Research on Screw Propulsion Performance of Amphibious Robot

-

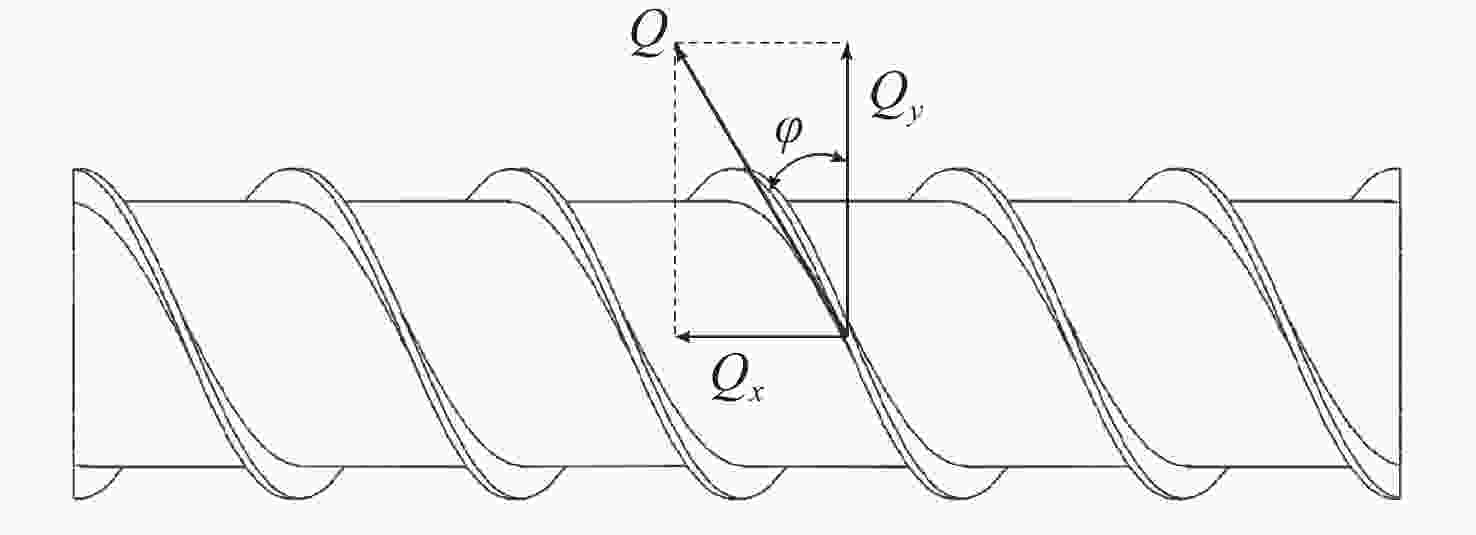

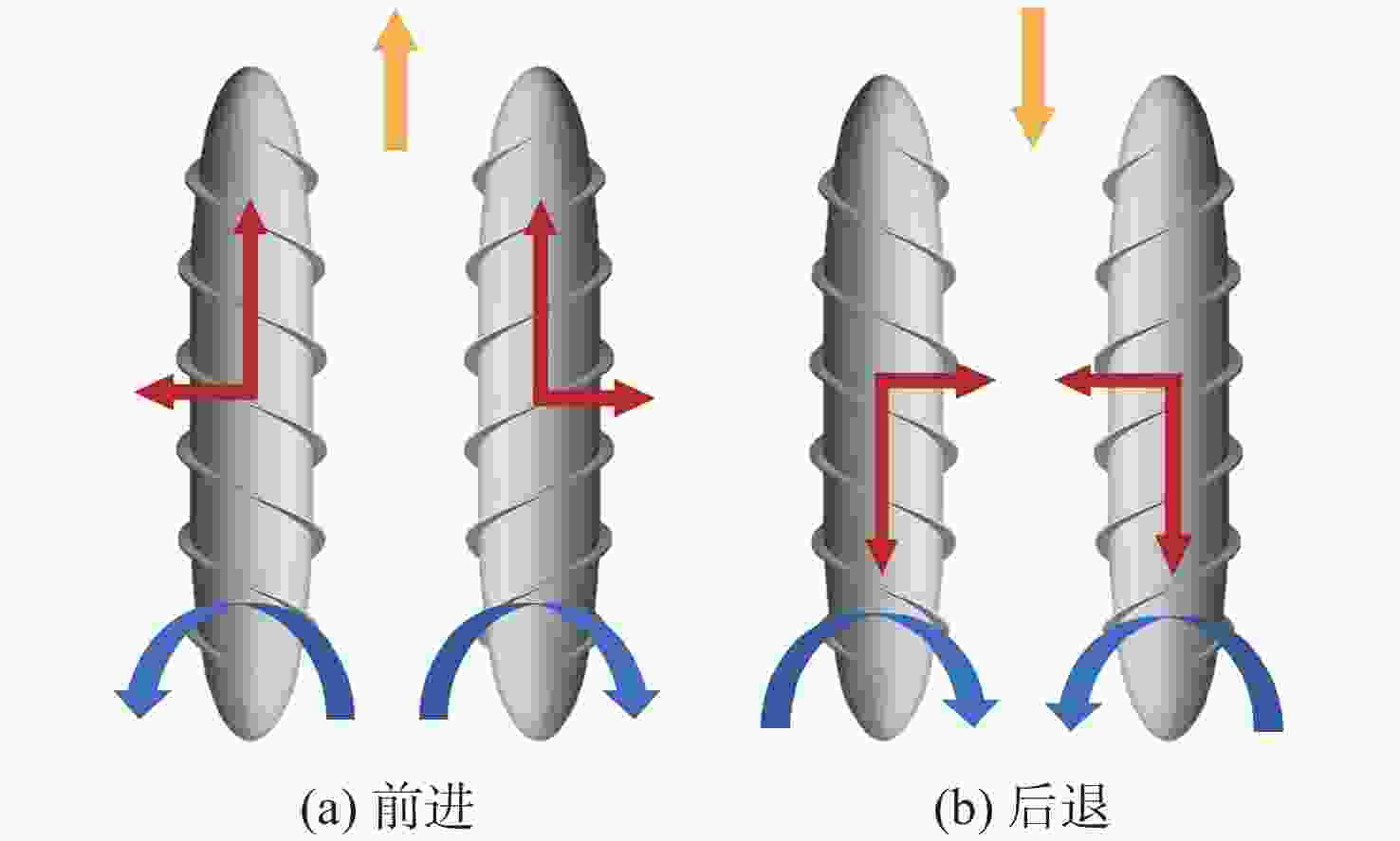

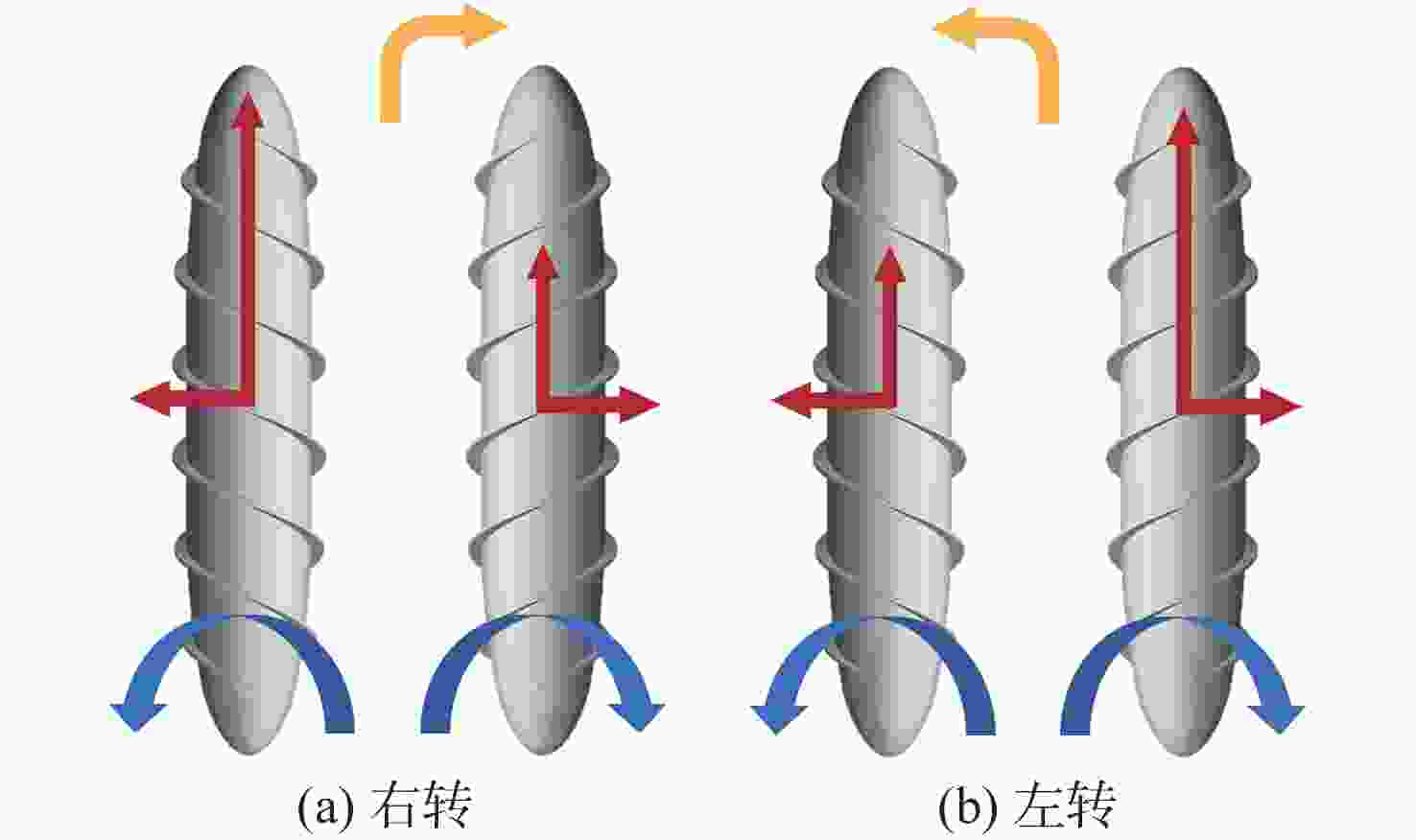

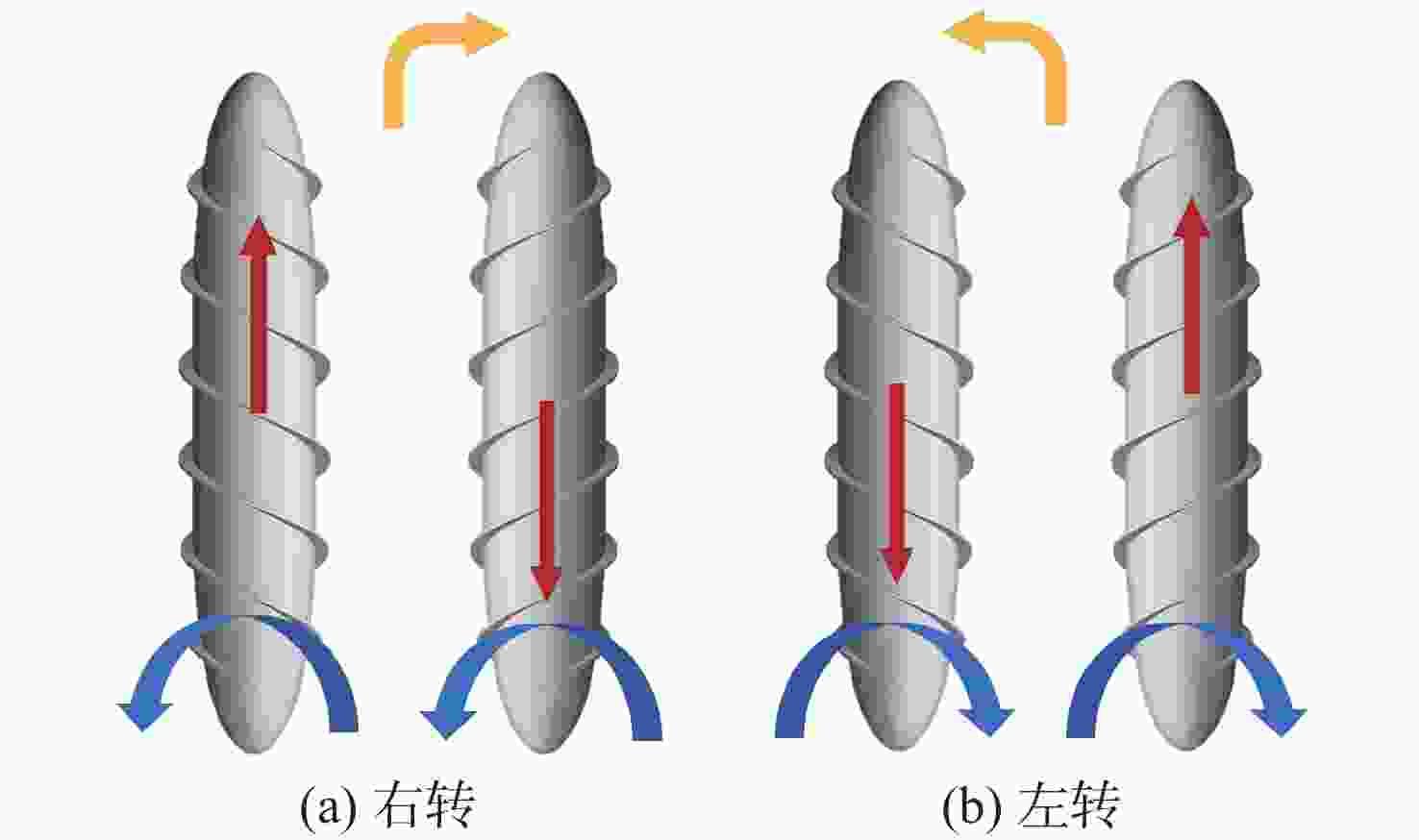

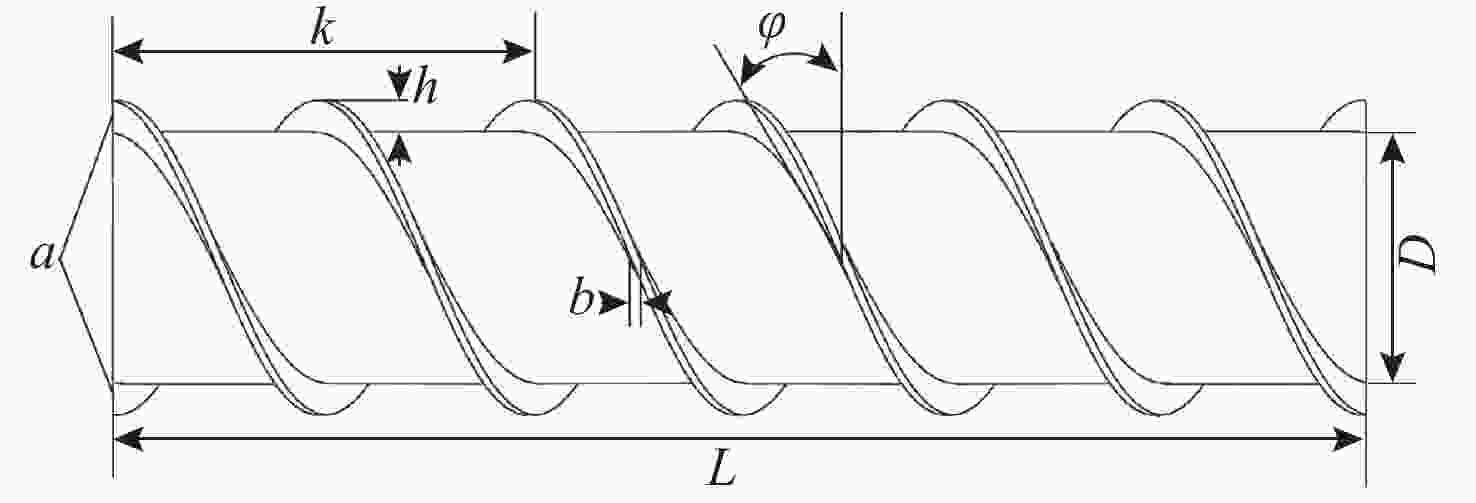

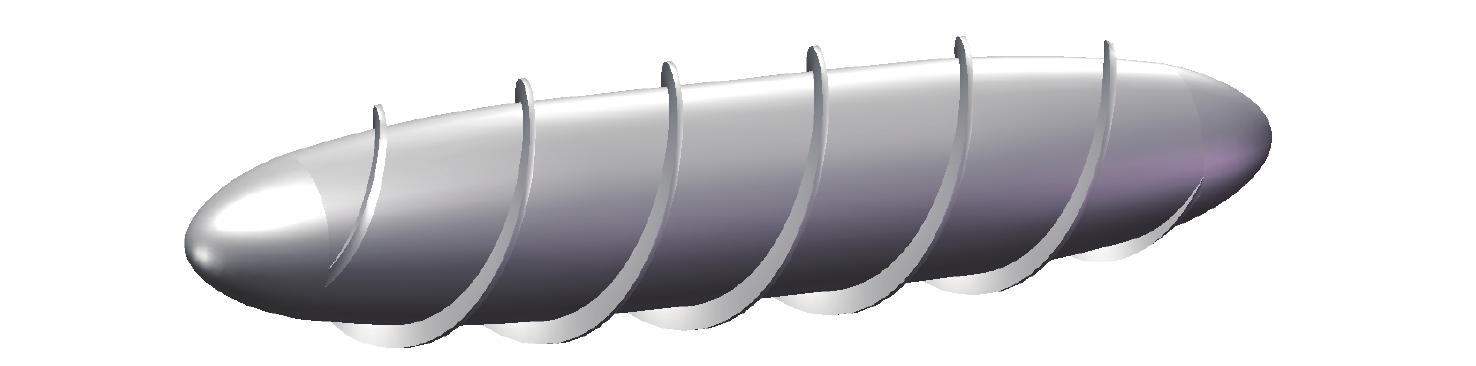

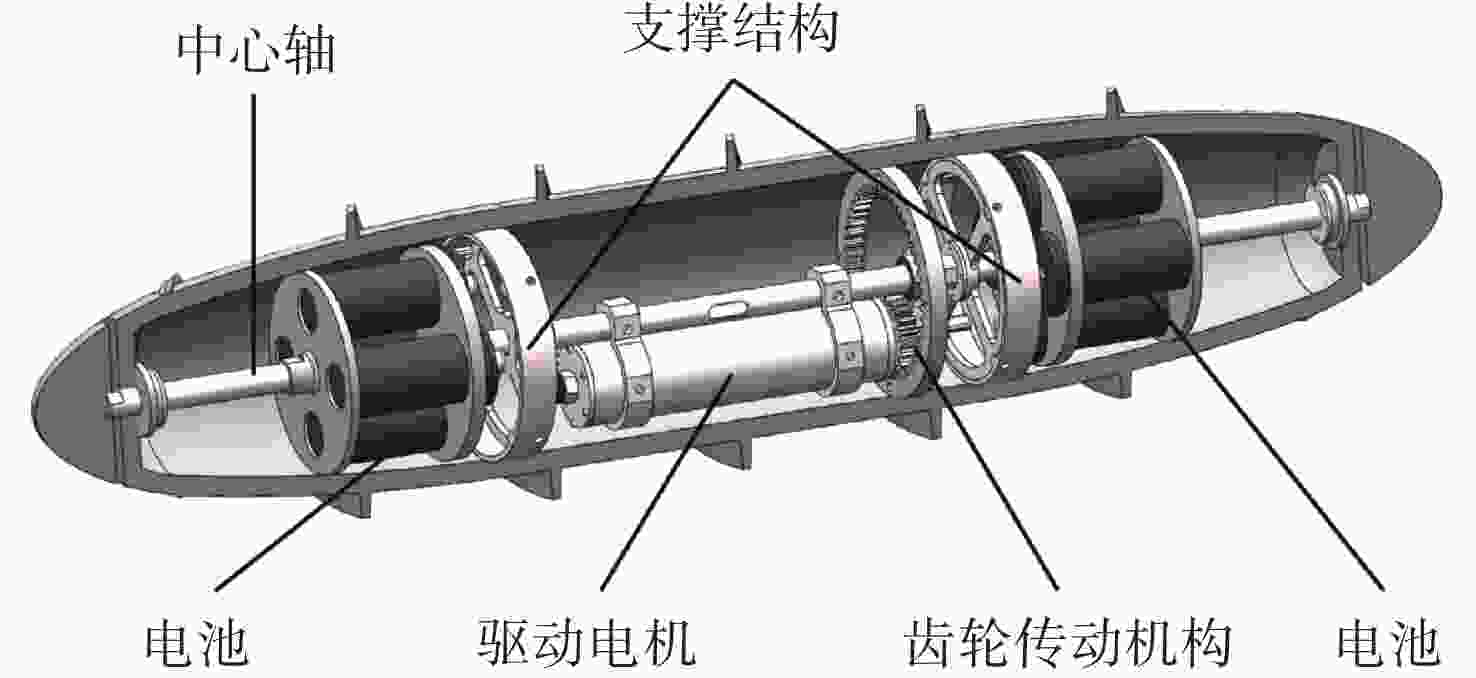

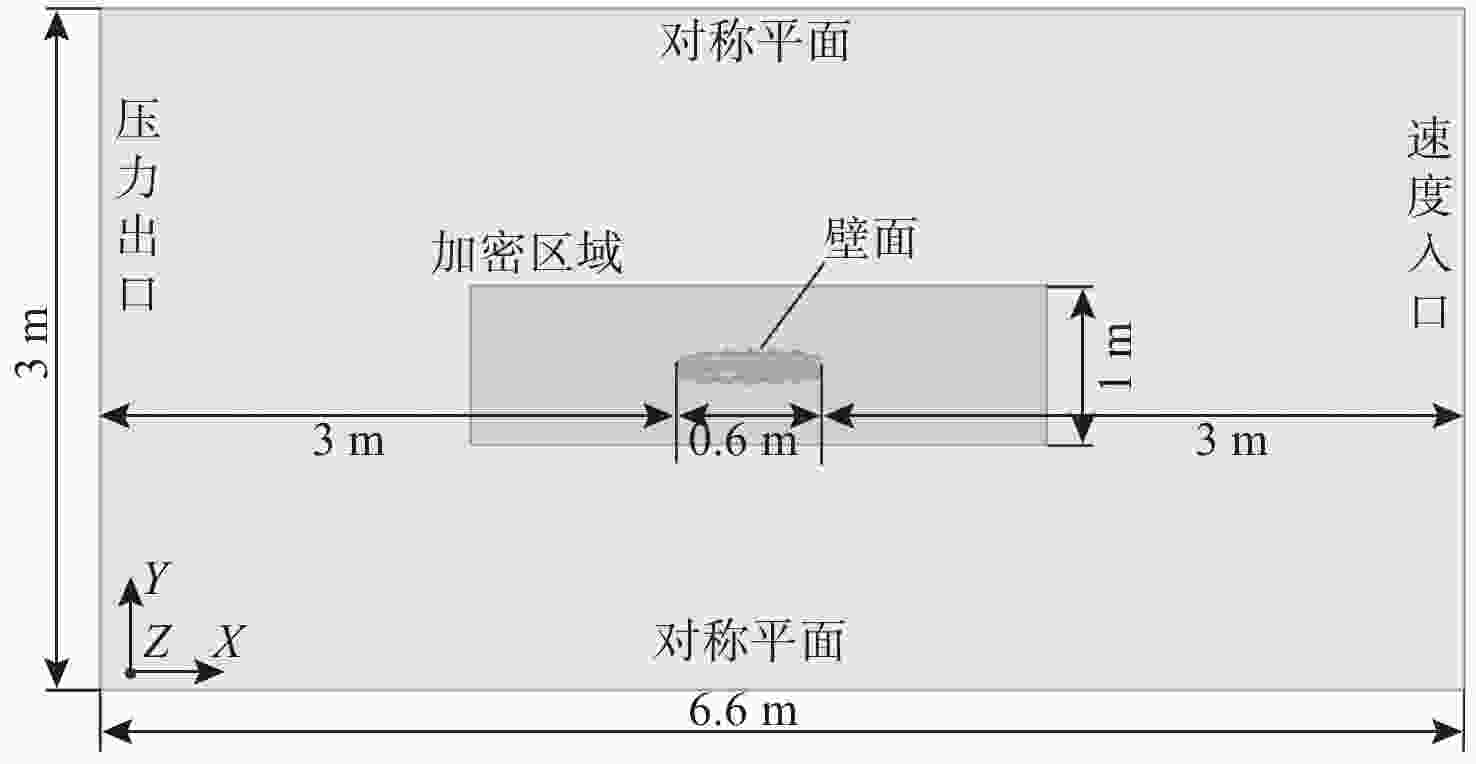

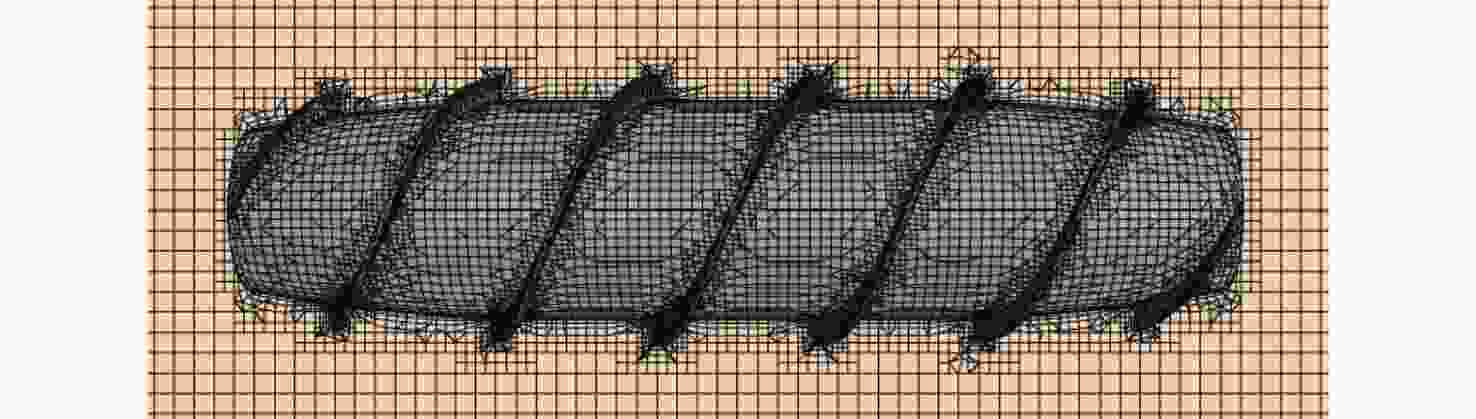

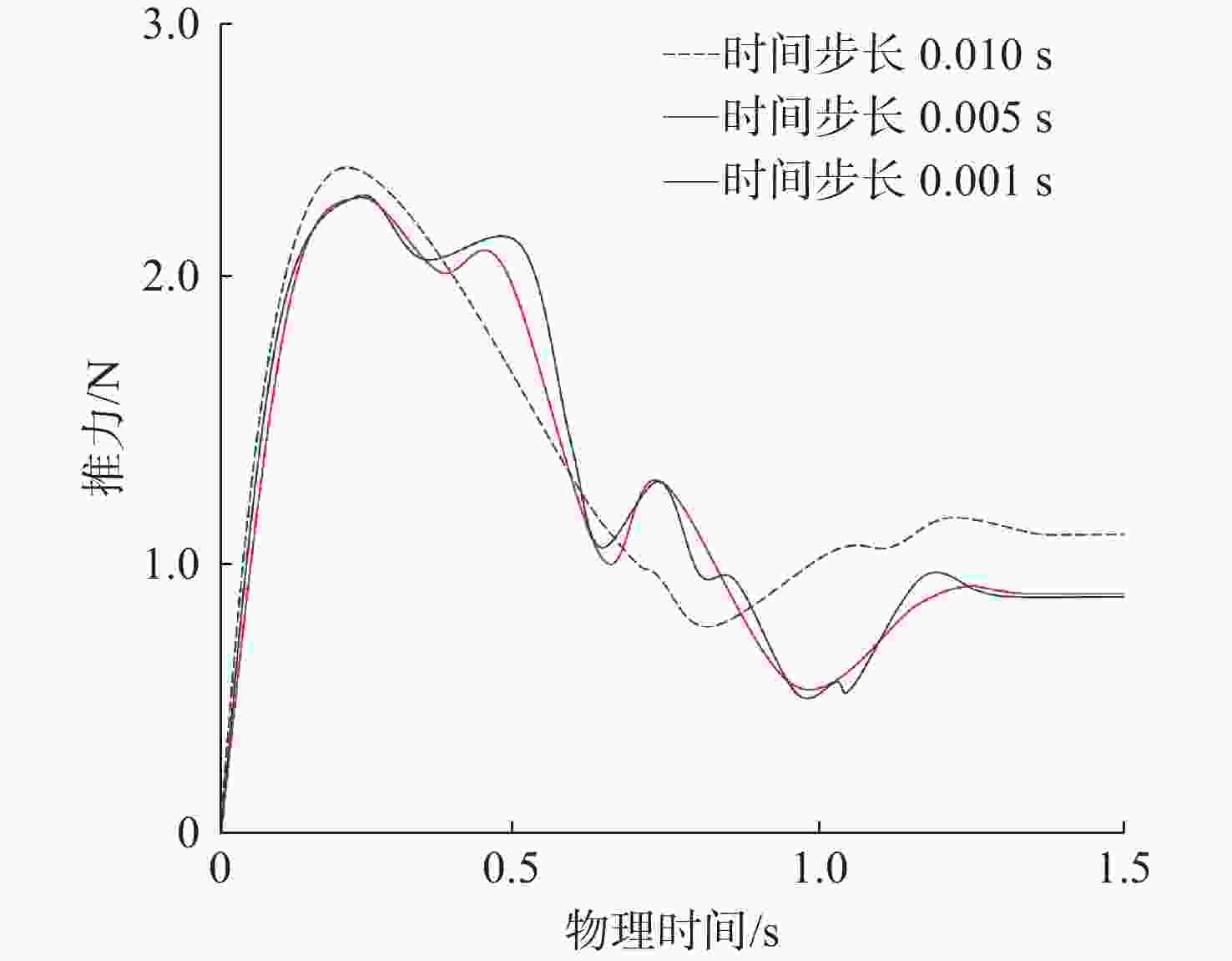

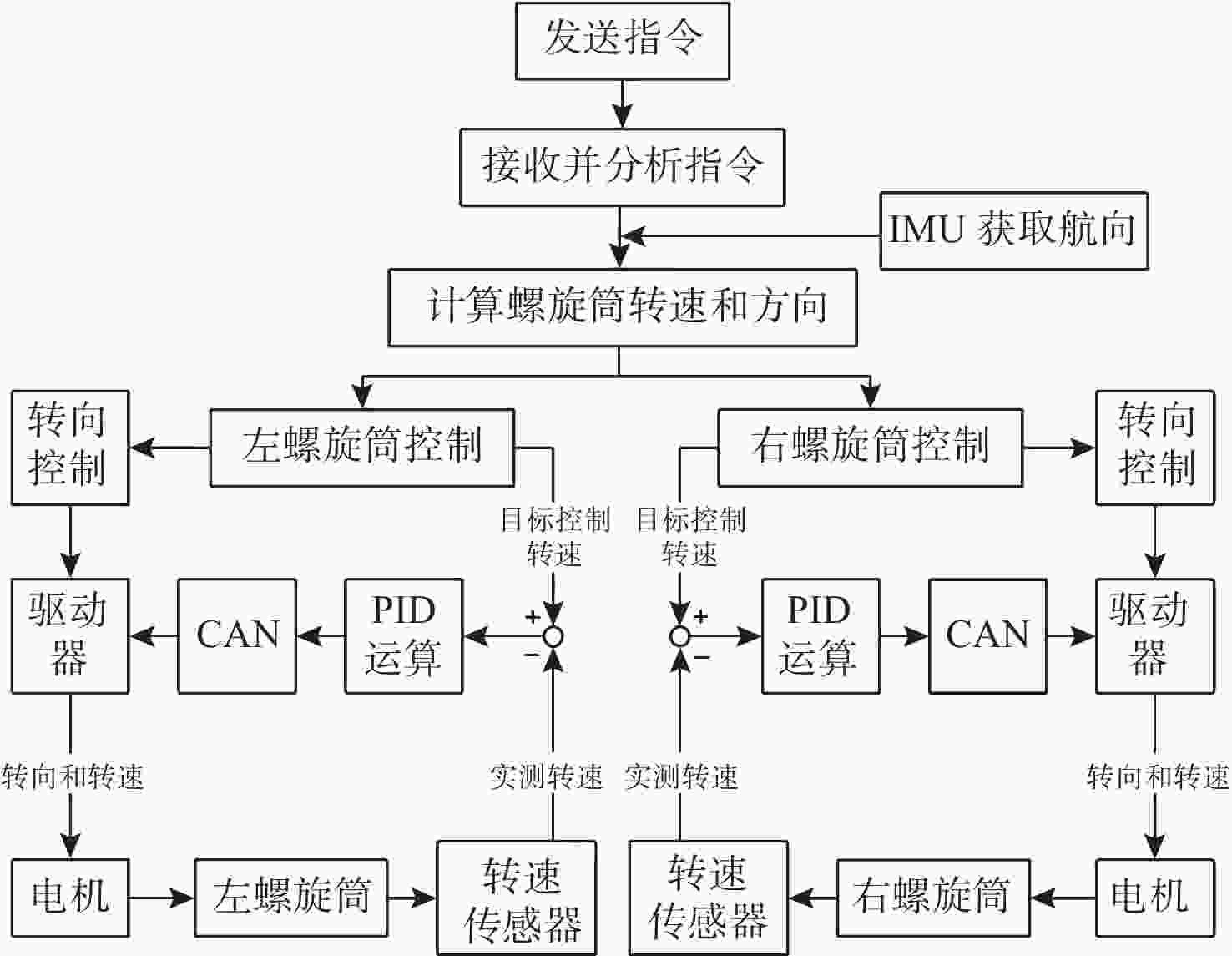

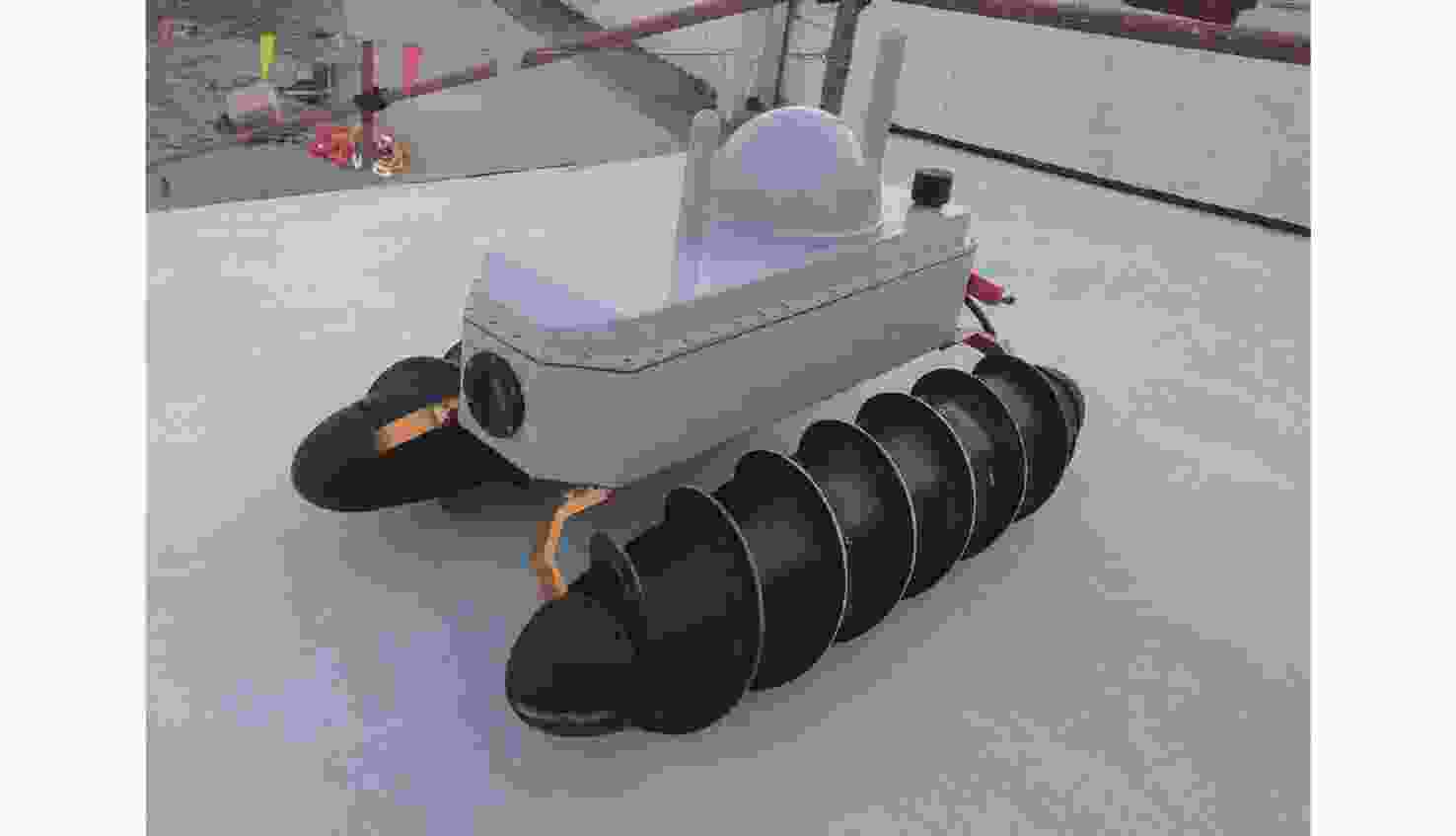

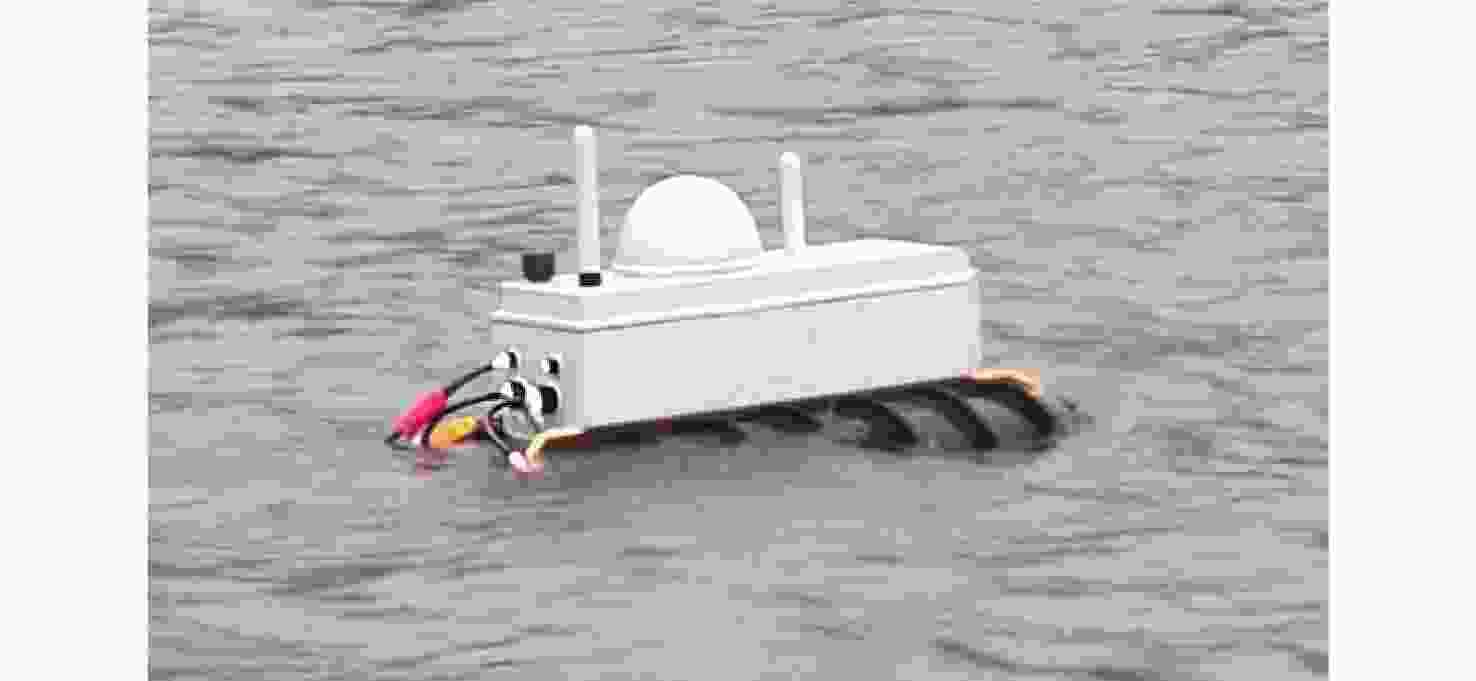

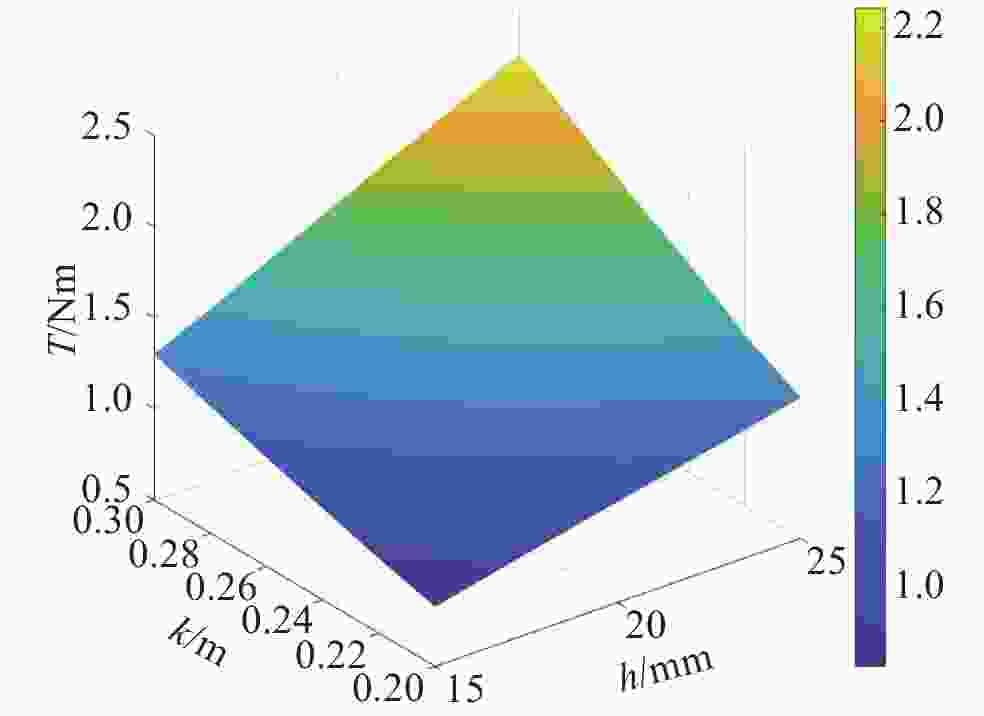

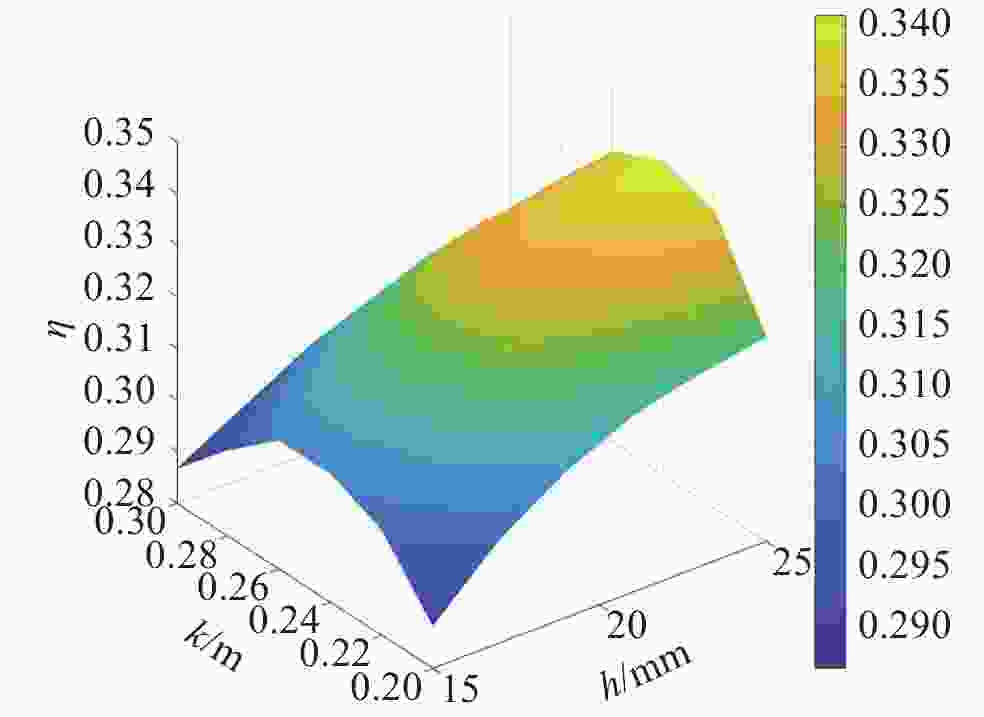

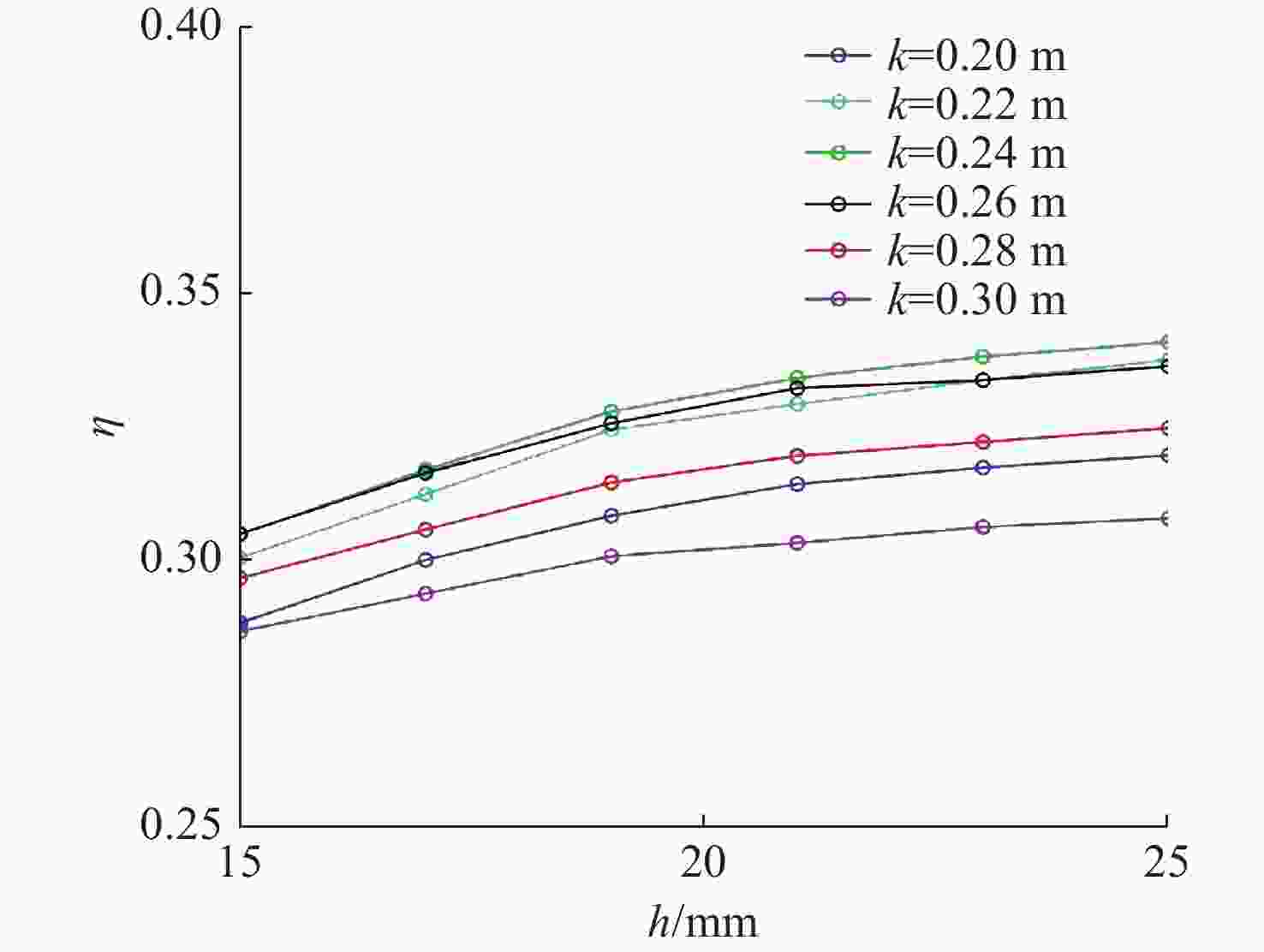

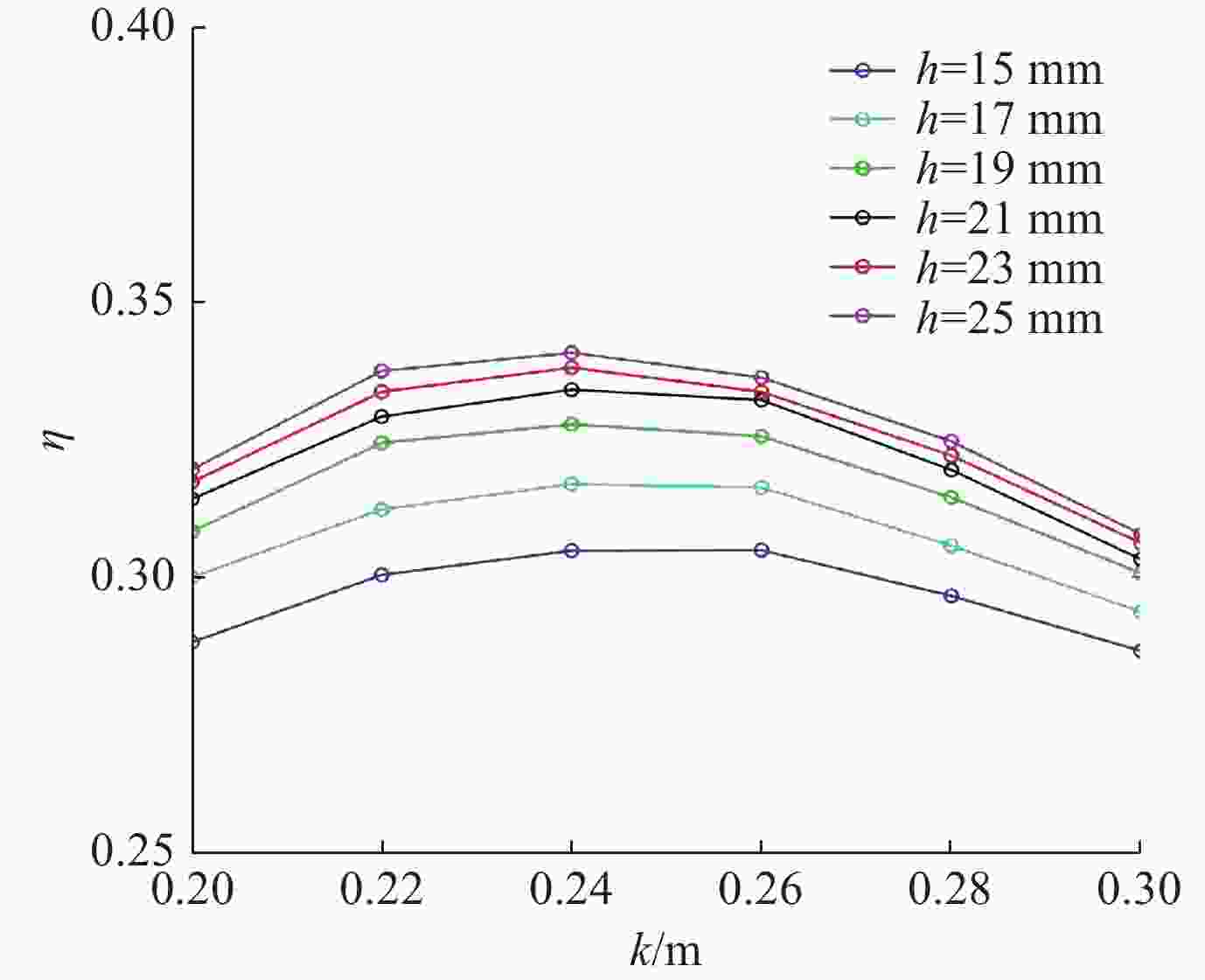

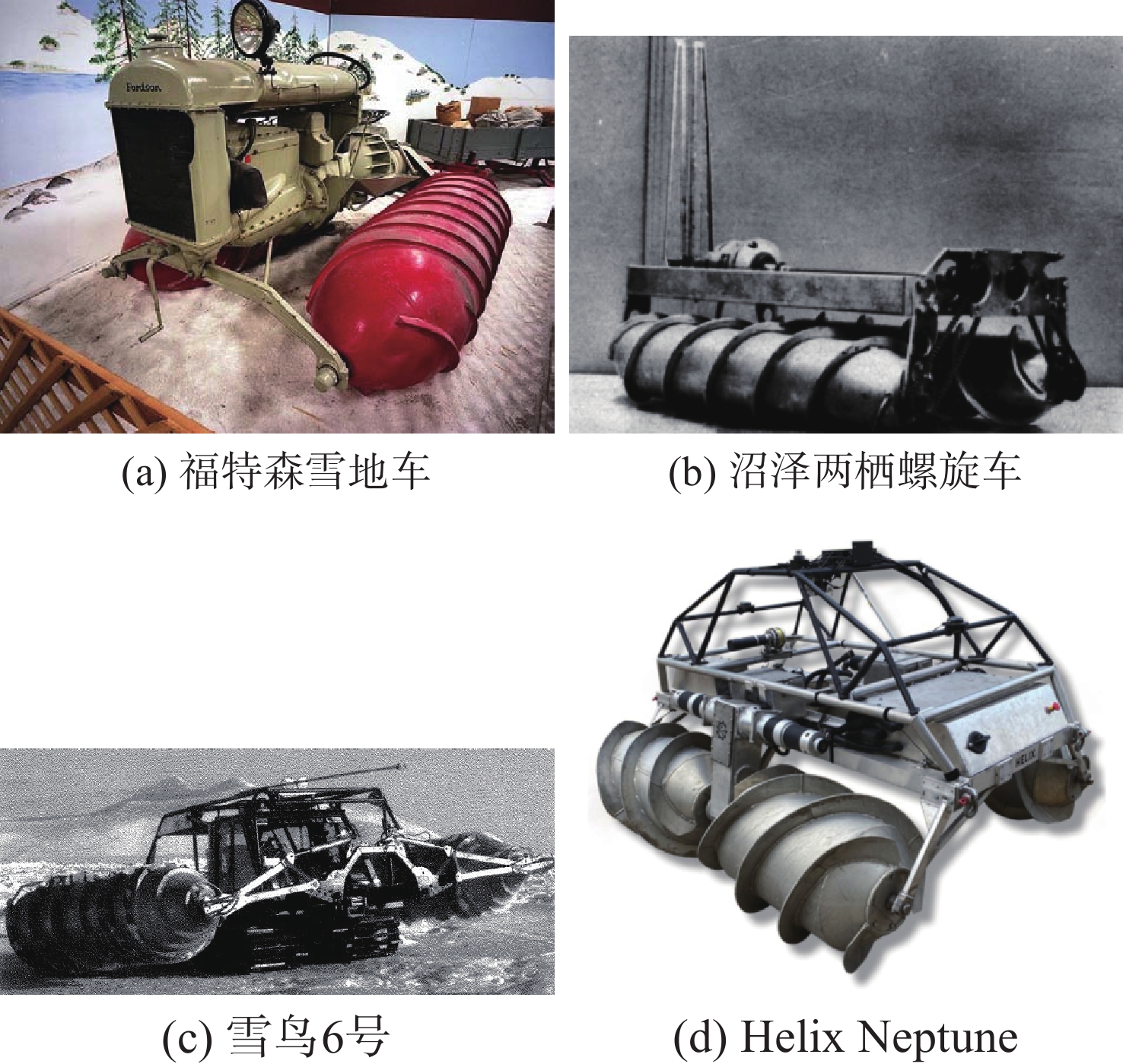

摘要: 传统水陆两栖运动方式多为轮式或履带式与螺旋桨结合的双系统形态。与之相比, 单系统的水陆两栖运动方式因系统复杂度低、运动效率高成为近年来的研究热点。螺旋推进作为一种单系统水陆两栖运动方式, 在沼泽、滩涂等半流体环境下具有较好的适应性, 多年来对其在陆上行驶的研究设计较多, 对其在水中行驶的研究较为缺乏。文中对螺旋推进装置的水中性能展开研究, 根据螺旋推进的原理, 提出螺旋筒的设计方法, 采用水动力仿真方法对不同浸没深度下的螺旋筒进行推力计算, 发现螺旋筒在0.9倍浸没深度时产生的推力最大。基于自主设计研发的水陆两栖机器人样机开展水中推进测试, 结果表明在水中螺旋筒推进状态稳定。进一步的, 使用响应面法从螺旋叶片高度、螺距2个方面对螺旋筒开展优化设计工作, 优化结果较原设计方案可提升18.2%的推进效率。Abstract: The traditional amphibious locomotion mode mainly features the dual system of wheel or track combined with a propeller. In contrast, single-system amphibious locomotion mode has become a research hotspot in recent years because of its low system complexity and high efficiency. As a single-system amphibious locomotion mode, screw propulsion has good adaptability in semi-fluid environments such as swamp and mud flat. Over the years, there have been many research designs on its driving on land, but few studies on its driving in water. In this paper, the underwater performance of the screw propulsion device was studied, and the design method of the screw cylinder was proposed according to the principle of screw propulsion. The hydrodynamic simulation method was used to calculate the thrust of the screw cylinder at different submerged depths, and it was found that the thrust generated by the screw cylinder was the largest at 0.9 times the submerged depth. Based on the self-designed and developed amphibious robot prototype, the underwater propulsion test was carried out, and the results show that the underwater screw cylinder propulsion state is stable. In addition, the response surface method is used to optimize the design of the screw cylinder from the two aspects of screw blade height and pitch, and the optimization results can increase the propulsion efficiency by 18.2% compared with the original design scheme.

-

Key words:

- amphibious robot /

- screw propulsion /

- underwater performance /

- hydrodynamic simulation

-

表 1 不同浸没深度下螺旋筒水动力计算结果

Table 1. Hydrodynamic calculation results of screw cylinder under different submerged depths

浸没深度

(基于螺旋筒直径)浮力/N 推力/N 0.5倍 38.455 0.887 0.6倍 46.146 1.034 0.7倍 53.837 1.363 0.8倍 61.528 1.443 0.9倍 69.219 1.863 1.0倍 76.910 0.781 1.1倍 76.910 1.032 1.2倍 76.910 1.208 表 2 样机相关参数

Table 2. Relevant parameters of the prototype

参数 值 长/mm 760 宽/mm 470 高/mm 460 总重/kg 13.5 螺距/m 0.2 螺旋筒长/mm 600 螺旋叶片厚度/mm 10 螺旋叶片高度/mm 15 螺旋筒直径/mm 134 最大螺旋筒外径/mm 164 表 3 电子舱硬件仪器型号

Table 3. Type of hardware instrument in the electronics bay

设备 型号 电池 18650 电机 M3508 P19 Brushless DC GNSS ZYSPR-F703 无线数字数据链 DDL-MH 交换机 LX-IS501-1 PC104 SCM9022 运动控制器 STM32F429 IMU ELLIPSE2-A-G4A3-B1 表 4 螺旋筒优化设计计算结果

Table 4. The calculation results of optimal design of screw cylinder

叶片高度/mm 螺距/m 推力/N 速度/(m/s) 扭矩/Nm 推进效率 15 0.20 10.003 1 1.001 4 0.829 6 0.288 3 15 0.22 11.125 5 1.032 5 0.912 6 0.300 5 15 0.24 12.188 5 1.051 1 1.003 0 0.304 9 15 0.26 13.256 3 1.059 0 1.098 9 0.305 0 15 0.28 14.115 5 1.053 3 1.196 4 0.296 7 15 0.30 14.891 6 1.048 6 1.300 1 0.286 7 17 0.20 11.603 9 0.998 9 0.922 2 0.300 1 17 0.22 12.951 4 1.031 5 1.020 9 0.312 4 17 0.24 14.322 0 1.050 0 1.132 6 0.317 0 17 0.26 15.584 6 1.060 1 1.246 7 0.316 4 17 0.28 16.510 9 1.056 4 1.361 7 0.305 8 17 0.30 17.372 6 1.049 3 1.481 3 0.293 8 19 0.20 13.140 1 0.993 6 1.010 6 0.308 4 19 0.22 14.875 0 1.028 9 1.126 0 0.324 5 19 0.24 16.531 4 1.049 2 1.262 9 0.327 9 19 0.26 18.032 0 1.060 7 1.401 8 0.325 7 19 0.28 19.094 5 1.061 9 1.538 7 0.314 6 19 0.30 20.044 2 1.056 1 1.680 0 0.300 8 21 0.20 14.743 0 0.981 4 1.099 0 0.314 3 21 0.22 16.582 1 1.020 8 1.227 0 0.329 3 21 0.24 18.675 9 1.043 6 1.392 2 0.334 2 21 0.26 20.224 5 1.062 9 1.544 3 0.332 3 21 0.28 21.491 7 1.064 0 1.708 2 0.319 6 21 0.30 22.545 4 1.055 1 1.872 4 0.303 3 23 0.20 16.220 8 0.970 3 1.183 7 0.317 4 23 0.22 18.370 8 1.012 5 1.330 2 0.333 8 23 0.24 20.601 1 1.038 5 1.510 3 0.338 2 23 0.26 22.274 9 1.057 8 1.685 1 0.333 8 23 0.28 23.778 9 1.062 2 1.871 5 0.322 2 23 0.30 24.898 2 1.059 6 2.056 3 0.306 3 25 0.20 17.810 4 0.958 3 1.274 7 0.319 7 25 0.22 20.224 8 1.004 4 1.436 6 0.337 6 25 0.24 22.815 2 1.029 5 1.644 8 0.340 9 25 0.26 24.557 1 1.049 8 1.829 8 0.336 4 25 0.28 26.212 9 1.055 7 2.034 1 0.324 8 25 0.30 27.478 1 1.053 3 2.244 0 0.307 9 表 5 优化设计结果

Table 5. Results of optimized design

参数 h/mm k/m η 原设计值 15 0.20 0.288 3 优化设计结果 25 0.24 0.340 9 相对变化率/% 66.7 20.0 18.2 -

[1] BAINES R, PATIBALLA S K, BOOTH J, et al. Multi-environment robotic transitions through adaptive morphogenesis[J]. Nature, 2022, 610(7931): 283-289. doi: 10.1038/s41586-022-05188-w [2] YU S, MA S, LI B, et al. An amphibious snake-like robot with terrestrial and aquatic gaits[C]//2011 IEEE International Conference on Robotics and Automation. Shanghai, China: IEEE, 2011: 2960-2961. [3] MA X, WANG G, LIU K. Design and optimization of a multimode amphibious robot with propeller-leg[J]. IEEE Transactions on Robotics, 2022, 38(6): 3807-3820. doi: 10.1109/TRO.2022.3182880 [4] ZENG Y, HU Q, YIN S, et al. The ground motion dynamics analysis of a bionic amphibious robot with undulatory fins[C]//2021 IEEE International Conference on Real-time Computing and Robotics(RCAR). Xining, China: IEEE, 2021: 1385-1390. [5] NEUMEYER M J, JONES B D. The marsh screw amphibian[J]. Journal of Terramechanics, 1965, 2(4): 83-88. doi: 10.1016/0022-4898(65)90133-3 [6] MAGAZINE T. Snow motors[EB/OL]. [2023-12-21]. http://conten-t.time.com/time/magazine/0,9263,7601260104,00.html. [7] DUGOFF H, EHLICH I R. Model tests of bouyant screw rotor configurations[J]. Journal of Terramechanics, 1967, 4(3): 9-22. doi: 10.1016/0022-4898(67)90123-1 [8] VILLACRÉS J, BARCZYK M, LIPSETT M. Literature review on archimedean screw propulsion for off-road vehicles[J]. Journal of Terramechanics, 2023, 108: 47-57. doi: 10.1016/j.jterra.2023.05.001 [9] 陈本灶. 基于螺旋推进的平粮机器人结构设计及仿真优化[D]. 杭州: 杭州电子科技大学, 2023. [10] 林吉照. 螺旋驱动式平粮机器人姿态控制及系统设计[D]. 长春: 吉林大学, 2023. [11] 王福军. 计算流体动力学分析: CFD 软件原理与应用[M]. 北京: 清华大学出版社有限公司, 2004. [12] MENTER F R. Two-equation eddy-viscosity turbulence models for engineering applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. doi: 10.2514/3.12149 [13] 李晓东, 吴乘胜, 王星. 船舶航行兴波CFD模拟的代数型VOF方法研究[J]. 水动力学研究与进展A辑, 2022, 37(2): 252-261.LI X D, WU C S, WANG X. Ship wave CFD simulation of algebraic model VOF method research[J]. Water Dynamics Research and Progress in A Series, 2022, 37(2): 252-261. [14] BOX G E P, WILSON K B. On the experimental attainment of optimum conditions[M]//Breakthroughs in statistics: Methodology and distribution. New York: Springer, 1992: 270-310. [15] 隋允康, 宇慧平. 响应面方法的改进及其对工程优化的应用[M]. 北京: 科学出版社, 2011. [16] 秦玉峰, 孙秀军, 林兴华, 等. 水下滑翔机低速螺旋桨的推进效率[J]. 解放军理工大学学报(自然科学版), 2017, 18(1): 61-67.QIN Y F, SUN X J, LIN X H, et al. Propulsion efficiency of low speed propeller of underwater glider[J]. Journal of PLA University of Science and Technology(Natural Science Edition), 2017, 18(1): 61-67. -

下载:

下载: