Prediction of Deformation Response of Target Plate in Underwater Explosion Based on Deep Learning Neural Network

-

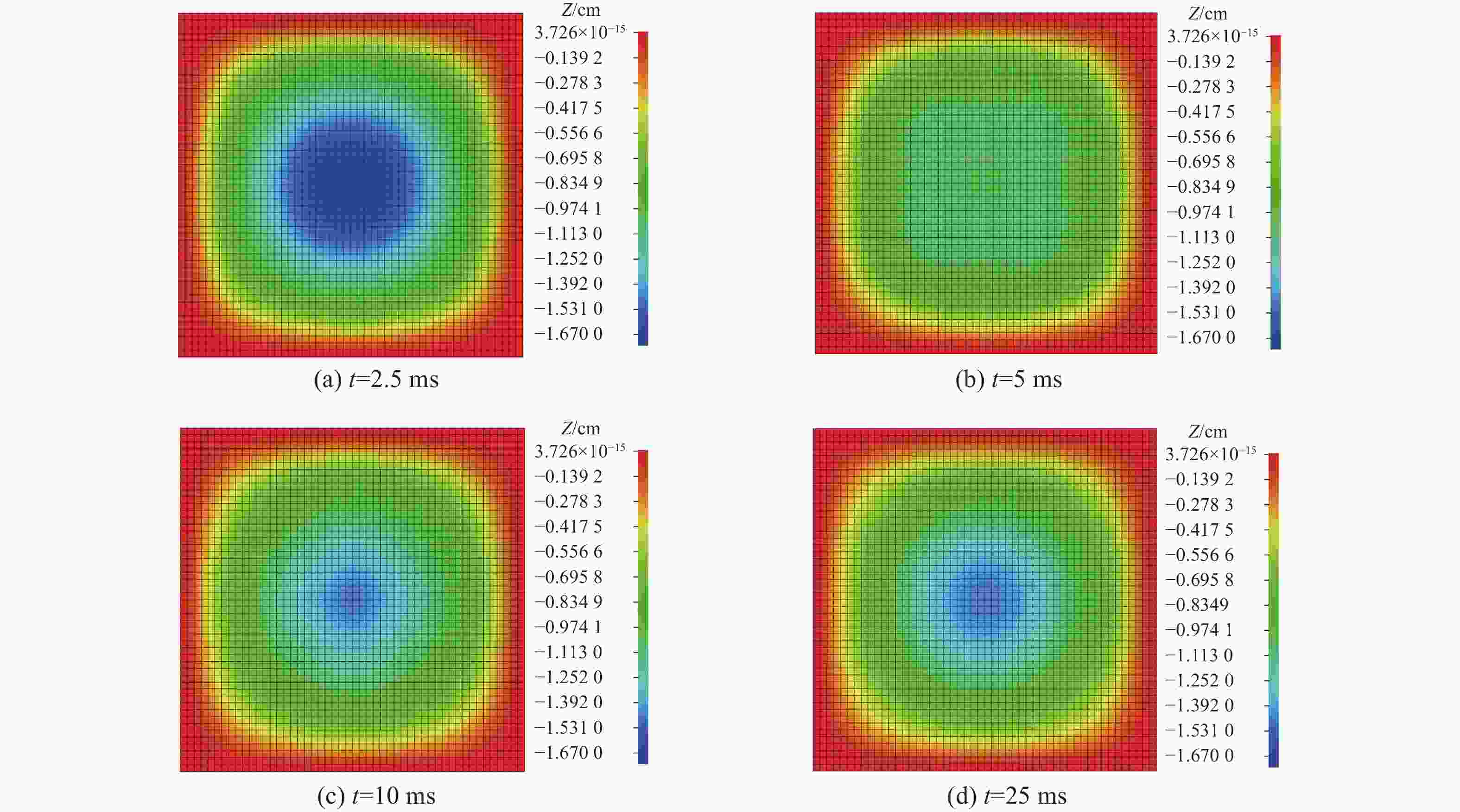

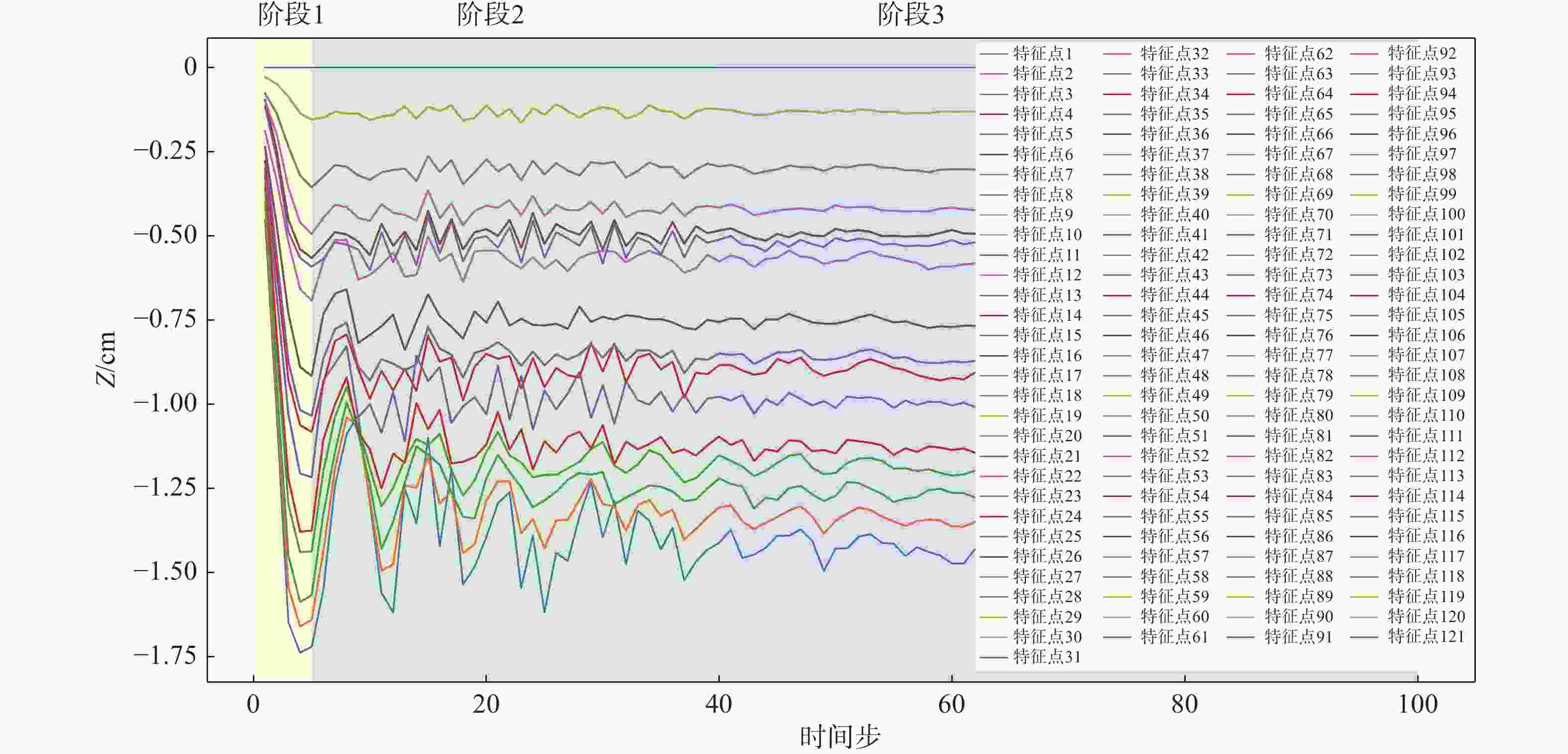

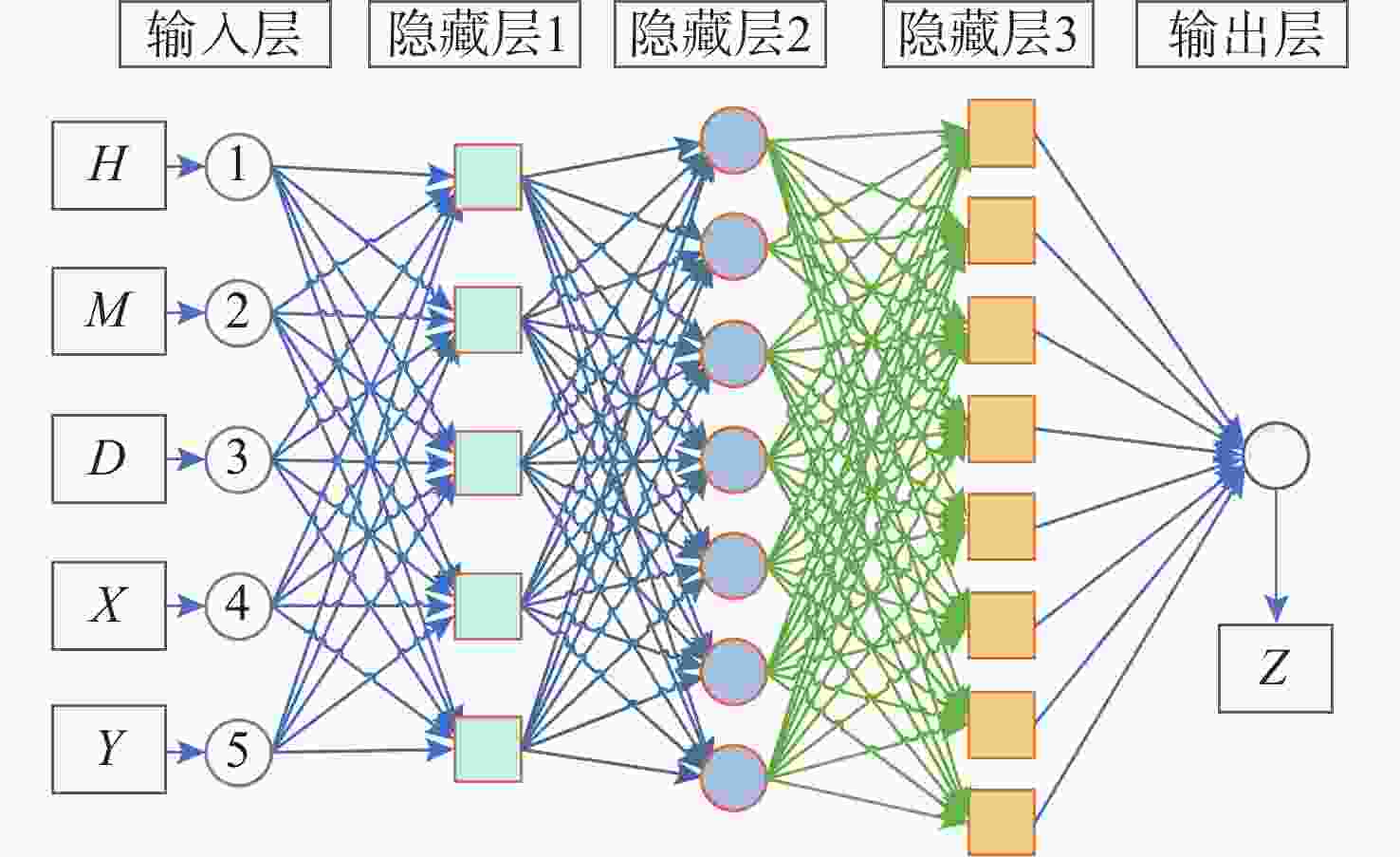

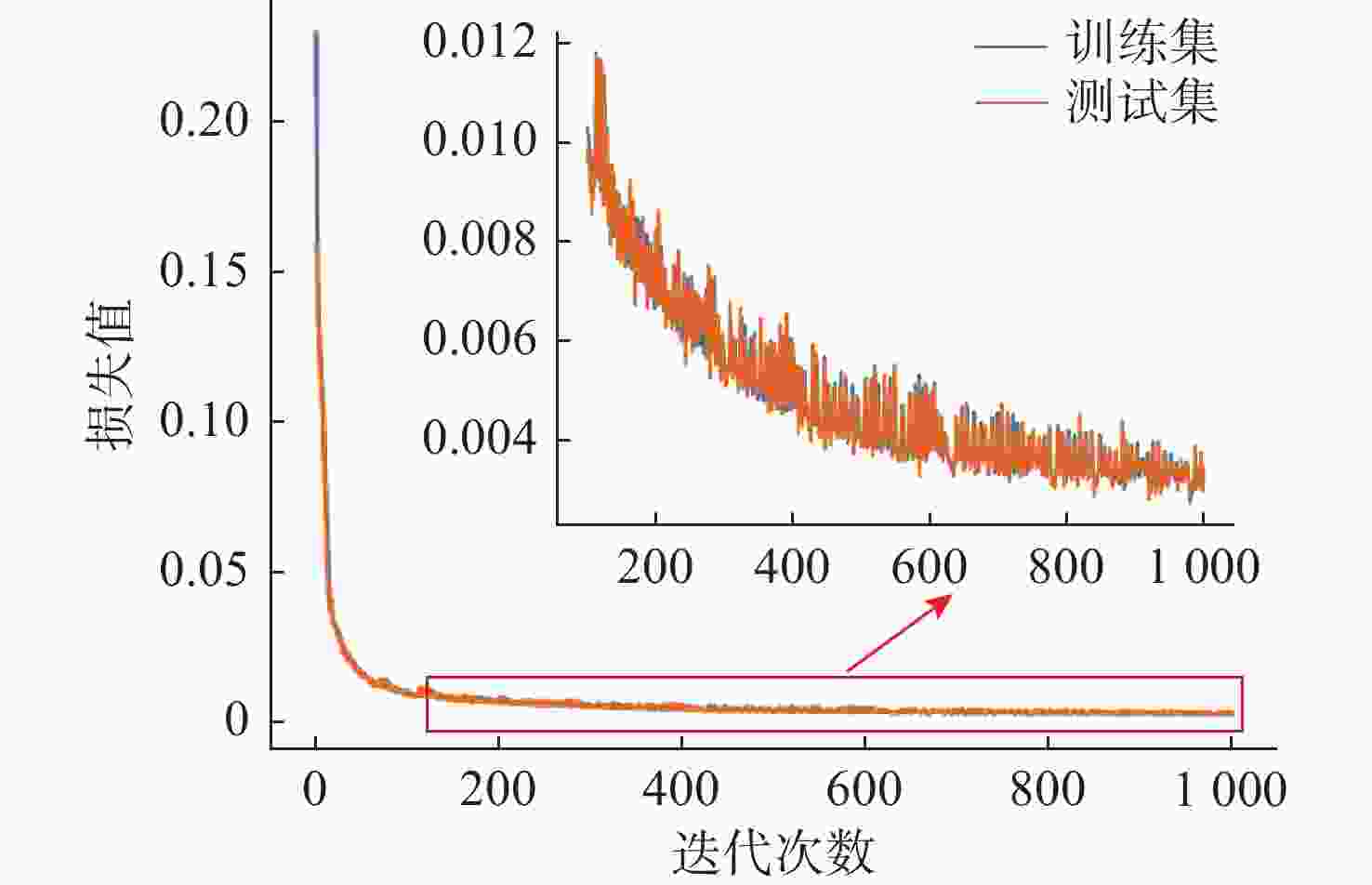

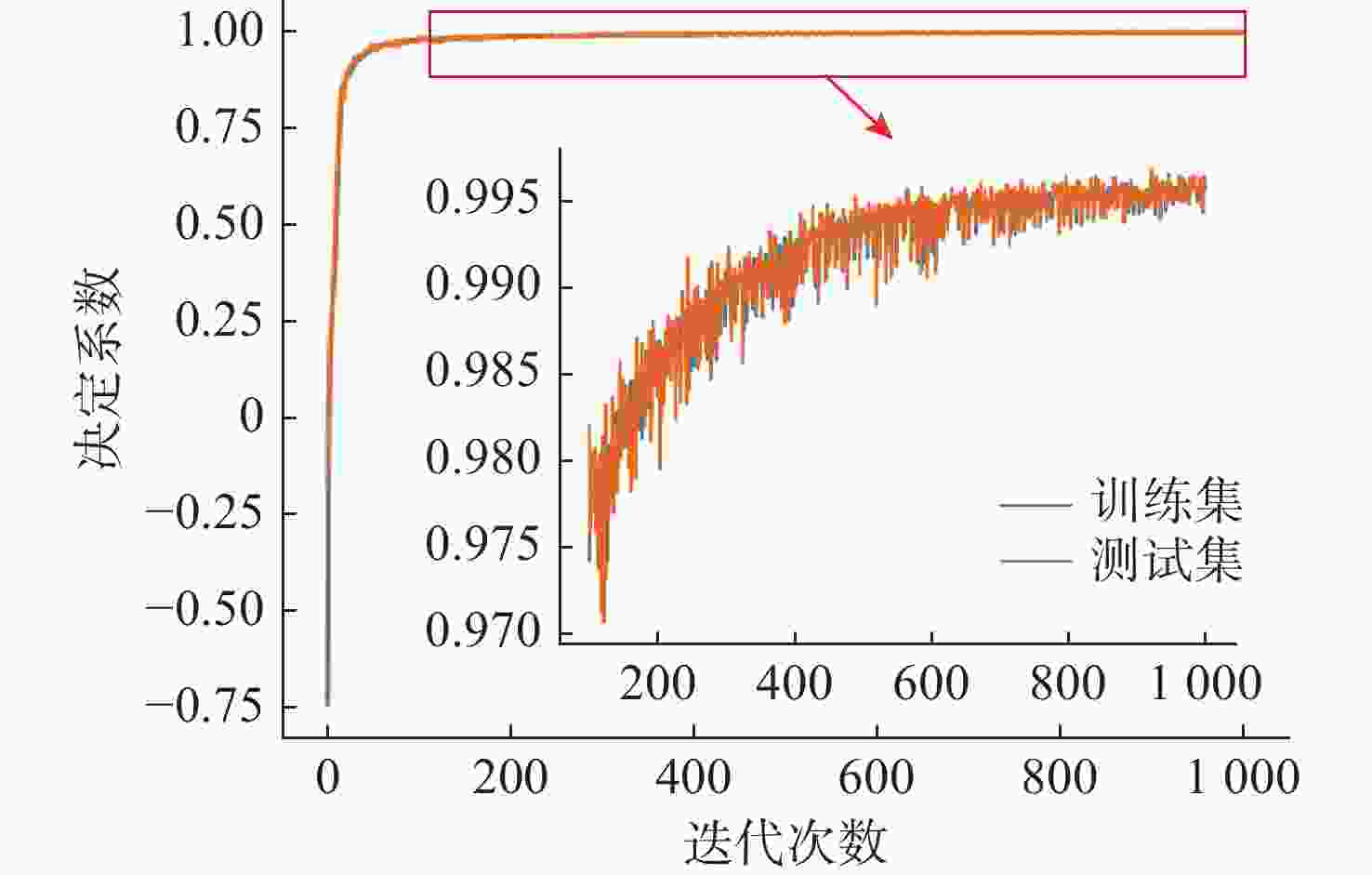

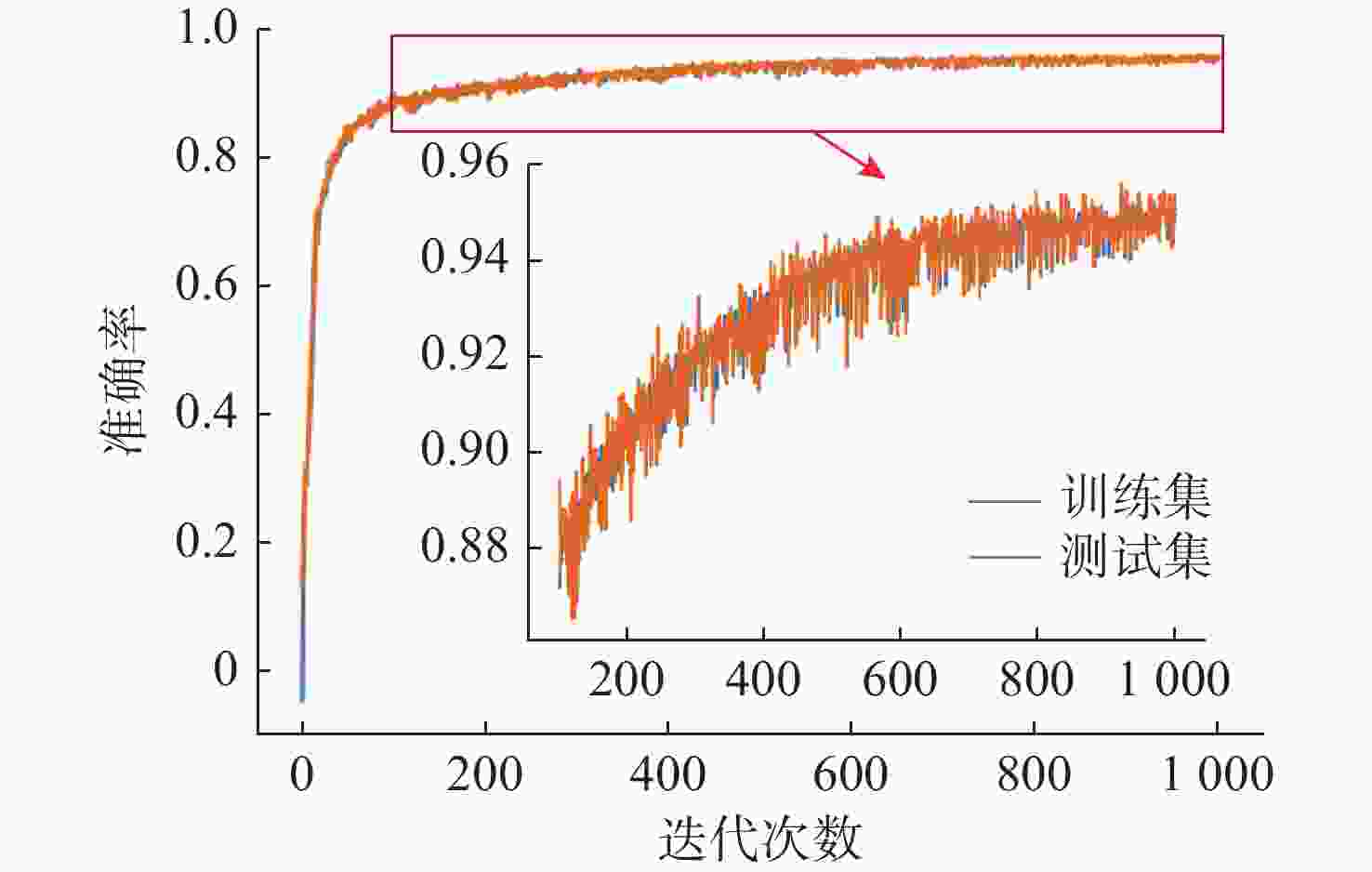

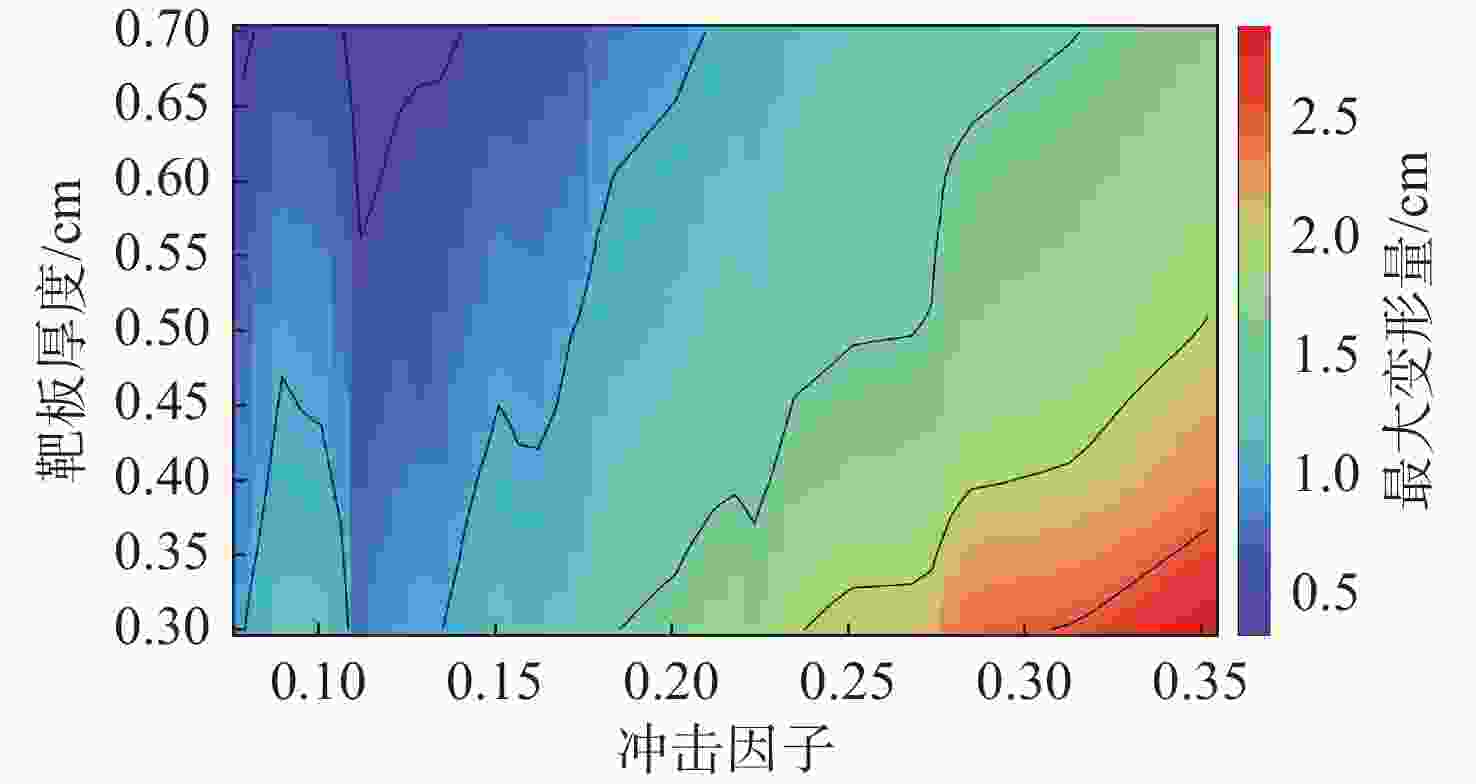

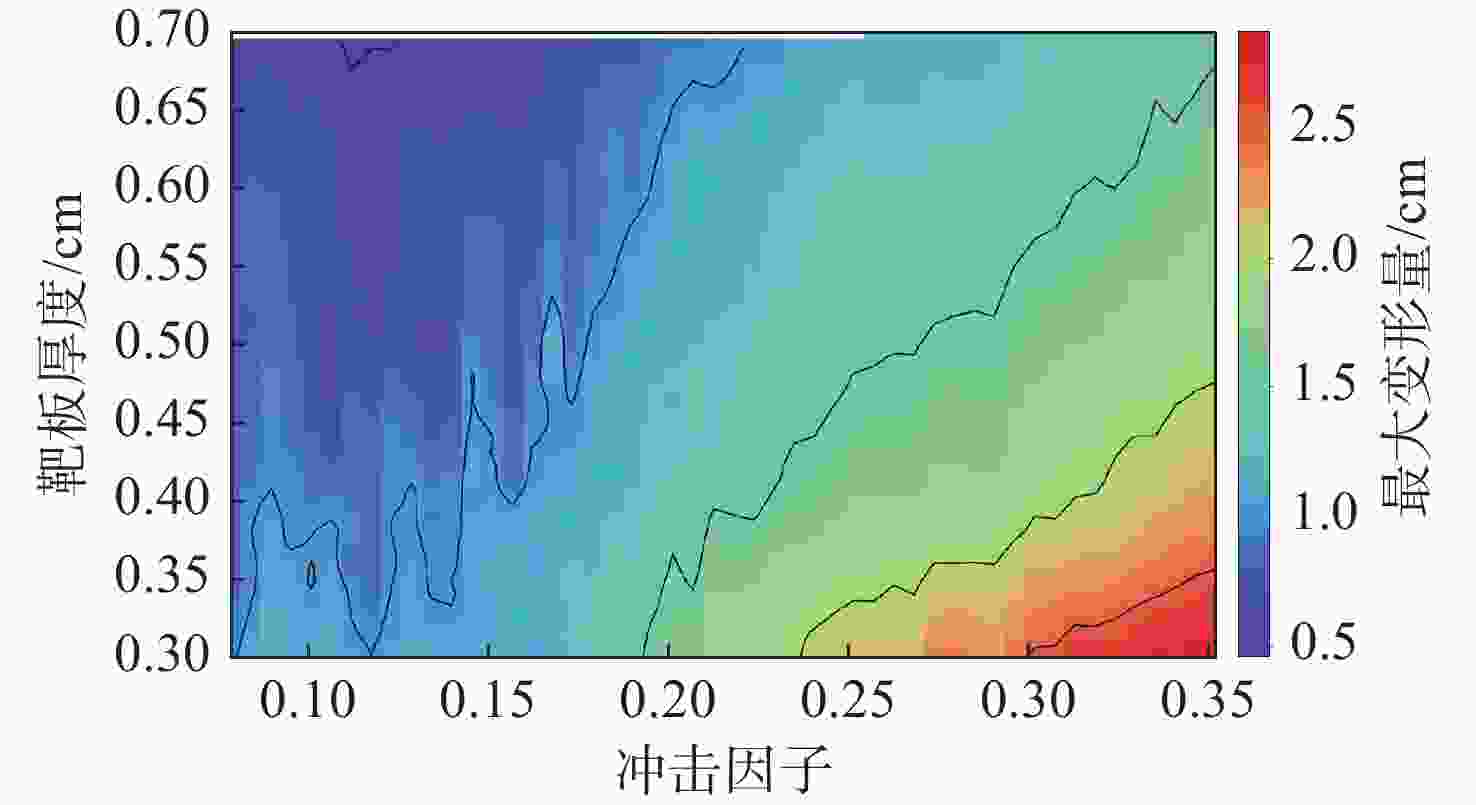

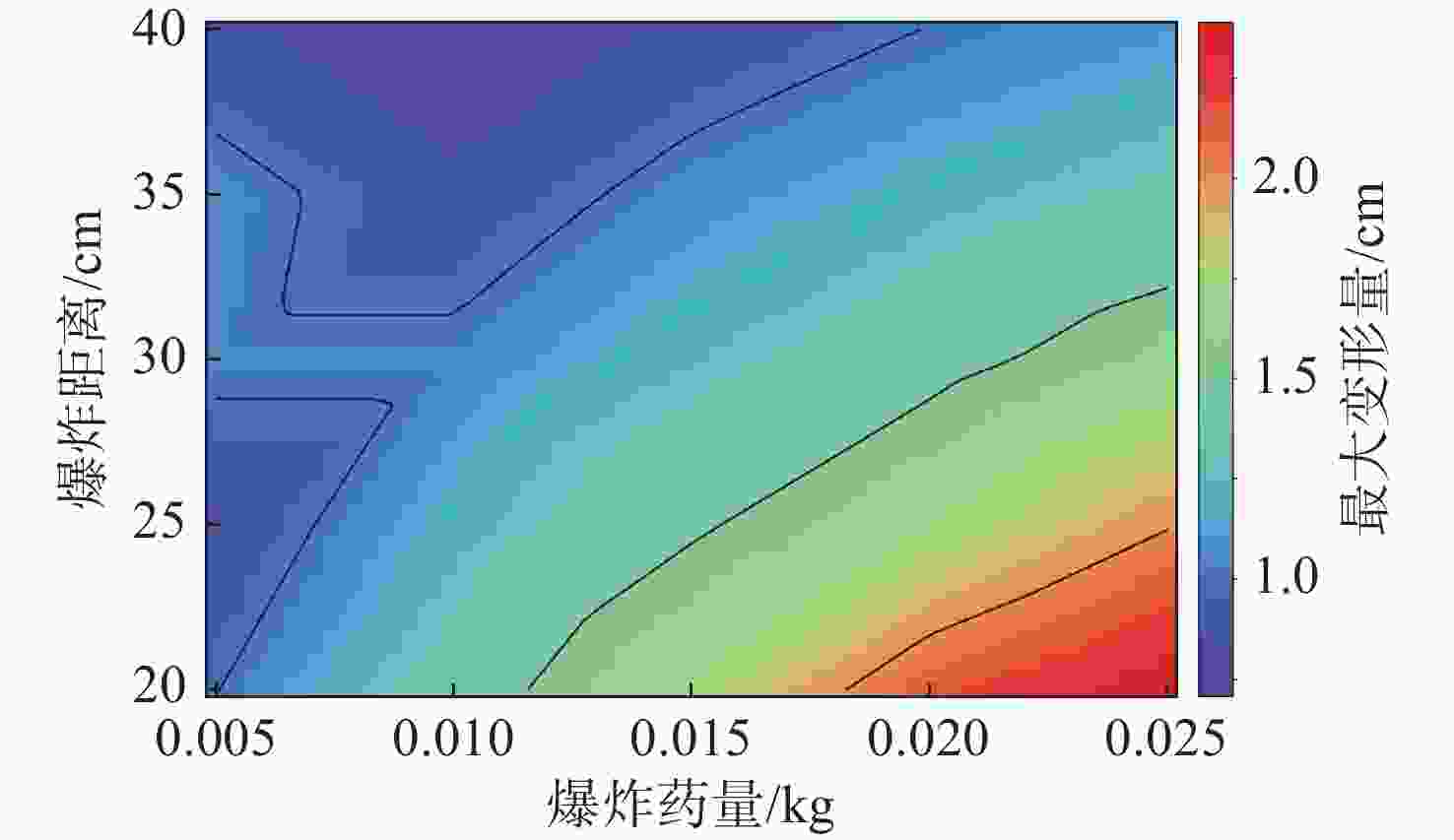

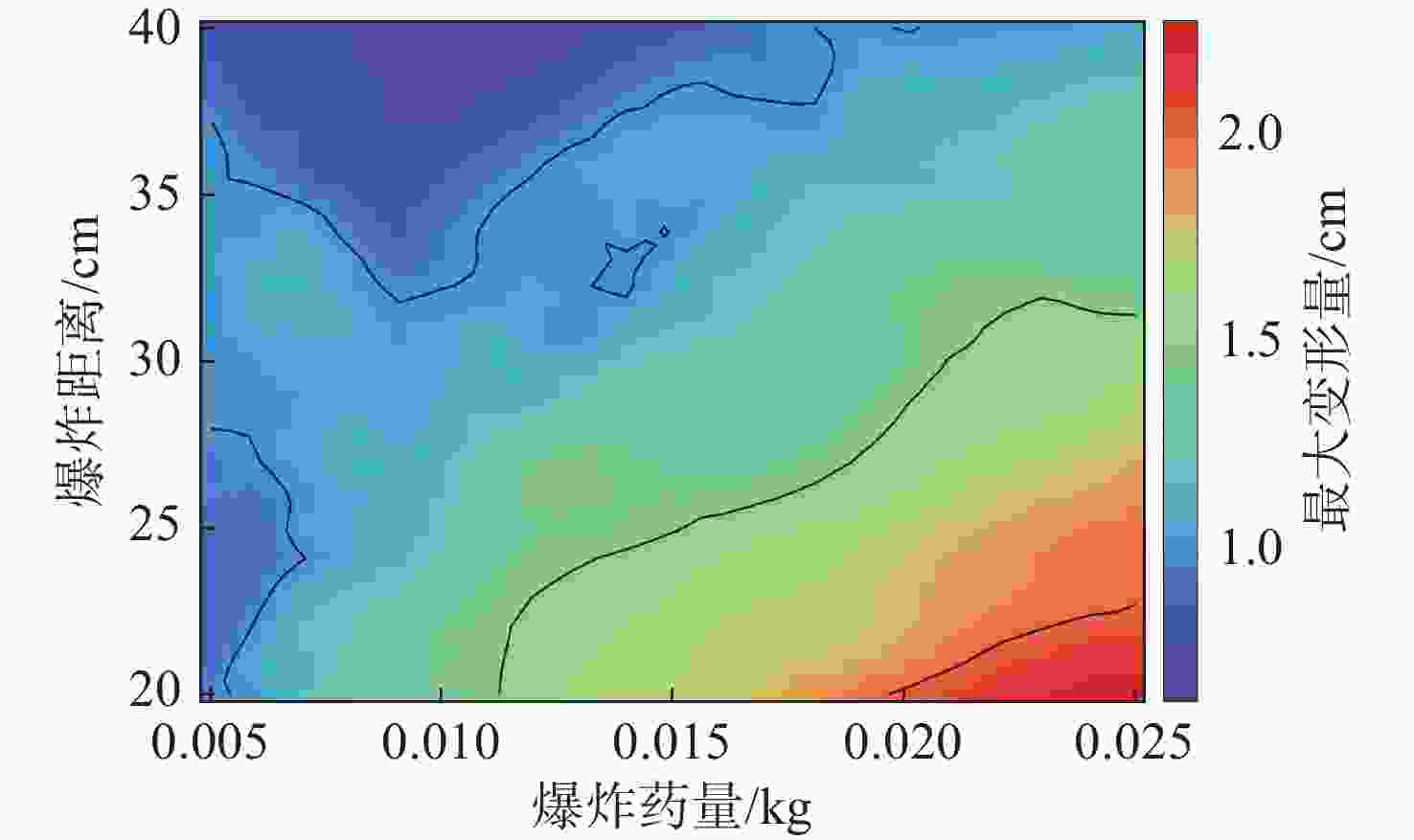

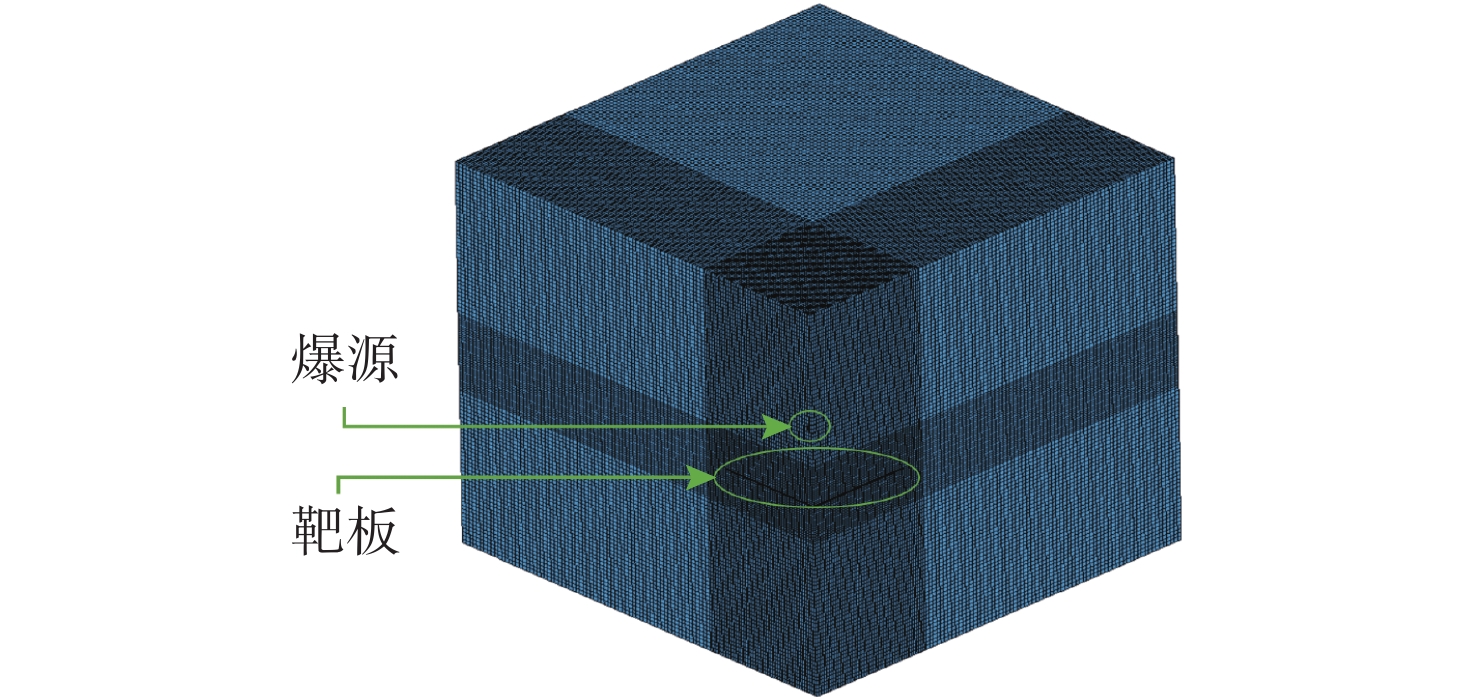

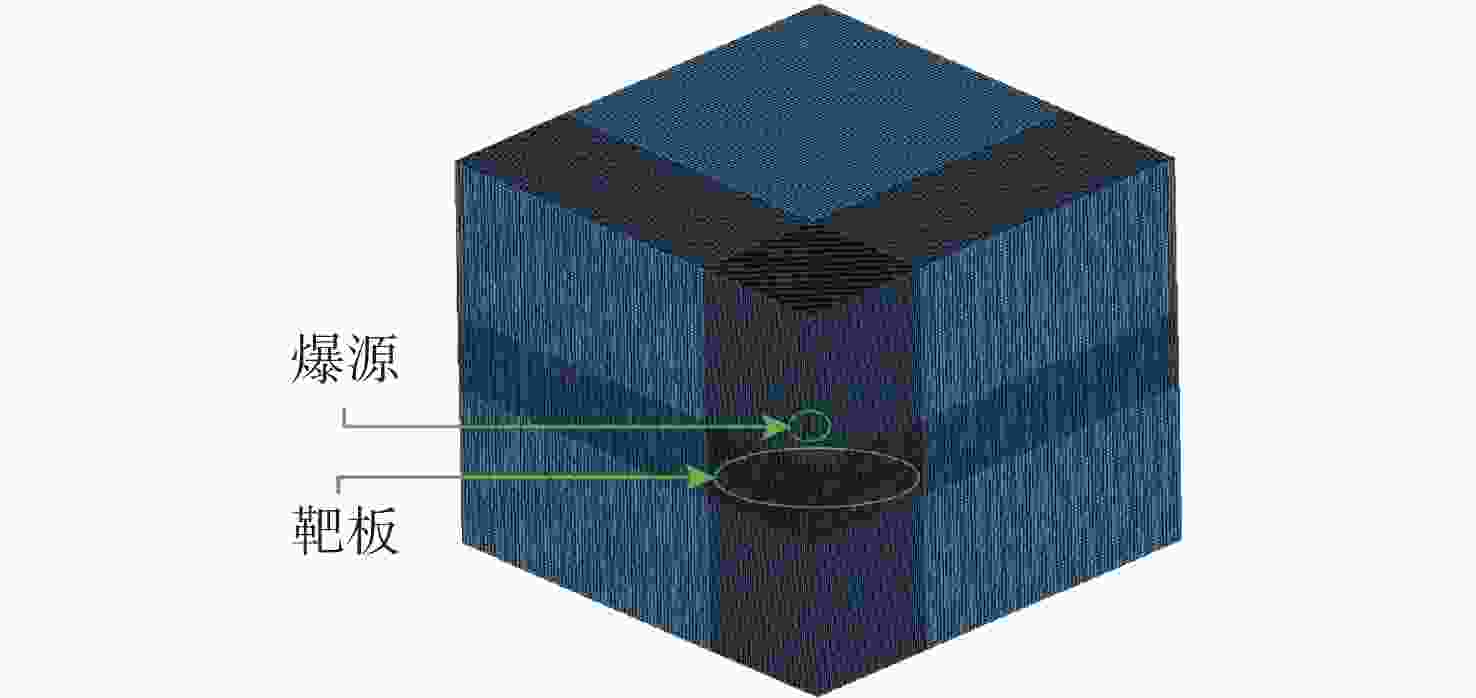

摘要: 水中爆炸靶板变形表现为结构与流体在冲击波作用下的复杂非线性耦合作用。文中通过设计和优化深度学习神经网络以预测输出不同靶板厚度、冲击因子、爆炸药量和爆炸距离条件下的靶板动态变形位移数据, 测试集预测的决定系数和准确率达到0.99和0.95。与25个仿真工况数据相比, 基于预测模型得到的9 261个工况数据形成的爆炸变形响应分析图能够覆盖更细致的特征参数范围和最大变形量变化趋势, 可为水中武器设计及水下防护应用提供重要参考依据。Abstract: The deformation of a target plate in underwater explosion is manifested as a complex nonlinear coupling interaction between the structure and the fluid under the impact of shock waves. In this paper, a deep learning neural network is designed and optimized to predict the dynamic deformation displacement data of the target plate under different conditions of target plate thickness, shock factor, explosive dosage, and explosion distance. The coefficient of determination and accuracy of prediction on the test set reach 0.99 and 0.95, respectively. Compared with 25 simulation conditions, the explosion deformation response analysis graph formed by 9 261 working conditions based on the prediction model can cover a more detailed range of characteristic parameters and the trend of maximum deformation variation, providing important reference for underwater weapon design and underwater protection applications.

-

Key words:

- underwater explosion /

- deep learning /

- neural network /

- deformation response /

- target plate

-

表 1 仿真工况表

Table 1. Simulation working condition table

靶板厚度/cm 爆炸药量/kg 爆炸距离/cm 0.3 0.005 20 0.4 0.010 25 0.5 0.015 30 0.6 0.020 35 0.7 0.025 40 表 2 3种材料模型关键参数

Table 2. Key parameters of three material models

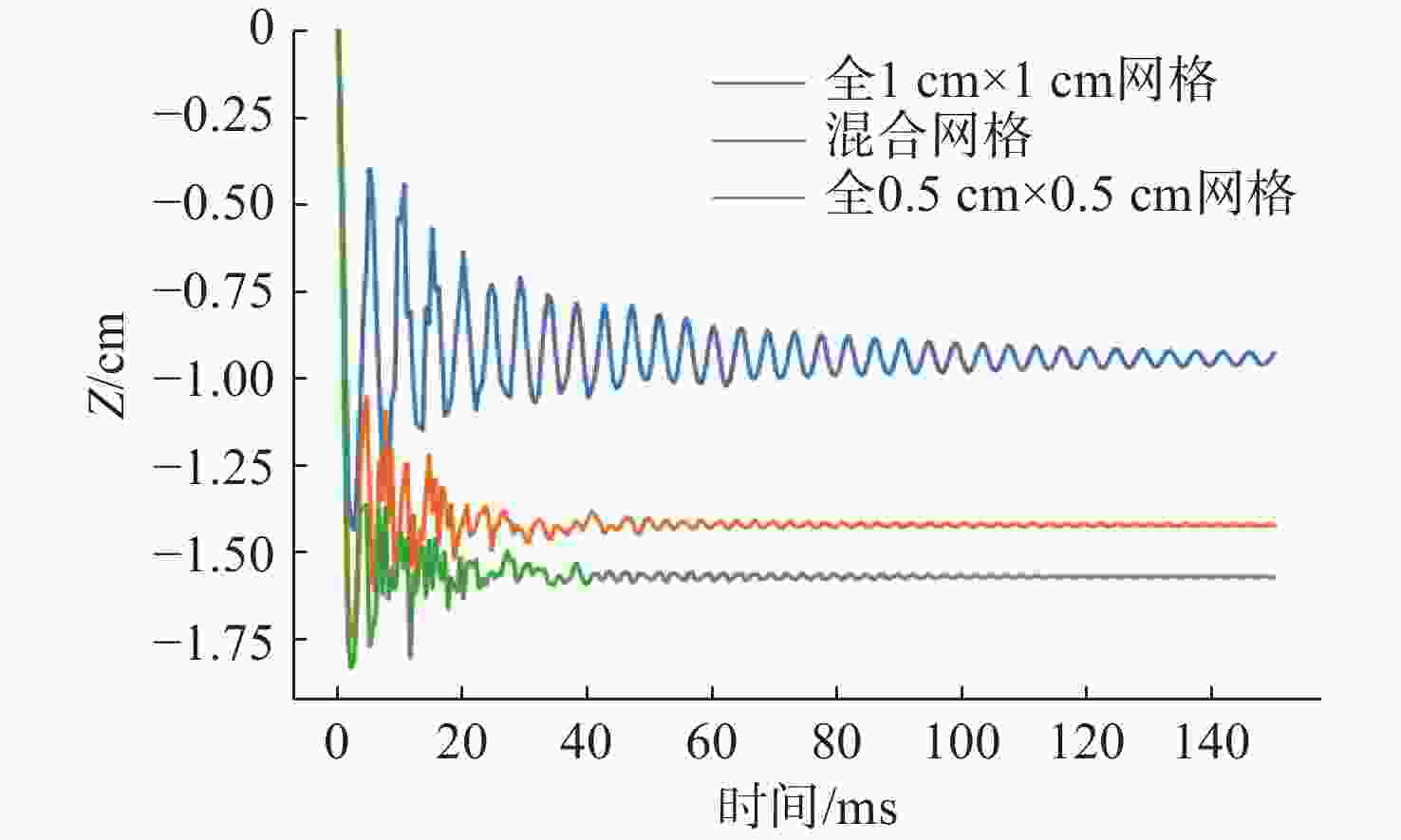

类别 参数 数值 炸药 密度/(g/cm3) 1.420 爆速/(cm/μs) 0.693 爆压/Mbar 0.210 水域 密度/(g/cm3) 1.000 水中声速/(cm/μs) 0.145 钢靶板 密度/(g/cm3) 7.830 弹性模量/GPa 200 泊松比 0.330 屈服应力/MPa 620 切线模量/MPa 196 表 3 不同网格下中心点位移结果对比

Table 3. Comparison of the results of the displacement of the central point under different grids

网格 运行时间/h 位移最

小值/cm最小值

时刻/ms中心点最

终位移/cm全1 cm×1 cm网格 111 −1.435 5 3.000 −0.943 4 混合网格 118 −1.742 7 2.500 −1.422 0 全0.5 cm×0.5 cm网格 227 −1.834 8 2.500 −1.570 9 表 4 125组工况数据集

Table 4. 125 sets of working condition dataset

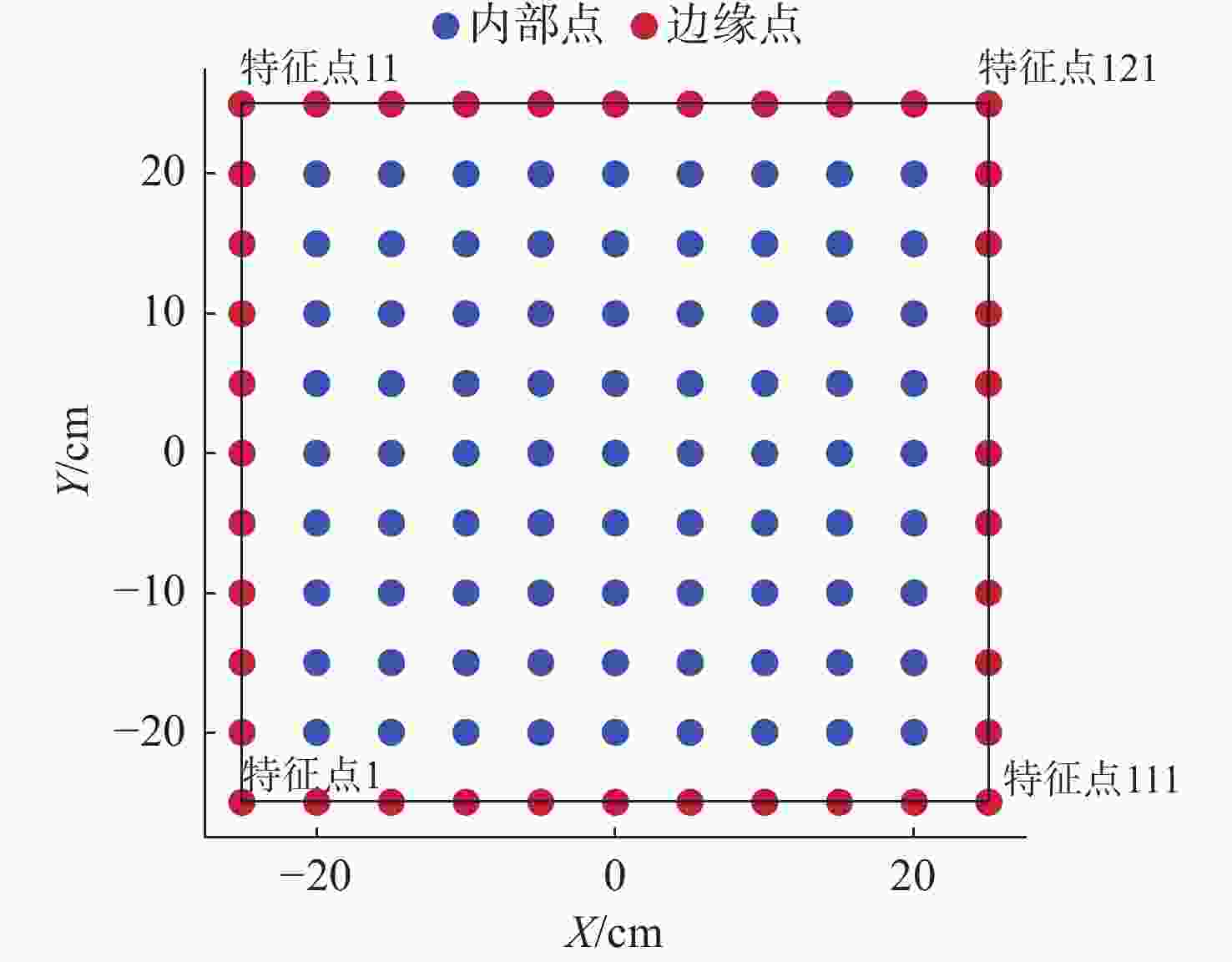

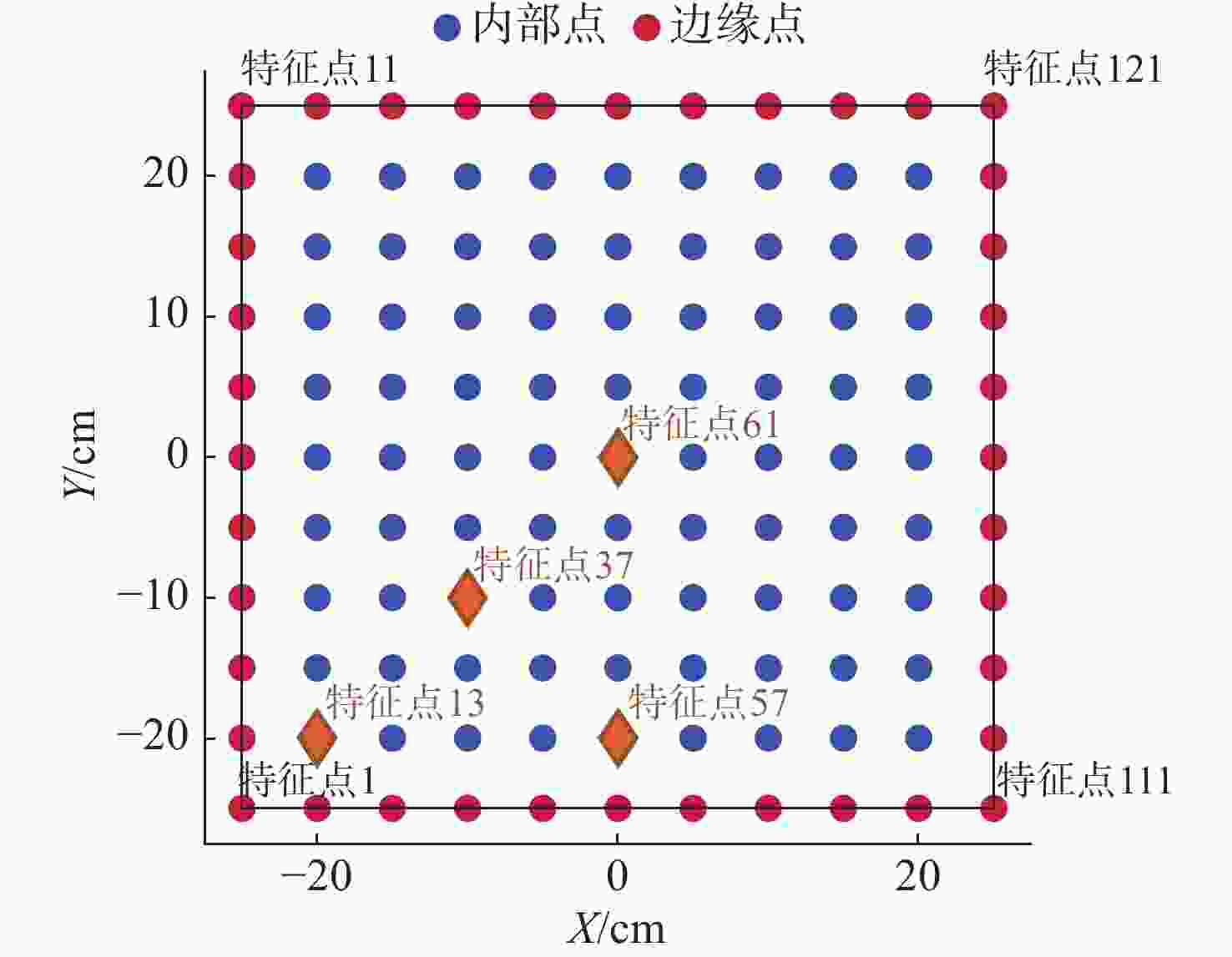

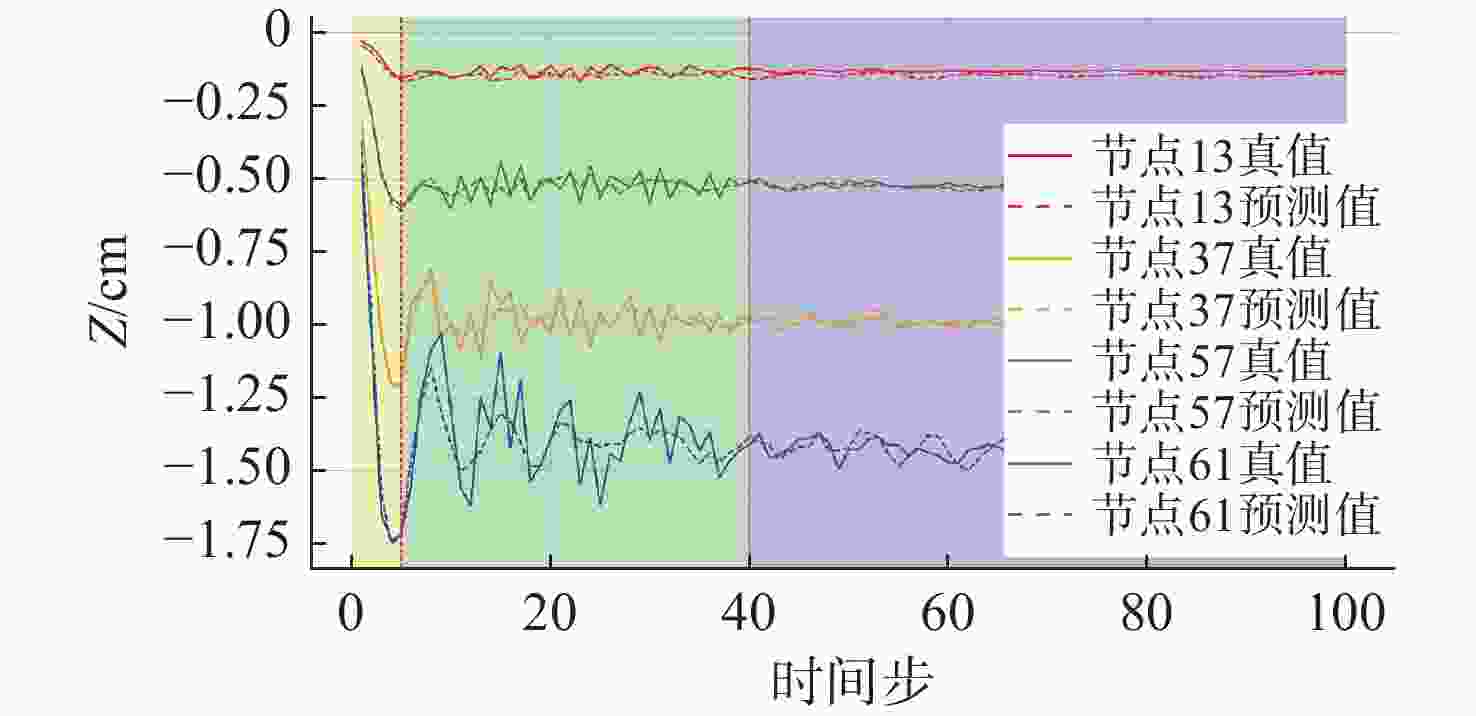

工况 特征点 位移/cm 时间步1 时间步2 时间步3 $\cdots $ 时间步100 1 1~12 0 0 0 0 0 13 −0.019 −0.026 −0.036 $\cdots $ −0.044 14 −0.042 −0.063 −0.094 $\cdots $ −0.108 15 −0.044 −0.089 −0.147 $\cdots $ −0.164 $\cdots $ 61 −0.185 −0.413 −0.808 $\cdots $ −0.569 $\cdots $ 110~121 0 0 0 0 0 2 1~12 0 0 0 0 0 13 −0.018 −0.024 −0.027 $\cdots $ −0.030 14 −0.039 −0.053 −0.073 $\cdots $ −0.065 15 −0.038 −0.075 −0.108 $\cdots $ − 0.0849 $\cdots $ 61 −0.116 −0.298 −0.519 $\cdots $ −0.244 $\cdots $ 110~121 0 0 0 0 0 3~124 $\cdots $ 125 1~12 0 0 0 0 0 13 −0.010 −0.007 −0.005 $\cdots $ −0.005 14 −0.022 −0.039 −0.045 $\cdots $ −0.016 15 −0.038 −0.076 −0.089 $\cdots $ −0.028 $\cdots $ 61 −0.101 −0.471 −0.609 $\cdots $ −0.135 $\cdots $ 110~121 0 0 0 0 0 表 5 4个特征点真值和预测值对比

Table 5. Comparison table of actual and predicted values for four feature points

特征点编号 类别 位移最小值/cm 最小值时刻/ms 13 真值 −0.164 7 12.0 预测值 −0.165 4 9.5 37 真值 −1.216 5 3.0 预测值 −1.204 3 3.0 57 真值 −0.601 7 5.5 预测值 −0.640 9 3.0 61 真值 −1.738 1 2.5 预测值 −1.781 0 2.5 -

[1] 杨允锴, 武双章, 高振儒, 等. 装药参数影响钢筋混凝土柱毁伤效应的试验与数值仿真研究[J]. 爆破, 2023, 40(3): 143-150.YANG Y K, WU S Z, GAO Z R, et al. Experimental and numerical analysis on influence of charge parameters on damage effect of RC column[J]. Blasting, 2023, 40(3): 143-150. [2] 何保福, 沈亚鹏. 板壳理论[M]. 1版. 西安: 西安交通大学出版社, 1993. [3] BEITER K A. The effect of stiffener smearing in a ship-like box structure subjected to an underwater explosion[D]. Monterey, CA: Naval Postgraduate School, 1998. [4] TRAN P, WU C, SALEH M, et al. Composite structures subjected to underwater explosive loadings: A comprehensive review[J]. Composite Structures, 2021, 263(2): 113684. [5] 王琰, 蒋海燕, 韩璐, 等. 爆炸冲击波作用下板架结构响应研究综述[J]. 兵器装备工程学报, 2024, 45(3): 151-160.WANG Y, JIANG H Y, HAN L, et al. A review of structural response of plate frame under explosive shock wave[J]. Journal of Ordnance Equipment Engineering, 2024, 45(3): 151-160. [6] 孙远翔, 刘新, 陈岩武, 等. 水下爆炸气泡射流载荷及对结构毁伤研究进展[J]. 舰船科学技术, 2024, 46(1): 1-7.SUN Y X, LIU X, CHEN Y W, et al. Research progress of underwater explosion bubble jet and its damage to structures[J]. Ship Science and Technology, 2024, 46(1): 1-7. [7] 李旭辉, 郭晓辉, 程帅, 等. 基于深度神经网络的鱼雷命中概率预测方法[J]. 水下无人系统学报, 2023, 31(5): 783-788.LI X H, GUO X H, CHENG S, et al. Torpedo hit probability prediction method based on deep neural network[J]. Journal of Unmanned Undersea Systems, 2023, 31(5): 783-788. [8] 刘文成, 李朋波, 任少飞, 等. 瞬态外压载荷时间特性对网格加筋圆柱壳动力屈曲影响[J]. 舰船科学技术, 2018, 40(19): 18-23. doi: 10.3404/j.issn.1672-7649.2018.10.004LIU W C, LI P B, REN S F, et al. Effects of transient pressure time characteristics on dynamic buckling of grid stiffened cylindrical shells[J]. Ship Science and Technology, 2018, 40(19): 18-23. doi: 10.3404/j.issn.1672-7649.2018.10.004 [9] COLLINS M. Discriminative training methods for hidden Markov models: Theory and experiments with perceptron algorithms[J]. Theoretical Computerence, 2002, 410(21-23): 2279-2284. [10] BRUNTON S L, NOACK B R, KOUMOUTSAKOS P. Machine learning for fluid mechanics[J]. Annual Review of Fluid Mechanics, 2020, 52(1): 477-508. doi: 10.1146/annurev-fluid-010719-060214 [11] 张树霞, 赵捍东, 韩志高. 基于 PSO-SVM 的侵彻效果预测方法[J]. 中北大学学报(自然科学版), 2015(2): 166-170, 175.ZHANG S X, ZHAO H D, HAN Z G. Method of penetrate result prediction based on PSO-SVM[J]. Journal of North University of China(Natural Science Edition), 2015(2): 166-170, 175. [12] MASOUD B, KEYVAN S. Incremental explosive analysis and its application to performance-based assessment of stiffened and unstiffened cylindrical shells subjected to underwater explosion[J]. Shock and Vibration, 2017, 2017: 1-17. [13] 王烁, 石全. 基于人工神经网络的侵彻毁伤模式识别[J]. 兵器装备工程学报, 2017, 38(10): 60-64.WANG S, SHI Q. Penetration pattern recognition based on artificial neural network[J]. Journal of Ordnance Equipment Engineering, 2017, 38(10): 60-64. [14] ABDULKADIR K, HASBI Y, OSMAN O, et al. Estimating the properties of ground-waste-brick mortars using DNN and ANN[J]. Computer Modeling in Engineering & Sciences, 2019, 118(1): 207-228 [15] TAEKYUNG L, BYUNG J K, JINYEONG Y, et al. Deep-learning approach to predict a severe plastic anisotropy of caliber-rolled Mg alloy[J]. Materials Letters, 2020, 269: 1-3. [16] 张爱然, 罗新荣, 杨飞, 等. 基于模糊神经网络的瓦斯爆炸危险性评价模型[J]. 黑龙江科技学院学报, 2008, 18(1): 54-57. [17] 陈聪, 候磊, 李乐乐, 等. 基于GRU改进RNN神经网络的飞机燃油流量预测[J]. 科学技术与工程, 2021, 21(27): 11663-11673.CHEN C, HOU L, LI L L, et al. Prediction of aircraft fuel flow based on recurrent neural network[J]. Science Technology and Engineering, 2021, 21(27): 11663-11673. [18] 王树山, 张静骁, 王传昊, 等. 水中爆炸冲击波对靶体结构的毁伤准则研究[J]. 火炸药学报, 2020, 43(3): 262-270.WANG S S, ZHANG J X, WANG C H, et al. Damage criterion of underwater explosion shock wave on target[J]. Chinese Journal of Explosives & Propellants, 2020, 43(3): 262-270. -

下载:

下载: