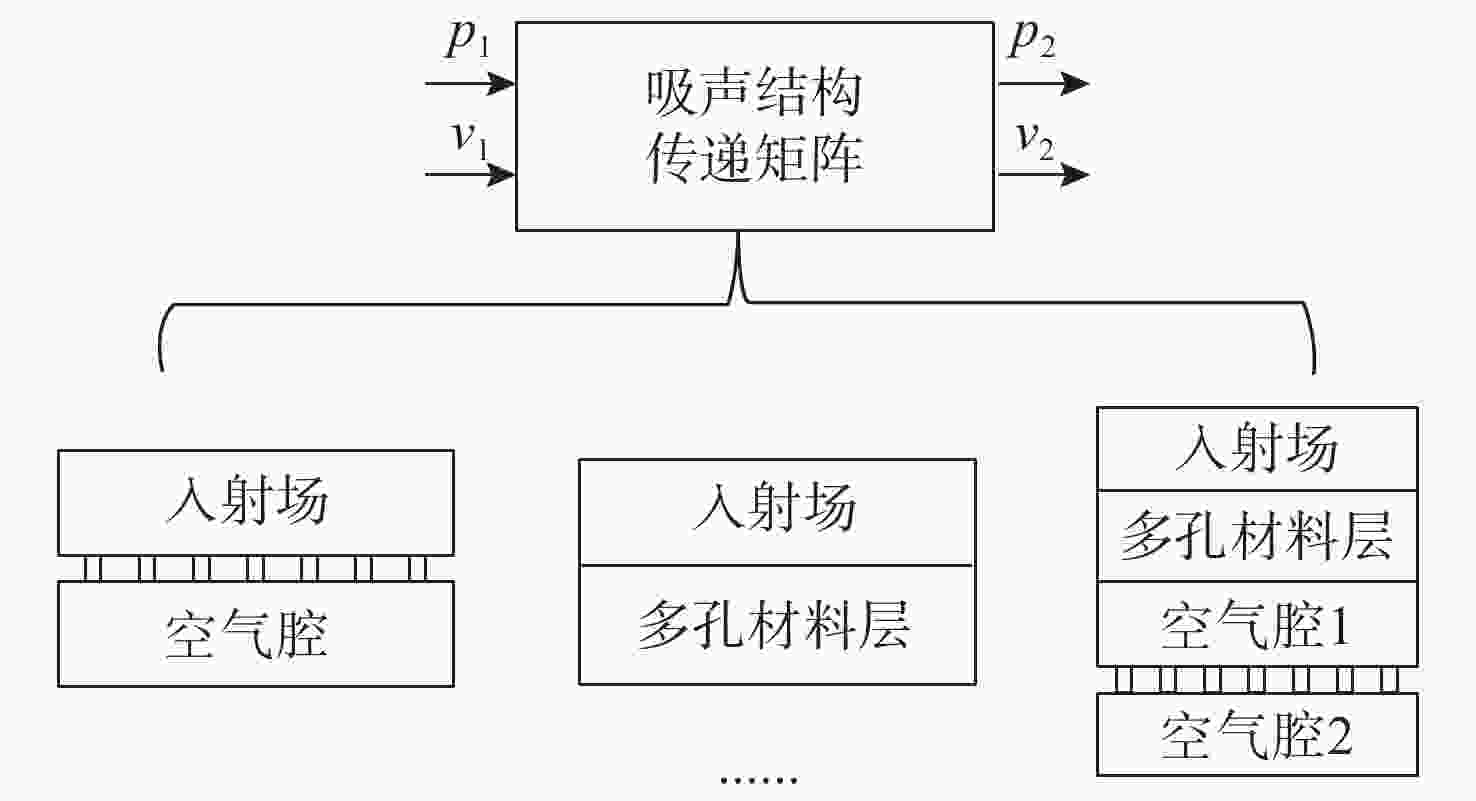

摘要: 机械噪声中的辐射噪声会对声学探测型水下滑翔机声学探测性能产生严重影响, 针对该问题, 文中将吸声结构引入水下滑翔机的辐射噪声降噪研究。首先建立不同吸声结构的理论模型, 根据微穿孔板和多孔材料吸声理论, 提出用于降低水下滑翔机辐射噪声的复合吸声结构, 并利用Comsol软件对复合吸声结构进行仿真分析, 用于指导复合吸声结构设计。仿真结果表明: 多孔材料层-空气腔-微穿孔板层-并联空气腔的复合吸声结构在0~2 000 Hz内的效果最好, 其在200~1 200 Hz内的平均吸声系数为0.663, 能有效降低水下滑翔机特定工况下的辐射噪声, 减小自噪声的干扰, 提高声学探测滑翔机的探测水平。Abstract: The radiation noise of mechanical noise has a significant impact on the acoustic detection performance of acoustic detection-based underwater gliders. In order to address this problem, this paper introduced sound absorption structure into the study of radiation noise of underwater gliders. Firstly, the theoretical models of different sound absorption structures were established, and according to the sound absorption theories of microperforated panel and porous materials, the composite sound absorption structure for reducing the radiation noise of underwater gliders was proposed, and the simulation analysis of the composite sound absorption structure was carried out by using Comsol software for guiding the design of the composite sound absorption structure. The simulation results show that the composite sound absorption structure of porous material layer-air cavity-microperforated panel-parallel air cavity has the best performance in the range of 0–2 000 Hz, and its average sound absorption coefficient is 0.663 in the range of 200–1 200 Hz, which can reduce the radiation noise of the underwater gliders under specific working conditions, weaken the interference of self-noise, and improve the detection ability of acoustic detection-based gliders.

-

Key words:

- underwater glider /

- radiation noise /

- sound absorption /

- microperforated panel /

- porous material.

-

表 1 多孔材料参数列表

Table 1. List of porous material parameters

孔隙率 流阻率

/(Pa·s/m2)曲折

因子粘性特征

长度/μm热特征

长度/μm0.92 6998 1.94 65 219 表 2 响应面自变量范围

Table 2. Range of response surface independent variables

D1/mm D2/mm t/mm d/mm D/mm s/% [0, 40] [0, 40] [0, 5] [0, 5] [0, 40] [0.1, 5] 表 3 遗传算法优化参数

Table 3. Parameters of the genetic algorithm optimistion

种群大小 最大进化代数 交叉概率 变异概率 100 100 0.8 0.05 表 4 复合吸声结构参数优化结果

Table 4. Optimisation results of composite sound absorption parameters

D1/mm D2/mm t/mm d/mm D/mm s/% 19.5 3.9 1.6 0.45 14.6 5 -

[1] RUDNICK D L, DAVIS R E, ERIKSEN C C, et al. Underwater gliders for ocean research[J]. Marine Technology Society Journal, 2004, 38(2): 73-84. doi: 10.4031/002533204787522703 [2] 王超, 韩梅, 孙芹东, 等. 水下声学滑翔机平台噪声测试与优化[J]. 水下无人系统学报, 2020, 28(4): 396-402.WANG C, HAN M, SUN Q D, et al. Noise measurement and optimization of underwater acoustic glider platform[J]. [J]. Journal of Unmanned Undersea Systems, 2020, 28(4): 396-402. [3] D'SPAIN G L, ZIMMERMAN R, BRODSKY P, et al. Decreasing the radiated acoustic and vibration noise of both prop-driven and buoyancy-driven autonomous underwater vehicles[J]. The Journal of the Acoustical Society of America, 2014, 135(4): 2192. [4] 周文臣. 水下滑翔机振动分析及减振降噪研究[D]. 天津: 天津大学, 2019. [5] LIU Y J, LIU J, PAN G, et al. Dynamic analysis of an autonomous underwater glider with single and two-stage vibration isolators[J]. Journal of Marine Science and Engineering, 2022, 10(2): 162-173. doi: 10.3390/jmse10020162 [6] LIU Y J, LIU J, PAN G, et al. Vibration analysis and isolator component design of the power system in an autonomous underwater glider[J]. The International Journal of Acoustics and Vibration, 2022, 27(2): 112-121. doi: 10.20855/ijav.2022.27.21841 [7] 刘记龙. 敷设阻尼层的水下滑翔机振动分析及辐射噪声研究[D]. 天津: 天津大学, 2021. [8] CAO L, FU Q, YANG S, et al. Porous materials for sound absorption[J]. Composites Communications, 2018, 10: 25-35. doi: 10.1016/j.coco.2018.05.001 [9] 马大猷. 微穿孔板吸声结构的理论和设计[J]. 中国科学, 1975(1): 38-50.MA D Y. Theory and design of microperforated plate sound-absorbing structures[J]. Science China, 1975(1): 38-50. [10] MA D. Potential of microperforated panel absorber[J]. Journal of the Acoustical Society of America, 1998, 104(5): 2861-2866. doi: 10.1121/1.423870 [11] JU H P, SEI H Y, HYEONG R L, et al. Optimization of low frequency sound absorption by cell size control and multiscale poroacoustics modeling[J]. Journal of Sound and Vibration, 2017, 397: 17-30. doi: 10.1016/j.jsv.2017.03.004 [12] 张斌, 陶泽光, 丁辉. 用传递矩阵法预测单层或多层微孔板的吸声性能[J]. 应用声学, 2007(3): 164-169. doi: 10.3969/j.issn.1000-310X.2007.03.006ZHANG B, TAO Z G, DING H. Prediction of acoustic performance of single or multi-layer microporous plates by transfer matrix method[J]. Journal of Applied Acoustics, 2007(3): 164-169. doi: 10.3969/j.issn.1000-310X.2007.03.006 [13] 董鹏, 龚强. 基于Comsol的夹芯板声学特性仿真分析[J]. 舰船科学技术, 2023, 45(9): 56-59. doi: 10.3404/j.issn.1672-7649.2023.09.012DONG P, GONG Q. Simulation analysis of acoustic characteristics of sandwich panel based on Comsol[J]. Ship Science and Technology, 2023, 45(9): 56-59. doi: 10.3404/j.issn.1672-7649.2023.09.012 [14] 李森琛. 基于微穿孔板吸声结构的直升机舱内降噪技术研究[D]. 南京: 南京航空航天大学, 2020. -

下载:

下载: