Research on Temperature Adaptability of Special Buffer Oil Cylinders

-

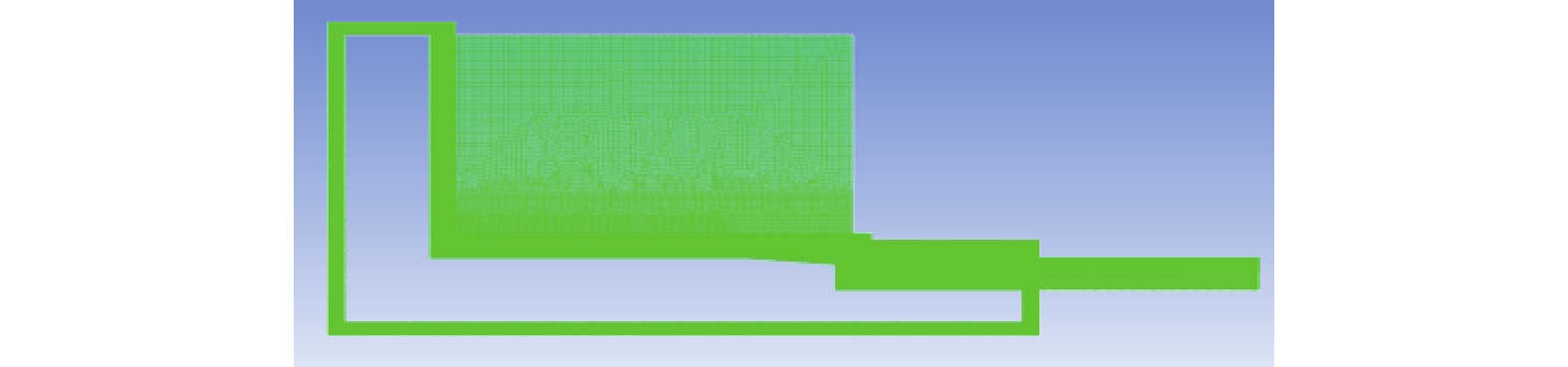

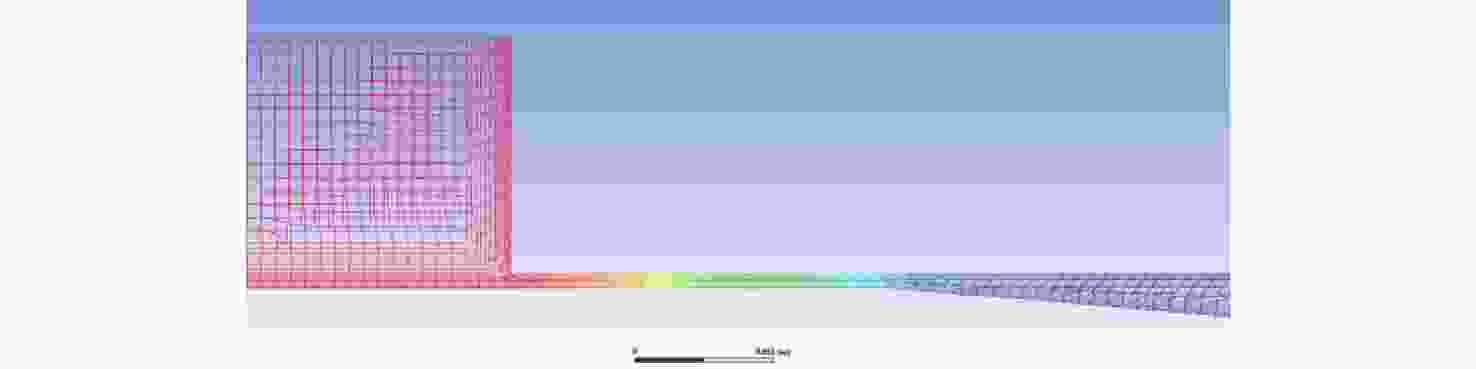

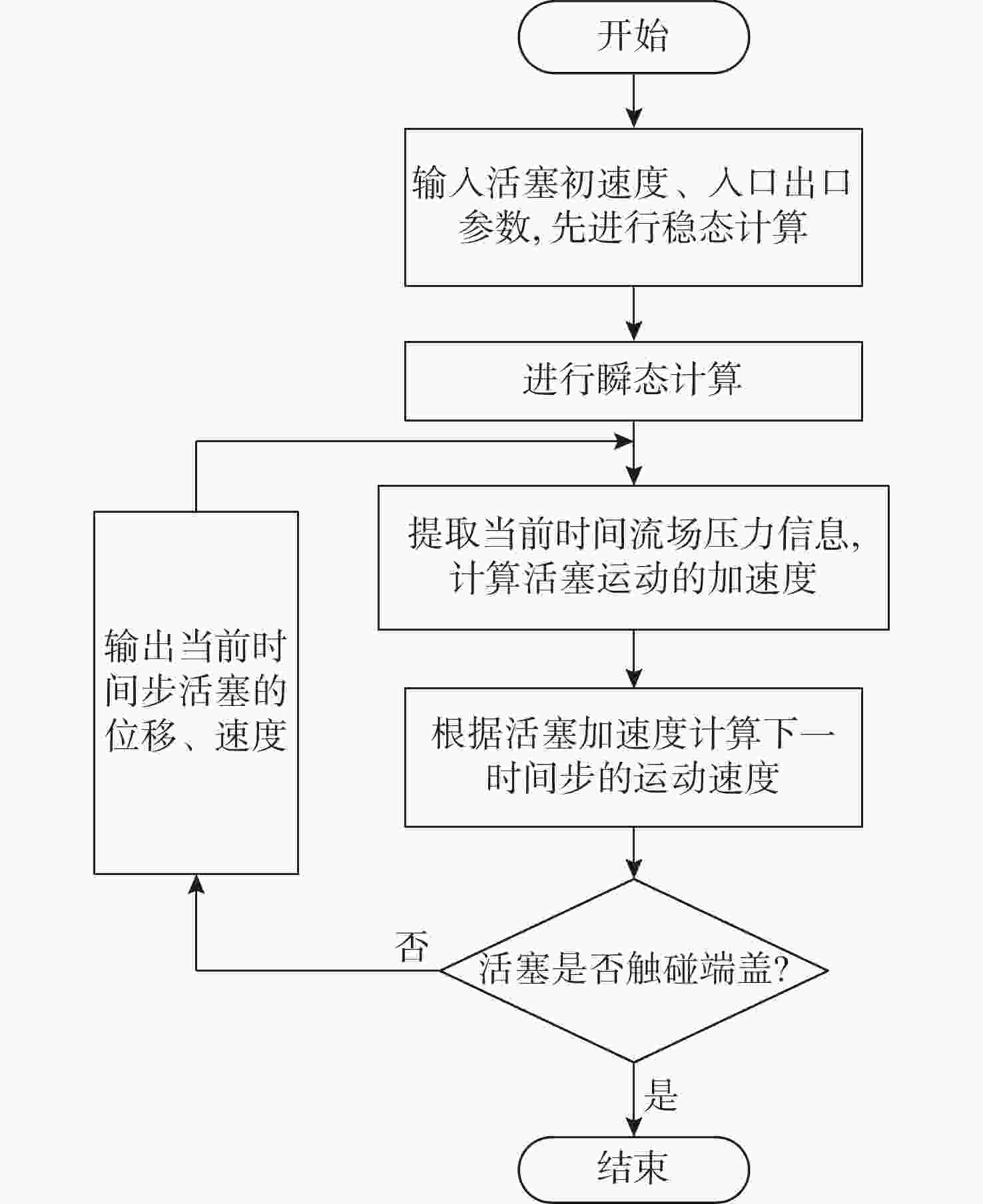

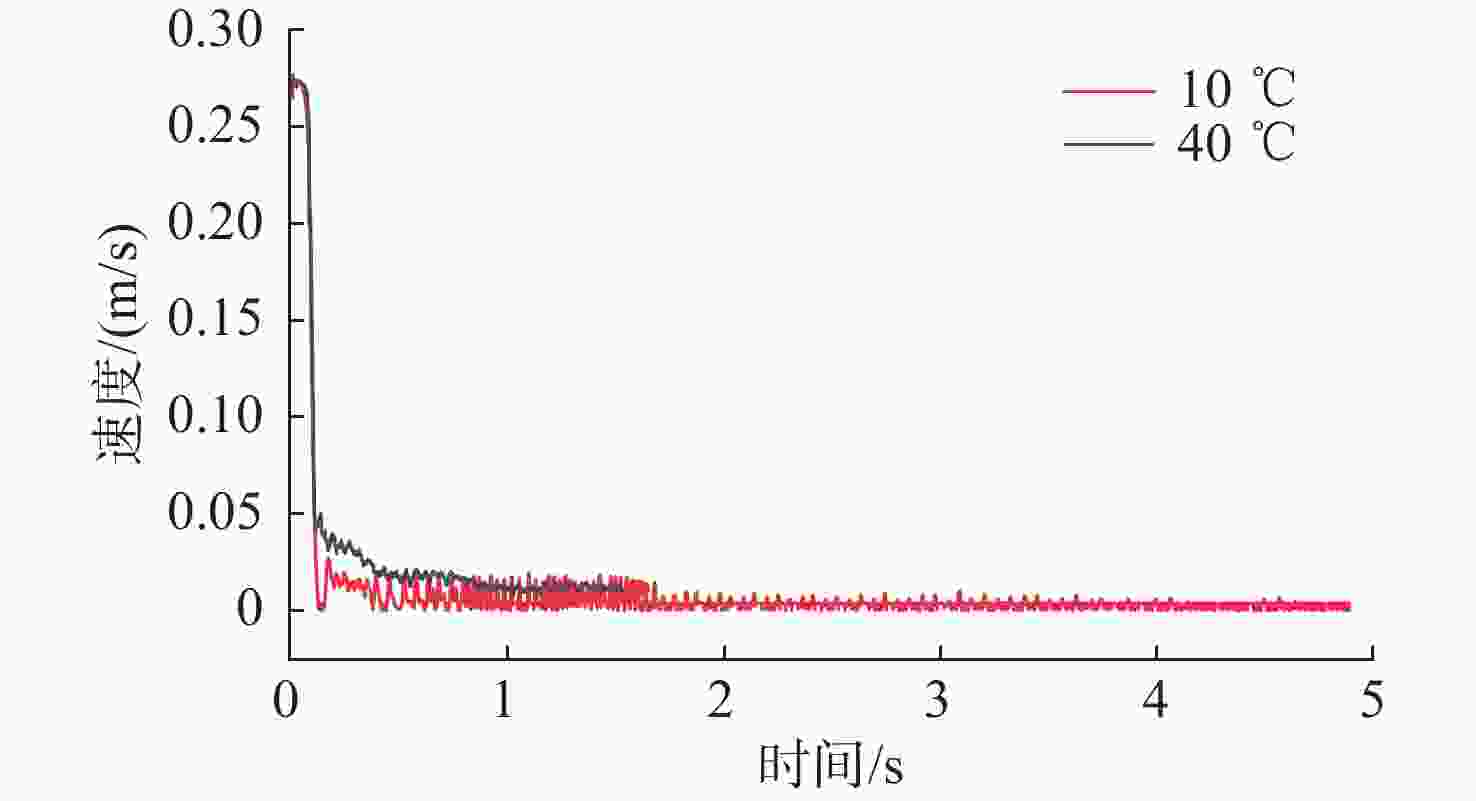

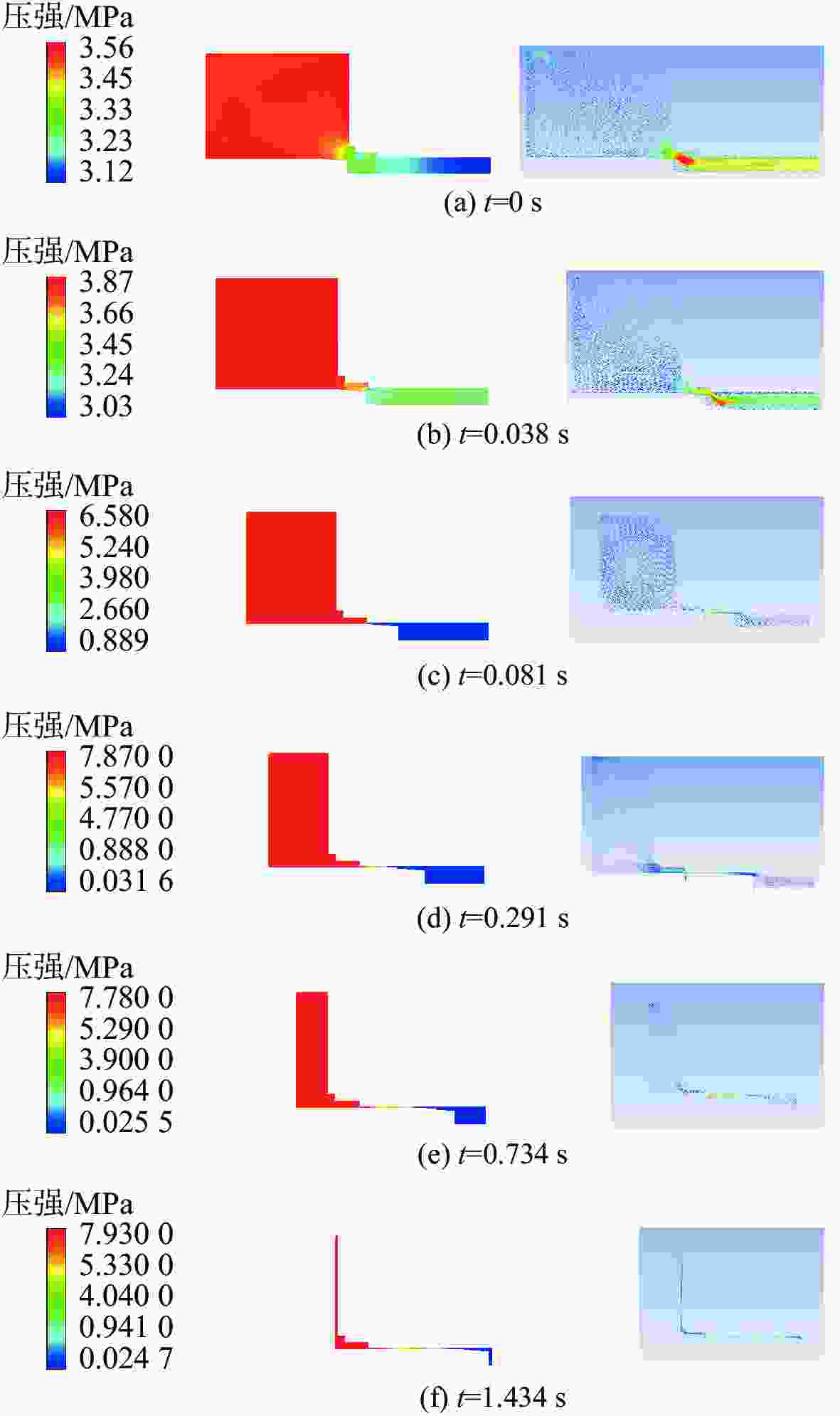

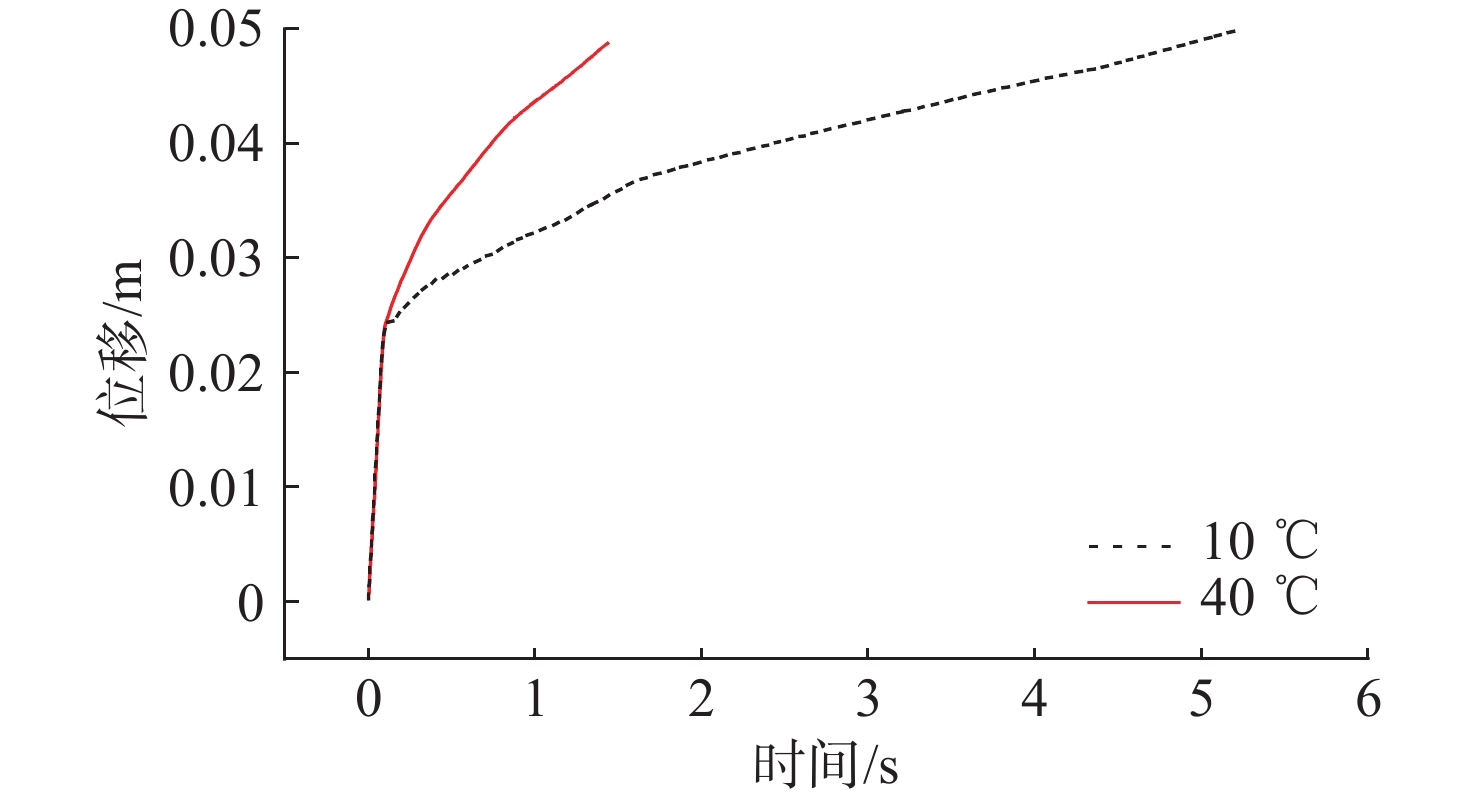

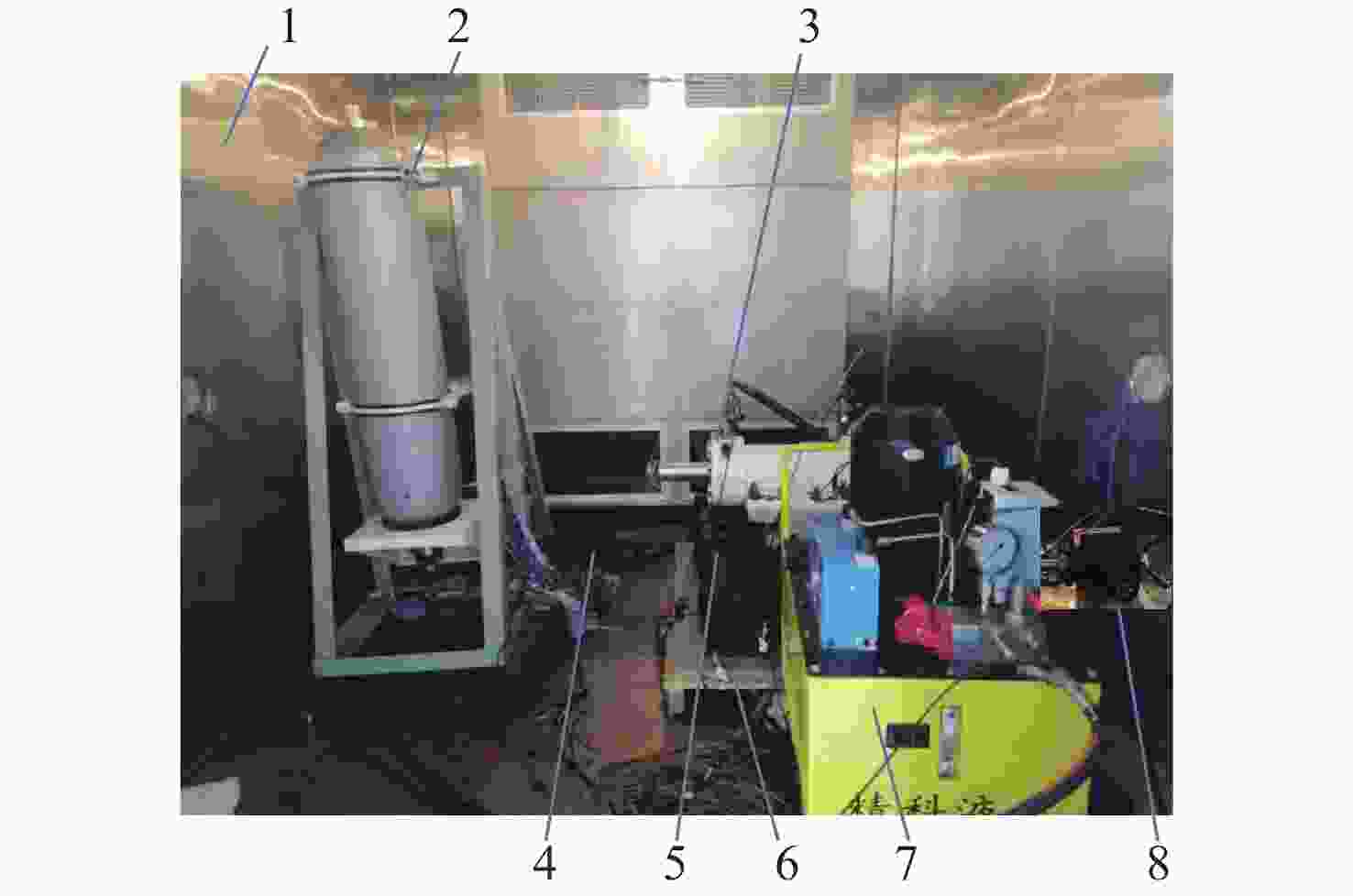

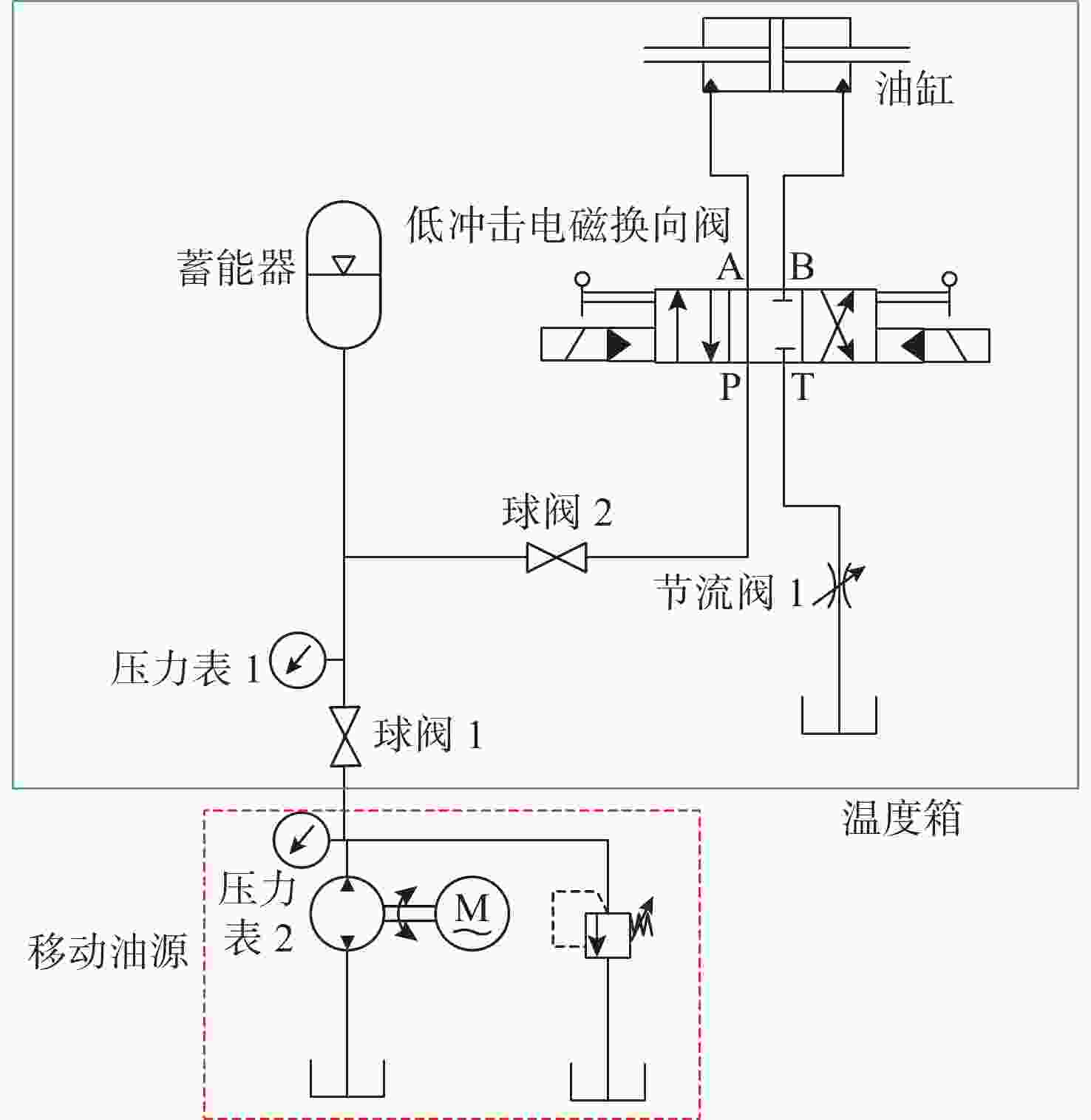

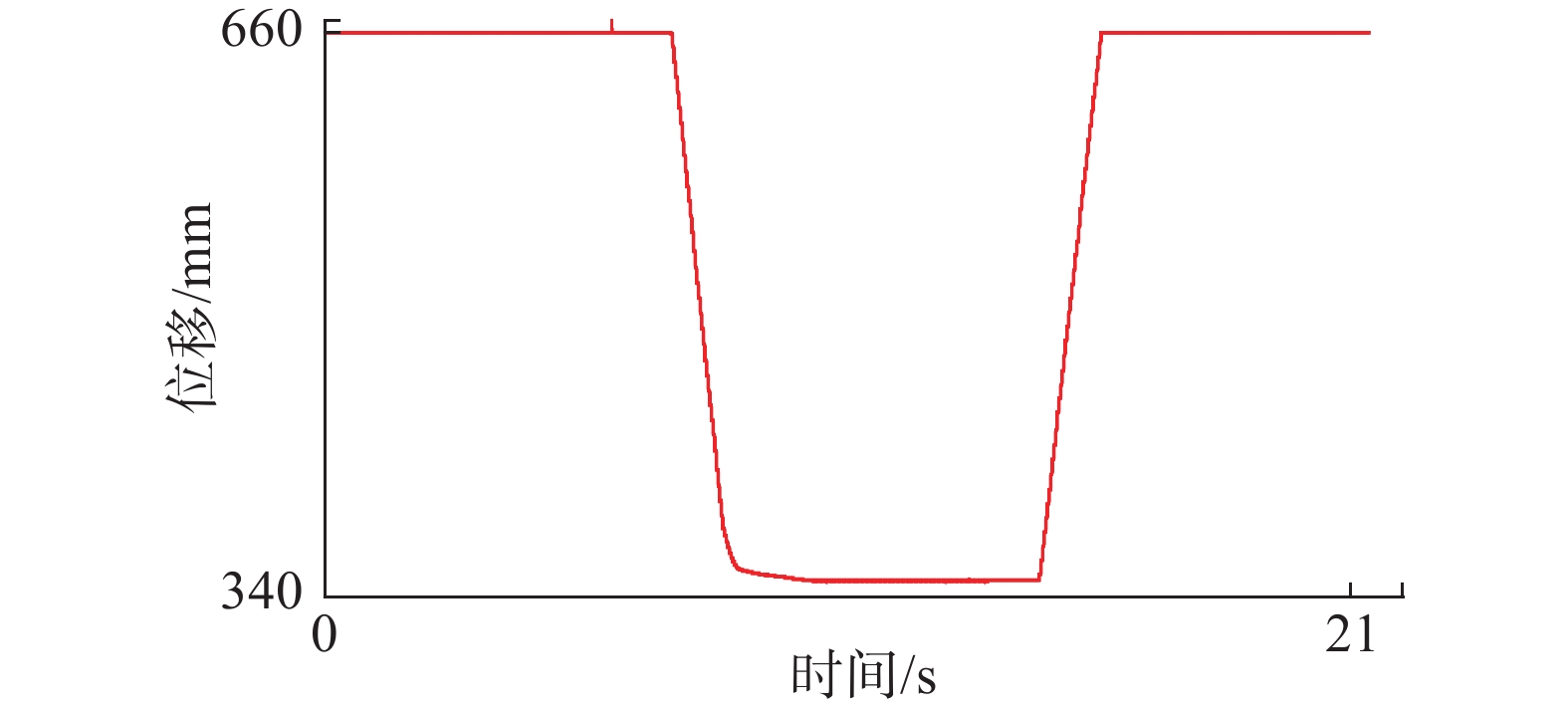

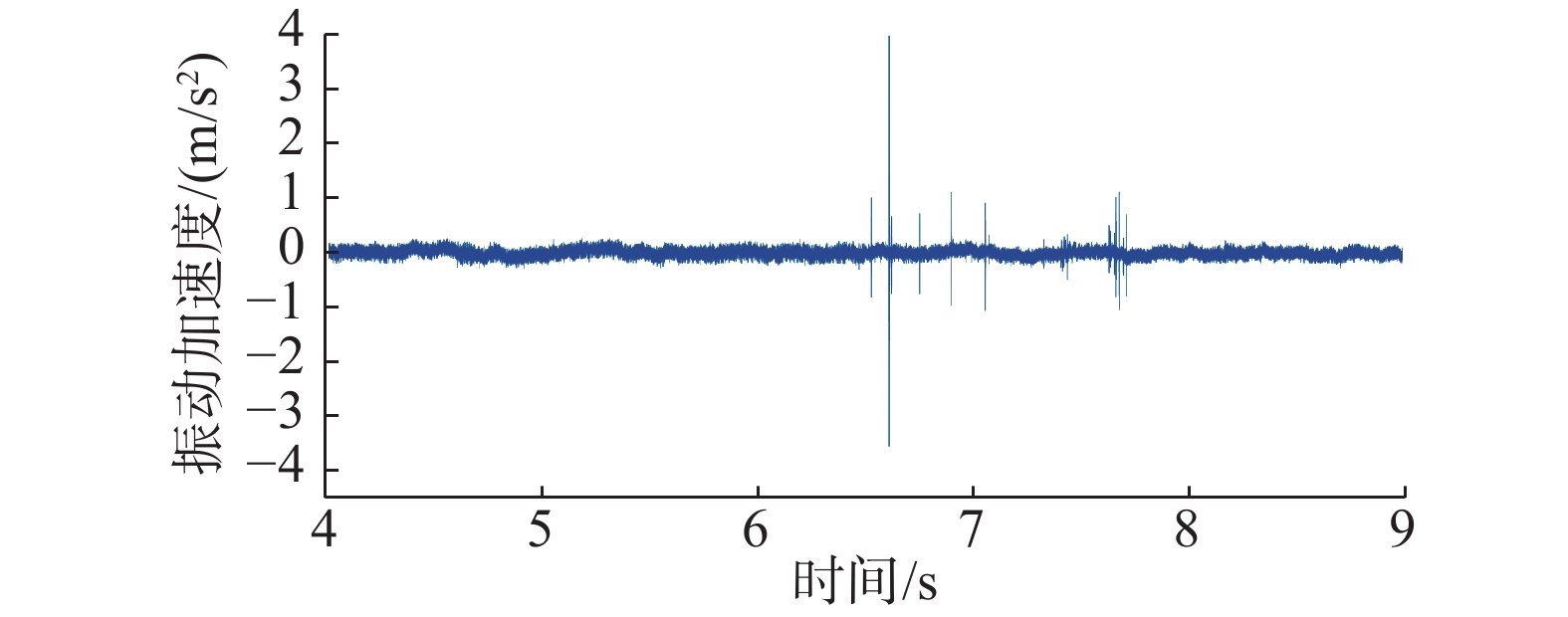

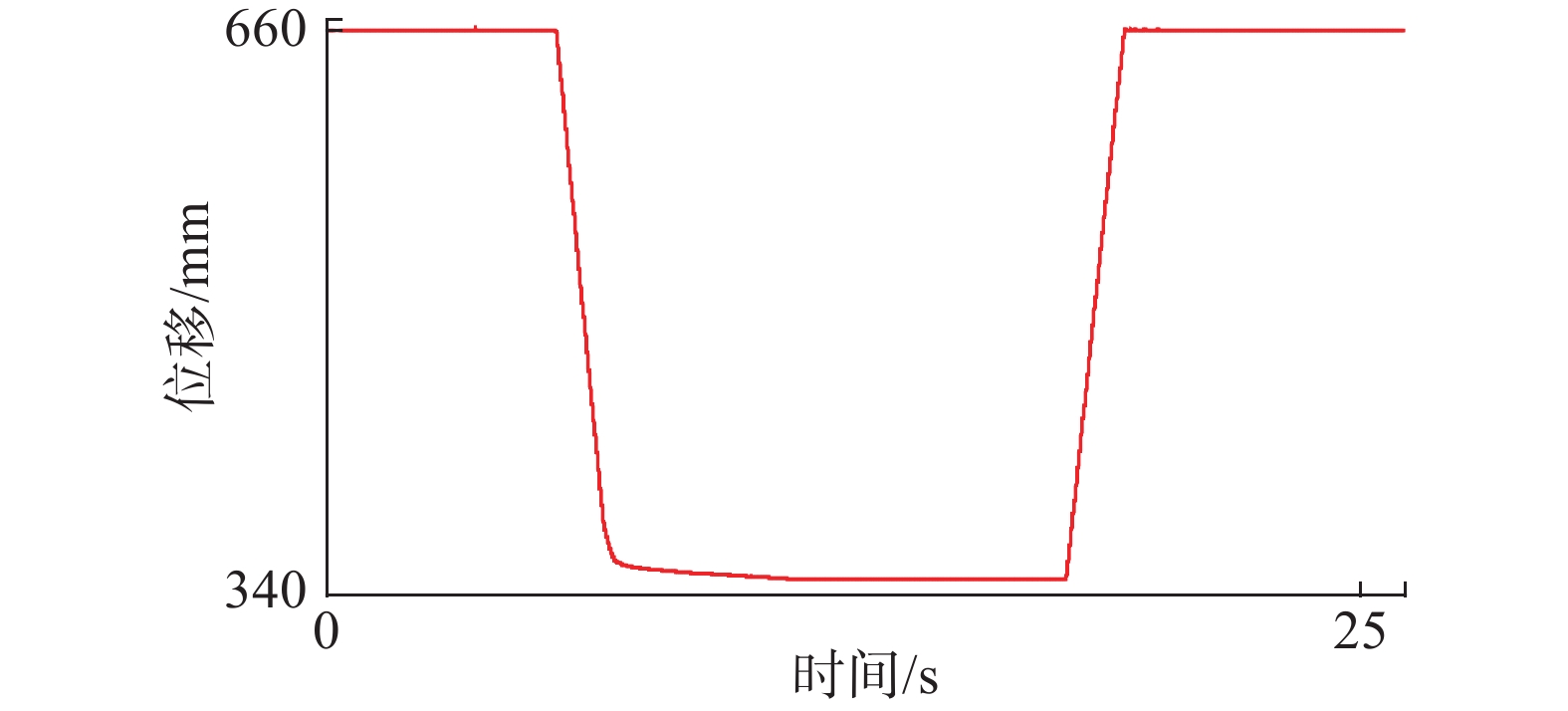

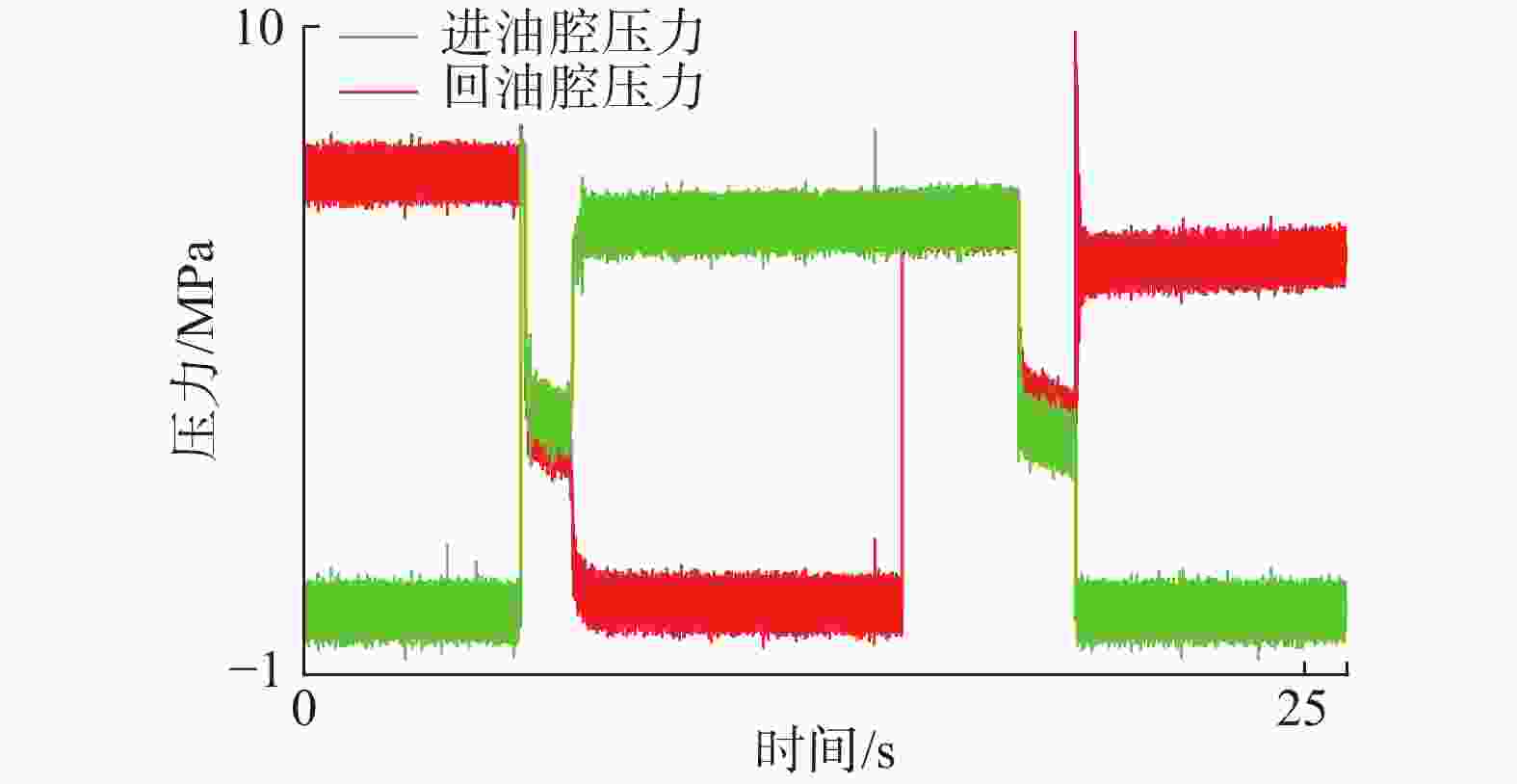

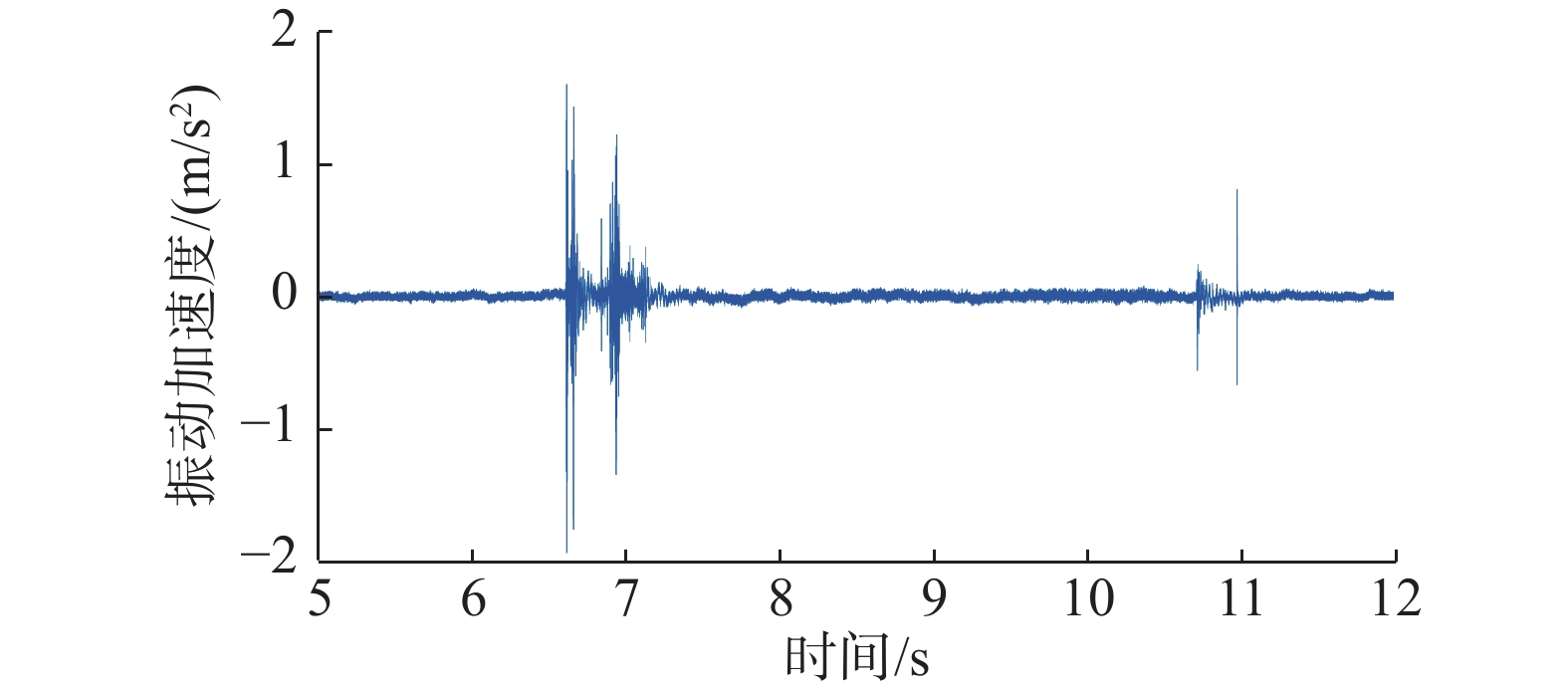

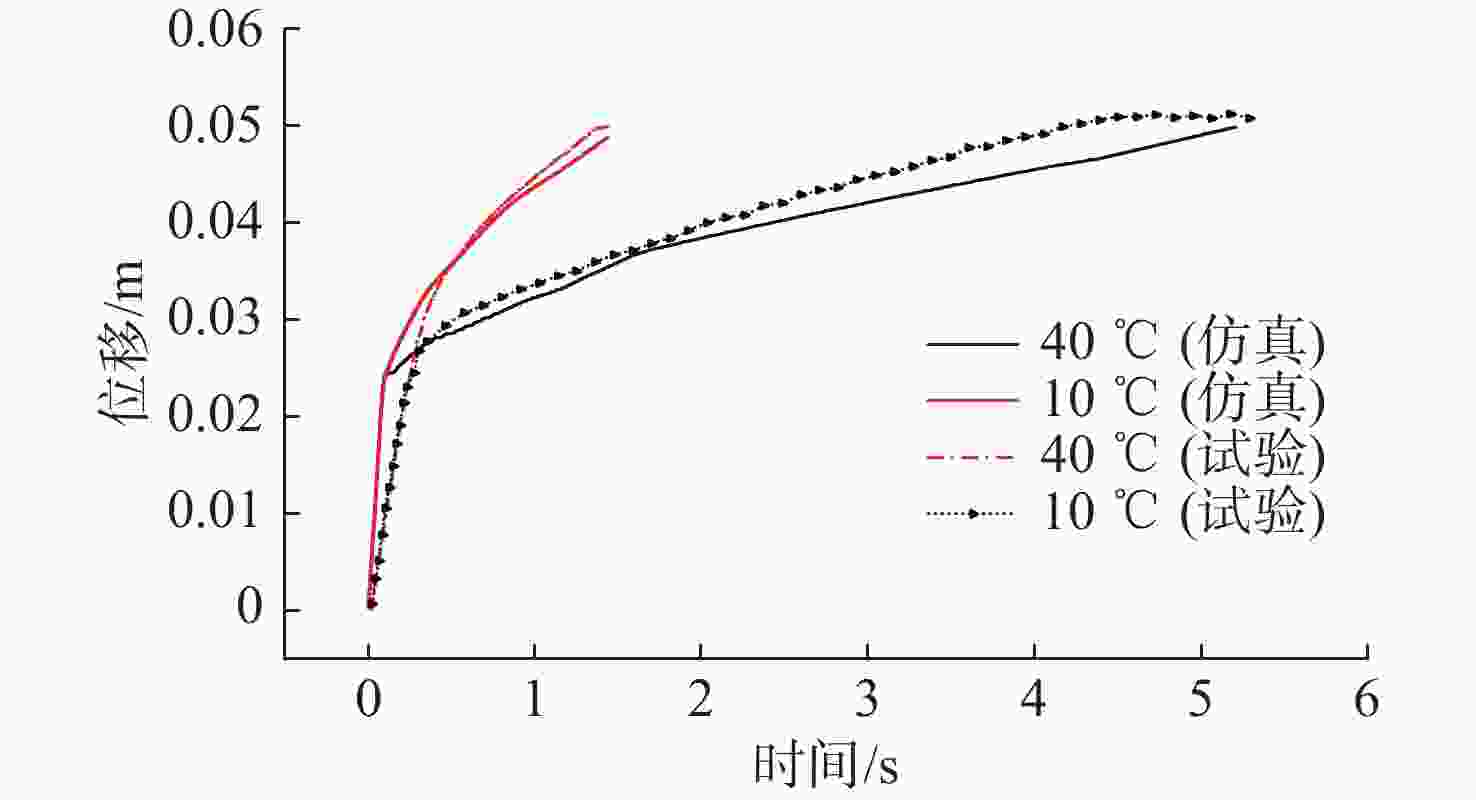

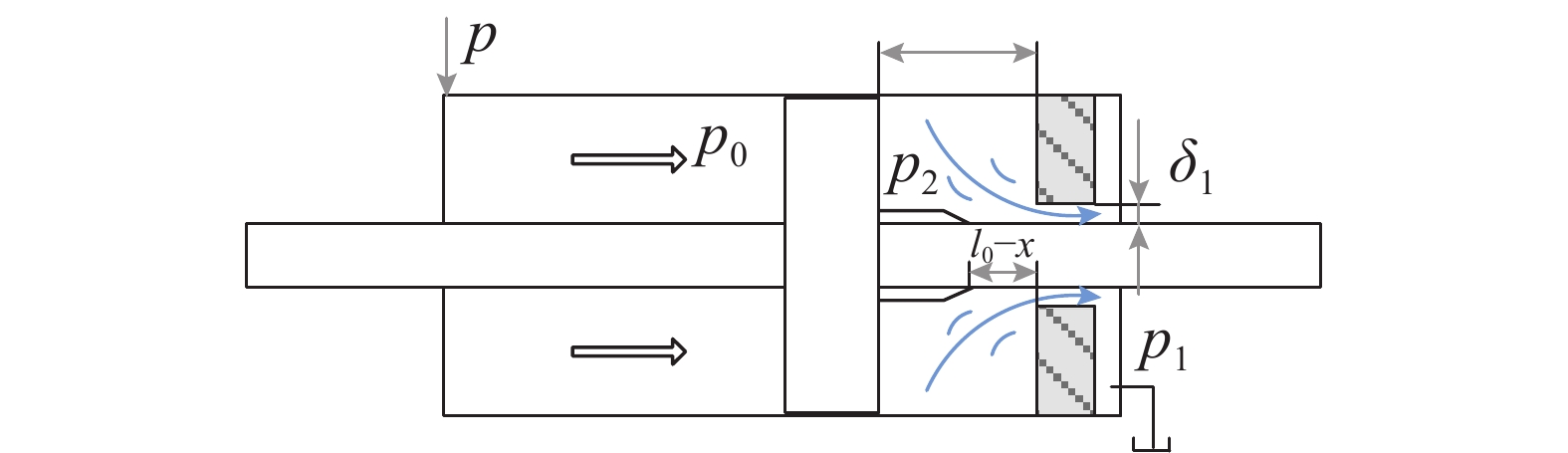

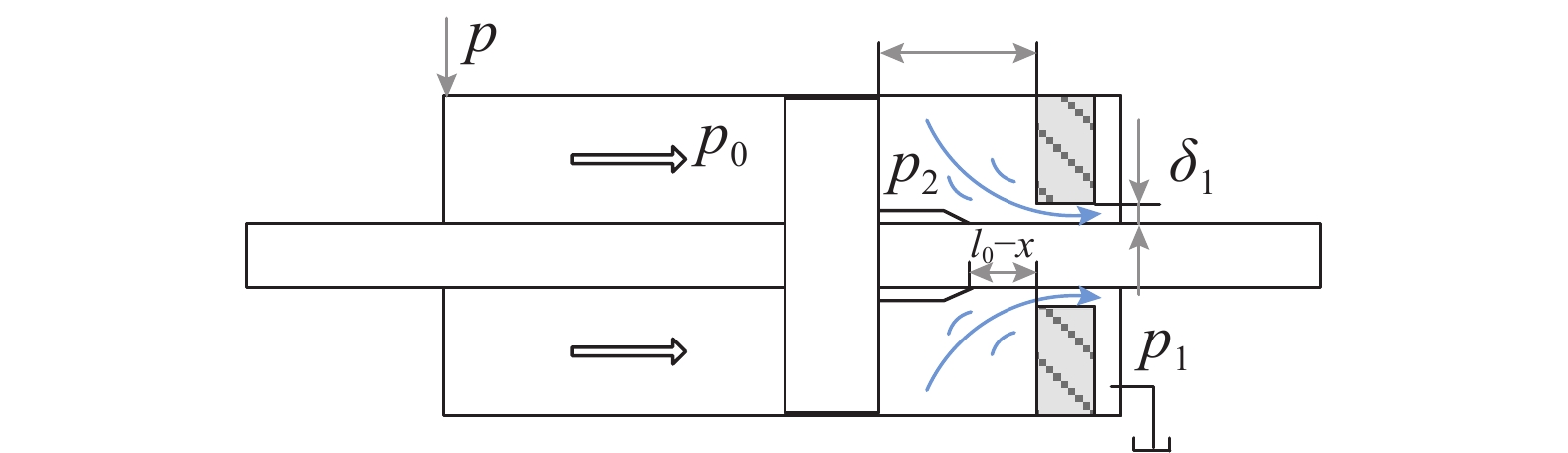

摘要: 在进行水中兵器减振降噪的研究过程中, 发现作为其重要传动部件的特种缓冲油缸是主要噪声源之一, 因此特种缓冲油缸的缓冲装置设计尤为重要, 而对缓冲效果的预测是缓冲设计的核心问题。由于特种缓冲油缸工作情况的特殊性, 其大多数时间都处于待机状态, 当间隔很长时间后启动时, 缓冲腔内的液压油温度等于所处安装环境温度, 一次启动和后续启动之间缓冲腔内的液压油会有较大的温差。为了保证在极端温度条件下也能满足工作要求, 需对特种缓冲油缸进行温度适应性研究。文中首先建立了特种油缸运动过程的数学模型, 在油液极端温度10±2 ℃、40±2 ℃, 供油压力7.5±0.2 MPa条件下, 利用Fluent软件进行了流场数值仿真。然后在大型温度箱中进行了温度适应性试验, 分别检测了2个极端温度条件下特种缓冲油缸的全行程运动时间和振动加速度级等参数。经对比发现, 试验结果与理论分析相近, 符合相应指标要求, 可为特种缓冲油缸的设计和减振降噪提供参考。Abstract: During the research on vibration and noise reduction of underwater weapons, it was found that the special buffer oil cylinder, as an important transmission component, is one of the main sources of noise. Therefore, the design of the buffer device for the special buffer oil cylinder is important, and the prediction of the buffer effect is the core of the buffer design. Due to the special working conditions, special buffer oil cylinders are mostly in standby mode. When a startup is started after a long interval, the hydraulic oil temperature in the buffer chamber is equal to the installation environment temperature. There will be a large temperature difference in the hydraulic oil in the buffer chamber between the first startup and subsequent startups. In order to ensure that the working requirements can be met even under extreme temperature conditions, temperature adaptability research needs to be conducted on the special buffer oil cylinders. Firstly, a mathematical model of the motion process of a special oil cylinder was established. Under extreme oil temperatures of 10±2 °C and 40±2 °C and oil supply pressure of 7.5±0.2 MPa, the flow field was numerically simulated using Fluent. Then, temperature adaptability tests were conducted in a large temperature box, and the full stroke motion time, vibration acceleration level, and other parameters of the special buffer oil cylinders were tested under two extreme temperature conditions. Finally, it was found through comparison that the experimental results were similar to the theoretical analysis and met the corresponding indicator requirements, which can provide a reference for the design and vibration and noise reduction of special buffer oil cylinders in the future.

-

表 1 缓冲间隙内网格层数变化下的网格总数和流量相对变化率

Table 1. The total number of meshes and the relative change rate of flow under changes in the number of mesh layers within the buffer gap

网格层数 网格总数 流量相对变化率/% 6 83 763 4.3 7 118 971 3.0 8 197 282 1.9 9 319 614 1.5 10 481 302 1.3 11 833 875 1.2 表 2 不同温度下特种缓冲油缸缓冲性能

Table 2. Cushioning performance of special buffer oil cylinders at different temperatures

温度/℃ 缓冲时间/s 活塞杆到位时

速度/(m/s)速度衰减/% 40 1.534 0.010 96.30 10 4.892 0.005 98.15 表 3 测点布置说明

Table 3. Instructions of the test point layout

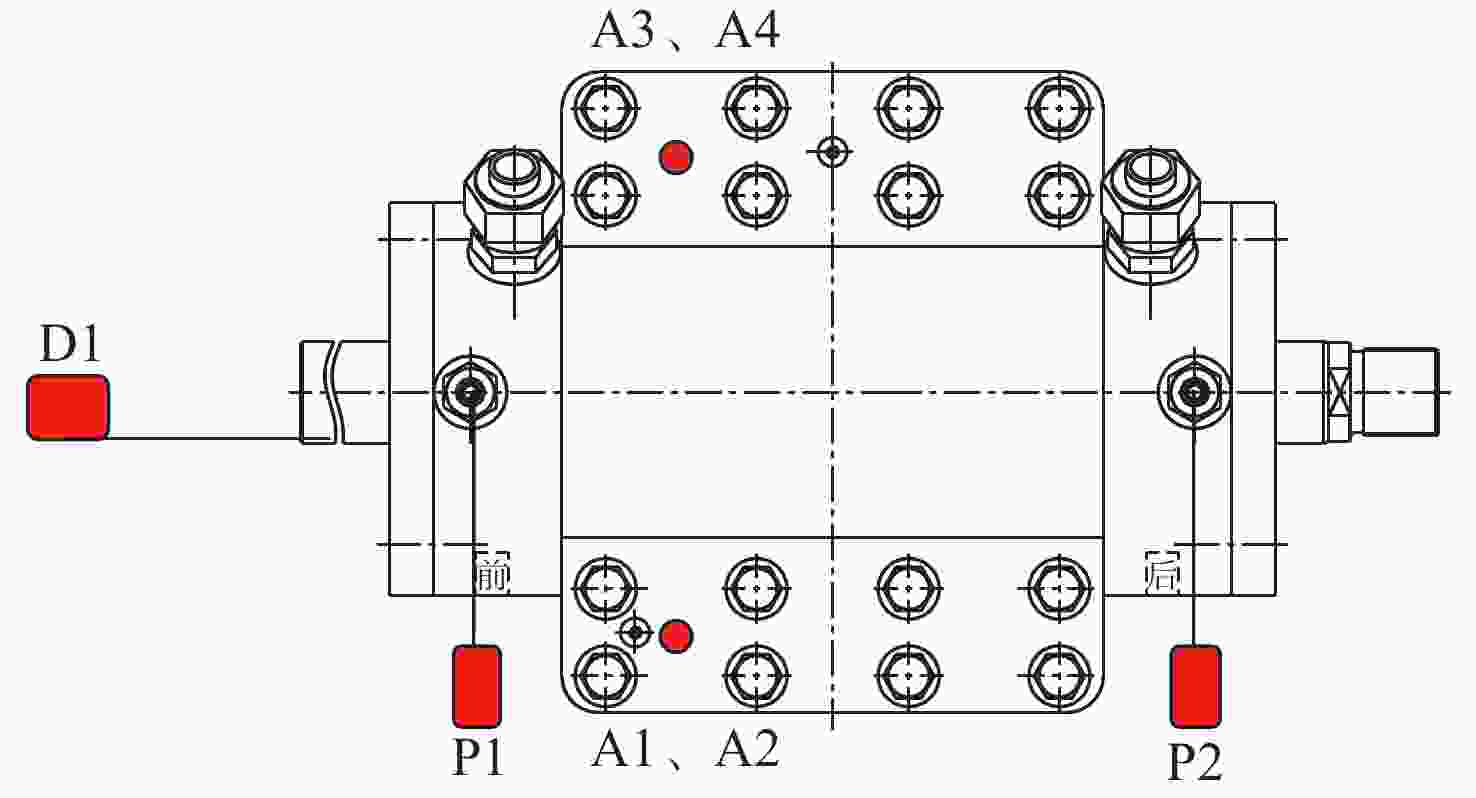

编号 位置描述 方向 检测物理量 A1 油缸机脚左前端 轴向 振动加速度 A2 油缸机脚左前端 垂向 振动加速度 A3 油缸机脚右前端 轴向 振动加速度 A4 油缸机脚右前端 垂向 振动加速度 D1 活塞杆前端 轴向 活塞杆位移 P1 油缸前端油口 油压 P2 油缸前端油口 油压 表 4 缓冲阶段振动加速度级

Table 4. Vibration acceleration level during buffering stage

测点编号 振动加速度级/dB 差值 /dB 高温40 ℃ 低温10 ℃ A1 125.4 119.6 5.8 A2 118.7 110.4 8.3 A3 124.3 121.0 3.3 A4 115.6 111.9 3.7 表 5 试验与仿真缓冲时间结果对比

Table 5. Comparison of buffer time results between experiments and simulations

温度/℃ 仿真结果/s 试验结果/s 差值/s 40 1.534 1.69 0.156 10 4.892 4.68 0.212 -

[1] 丁凡, 路甬祥. 短笛型缓冲结构的高速液压缸缓冲过程的研究[J]. 中国机械工程, 1998, 9(10): 58-60. [2] 武晓凤, 赵秋霞, 姚平喜. 液压缸复合缓冲结构及缓冲过程的分析[J]. 液压与气动, 2013(3): 23-26. doi: 10.3969/j.issn.1000-4858.2013.03.006Wu Xiaofeng, Zhao Qiuxia, Yao Pingxi. The analysis of composite buffer structure of the hydraulic cylinder and buffering process[J]. Chinese Hydraulics & Pneumatics, 2013(3): 23-26. doi: 10.3969/j.issn.1000-4858.2013.03.006 [3] 李纪仁. 油缸的缓冲装置[J]. 机械技术, 1984(3): 21-23. [4] 李进, 张叶军, 丁能超, 等. 潜艇密闭环境下主要微生物分布及抗菌药物敏感性比较分析[J]. 军事医学, 2017, 41(4): 322-324. [5] 杨理华, 张骁, 张翔鹏, 等. 潜艇舱室环境噪声危害及治理进展研究[J]. 舰船科学技术, 2022, 44(12): 1-5. doi: 10.3404/j.issn.1672-7649.2022.12.001Yang Lihua, Zhang Xiao, Zhang Xiangpeng, et al. Research on environmental noise hazards and control progress in submarine cabins[J]. Ship Science and Technology, 2022, 44(12): 1-5. doi: 10.3404/j.issn.1672-7649.2022.12.001 [6] 潘绪文, 李宝仁, 杨钢, 等. 基于遗传算法的旋塞阀液压缸缓冲优化研究[J]. 液压与气动, 2015(9): 6-9. doi: 10.11832/j.issn.1000-4858.2015.09.002Pan Xuwen, Li Baoren, Yang Gang, et al. Optimization based on genetic algorithm for cushioning of four-way stopcock's hydraulic cylinder[J]. Chinese Hydraulics & Pneumatics, 2015(9): 6-9. doi: 10.11832/j.issn.1000-4858.2015.09.002 [7] 谭西都, 顾临怡, 刘松, 等. 深海潜水器液压油粘压特性研究[C]//协同创新 砥砺奋进——船舶力学学术委员会第九次全体会议. 江苏 无锡: 中国造船工程学会船舶力学学术委员会, 2018. [8] 江海南. 结构重叠网格方法及其应用研究[D]. 南京: 南京航空航天大学, 2014. [9] 邓成香, 宋鹏云. 螺旋槽干气密封数值模拟网格独立性分析[J]. 润滑与密封, 2016, 41(7): 86-90, 101.Deng Chengxiang, Song Pengyun. Mesh independence analysis of numerical simulation in spiral groove dry gas seal[J]. Lubrication Engineering, 2016, 41(7): 86-90, 101. [10] 周文平, 杨彬, 何勇. 基于动网格的液压缸缓冲性能数值模拟[J]. 机床与液压, 2019, 47(15): 166-169. doi: 10.3969/j.issn.1001-3881.2019.15.035 -

下载:

下载: