Temperature Adaptability Analysis of Closed Cycle Using CO2-Based Mixed Working Fluid for Underwater Platforms

-

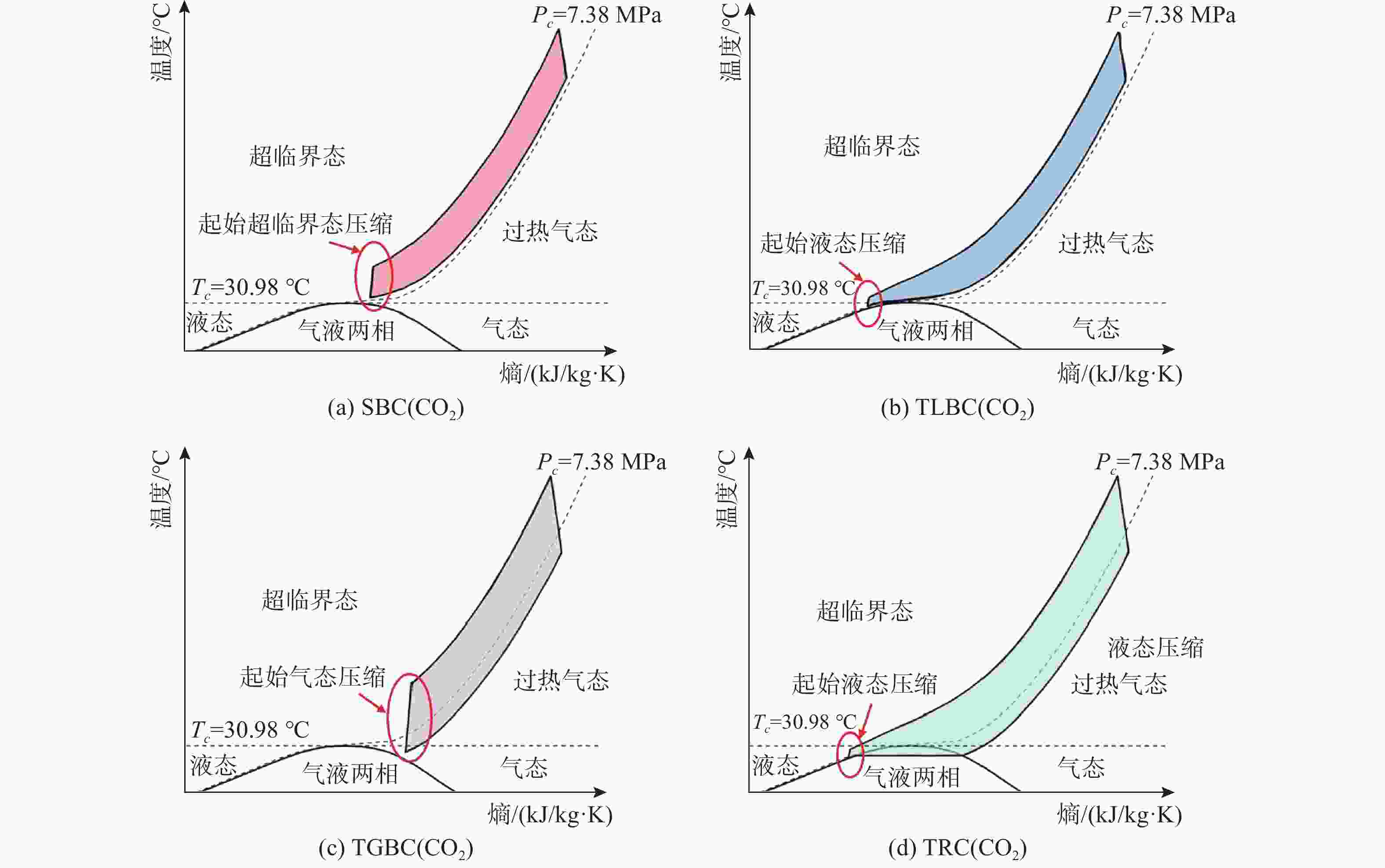

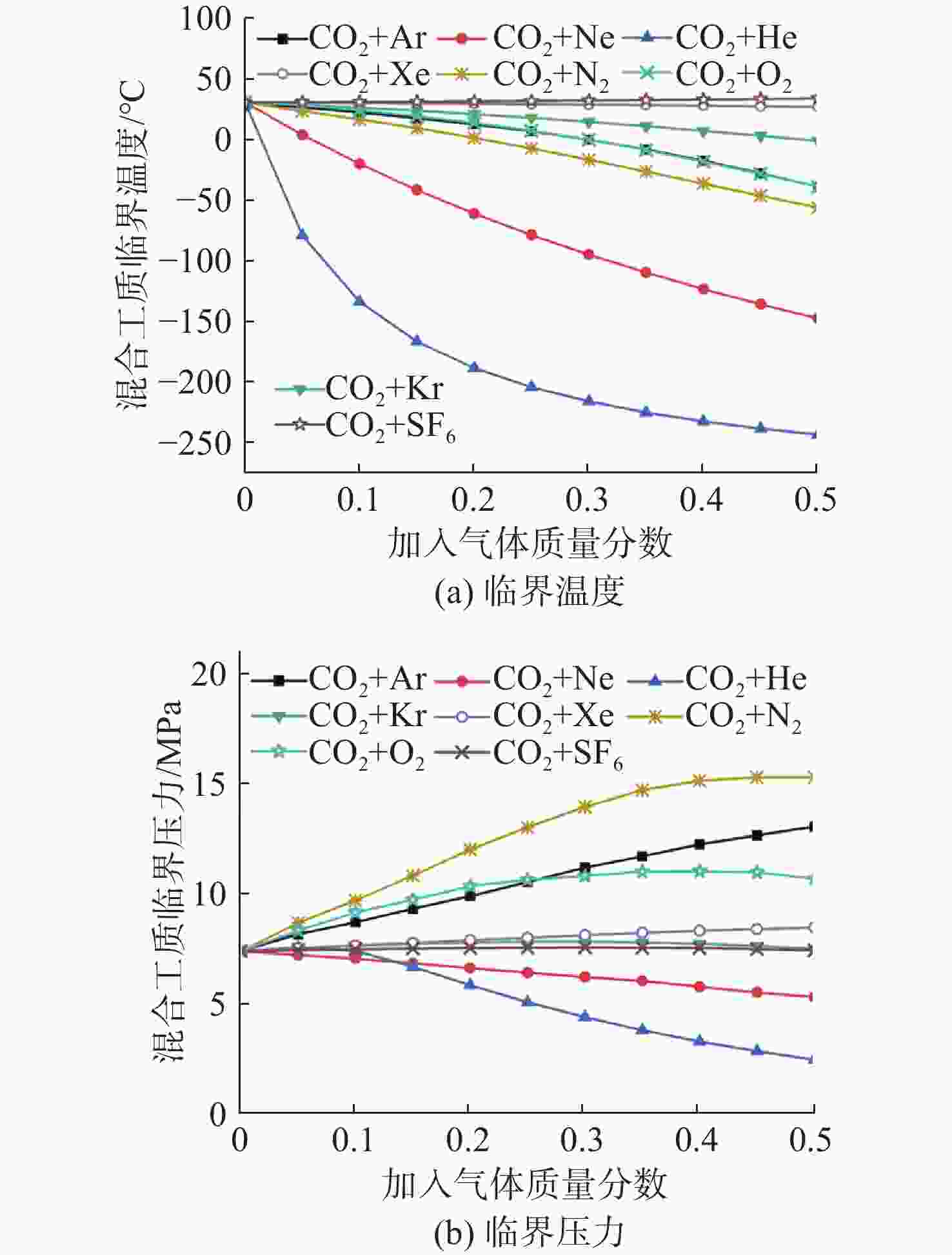

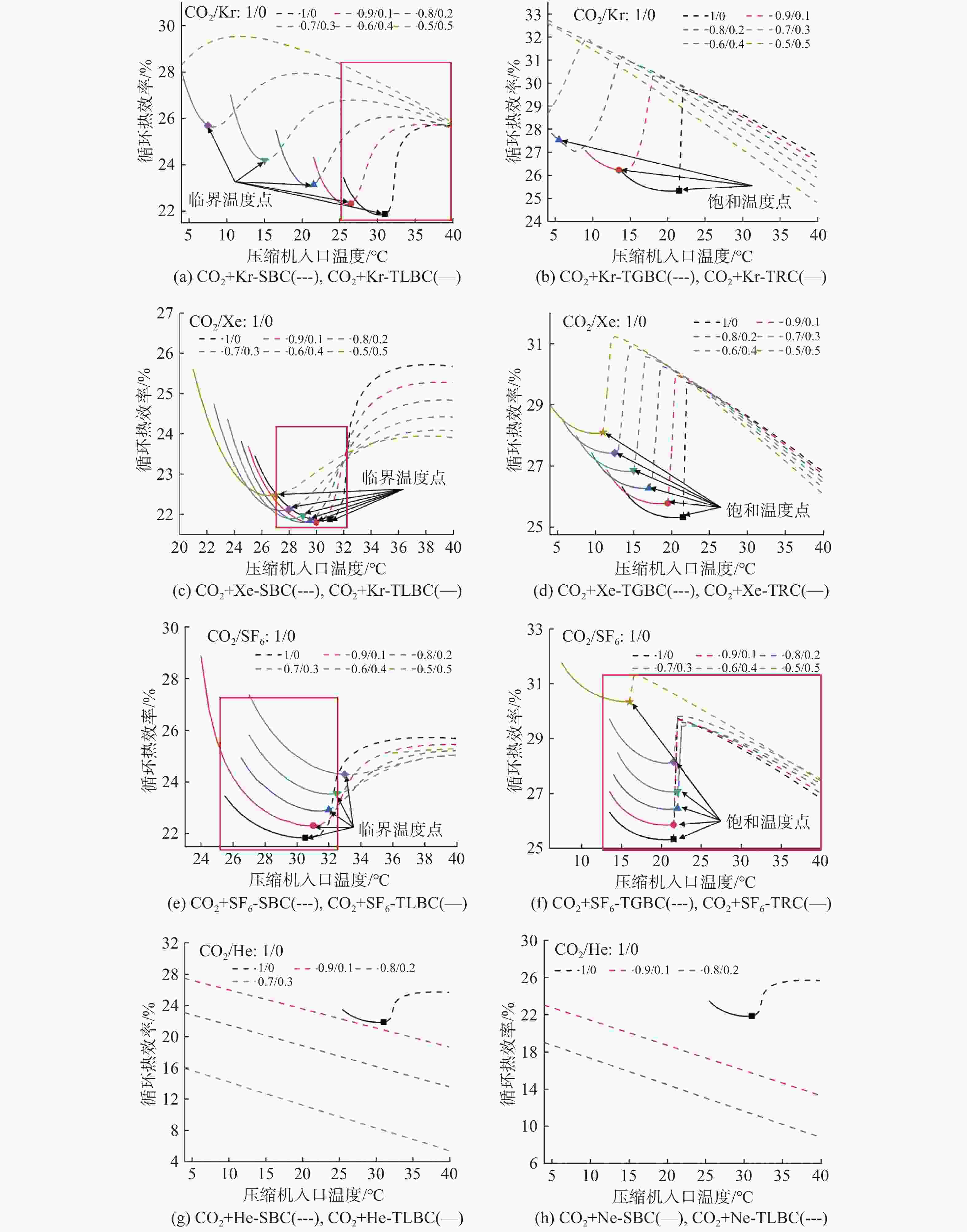

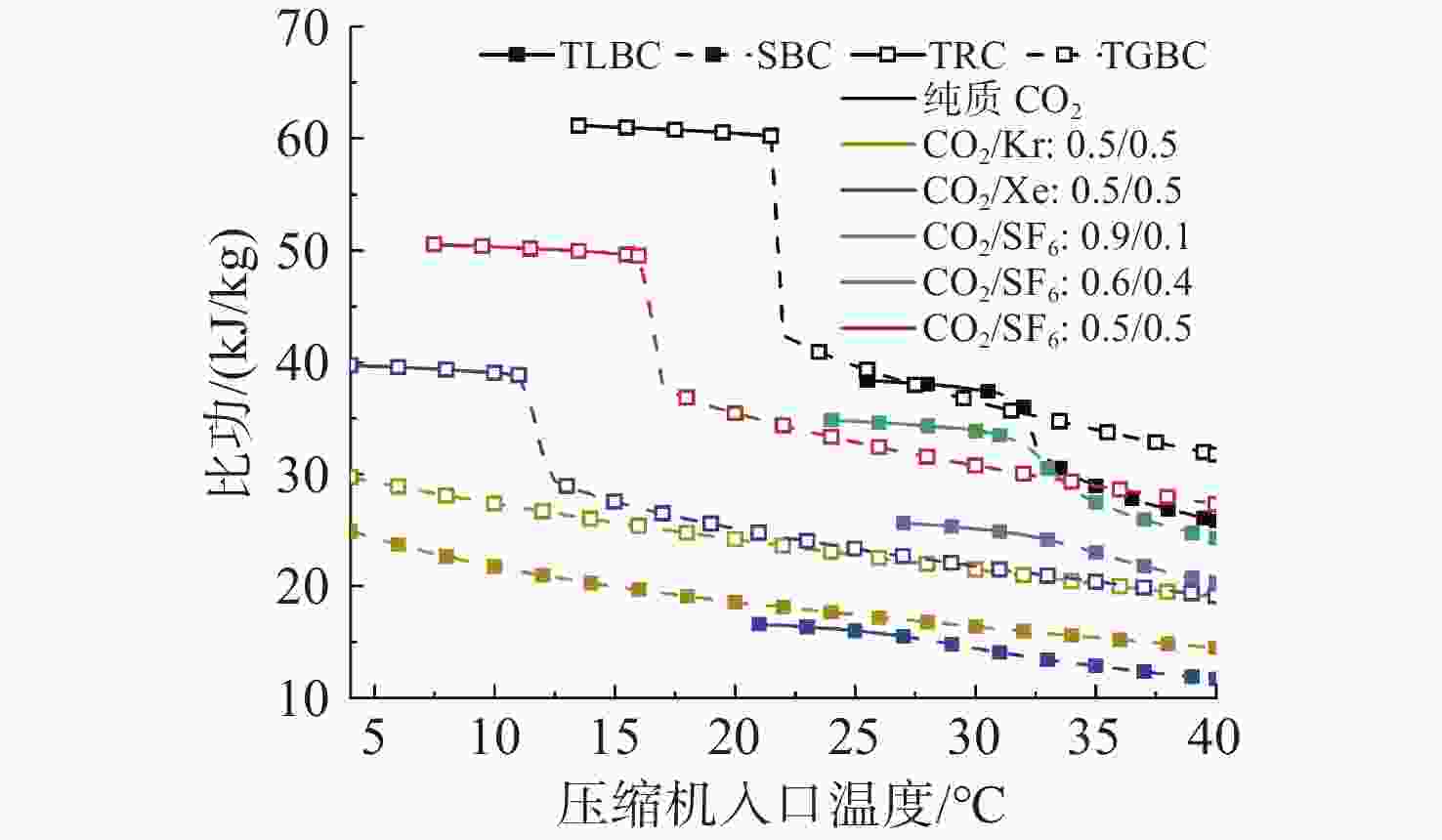

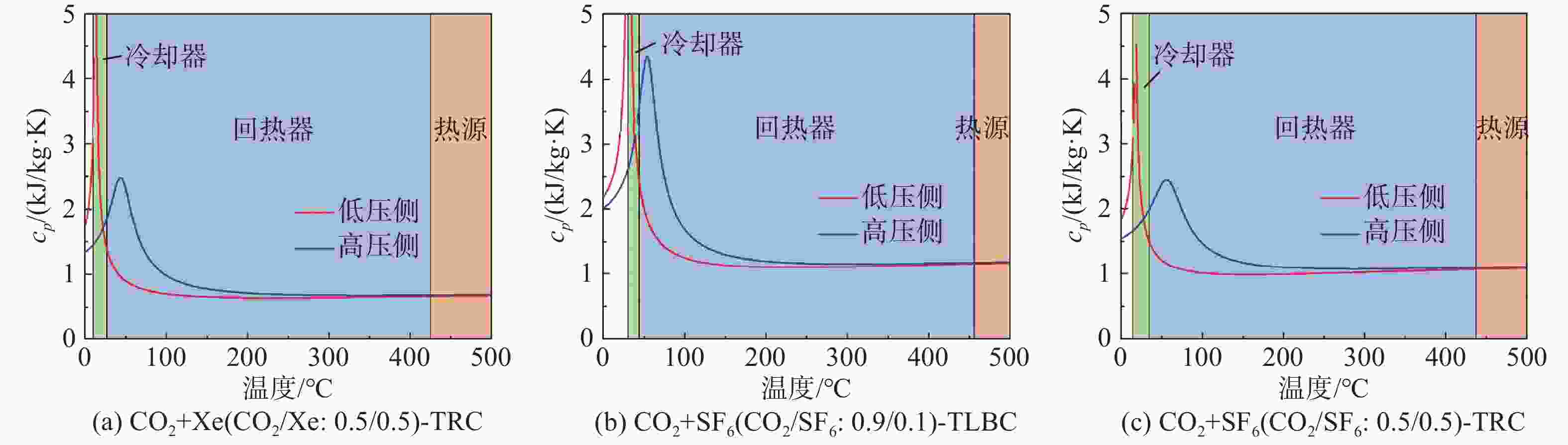

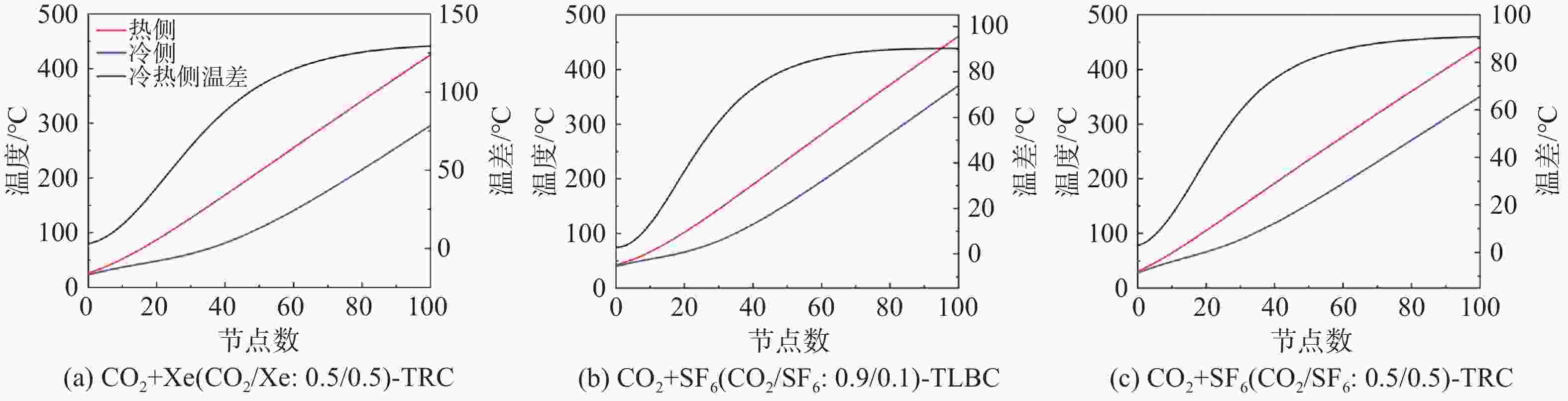

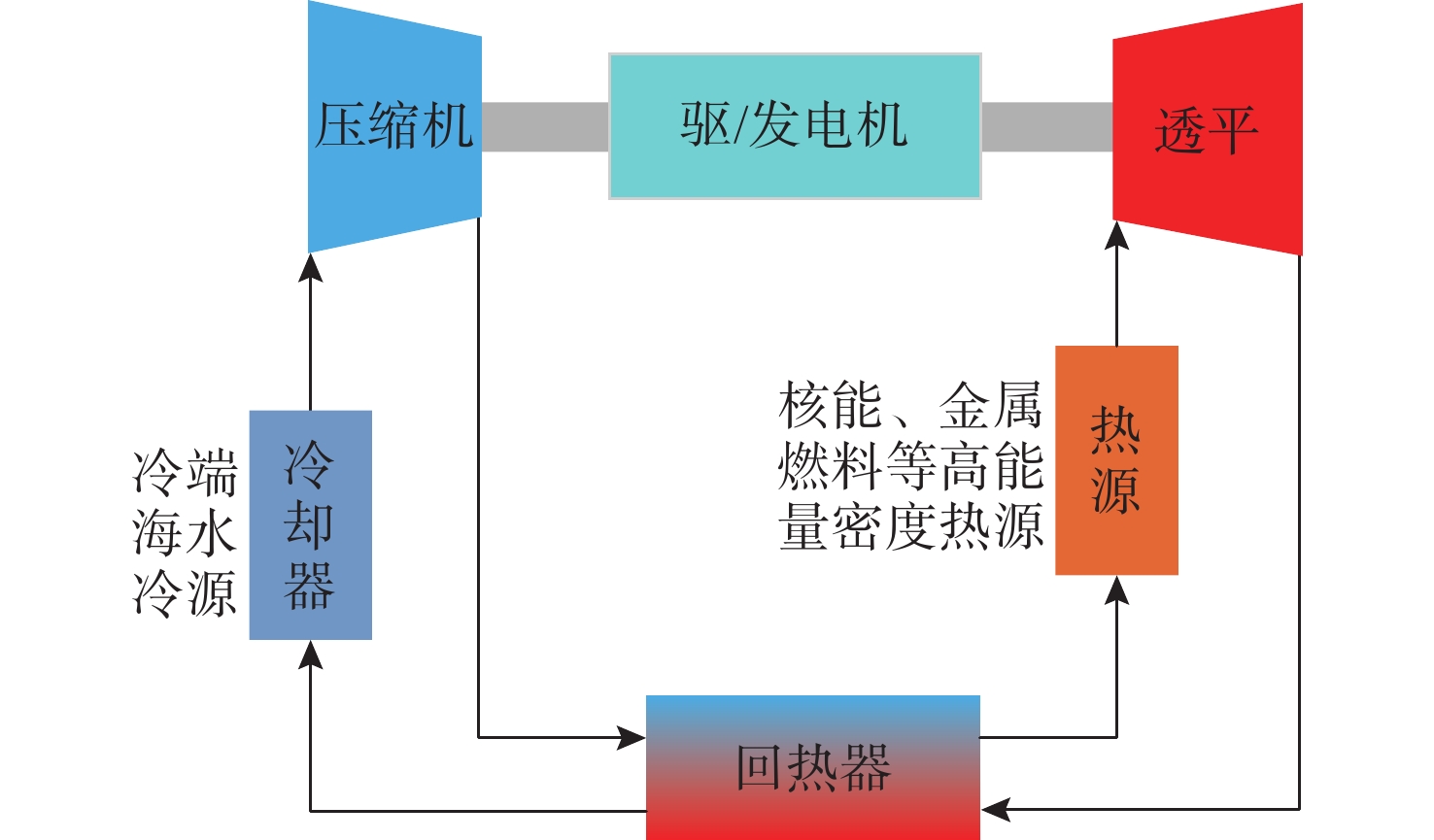

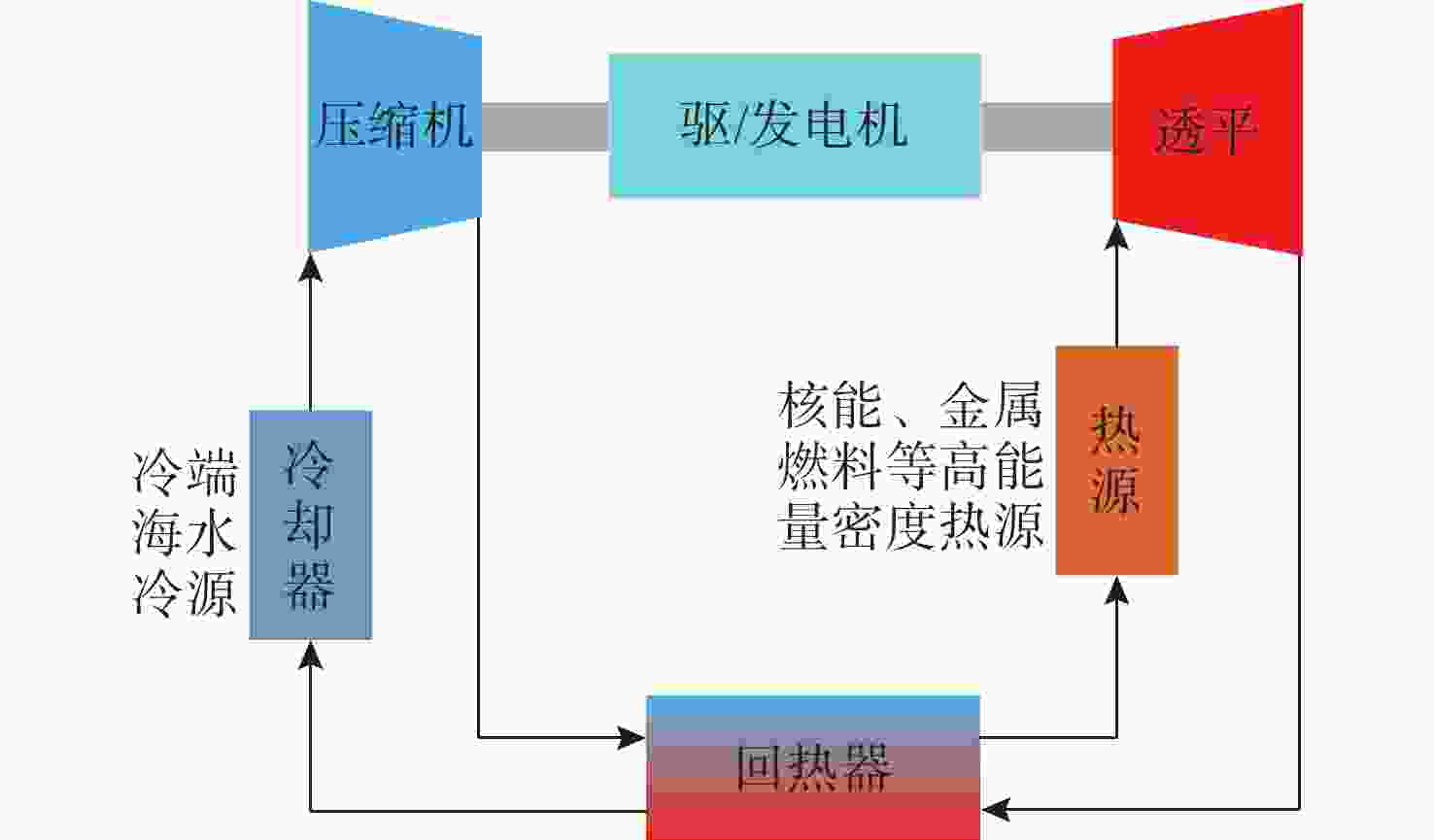

摘要: 超临界CO2布雷顿循环系统是水下平台动力技术的重要发展方向, 但由于深海低温较远离CO2临界温度, 致使循环系统存在温度适应性问题。文中提出了利用CO2基混合工质改善循环温度适应性并进一步优化循环性能的方案, 建立了简单回热循环热力学模型, 分析了CO2基混合工质临界参数随加入气体种类和质量分数的变化规律, 阐明了压缩机入口状态参数对CO2基混合工质闭式循环热力学性能的影响规律, 探讨了混合工质拟临界点位置对回热器夹点和热惯性等的影响。结果表明: 低临界参数混合工质循环可进一步扩大循环温度范围和压比, 以改善循环热力学性能, 但仅扩大温度范围而降低压比可能会对其造成不利影响; 综合考虑循环热效率、比功、回热器内部夹点及热惯性, CO2+Xe(CO2/Xe: 0.5/0.5)-跨临界朗肯循环、CO2+SF6(CO2/SF6: 0.9/0.1)-跨临界液体布雷顿循环以及CO2+SF6(CO2/SF6: 0.5/0.5)-跨临界朗肯循环较超临界CO2布雷顿循环热效率最大可提高3.79%, 比功最大可提升31.6%, 回热器夹点位于冷端并未加剧其热惯性, 不会减缓系统响应速度。Abstract: The supercritical CO2 Brayton cycle system is an important development direction of underwater platform power technology. However, due to the low temperature in the deep sea which is far away from the critical temperature of CO2, the cycle system has temperature adaptability problems. This paper proposed the plan to use CO2-based mixed working fluid to improve cycle temperature adaptability and further optimize cycle performance. A simple recuperative closed cycle thermodynamic model was established, and the changes in critical parameters of CO2-based mixed working fluid with the type and mass fraction of added gas were analyzed. The influence of the compressor inlet state parameters on the thermodynamic properties of the closed cycle of CO2-based mixed working fluid was clarified. Besides, the influence of the pseudo-critical point position of the mixed working fluid on the pinch point and thermal inertia of the regenerator was discussed. The results show that the mixed working fluid cycle with low critical parameters can further expand the cycle temperature range and pressure ratio to improve the cycle thermodynamic performance. However, only expanding the temperature range and reducing the pressure ratio may have an adverse impact on it. Comprehensive consideration of cycle thermal efficiency, specific power, and pinch point and thermal inertia of regenerator, the maximum thermal efficiency of CO2 + Xe(CO2/Xe: 0.5/0.5)- transcritical Rankine cycle, CO2 + SF6(CO2/SF6: 0.9/0.1)-transcritical liquid Brayton cycle, CO2 + SF6(CO2/SF6: 0.5/0.5)-transcritical Rankine cycle can be increased by 3.79% than that of the supercritical CO2 Breton cycle, and the maximum specific power can be increased by 31.6%. The pinch point of the regenerator is located at the cold end, which does not increase its thermal inertia and does not slow down the system response speed.

-

表 1 工质性质参数

Table 1. Table of working fluid property parameters

临界温度

/℃临界压力

/MPa密度

/(kg/m3)导热系数

/(W/m·K)黏度

/(μPa·s)摩尔质量

/(g/mol)Ar −122.46 4.86 535.60 0.019 0 24.20 39.9 Ne −228.75 2.66 486.31 0.051 7 33.46 20.2 He −267.95 0.23 69.58 0.164 3 20.97 4.0 Kr −63.67 5.53 909.21 0.010 2 27.24 83.8 Xe 16.58 5.84 1102.90 0.006 0 24.99 131.3 N2 −146.96 3.40 313.30 0.027 6 18.95 28.0 O2 −118.57 5.04 436.14 0.028 3 21.93 32.0 SF6 45.57 3.76 742.30 0.170 8 42.37 146.0 CO2 30.98 7.38 467.60 0.019 0 16.12 44.0 -

[1] 潘光, 宋保维, 黄桥高, 等. 水下无人系统发展现状及其关键技术[J]. 水下无人系统学报, 2017, 25(2): 44-51.PAN G, SONG B W, HUANG Q G, et al. Development and key techniques of unmanned undersea system[J]. Journal of Unmanned Undersea Systems, 2017, 25(2): 44-51. [2] 邱志明, 马焱, 孟祥尧, 等. 水下无人装备前沿发展趋势与关键技术分析[J]. 水下无人系统学报, 2023, 31(1): 1-9.QIU Z M, MA Y, MENG X Y, et al. Analysis on the development trend and key technologies of unmanned underwater equipment[J]. Journal of Unmanned Undersea Systems, 2023, 31(1): 1-9. [3] ZHOU A, LI X, REN X, et al. Improvement design and analysis of a supercritical CO2/transcritical CO2 combined cycle for offshore gas turbine waste heat recovery[J]. Energy, 2020, 210: 118562. [4] 赵德材, 秦政, 刘惠民. 超临界二氧化碳布雷顿发电系统热力循环分析[J]. 能源与节能, 2018, 6: 2-6.ZHAO D C, QIN Z, LIU H M. Thermodynamic cycle analysis of supercritical carbon dioxide Brayton power generation system[J]. Energy and Energy Conservation, 2018, 6: 2-6. [5] FEHER E G. The supercritical thermodynamic power cycle[J]. Energy Conversion, 1968, 8(2): 85-90. doi: 10.1016/0013-7480(68)90105-8 [6] ANGELINO G. Real gas effects in carbon dioxide cycles[M]. Newyork: American Society of Mechanical Engineers, 1969. [7] WHITE M T, BIANCHI G, CHAI L, et al. Review of supercritical CO2 technologies and systems for power generation[J]. Applied Thermal Engineering, 2021, 185: 116447. [8] HELD T J. Initial test results of a megawatt-class supercritical CO2 heat engine[C]//The 4th International Symposium on Supercritical CO2 Power Cycles. Pittsburgh: GE Global Research Center, 2014: 9-10. [9] WRIGHT S A, CONBOY T M, RADEL R F, et al. Modeling and experimental results for condensing supercritical CO2 power cycles[R]. CA, Unite States: USDOE, 2011. [10] JIANG Y, ZHAN L, TIAN X, et al. Thermodynamic performance comparison and optimization of SCO2 Brayton cycle, TCO2 Brayton cycle and TCO2 rankine cycle[J]. Journal of Thermal Science, 2023, 32(2): 611-627. doi: 10.1007/s11630-023-1708-z [11] LI Y, FENG J, ZHANG X, et al. Technical benefits of the subcritical inlet condition for high-speed CO2 centrifugal compressor in the advanced power-generation cycle[J]. Energy, 2023, 284: 128733. doi: 10.1016/j.energy.2023.128733 [12] LIU Y, ZHAO Y, YANG Q, et al. Thermodynamic comparison of CO2 power cycles and their compression processes[J]. Case Studies in Thermal Engineering, 2020, 21: 100712. doi: 10.1016/j.csite.2020.100712 [13] PAN L, LI B, SHI W, et al. Optimization of the self-condensing CO2 transcritical power cycle using solar thermal energy[J]. Applied Energy, 2019, 253: 113608. doi: 10.1016/j.apenergy.2019.113608 [14] HABIBOLLAHZADE A, PETERSEN K, ALIAHMADI M, et al. Comparative thermoeconomic analysis of geothermal energy recovery via super/transcritical CO2 and subcritical organic Rankine cycles[J]. Energy Conversion and Management, 2022, 251: 115008. doi: 10.1016/j.enconman.2021.115008 [15] WU P, MA Y, GAO C, et al. A review of research and development of supercritical carbon dioxide Brayton cycle technology in nuclear engineering applications[J]. Nuclear Engineering and Design, 2020, 368: 110767. doi: 10.1016/j.nucengdes.2020.110767 [16] LIU W, XU X, CHEN F, et al. A review of research on the closed thermodynamic cycles of ocean thermal energy conversion[J]. Renewable and Sustainable Energy Reviews, 2020, 119: 109581. doi: 10.1016/j.rser.2019.109581 [17] WANG G, YANG Y, WANG S, et al. Ocean thermal energy application technologies for unmanned underwater vehicles: A comprehensive review[J]. Applied Energy, 2020, 278: 115752. doi: 10.1016/j.apenergy.2020.115752 [18] SON S, HEO J Y, LEE J I. Prediction of inner pinch for supercritical CO2 heat exchanger using artificial neural network and evaluation of its impact on cycle design[J]. Energy Conversion and Management, 2018, 163: 66-73. doi: 10.1016/j.enconman.2018.02.044 [19] WANG R, WANG X, TIAN H, et al. Dynamic performance comparison of CO2 mixture transcritical power cycle systems with variable configurations for engine waste heat recovery[J]. Energies, 2019, 13(1): 1-24. doi: 10.3390/en13010032 [20] WHITE M T, BIANCHI G, CHAI L, et al. Review of supercritical CO2 technologies and systems for power generation[J]. Applied Thermal Engineering, 2021, 185: 116447. doi: 10.1016/j.applthermaleng.2020.116447 [21] 王典乐, 黄彦平, 殷凯凯, 等. 低温热阱环境下超临界二氧化碳动力循环概念设计研究[J]. 原子能科学技术, 2023, 57(9): 1681-1690.WANG D L, HUANG Y P, YIN K K, et al. Optimization design research of supercritical carbon dioxide power cycle under low-temperature heat sink environment[J]. Atomic Energy Science and Technology, 2023, 57(9): 1681-1690. [22] LEMMON E W, BELL I H, HUBER M, et al. NIST standard reference database 23: Reference fluid thermodynamic and transport properties-REFPROP, version 10.0, national institute of standards and technology[DB/OL]. [S.l.]: NIST NSRDS, 2013[2015-01-01]. https://www.nist.gov/publications/nist-standard-reference-database-23-reference-fluid-thermodynamic-and-transport [23] FENG J, WANG J, CHEN Z, et al. Thermo-economic analysis of regenerative supercritical CO2 Brayton cycle considering turbomachinery leakage flow[J]. Energy, 2024, 290: 130098. doi: 10.1016/j.energy.2023.130098 [24] HAQ M Z, AYON M S R, NOUMAN M W B, et al. Thermodynamic analysis and optimisation of a novel transcritical CO2 cycle[J]. Energy Conversion and Management, 2022, 273: 116407. doi: 10.1016/j.enconman.2022.116407 [25] SAKAKURA T, CHOI J C, YASUDA H. Transformation of carbon dioxide[J]. Chemical Reviews, 2007, 107(6): 2365-2387. doi: 10.1021/cr068357u [26] 杨富方, 刘航滔, 杨震, 等. 超临界二氧化碳循环工质热物性研究进展[J]. 热力发电, 2020, 49(10): 21-29.YANG F F, LIU H T, YANG Z, et al. Thermophysical properties of working fluid of supercritical carbon dioxide cycle: Research progress[J]. Thermal Power Generation, 2020, 49(10): 21-29. [27] LI H, YAN J. Impacts of equations of state(EOS) and impurities on the volume calculation of CO2 mixtures in the applications of CO2 capture and storage(CCS) processes[J]. Applied Energy, 2009, 86(12): 2760-2770. doi: 10.1016/j.apenergy.2009.04.013 [28] MAZZOCCOLI M, BOSIO B, ARATO E, et al. Comparison of equations-of-state with P–ρ–T experimental data of binary mixtures rich in CO2 under the conditions of pipeline transport[J]. The Journal of Supercritical Fluids, 2014, 95: 474-490. doi: 10.1016/j.supflu.2014.09.047 -

下载:

下载: