| [1] |

辛春亮, 王俊林, 薛再清, 等. 反舰导弹战斗部现状及发展趋势[J]. 战术导弹技术, 2016(6): 105-110.XIN C L, WANG J L, XUE Z Q, et al. Current situation and development trend of anti-ship missile warhead[J]. Tactical Missile Technology, 2016(6): 105-110.

|

| [2] |

WIERNICKI C J, LIEM F, WOODS G D, et al. Structural analysis methods for lightweight metallic corrugated core sandwich panels subjected to blast loads[J]. Naval Engineers Journal, 1991, 103(3): 192-202. doi: 10.1111/j.1559-3584.1991.tb00949.x

|

| [3] |

周晓松, 梅志远, 张焱冰. 复合材料夹层结构在舰艇碰撞防护中的研究进展[J]. 爆炸与冲击, 2018, 38(3): 696-706. doi: 10.11883/bzycj-2016-0303ZHOU X S, MEI Z Y, ZHANG Y B. Research progress of composite sandwich structure in ship collision protection[J]. Explosion and Shock Waves, 2018, 38(3): 696-706. doi: 10.11883/bzycj-2016-0303

|

| [4] |

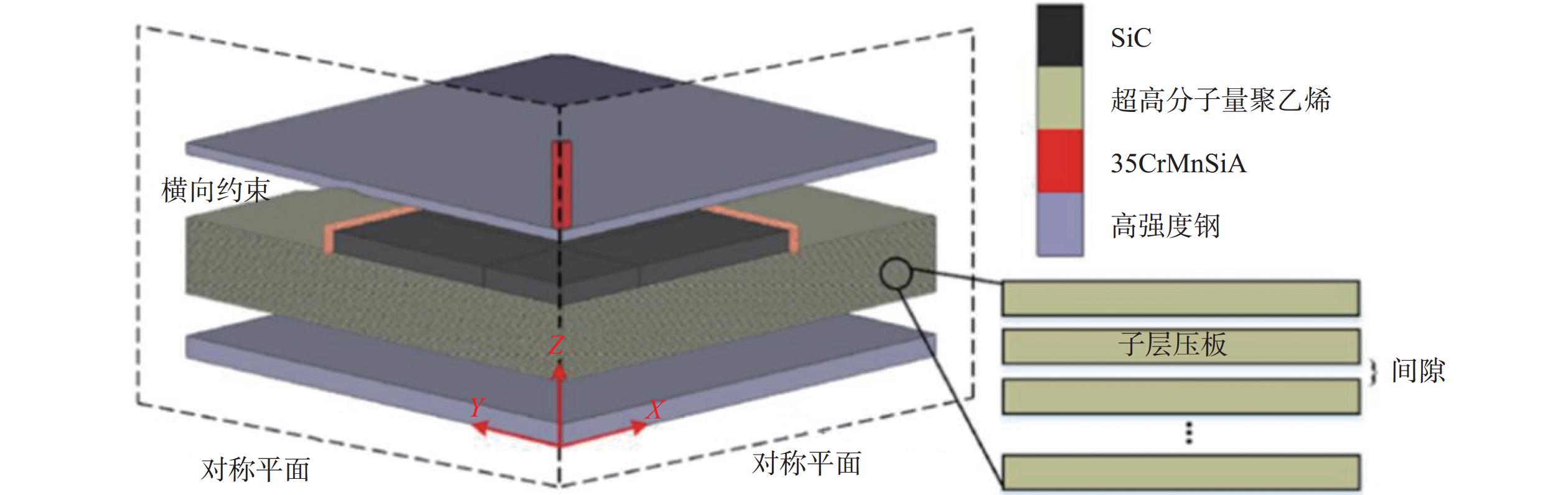

HU P, CHENG Y, ZHANG P, et al. A metal/UHMWPE/ SiC multi-layered composite armor against ballistic impact of flat-nosed projectile[J]. Ceramics International, 2021, 47(16): 22497-22513. doi: 10.1016/j.ceramint.2021.04.259

|

| [5] |

施兴华, 许文强, 袁海, 等. 舰船复合材料防护结构的选择与优化[J]. 舰船科学技术, 2020, 42(7): 36-40.SHI X H, XU W Q, YUAN H, et al. Selection and optimization of ship composite protective structure[J]. Ship Science and Technology, 2020, 42(7): 36-40.

|

| [6] |

张延昌, 王自力, 顾金兰, 等. 夹层板在舰船舷侧防护结构中的应用[J]. 中国造船, 2009, 50(4): 36-44. doi: 10.3969/j.issn.1000-4882.2009.04.006ZHANG Y C, WANG Z L, GU J L, et al. Application of sandwich plate in ship side protection structure[J]. Shipbuilding of China, 2009, 50(4): 36-44. doi: 10.3969/j.issn.1000-4882.2009.04.006

|

| [7] |

李典, 侯海量, 朱锡, 等. 舰艇装甲防护结构抗弹道冲击的研究进展[J]. 中国造船, 2018, 59(1): 237-250. doi: 10.3969/j.issn.1000-4882.2018.01.023LI D, HOU H L, ZHU X, et al. Research progress of ship armor protection structure against ballistic impact[J]. Shipbuilding of China, 2018, 59(1): 237-250. doi: 10.3969/j.issn.1000-4882.2018.01.023

|

| [8] |

严效男. 金属/陶瓷异质点阵结构设计与冲击防护性能研究[D]. 徐州: 中国矿业大学, 2021.

|

| [9] |

罗家元, 陈哲伦, 李世岳, 等. 典型防护材料空爆载荷作用下动态响应及抗冲击设计研究现状[J]. 复合材料科学与工程, 2024(10): 150-160.LUO J Y, CHEN Z L, LI S Y, et al. Research status of dynamic response and shock resistance design of typical protective materials under airburst loads[J]. Composite Materials Science and Engineering, 2024(10): 150-160.

|

| [10] |

BRENNAN M L, DELGADO J P, FERREIRO L D, et al. Discovery and initial documentation of USS Nevada(BB-36): An artifact of two world wars and the advent of the Cold War[J]. Journal of Maritime Archaeology, 2022, 17(1): 93-129. doi: 10.1007/s11457-022-09324-5

|

| [11] |

余毅磊, 蒋招绣, 王晓东, 等. 轻型陶瓷/金属复合装甲抗垂直侵彻过程中陶瓷碎裂行为研究[J]. 爆炸与冲击, 2021, 41(11): 82-91.YU Y L, JIANG Z X, WANG X D, et al. Research on ceramic fragmentation behavior of light ceramic/metal composite armor against vertical penetration[J]. Explosion and Shock Waves, 2021, 41(11): 82-91.

|

| [12] |

孔祥韶. 爆炸载荷及复合多层防护结构响应特性研究[D]. 武汉: 武汉理工大学, 2013.

|

| [13] |

周红兵, 梅志远. 多层复合舰用装甲结构抗高速破片特性比较研究[J]. 材料开发与应用, 2011, 26(4): 1-6. doi: 10.3969/j.issn.1003-1545.2011.04.001ZHOU H B, MEI Z Y. Comparative study on high speed fragmentation resistance of multi-layer composite naval armor structure[J]. Materials Development and Application, 2011, 26(4): 1-6. doi: 10.3969/j.issn.1003-1545.2011.04.001

|

| [14] |

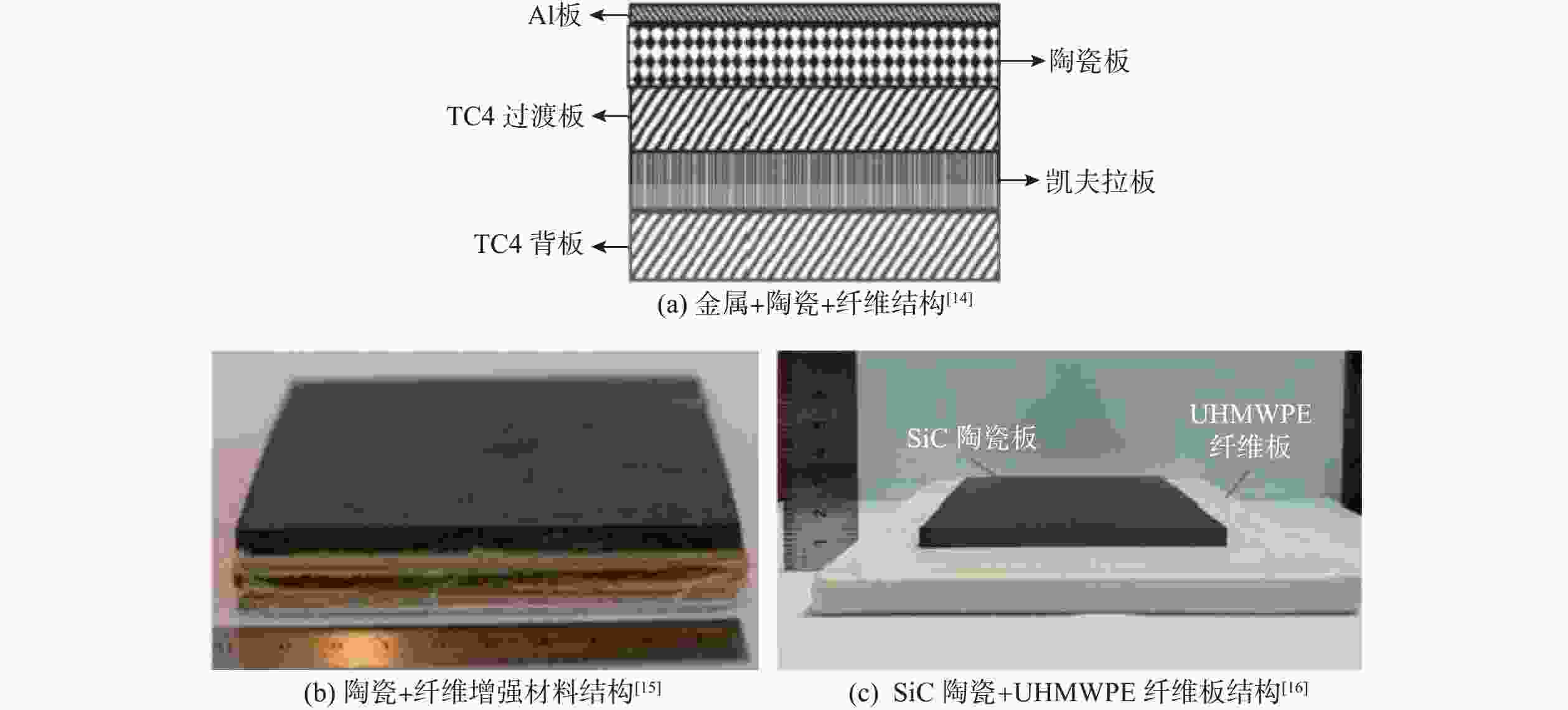

CAO J, LAI J, ZHOU J, et al. Experiments and simulations of the ballistic response of ceramic composite armors[J]. Journal of Mechanical Science, 2020, 34: 2783-2793.

|

| [15] |

PENG L, TAN M T, ZHANG X, et al. Investigations of the ballistic response of hybrid composite laminated structures[J]. Composite Structures, 2022, 282: 115019. doi: 10.1016/j.compstruct.2021.115019

|

| [16] |

李永鹏, 徐豫新, 张健, 等. SiC 陶瓷/UHMWPE 纤维复合结构抗 12.7 mm 穿甲燃烧弹试验与仿真[J]. 兵工学报, 2022, 43(6): 1355-1364.LI Y P, XU Y X, ZHANG J, et al. Test and simulation of SiC ceramic /UHMWPE fiber composite structure against 12.7 mm armor-piercing Incendiary bomb[J]. Acta Ordnance Engineering, 2022, 43(6): 1355-1364.

|

| [17] |

张弩, 于馨, 明付仁. 复合材料层合板在水下多层防护结构中的抗爆效能[J]. 兵工学报, 2021, 42(S1): 135-141.ZHANG N, YU X, MING F R. Antiknock performance of composite laminates in underwater multilayer protective structures[J]. Acta Ordnance Engineering, 2021, 42(S1): 135-141.

|

| [18] |

程远胜, 谢杰克, 李哲, 等. 冲击波和破片群联合作用下高强聚乙烯/泡沫铝夹芯复合结构毁伤响应特性[J]. 兵工学报, 2021, 42(8): 1753-1762.CHENG Y S, XIE J K, LI Z, et al. Damage response characteristics of high-strength polyethylene/aluminum foam sandwich composite structures under the combined action of shock wave and fragment group[J]. Journal of Ordnance Engineering, 2021, 42(8): 1753-1762.

|

| [19] |

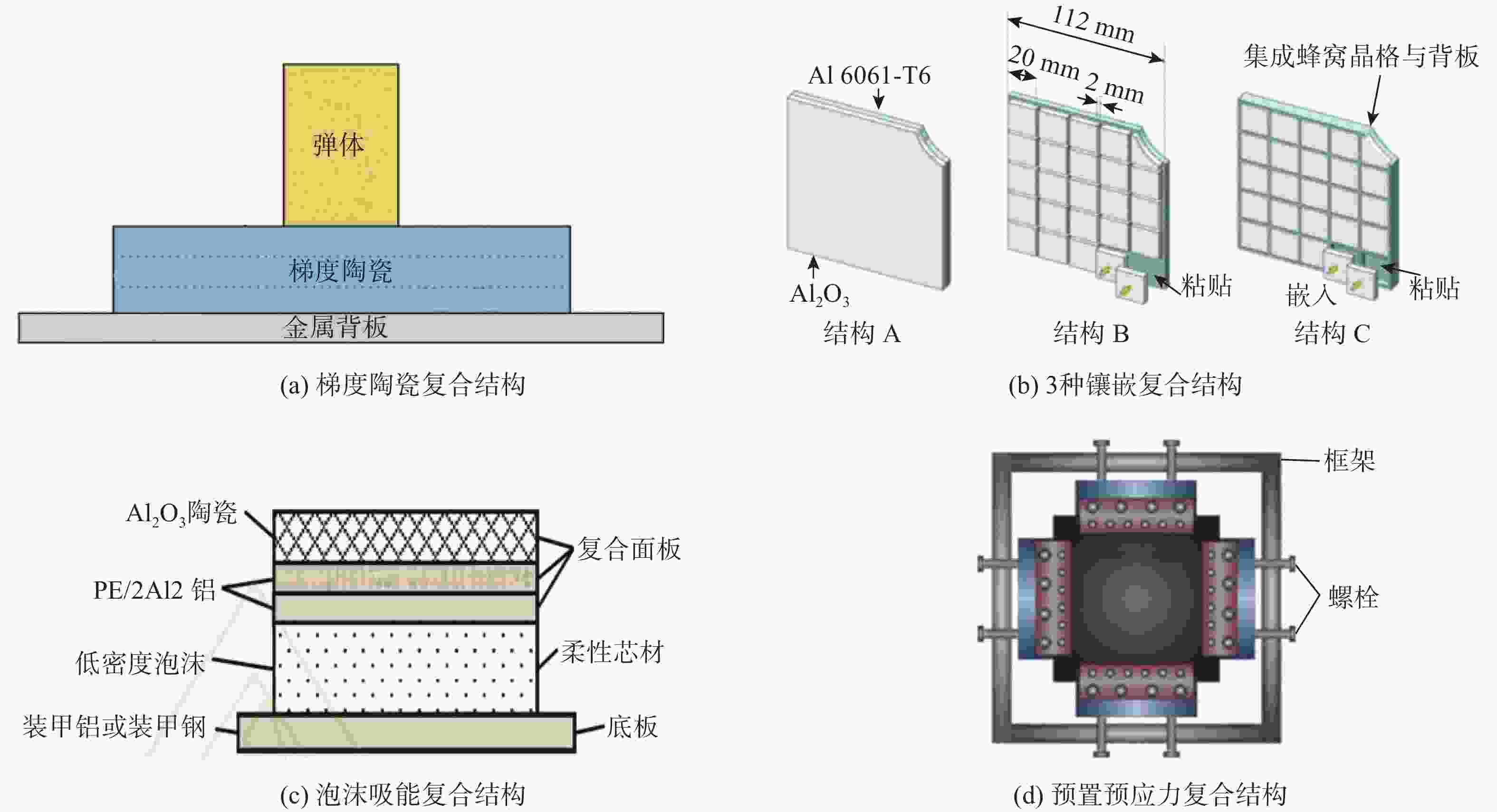

焦丽娟, 李军. 装甲防护材料的新葩——陶瓷-金属功能梯度复合材料[J]. 纤维复合材料, 2007(1): 55-58. doi: 10.3969/j.issn.1003-6423.2007.01.018JIAO L J, LI J. A new patter-ceramic-metal functional gradient composite for armor protection materials[J]. Fiber Composite Materials, 2007(1): 55-58. doi: 10.3969/j.issn.1003-6423.2007.01.018

|

| [20] |

FARAH S, FUGUO L, ZAHID M H, et al. Design and performance of layered heterostructure composite material system for protective armors[J]. Materials, 2023, 16(14): 5169.

|

| [21] |

叶中豹. 新型复合防护材料的动静态力学特性和工程应用研究[D]. 合肥: 中国科学技术大学, 2018.

|

| [22] |

GUO G, ALAM S, PEEL L D. An investigation of the effect of a Kevlar-29 composite cover layer on the penetration behavior of a ceramic armor system against 7.62 mm APM2 projectiles[J]. International Journal of Impact Engineering, 2021, 157: 104000. doi: 10.1016/j.ijimpeng.2021.104000

|

| [23] |

侯海量, 朱锡, 李伟. 轻型陶瓷/金属复合装甲抗弹机理研究[J]. 兵工学报, 2013, 34(1): 105-114.HOU H L, ZHU X, LI W. Research on elastic resistance mechanism of lightweight ceramic/metal composite armor[J]. Acta Ordnance Engineering, 2013, 34(1): 105-114.

|

| [24] |

龙奎, 邓勇军, 陈小伟, 等. 基于 SHPB 试验的 B4C/Al 复合材料动态力学性能研究[J]. 稀有金属材料与工程, 2022, 51(10): 3826-3834.LONG K, DENG Y J, CHEN X W, et al. Study on dynamic mechanical properties of B4C/Al composites based on SHPB test[J]. Rare Metal Materials and Engineering, 2022, 51(10): 3826-3834.

|

| [25] |

苏罗川, 宜晨虹, 刘文杰, 等. 轻质抗侵彻材料及结构研究现状[J]. 兵器装备工程学报, 2018, 39(1): 157-167. doi: 10.11809/bqzbgcxb2018.01.034SU L C, YI C H, LIU W J, et al. Research status of lightweight anti-penetration materials and structures[J]. Journal of Ordnance Equipment Engineering, 2018, 39(1): 157-167. doi: 10.11809/bqzbgcxb2018.01.034

|

| [26] |

ÜBEYLI M, YILDIRIM R O, ÖGEL B. Investigation on the ballistic behavior of Al2O3/Al2O24 laminated composites[J]. Journal of Materials Processing Technology, 2008, 196(1-3): 356-364. doi: 10.1016/j.jmatprotec.2007.05.050

|

| [27] |

CHEN Y L, HUANG W K, YEH J N. Theoretical analysis of bulletproof capability of multilayer ceramic composites subjected to impact by an armor piercing projectile[J]. Advances in Materials Science Engineering, 2021, 2021: 1-13.

|

| [28] |

ZHAO Z N, HAN B, LI F H, et al. Enhanced bi-layer mosaic armor: experiments and simulation[J]. Ceramics International, 2020, 46(15): 23854-23866. doi: 10.1016/j.ceramint.2020.06.162

|

| [29] |

张林, 陈斌, 谭清华, 等. 陶瓷复合装甲抗 14.5 mm 穿燃弹侵彻性能[J]. 兵工学报, 2022, 43(4): 758-767.ZHANG L, CHEN B, TAN Q H, et al. Resistance of ceramic composite armor to penetration of 14.5 mm projectile[J]. Acta Ordnance Engineering, 2022, 43(4): 758-767.

|

| [30] |

WANG C, SUO T, HANG C, et al. Influence of in-plane tensile preloads on impact responses of composite laminated plates[J]. International Journal of Mechanical Sciences, 2019, 161: 105012.

|

| [31] |

SHEN Y, WANG Y, DU S, et al. Effects of the adhesive layer on the multi-hit ballistic performance of ceramic/metal composite armors[J]. Journal of Materials Research Technology, 2021, 13: 1496-1508. doi: 10.1016/j.jmrt.2021.05.058

|

| [32] |

徐国军. 点阵金属陶瓷复合材料抗侵彻性能研究[D]. 上海: 上海海洋大学, 2019.

|

| [33] |

张征, 吴化平, 李祥辉, 等. 金字塔点阵复合材料结构力学性能分析与优化[J]. 轻工机械, 2013, 31(1): 74-79.ZHANG Z, WU H P, LI X H, et al. Mechanical properties analysis and optimization of pyramid lattice composite structures[J]. Light Industry Machinery, 2013, 31(1): 74-79.

|

| [34] |

ZHANG T, CHENG X, GUO C, et al. Toughness-improving design of lattice sandwich structures[J]. Materials Design, 2023: 111600.

|

| [35] |

USTA F, TÜRKMEN H S, SCARPA F. Low-velocity impact resistance of composite sandwich panels with various types of auxetic and non-auxetic core structures[J]. Thin-Walled Structures, 2021, 163: 107738. doi: 10.1016/j.tws.2021.107738

|

| [36] |

韩宾, 于渤, 秦科科, 等. 低速冲击载荷下金属点阵夹芯板的动态响应分析[J]. 应用力学学报, 2014, 31(5): 782-788+835.HAN B, YU B, QIN K K, et al. Dynamic response analysis of metal lattice sandwich plate under low speed impact load[J]. Chinese Journal of Applied Mechanics, 2014, 31(5): 782-788+835.

|

| [37] |

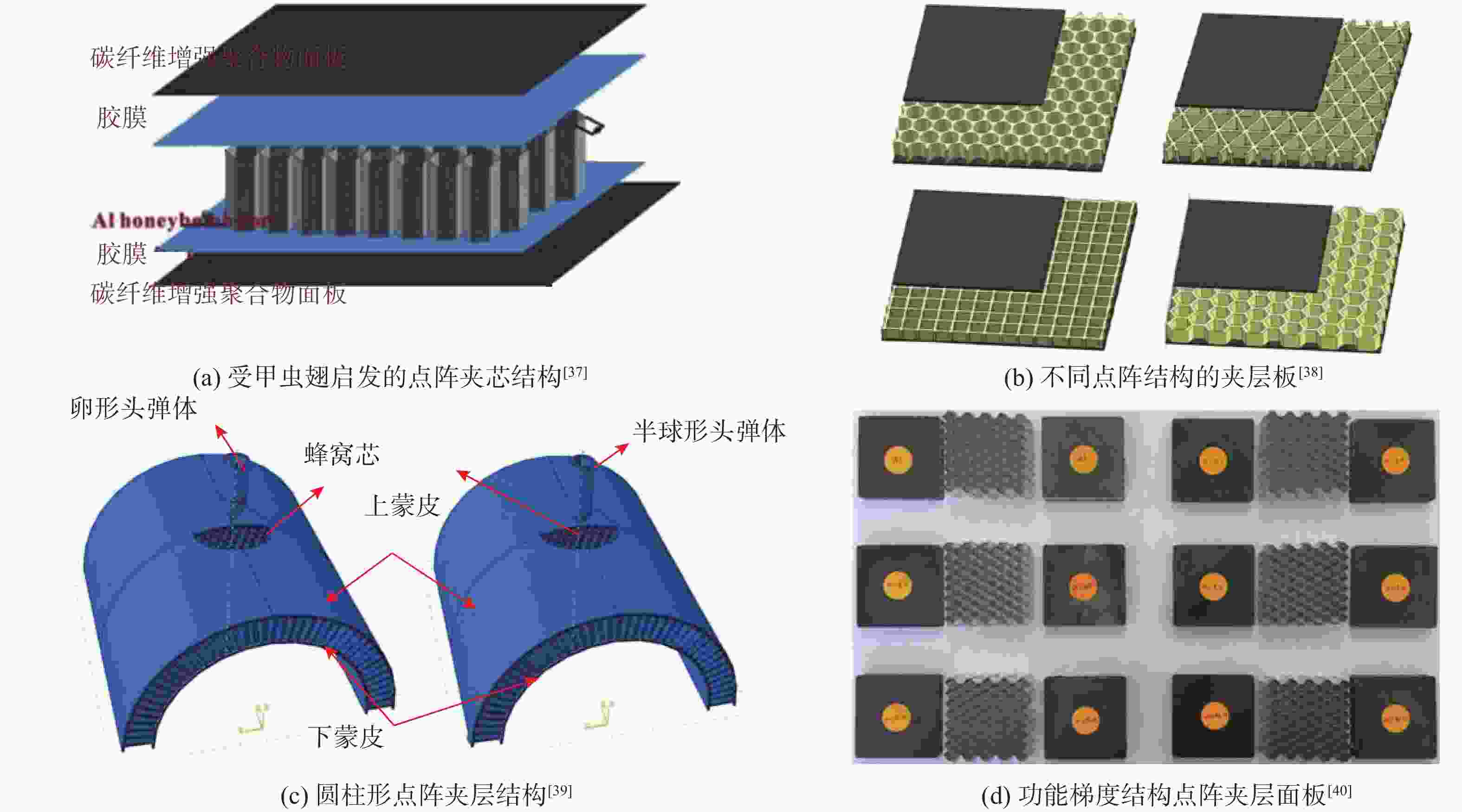

CAI Z B, LI Z Y, DING Y, et al. Preparation and impact resistance performance of bionic sandwich structure inspired from beetle forewing[J]. Composites Part B: Engineering, 2019, 161: 490-501. doi: 10.1016/j.compositesb.2018.12.139

|

| [38] |

王金友. 基于船舶轻量化的蜂窝夹层板的结构设计及隔声性能研究[D]. 镇江: 江苏科技大学, 2021.

|

| [39] |

TIWARI G, KHAIRE N. Ballistic performance and energy dissipation characteristics of cylindrical honeycomb sandwich structure[J]. International Journal of Impact Engineering, 2022, 160: 104065. doi: 10.1016/j.ijimpeng.2021.104065

|

| [40] |

ARSLAN K, GUNES R. Experimental damage evaluation of honeycomb sandwich structures with Al/B4C FGM face plates under high velocity impact loads[J]. Composite Structures, 2018, 202: 304-312. doi: 10.1016/j.compstruct.2018.01.087

|

| [41] |

亓昌, 郝鹏程, 舒剑, 等. 金字塔型点阵材料夹芯板抗爆性能仿真与优化[J]. 振动与冲击, 2019, 38(16): 245-252.QI C, HAO P C, SHU J, et al. Simulation and optimization of antiknock performance of sandwich plate with pyramidal lattice material[J]. Journal of Vibration and Shock, 2019, 38(16): 245-252.

|

| [42] |

RUSINOV P, BLEDNOVA Z, RUSINOVA A, et al. Development and research of new hybrid composites in order to increase reliability and durability of structural elements[J]. Metals, 2023, 13(7): 1177.

|

| [43] |

魏化震, 钟蔚华, 于广. 高分子复合材料在装甲防护领域的研究与应用进展[J]. 材料工程, 2019, 48(8): 25-32.WEI H Z, ZHONG W H, YU G. Research and application progress of polymer composites in armor protection[J]. Journal of Materials Engineering, 2019, 48(8): 25-32.

|

| [44] |

郭克星, 夏鹏举. 智能复合材料的研究进展[J]. 功能材料, 2019, 50(4): 4017-4022, 4029.GUO K X, XIA P J. Research progress of intelligent composites[J]. Journal of Functional Materials, 2019, 50(4): 4017-4022, 4029.

|

| [45] |

王玉立. 金属/陶瓷异质结构复合成型与防护性能研究[D]. 徐州: 中国矿业大学, 2022.

|

| [46] |

廖祖伟. 钢板—支撑钢筋—聚氨酯复合材料结构的性能及其在地下防护工程中的应用研究[D]. 成都: 西南交通大学, 2008.

|

| [47] |

陶然, 贺春旺, 罗俊荣, 等. 复合材料构件设计理论及仿真研究进展[J]. 中国工程科学, 2023, 25(1): 121-130.TAO R, HE C W, LUO J R, et al. Research progress of composite component design theory and simulation[J]. Engineering Science, 2023, 25(1): 121-130.

|

| [48] |

杨智帆, 张永康. 复合增材制造技术研究进展[J]. 电加工与模具, 2019(2): 1-7. doi: 10.3969/j.issn.1009-279X.2019.02.001YANG Z F, ZHANG Y K. Research progress of composite additive manufacturing technology[J]. Electromachining & Mould, 2019(2): 1-7. doi: 10.3969/j.issn.1009-279X.2019.02.001

|

| [49] |

王慧远, 李超, 李志刚, 等. 纳米增强体强化轻合金复合材料制备及构型设计研究进展与展望[J]. 金属学报, 2019, 55(6): 683-691. doi: 10.11900/0412.1961.2018.00517WANG H Y, LI C, LI Z G, et al. Research progress and prospect on preparation and configuration design of light alloy composite reinforced by nano-reinforcement[J]. Acta Metalica Sinica, 2019, 55(6): 683-691. doi: 10.11900/0412.1961.2018.00517

|

| [50] |

陈泽中, 李生娟. 面向智能制造的材料成型及控制工程升级探索[J]. 教育教学论坛, 2020(27): 220-221.CHEN Z Z, LI S J. Exploration of material forming and control engineering upgrading for intelligent manufacturing[J]. Education and Teaching Forum, 2020(27): 220-221.

|

下载:

下载: