Mechanism Design and Simulation Analysis of Hybrid Serial-Parallel Underwater Dredging Manipulator

-

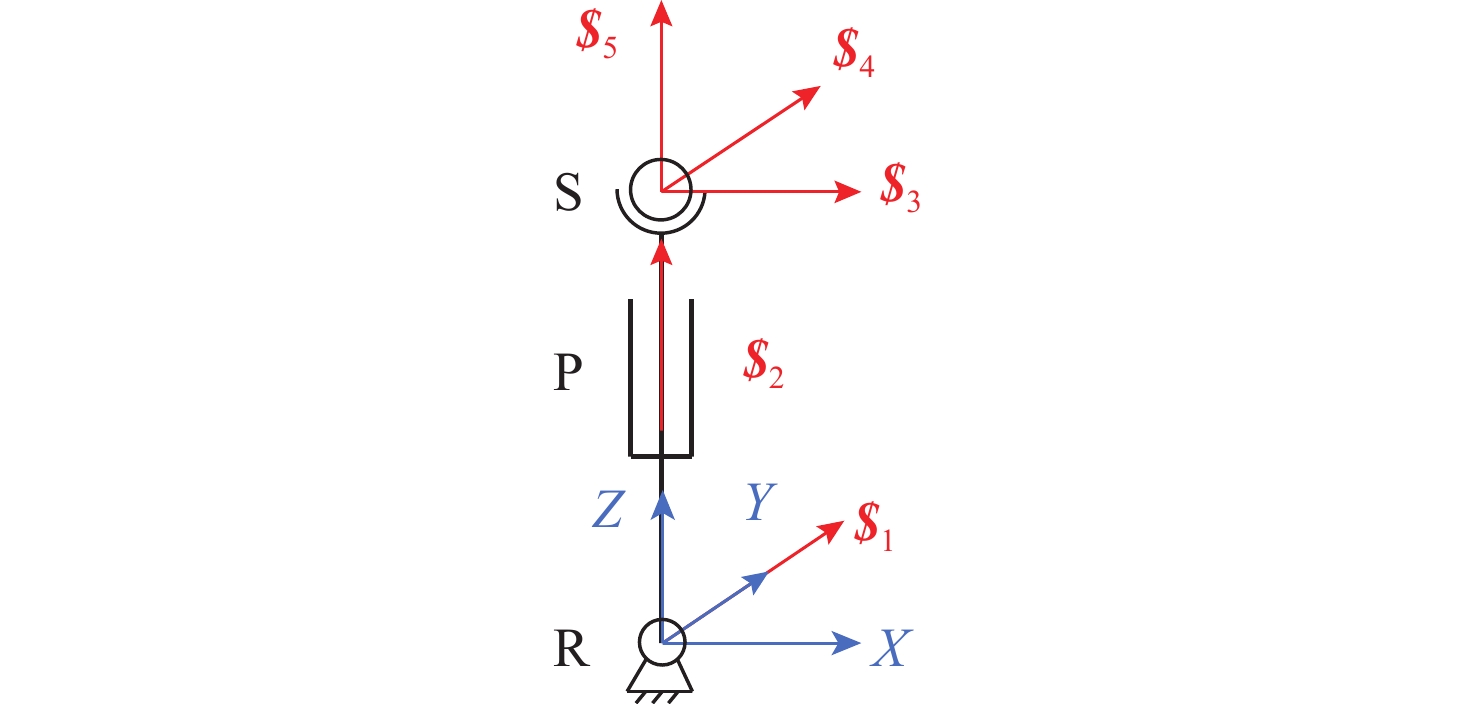

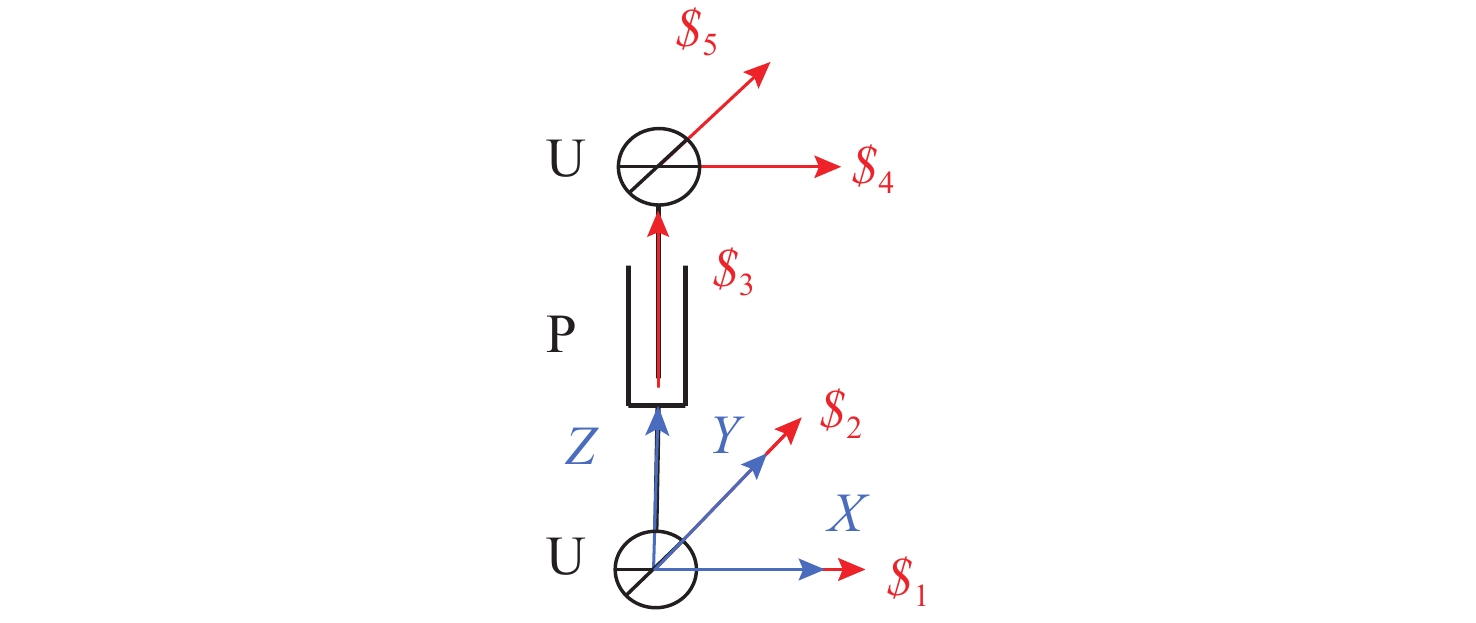

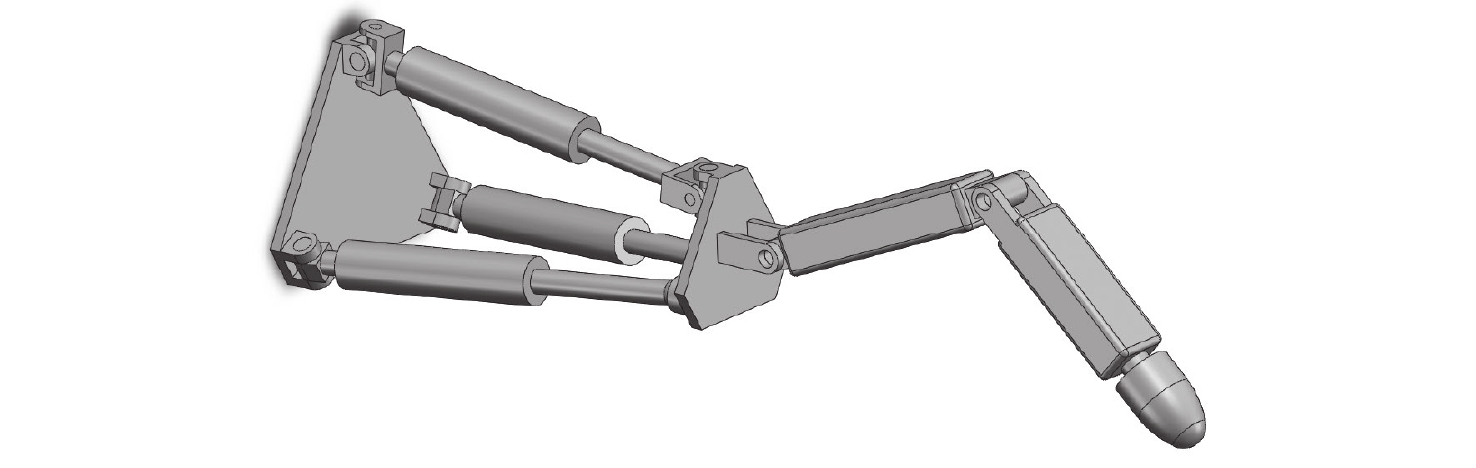

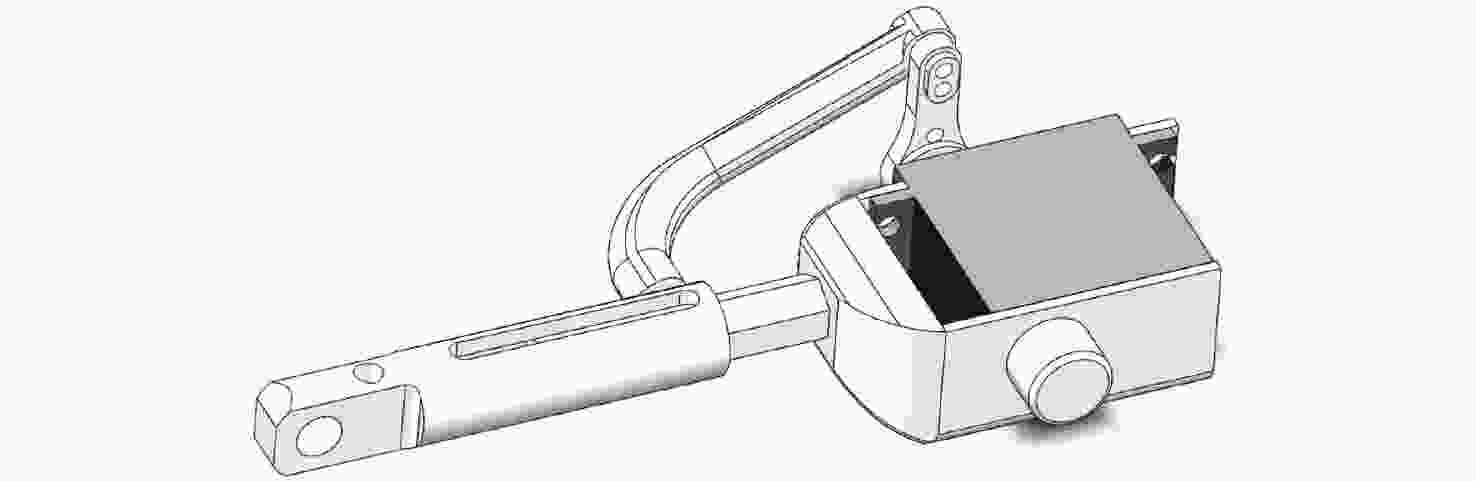

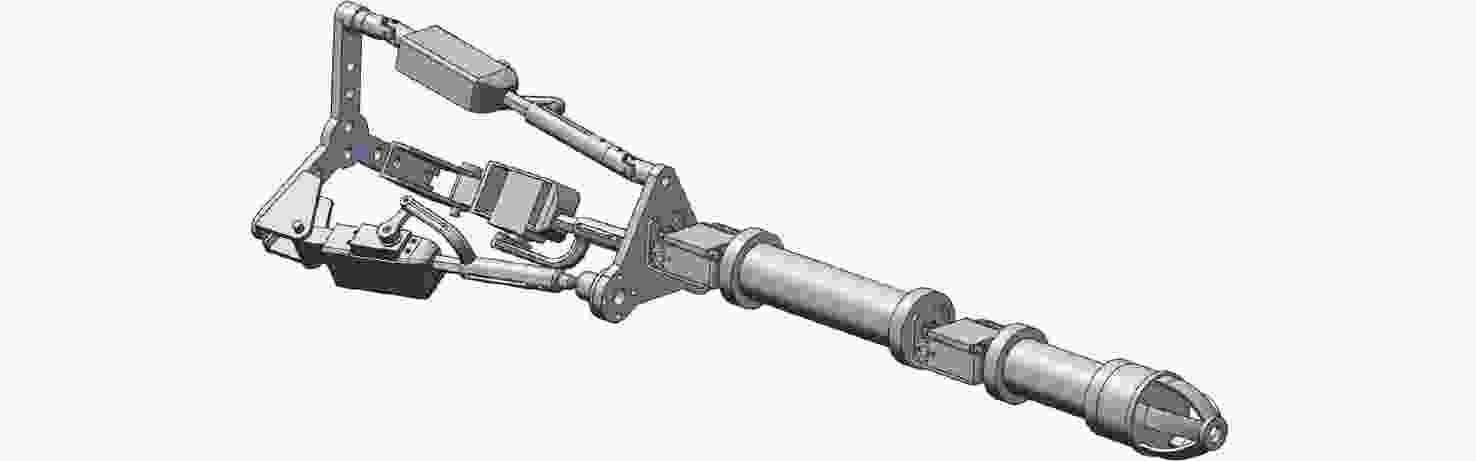

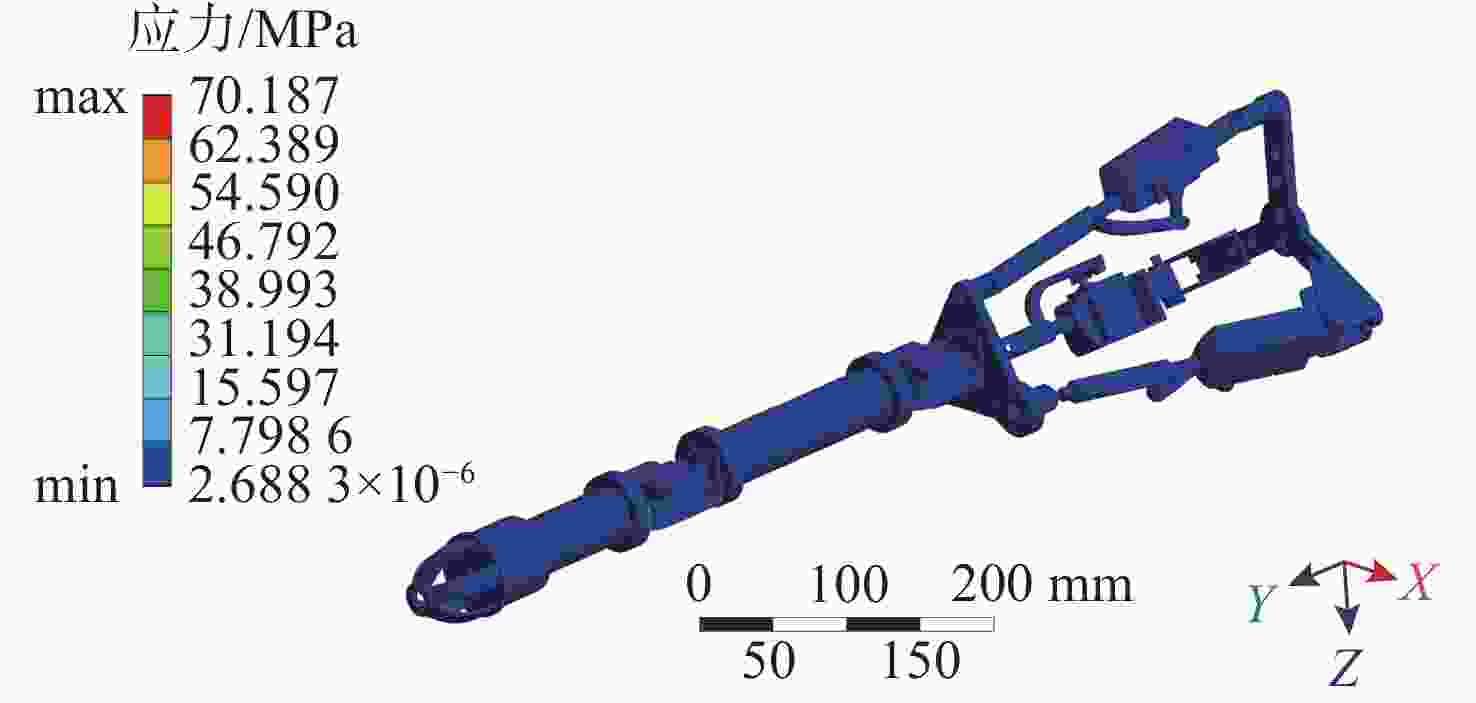

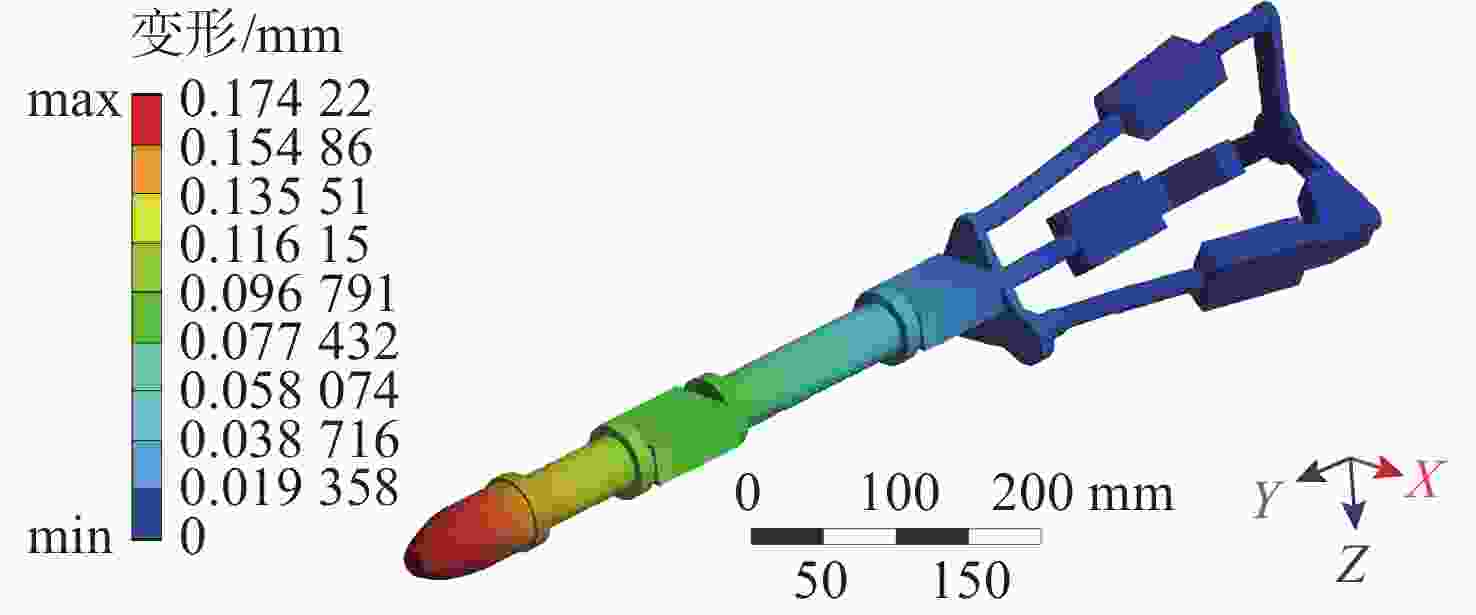

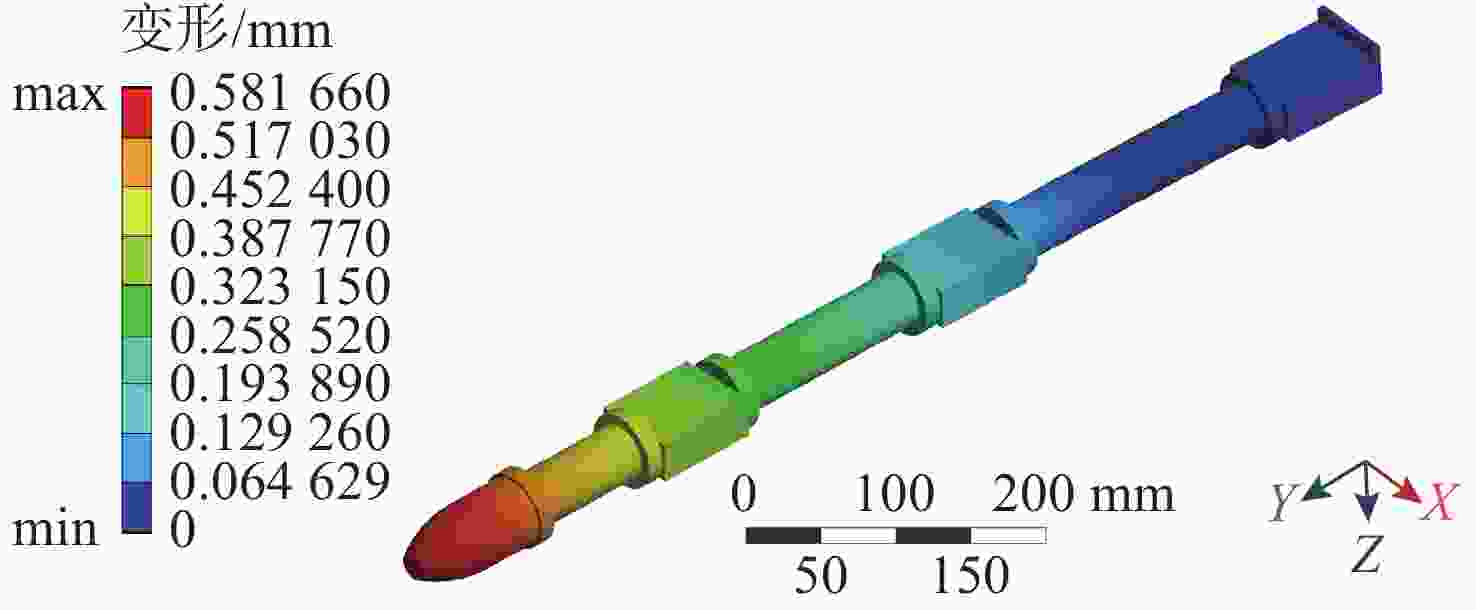

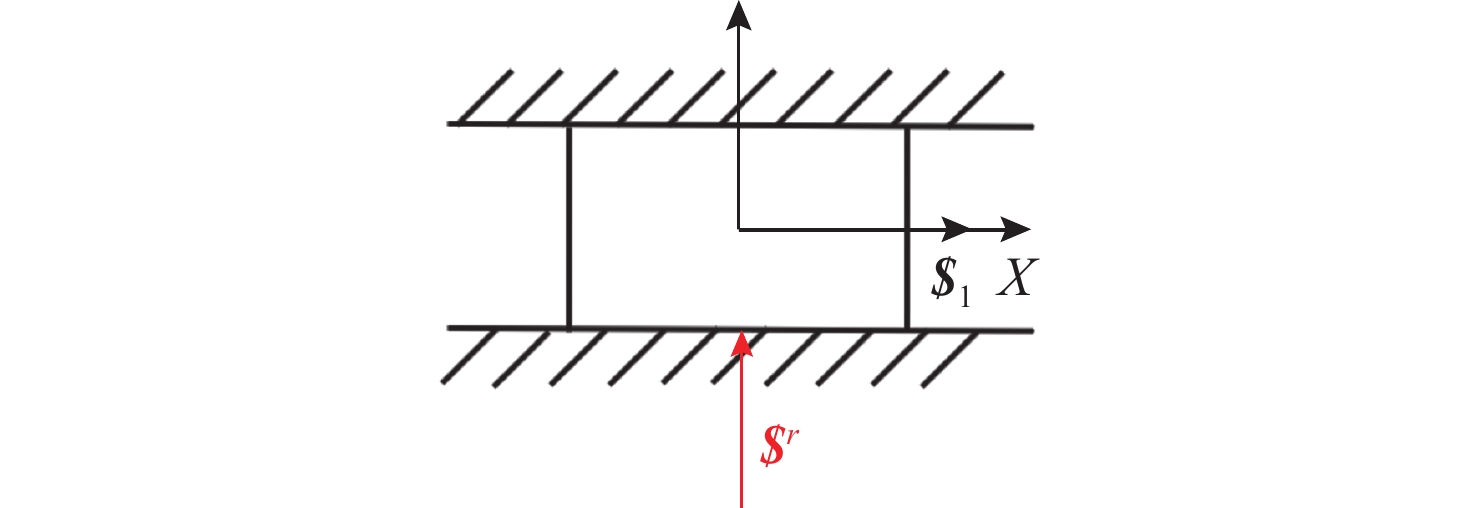

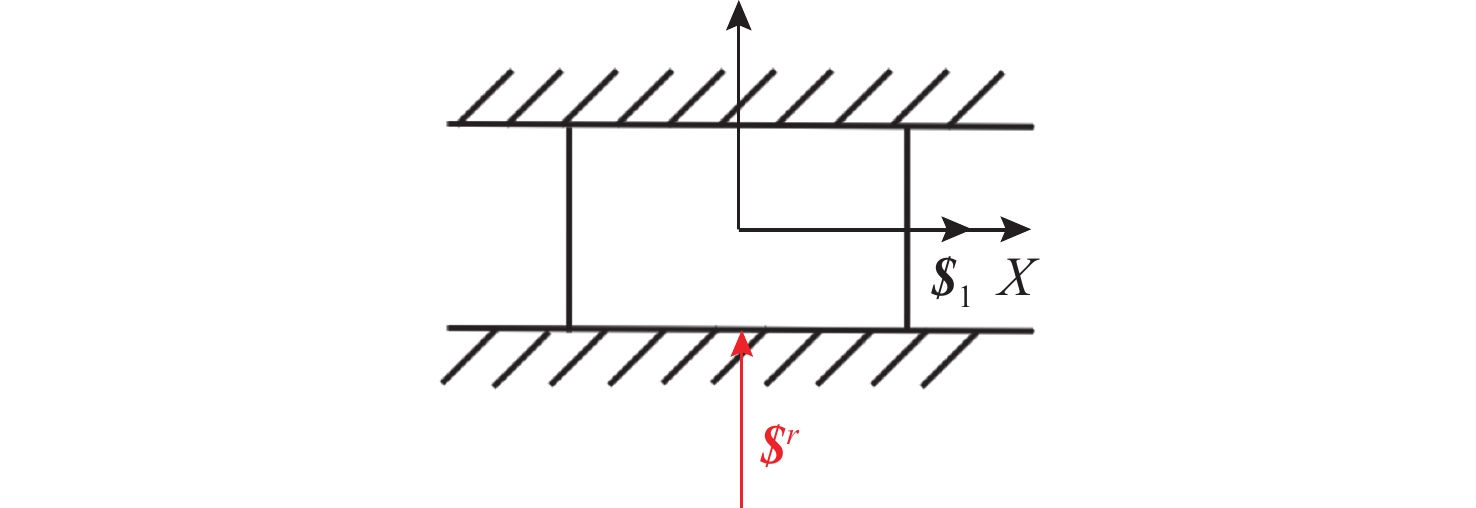

摘要: 近年来, 采用水下机器人清理水库底部淤泥逐渐成为一种全新的水下清淤解决方案, 水下机械臂则是其实现清淤作业的主要工具。针对清淤过程中串联机械臂结构刚度低、可靠性差等问题, 文中结合串联机械臂和并联机械臂设计了一款水下串并混联机械臂。首先通过螺旋理论设计了混联机构并完成了机械臂结构设计, 然后通过有限元仿真软件进行强度校核和静刚度分析, 结果表明串并混联机械臂与串联机械臂相比具有更高的结构刚度。该研究结果可对进一步改进和优化水下机械臂的设计提供理论与技术支撑。Abstract: In recent years, underwater robots have emerged as a novel solution for the removal of sediments at the bottom of reservoirs, with underwater manipulators being the primary tool for dredging operations. To address issues faced by serial manipulators, such as low structural stiffness and poor reliability, a hybrid serial-parallel underwater manipulator was designed, integrating serial and parallel manipulator mechanisms. By using screw theory, a hybrid mechanism and the manipulator structure were designed. A finite element analysis(FEA) software was then used for strength verification and static stiffness simulation analysis. The results indicate that the hybrid serialiparallel manipulator has higher structural stiffness than serial manipulators. The result can provide theoretical and technical support for optimizing underwater manipulator design.

-

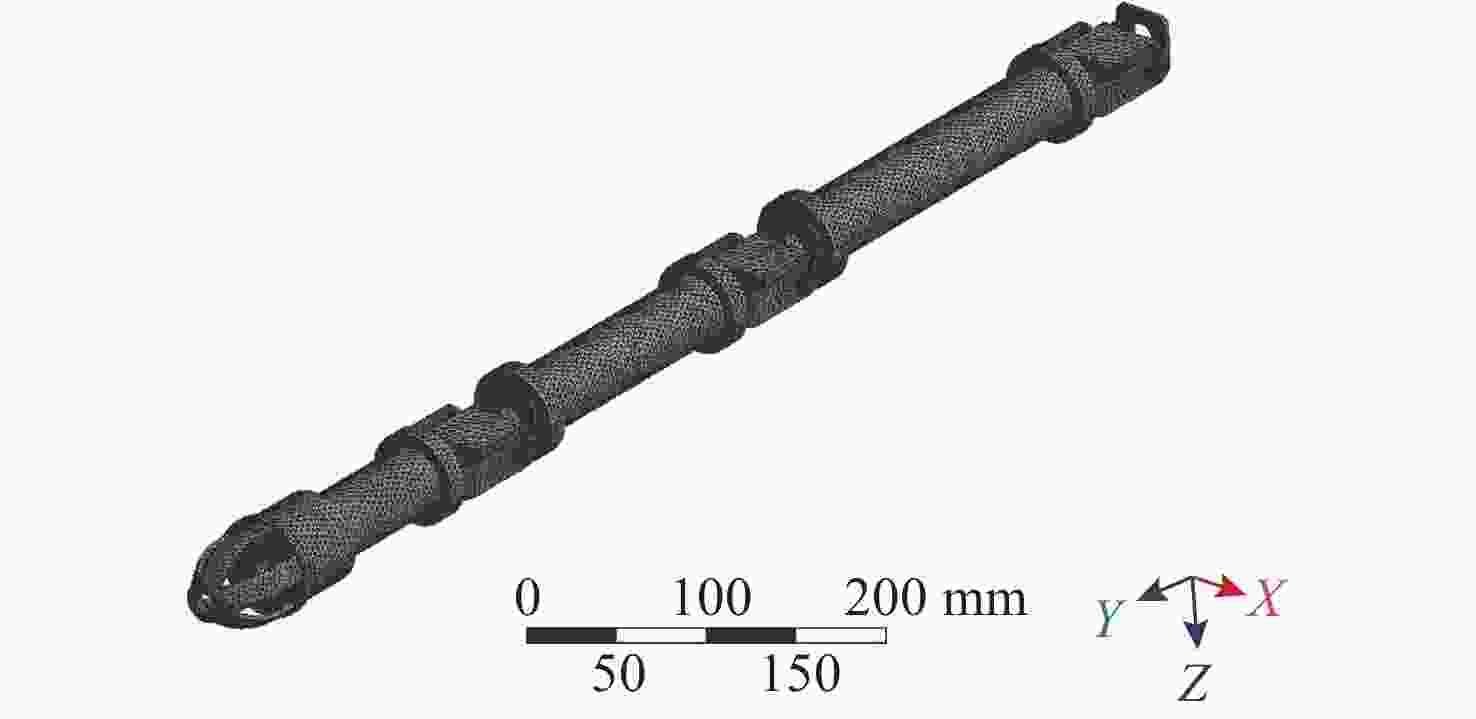

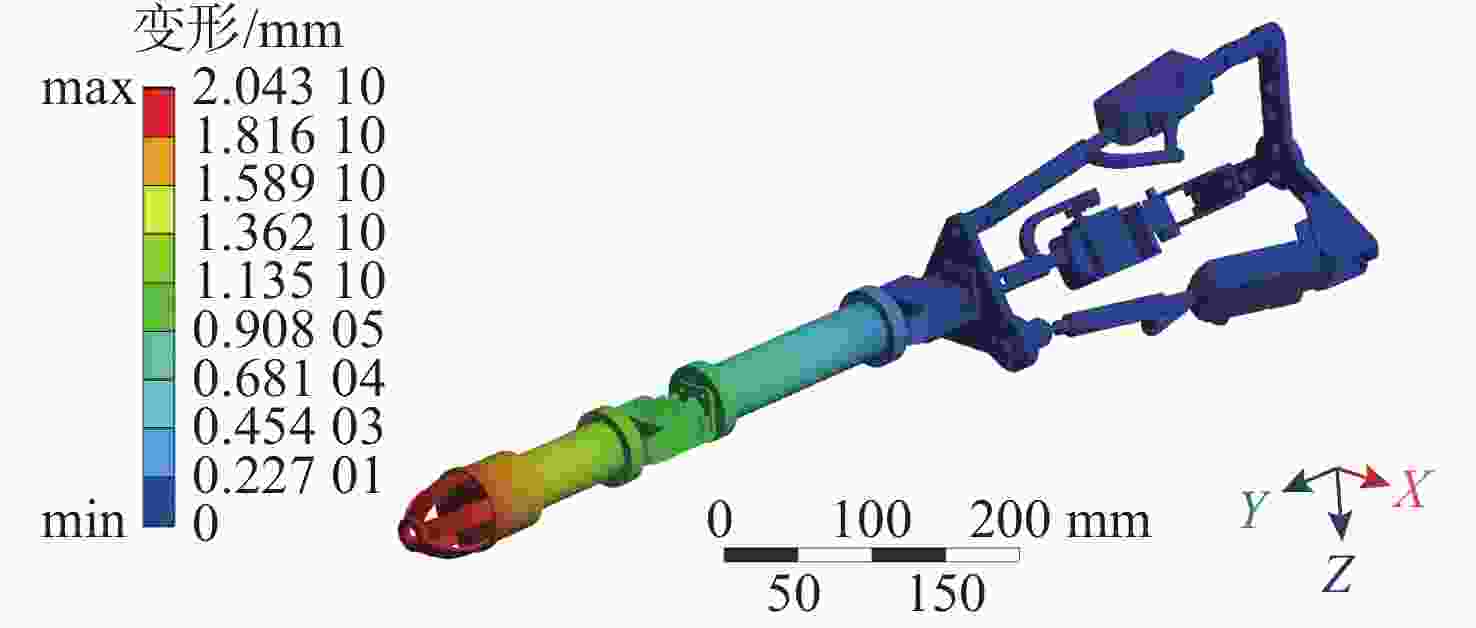

表 1 串并混联机械臂网格无关性检验结果

Table 1. Grid independence test results of serial-parallel hybrid manipulator

网格大小/mm 网格数量 末端变形量/mm 误差/% 10.0 148 672 1.986 9 — 5.0 166 842 2.510 0 26.33 4.0 221 433 2.368 5 13.74 3.5 260 236 2.043 1 5.64 3.0 320 094 1.960 1 4.06 表 2 水下混联机械臂末端变形量

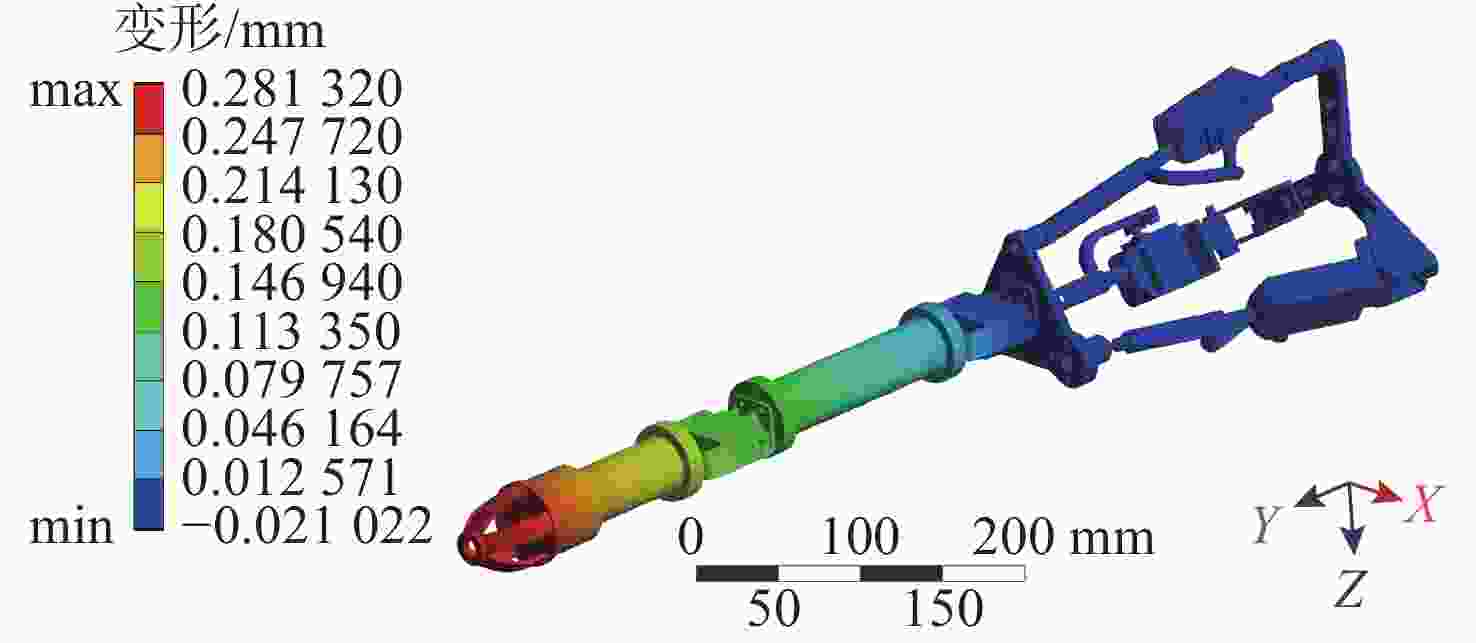

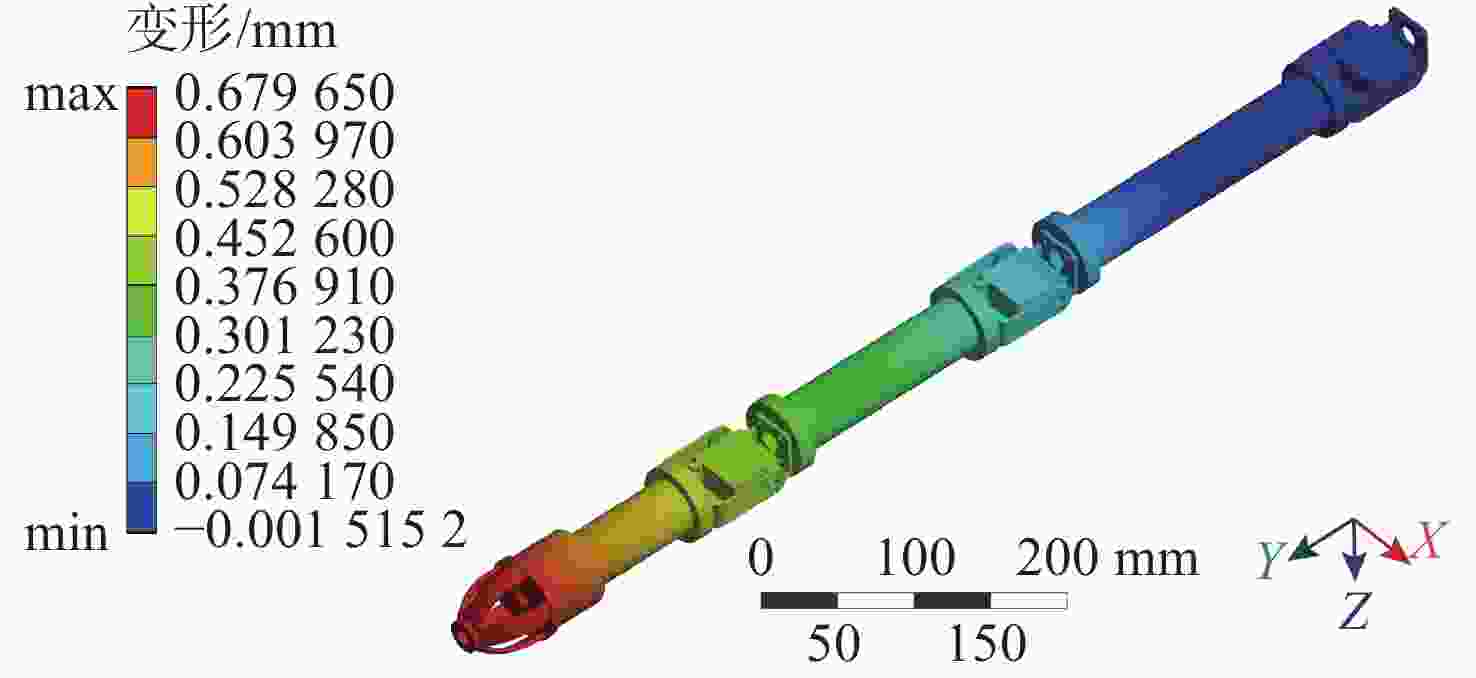

Table 2. Deformation of the end effector of underwater hybrid manipulator

载荷方向 变形量/mm X 方向 Y 方向 Z 方向 X 轴 3.68×10−1 1.66×10−2 6.97×10−3 Y 轴 1.27×10−3 3.07×10−3 7.24×10−3 Z 轴 7.02×10−3 3.29×10−2 4.09×10−1 表 3 水下混联机械臂末端偏转角

Table 3. Deflection angle of the end effector of underwater hybrid manipulator

载荷方向 偏转角/rad X 方向 Y 方向 Z 方向 X 轴 8.41×10−6 2.49×10−4 3.39×10−4 Y 轴 3.41×10−4 3.54×10−4 2.65×10−4 Z 轴 4.93×10−4 2.51×10−4 8.47×10−6 表 4 串联机械臂网格无关性检验结果

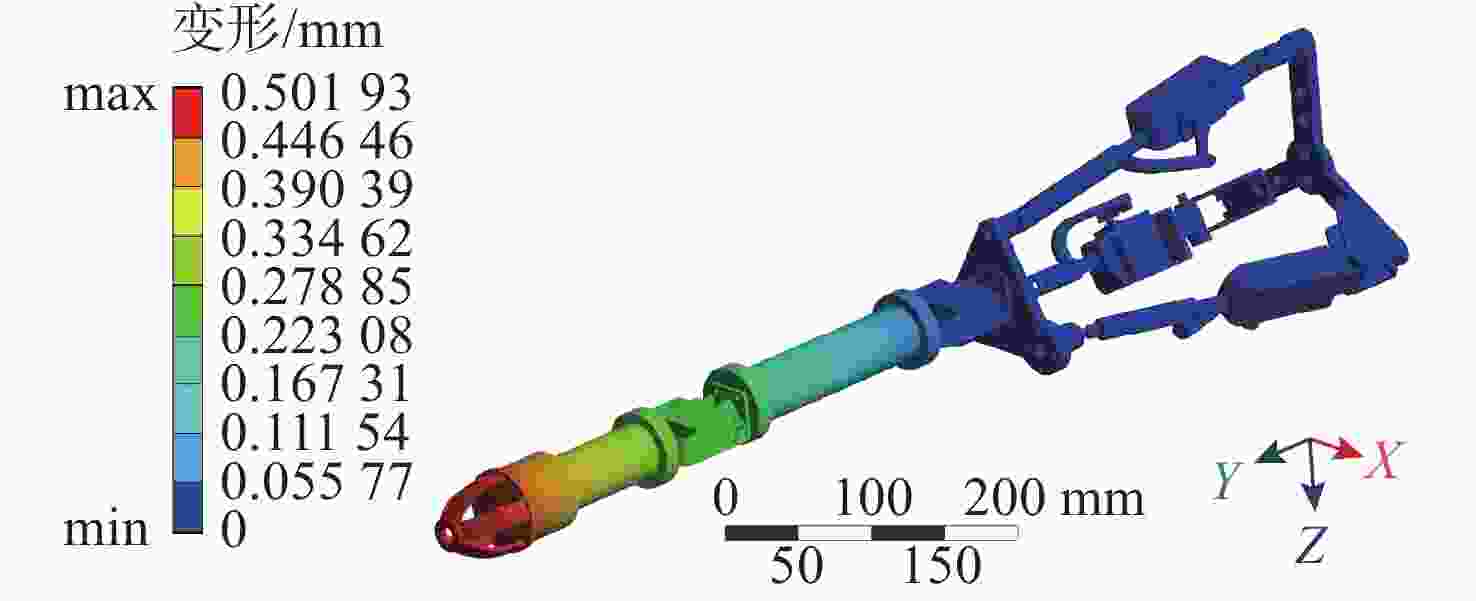

Table 4. Grid independence test results of serial manipulator

网格大小/mm 网格数量 末端变形量/mm 误差/% 10.0 104 327 0.597 6 — 5.0 118 715 0.796 5 24.97 4.0 166 938 0.705 3 11.45 3.5 189 026 0.593 6 15.84 3.0 215 757 0.585 8 1.31 表 5 水下串联机械臂末端变形量

Table 5. Deformation of the end effector of underwater serial manipulator

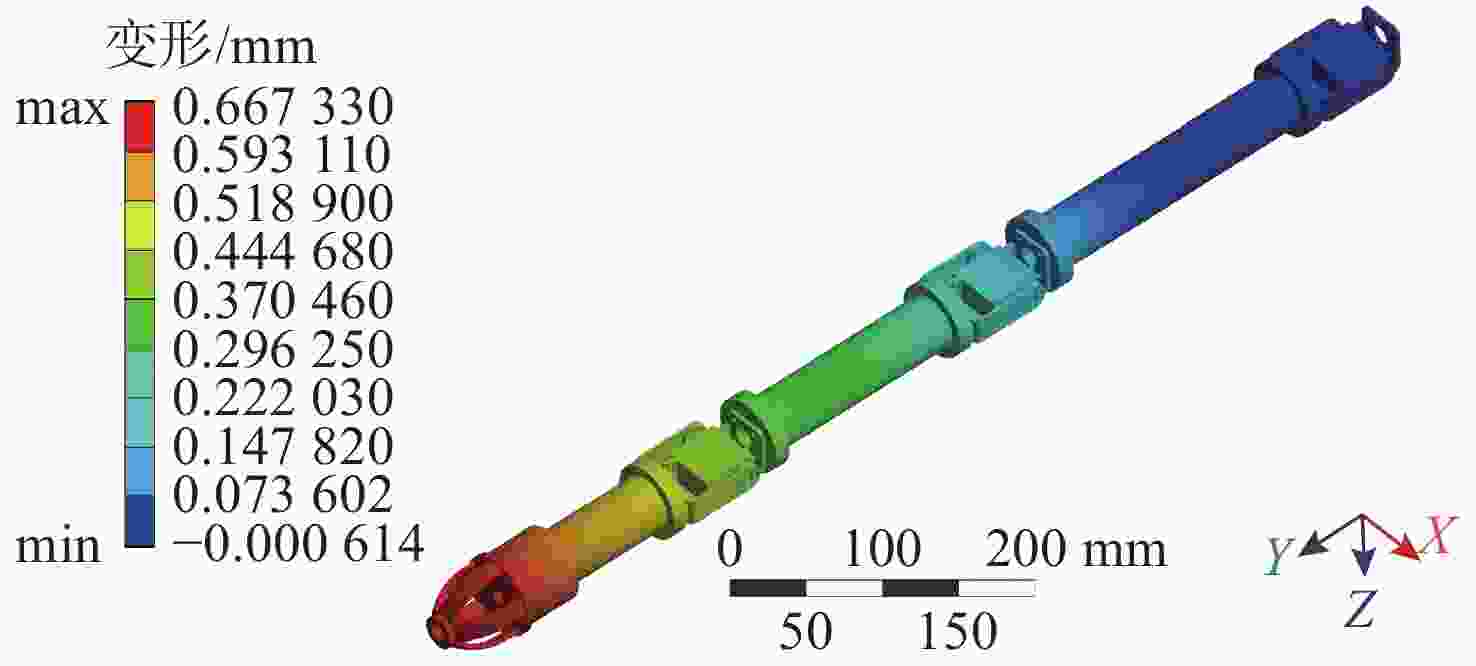

载荷方向 变形量/mm X 方向 Y 方向 Z 方向 X 轴 6.67×10−1 3.13×10−2 1.95×10−3 Y 轴 2.28×10−4 3.49×10−3 8.15×10−3 Z 轴 2.27×10−3 4.29×10−2 6.64×10−1 表 6 水下串联机械臂末端偏转角

Table 6. Deflection angle of the end effector of underwater serial manipulator

载荷方向 偏转角/rad X 方向 Y 方向 Z 方向 X 轴 2.35×10−6 6.96×10−5 8.04×10−4 Y 轴 4.03×10−4 2.11×10−4 5.91×10−4 Z 轴 8.01×10−4 8.11×10−5 2.73×10−6 表 7 串并混联机械臂外流场网格无关性检验结果

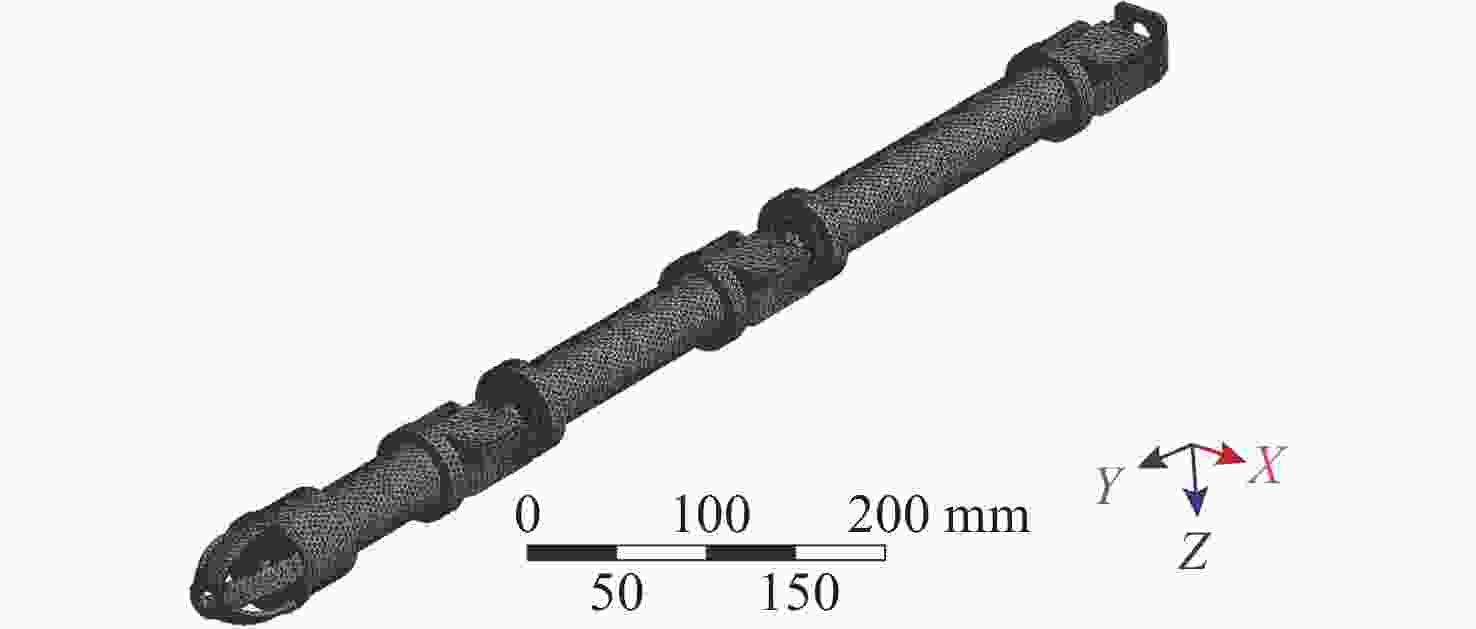

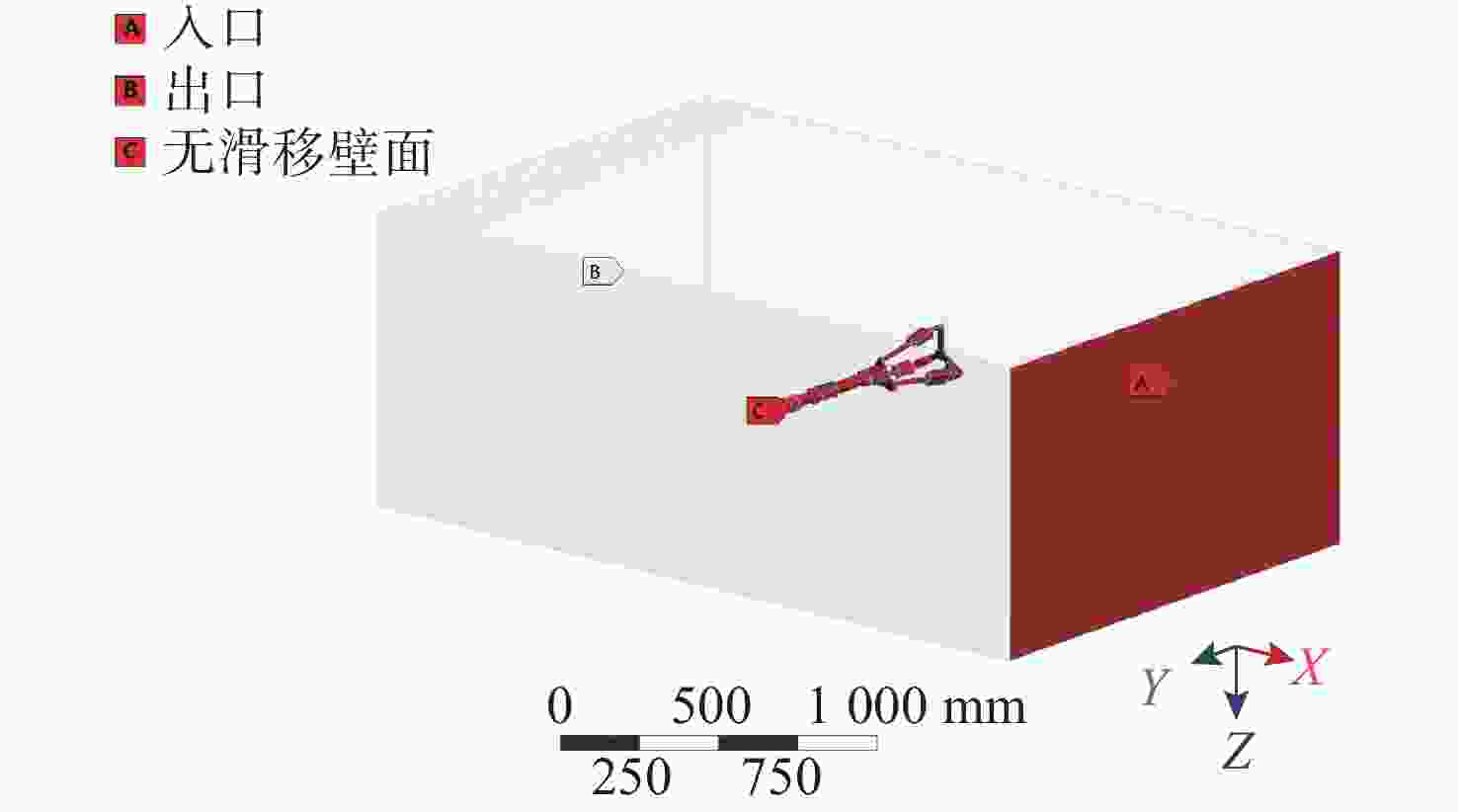

Table 7. Grid independence test results of the external flow field of serial-parallel hybrid manipulator

编号 网格数量 水阻力/N 误差/% 1 1 013 415 14.958 — 2 1 520 812 14.148 7.92 3 1 947 141 15.268 5.73 4 2 543 590 15.131 0.90 表 8 串并混联机械臂外流场网格无关性检验结果

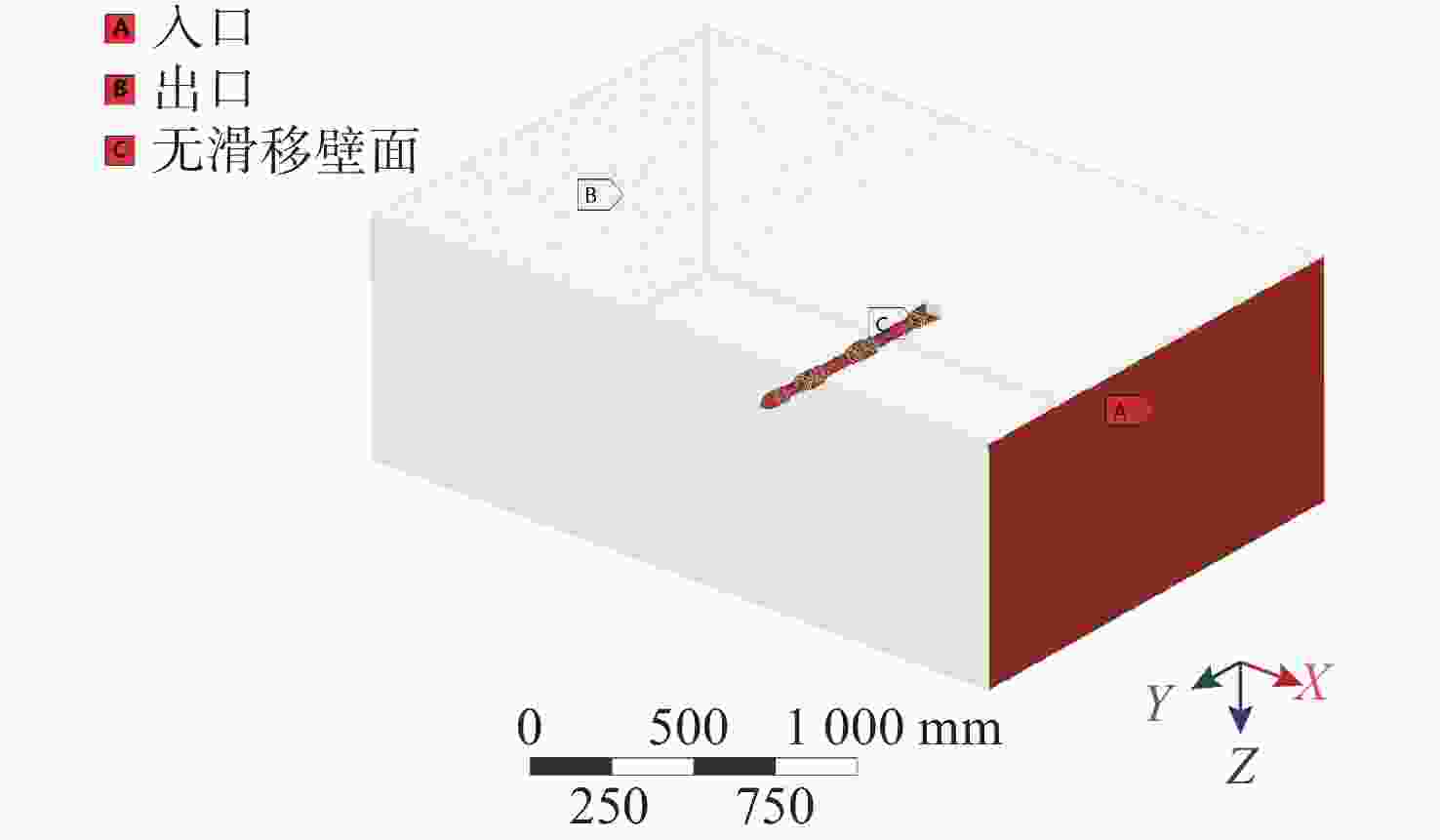

Table 8. Grid independence test results of the external flow field of serial-parallel hybrid manipulator

编号 网格数量 水阻力/N 误差/% 1 508 940 10.17 — 2 747 929 10.00 1.65 3 1 015 026 10.37 3.70 4 1 562444 9.90 4.53 -

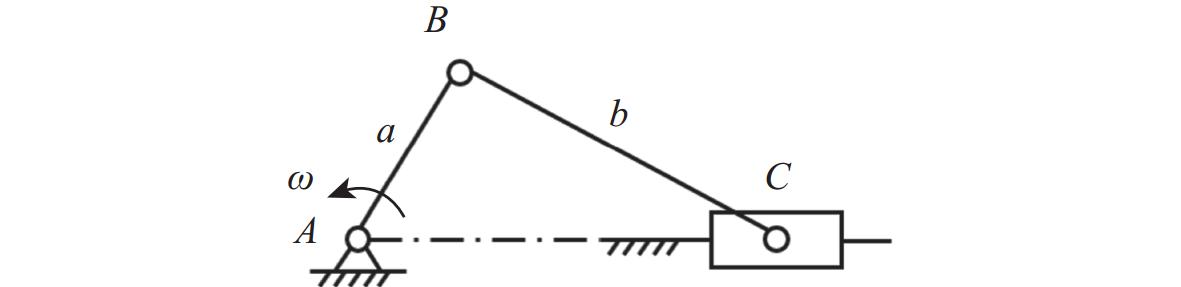

[1] 董索, 李建清, 陈利强. 水库清淤技术概述[J]. 水利水电快报, 2019, 40(11): 49-52, 63. [2] BARBIERI L, BRUNO F, GALLO A, et al. Design, prototyping and testing of a modular small-sized underwater robotic arm controlled through a Master-Slave approach[J]. Ocean Engineering, 2018, 158: 253-262. doi: 10.1016/j.oceaneng.2018.04.032 [3] YUTAKA S, SHINICHI S, RADZI A. Impedance control of dual-arm 3-link underwater robot: In the case of grasping a fixed object lightly with one hand[C]//2018 International Conference on Information and Communication Technology Robotics. Busan, South Korea: ICT-ROBOT, 2018: 1-4. [4] SKALDEBO B, HAUGALOKKEN B, SCHJOLBERG I. SeaArm-2-Fully electric underwater manipulator with integrated end-effector camera[C]//2021 European Control Conference. Delft, Netherlands: ECC, 2021: 236-242. [5] 刘涛, 张奇峰, 张运修, 等. 水下大臂展机械手动力学建模与仿真分析[J]. 液压与气动, 2021, 45(5): 25-32.LIU T, ZHANG Q F, ZHANG Y X, et al. Dynamic modeling and simulation analysis of underwater manipulator with large arms[J], Chinese Hydraulics & Pneumatics, 2021, 45(5): 25-32. [6] 甘帅奇. 水下双臂机械手协同作业系统研究[D]. 武汉: 华中科技大学, 2019. [7] 马小委. 水下水液压机械手系统设计及位置测量技术研究[D]. 哈尔滨: 哈尔滨工程大学, 2015. [8] 郭锐. 六自由度水下机械臂系统设计及试验[D]. 哈尔滨: 哈尔滨工程大学, 2018. [9] 张吉. 水下机械臂的设计及特性分析[D]. 西安: 西安工业大学, 2019. [10] 郭伟明. 水下机器人并联式机械臂设计及其运动控制研究[D]. 哈尔滨: 哈尔滨工业大学, 2021. [11] LI Y, YANG S, XU Y, et al. Disturbance rejection fixed point control of DELTA parallel manipulator mounted on autonomous underwater vehicle[C]//International Conference on Intelligent Robotics and Applications. Singapore: Springer Nature Singapore, 2023: 451-463. [12] ZHANG Y, WEI X, ZHANG S, et al. Type synthesis of the fully-decoupled two-rotational and one-translational parallel mechanism[J]. Journal of Mechanical Science and Technology. 2023, 37(12): 6669-6678. [13] ANTONOV A, FOMIN A, GLAZUNOV V, et al. Type synthesis of 5-DOF hybrid(parallel-serial) manipulators designed from open kinematic chains[J]. Robotics, 2023, 12(98): 98. [14] LONG S, TERAKAWA T, KOMORI M. Type synthesis of 6-DOF mobile parallel link mechanisms based on screw theory[J]. Journal of Advanced Mechanical Design, Systems, and Manufacturing, 2022, 16(1): 19. doi: 10.1299/jamdsm.2022jamdsm0005 [15] 黄真, 赵永生, 赵铁石. 高等空间机构学[M]. 2版. 北京: 高等教育出版社, 2014. [16] 蔡玉强, 朱东升, 吴楠. 基于Matlab/Simulink的高速压力机曲柄滑块机构的动力学研究[J]. 机械设计与制造, 2018(1):192-194.CAI Y Q, ZHU D S, WU N. Dynamic of slider-crank mechanism in high-speed press based on Matlab/Simulink[J]. Machinery Design & Manufacture, 2018(1):192-194. [17] GUO M, TIAN Y. Review on structural design of underwater manipulator[J]. Proceedings of SPIE, 2022, 12309: 123091A-6. [18] 王正军, 孙立明. ANSYS 18.0有限元分析基础与实例教程[M]. 北京: 机械工业出版社, 2018. [19] KIRSANOV D, SEVOSTIANOV I, RODIONOV O, et al. Stiffness analisys of the tripteron parallel manipulator[C]//2020 International Conference Nonlinearity, Information and Robotics. Innopolis, Russia: NIR, 2020: 1-6. [20] WU Z, WANG B, YAN L, et al. Design of a cable-driven 7-DOF anthropomorphic robotic arm and its stiffness modeling and performance analysis[J]. Journal of Mechanical Engineering, 2023, 59(17): 17-32. doi: 10.3901/JME.2023.17.017 [21] ZHANG Y, HUANG K, LIU C, et al. Stiffness analysis and error compensation of lunar sampling manipulator[J]. Journal of Deep Space Exploration, 2023, 10(2): 169-177. [22] 毛嘉炜, 贺帅, 刘昌儒, 等. 空间机械臂在轨刚度计算与验证[J]. 机床与液压, 2022, 50(9): 1-6.MAO J W, HE S, LIU C R, et al. Calculation and verification of on-orbit stiffness of space manipulator[J]. Machine Tool & Hydraulics, 2022, 50(9): 1-6. -

下载:

下载: