Numerical Simulation on Flow Field Characteristics of Vehicle Planing

-

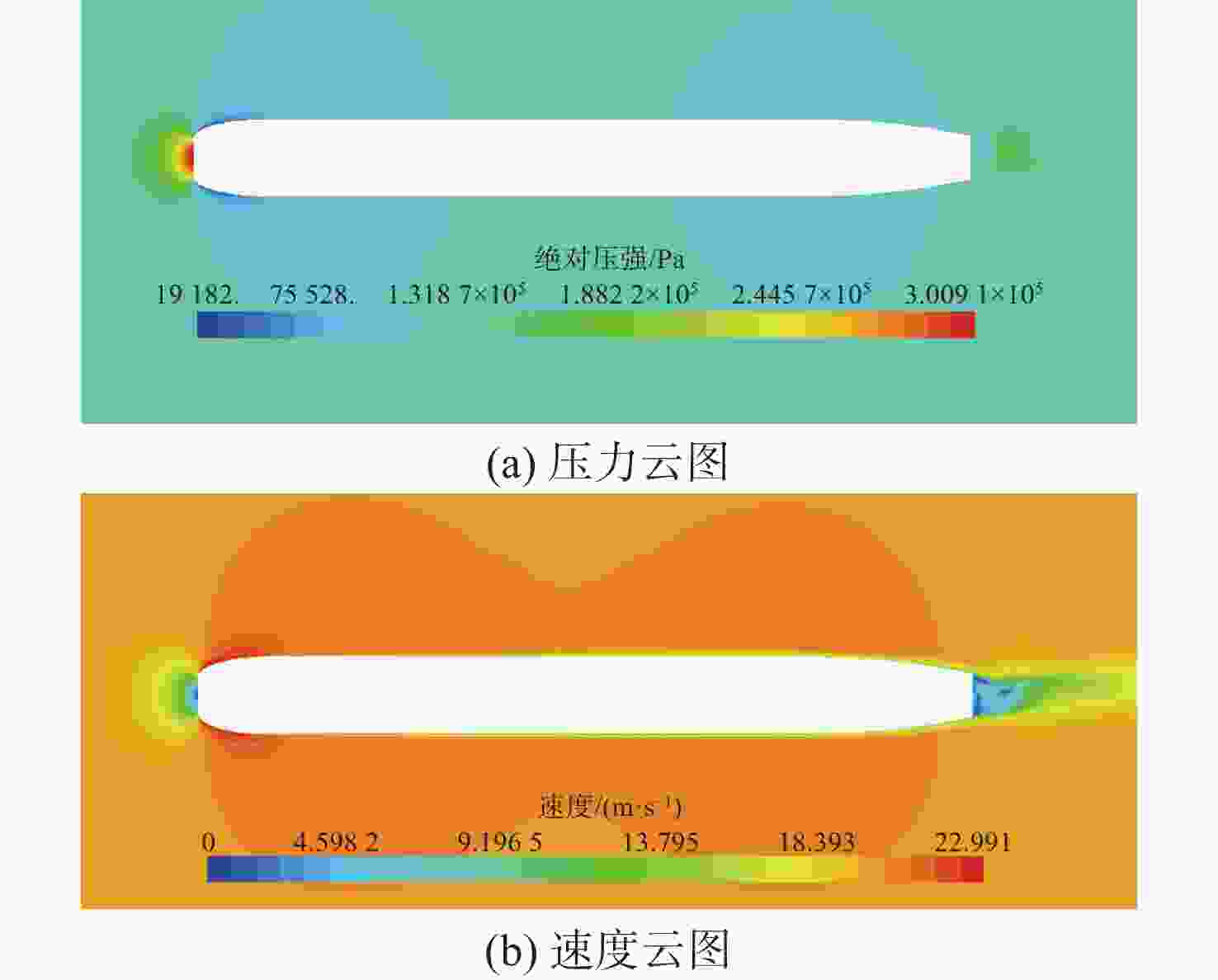

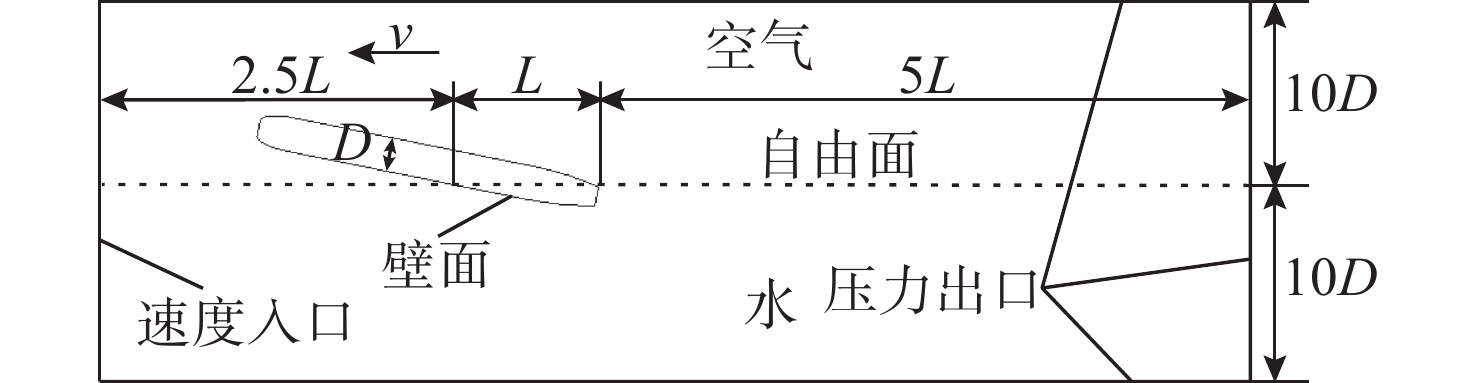

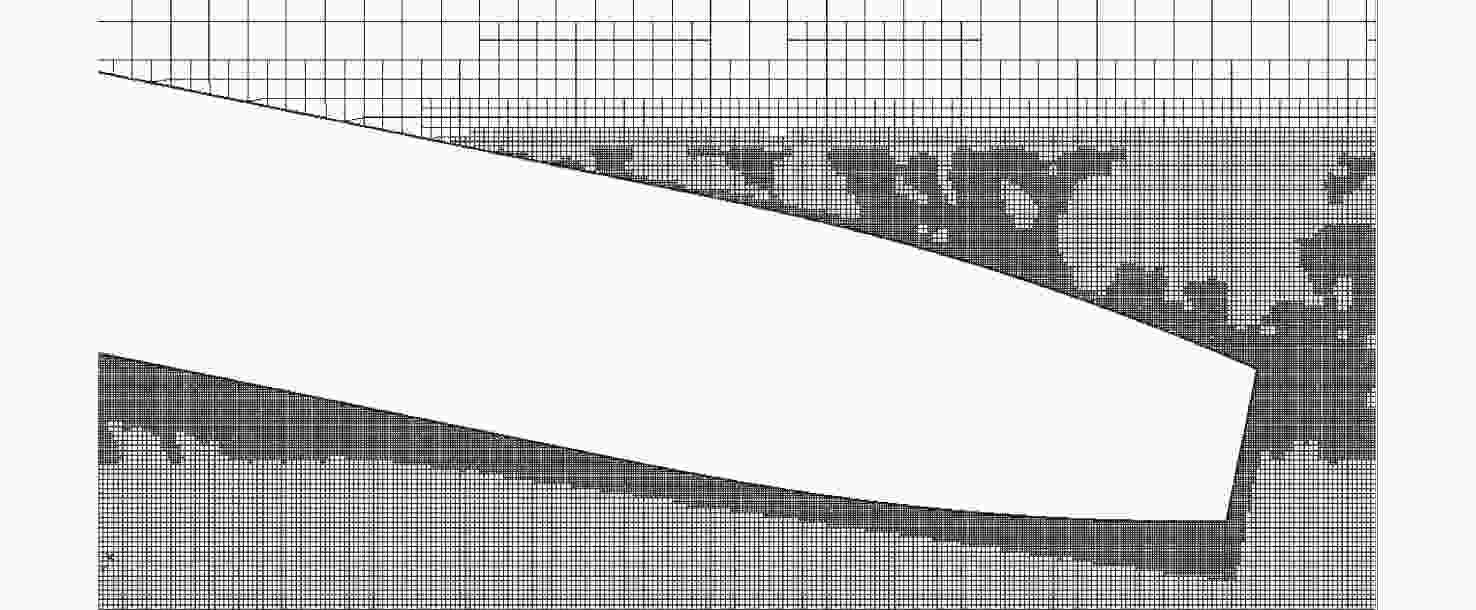

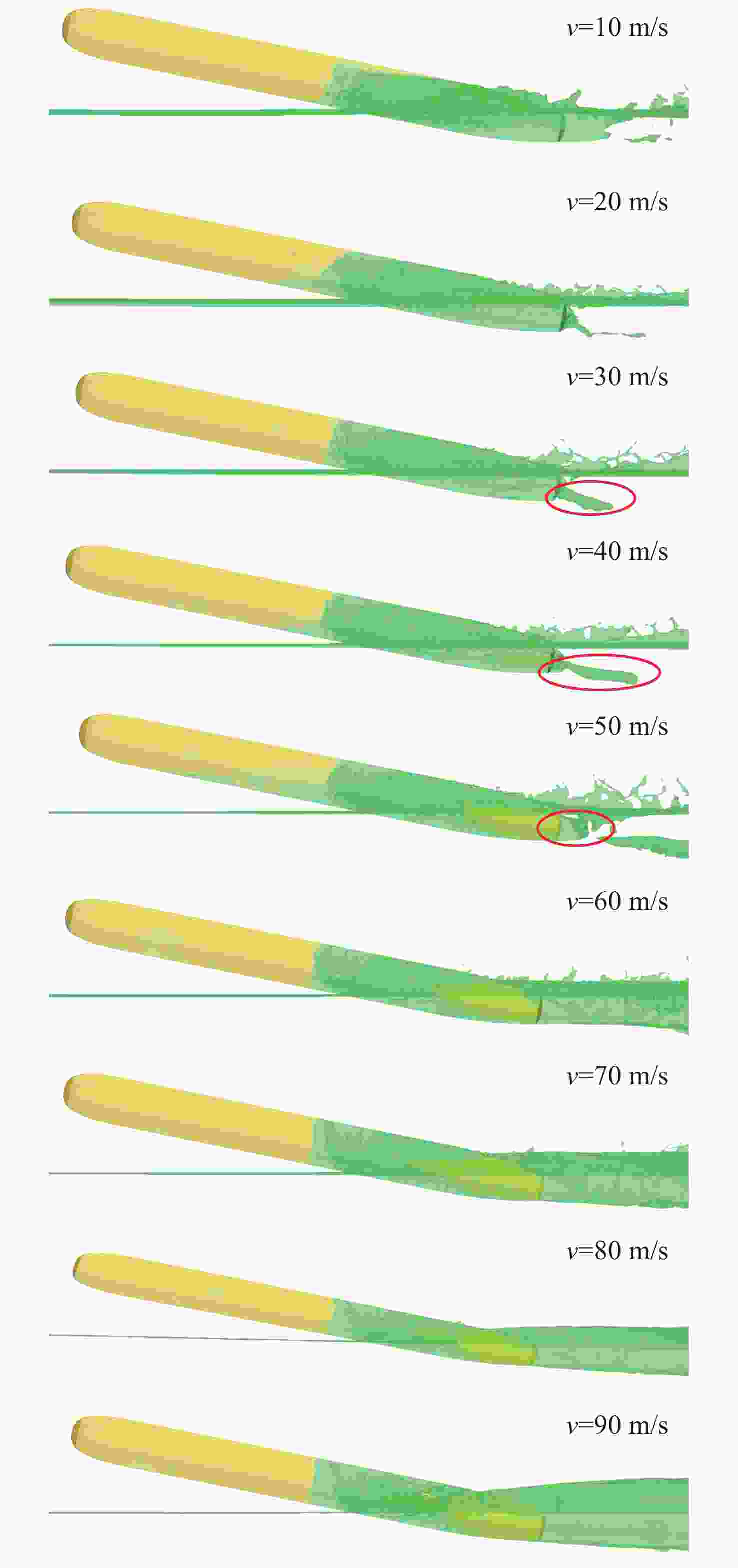

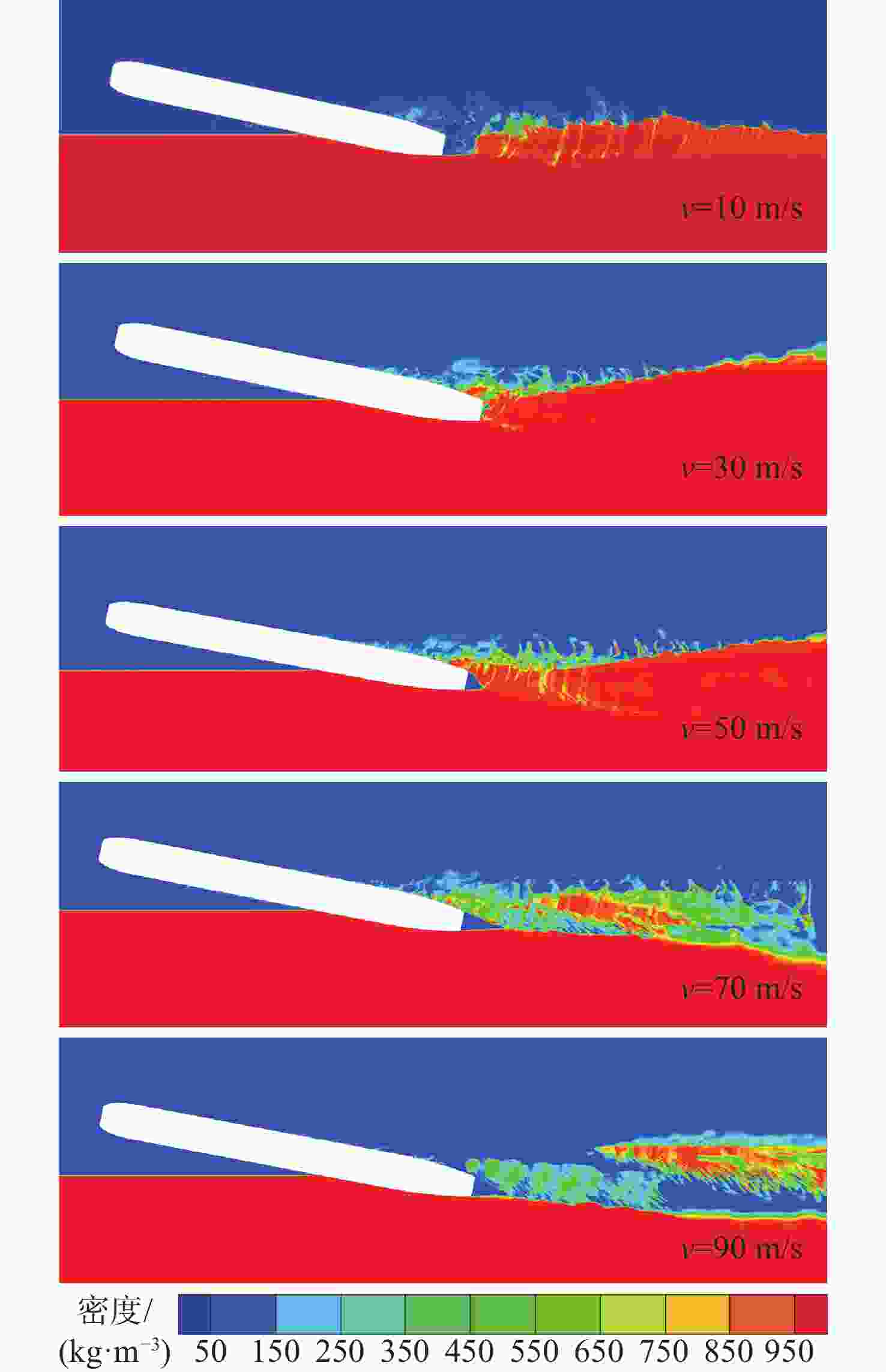

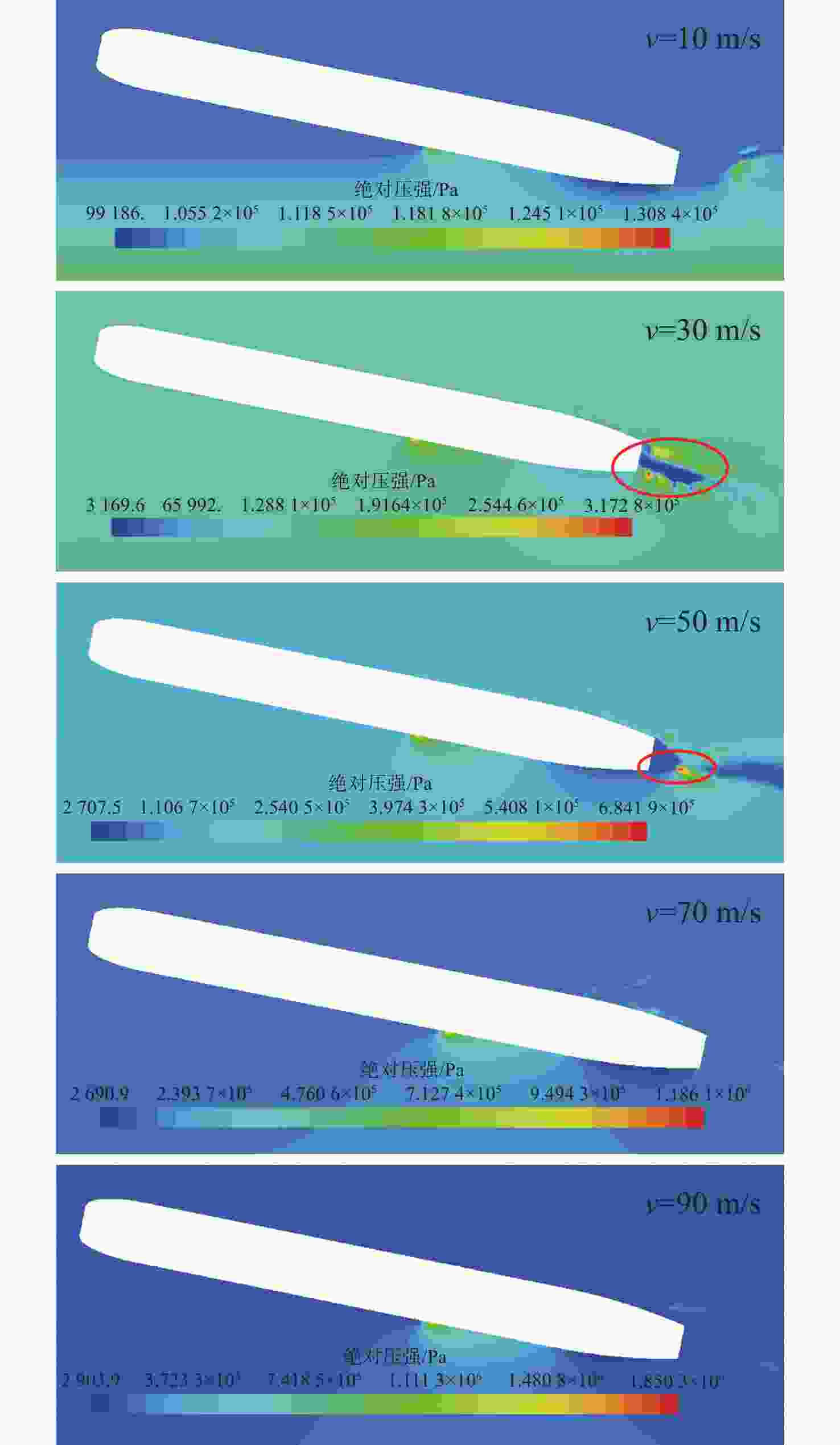

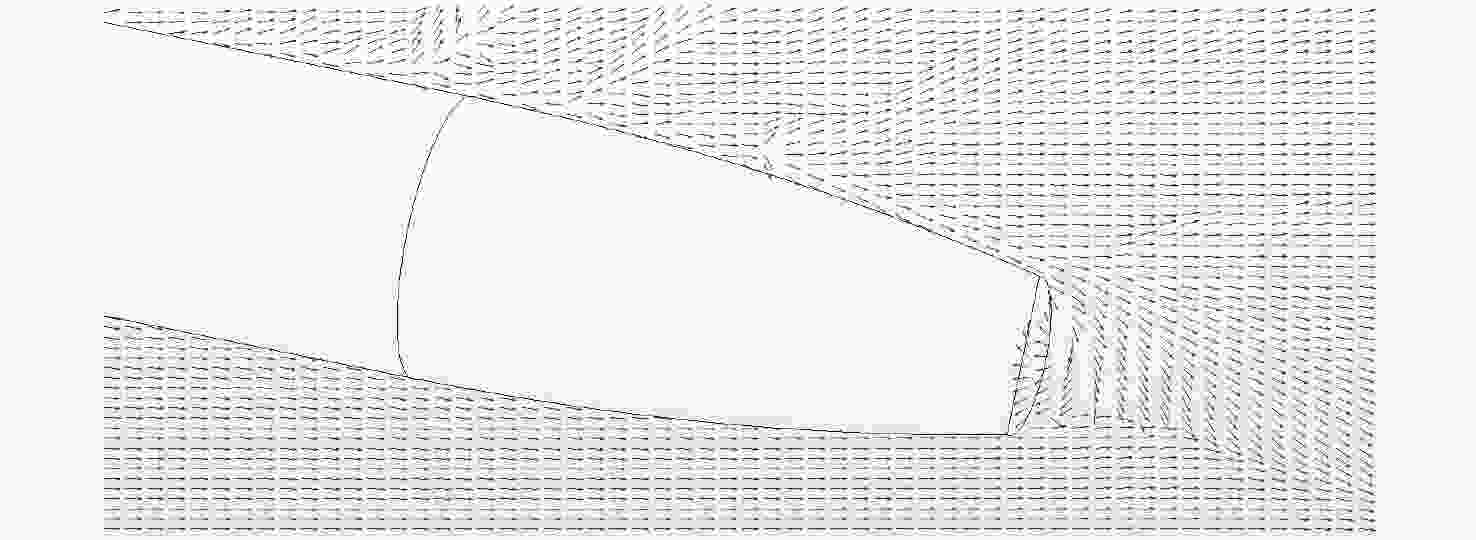

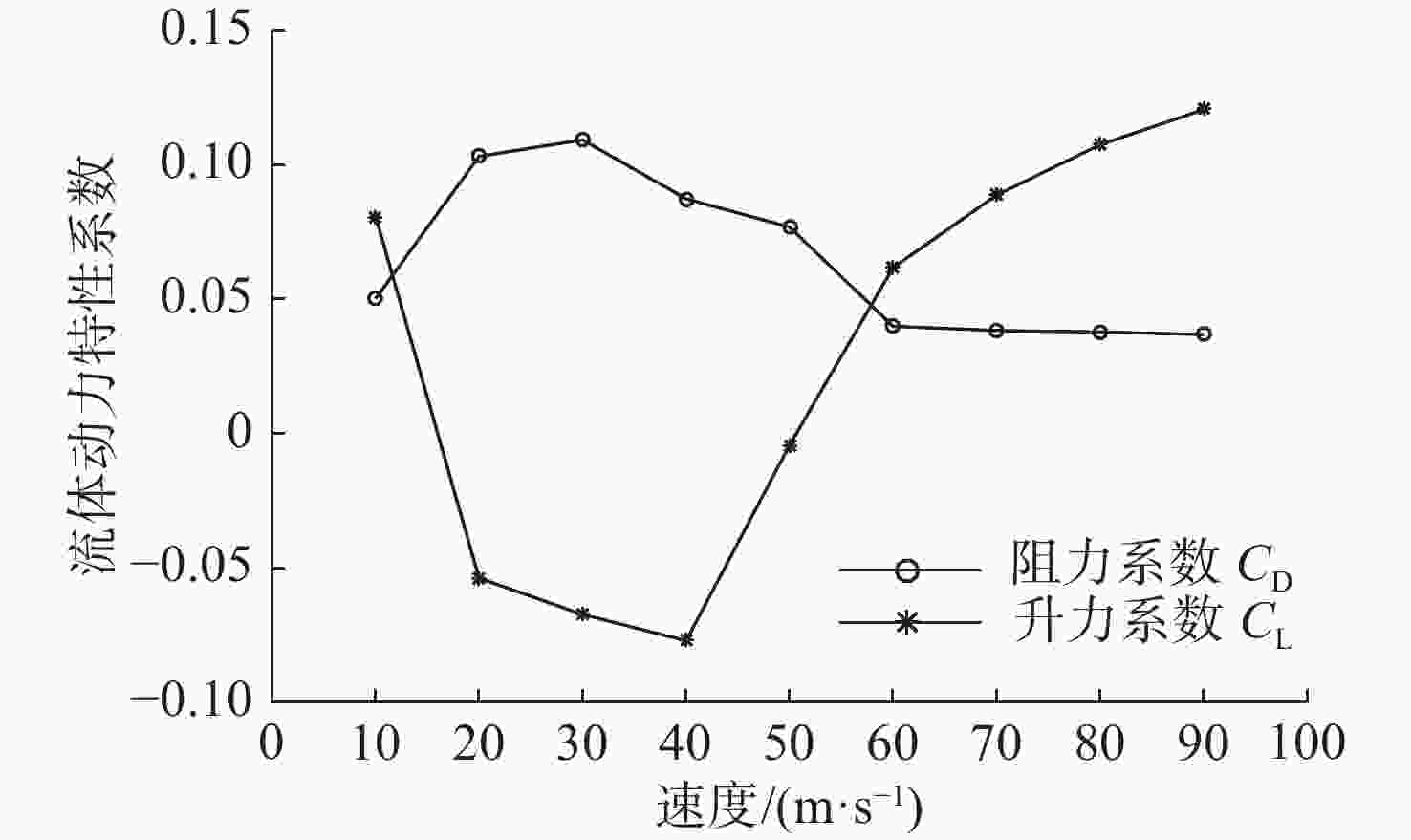

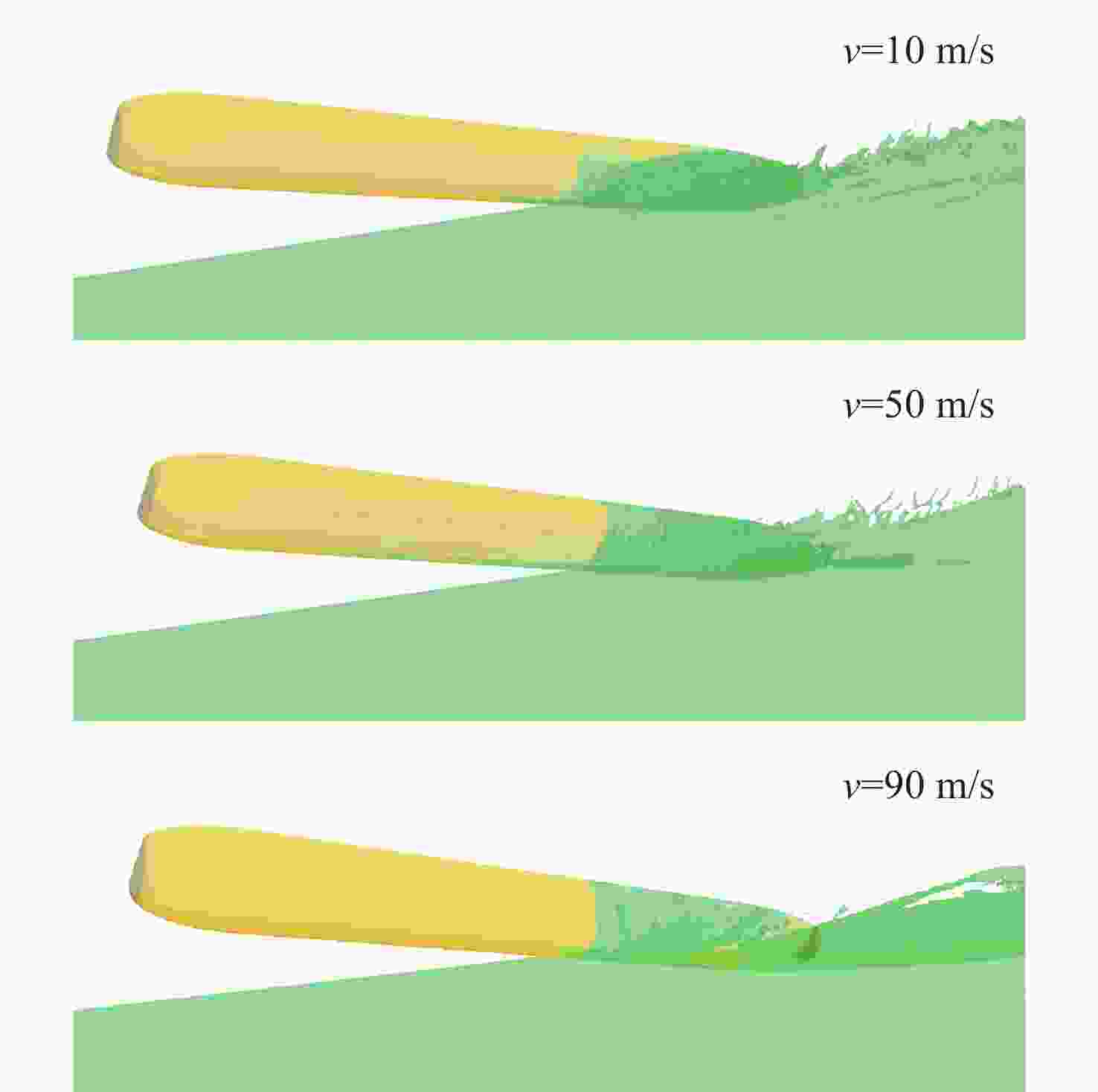

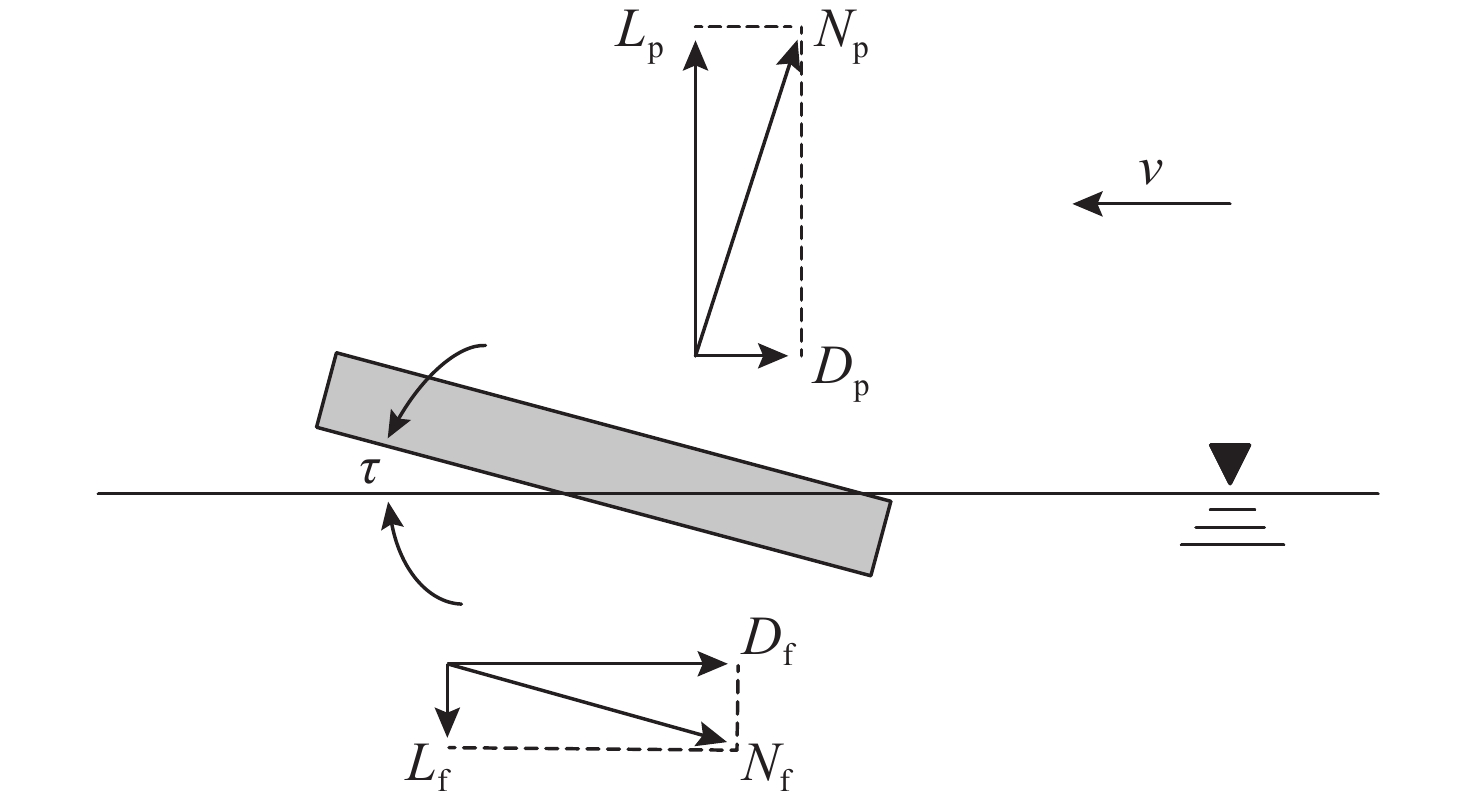

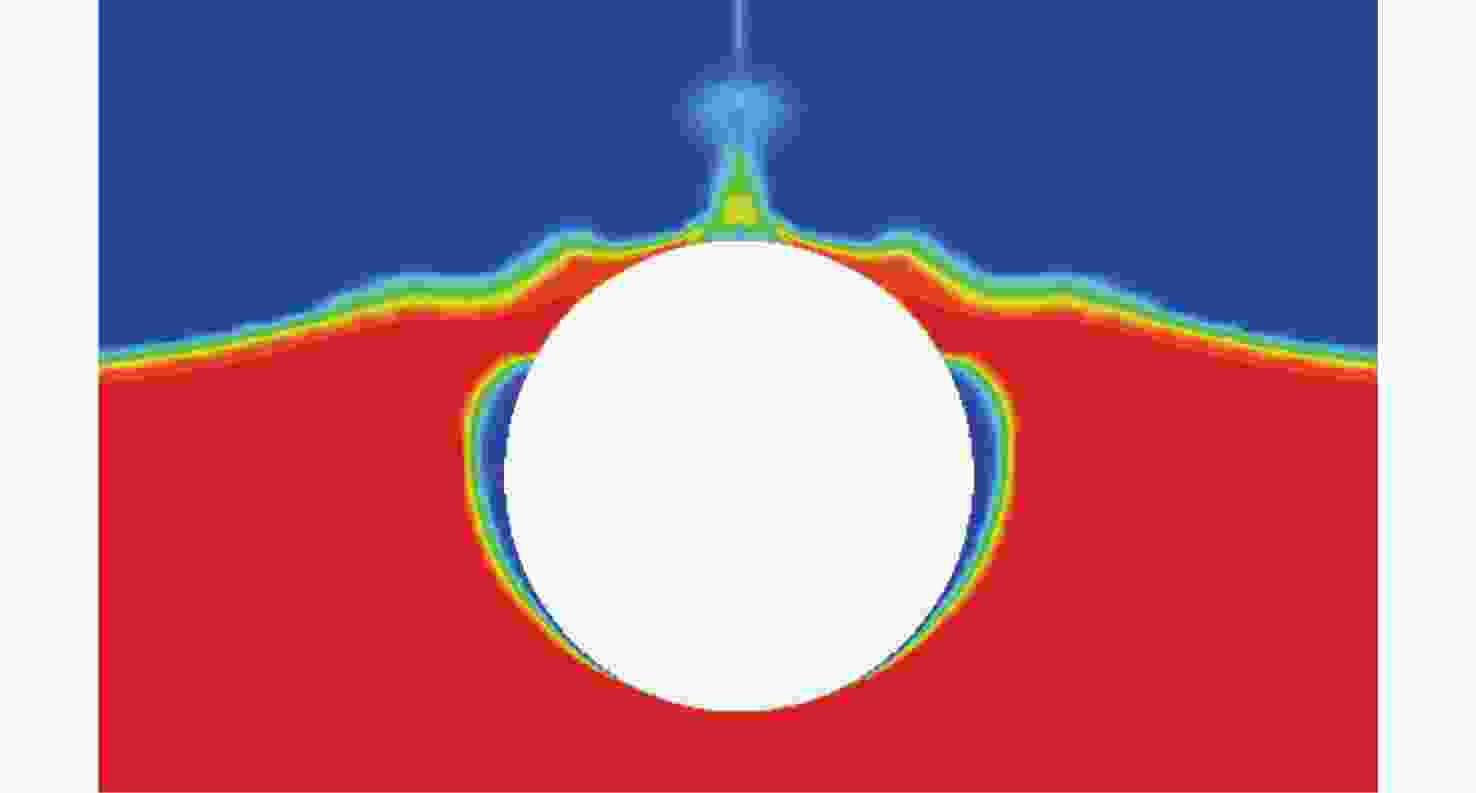

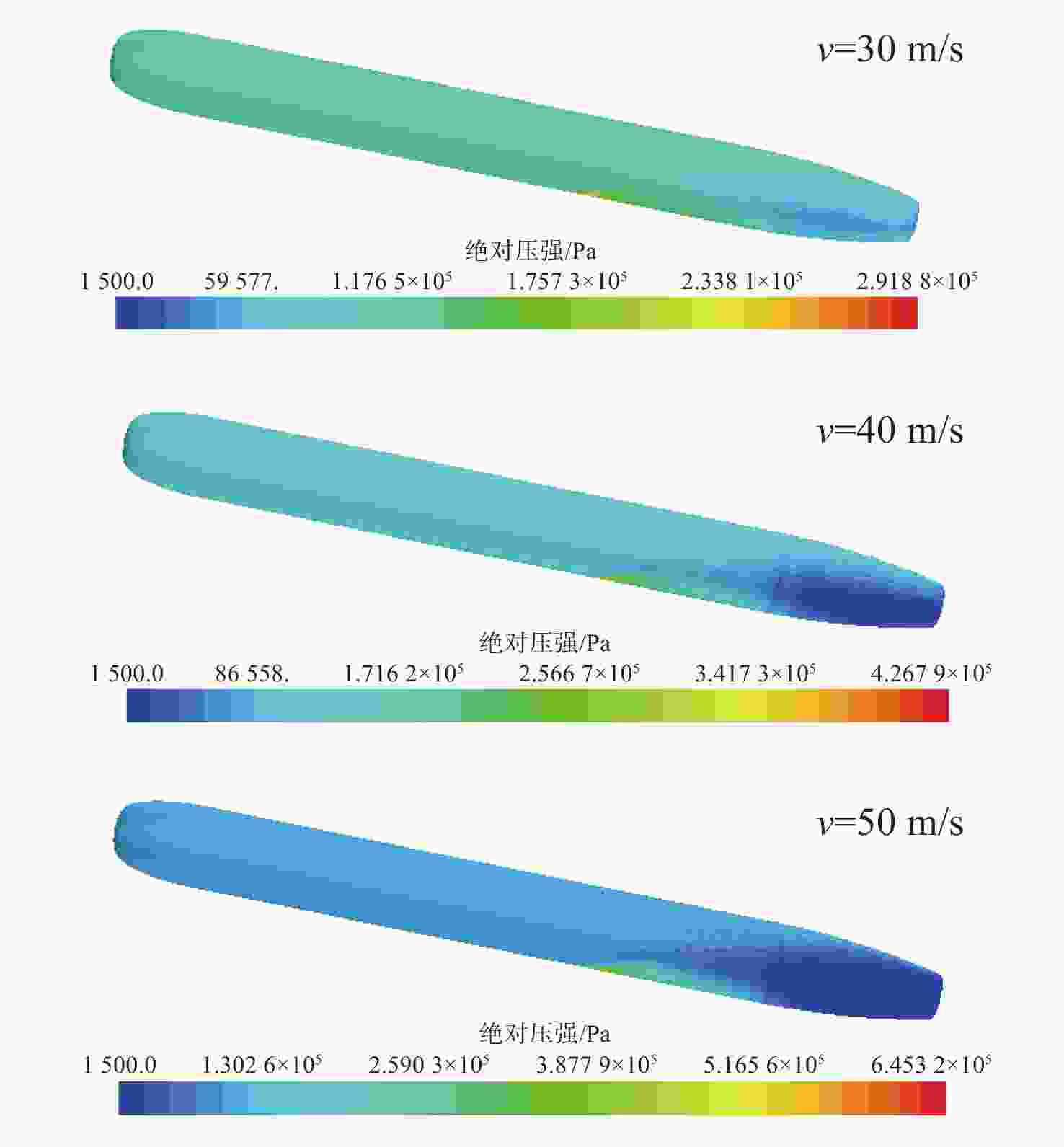

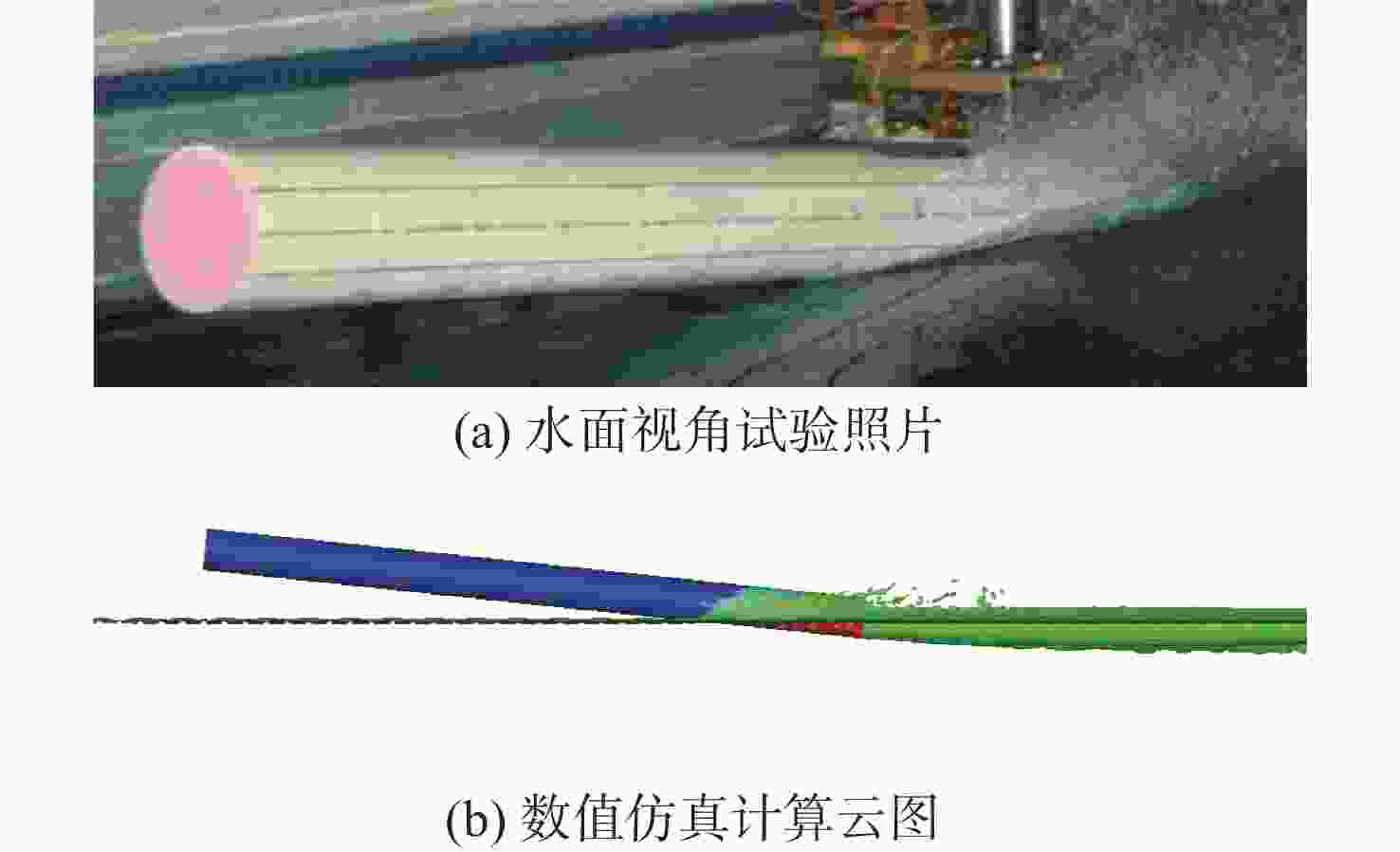

摘要: 基于STAR-CCM+数值计算软件, 选用剪切应力传输k-ω湍流模型, 采用流体体积波和多重运动参考系构建航行器水面滑行数值仿真模型, 并进行了可行性验证。利用该模型对航行器在不同速度下的水面滑行工况进行数值仿真, 研究其流场特性和流体动力特性。仿真结果表明, 航行器在水面滑行速度高于30 m/s时, 尾端发生空化, 空泡内压力低于航行器尾端沾湿面压力; 空泡发生形变, 液面向航行器尾部卷曲并形成飞溅, 航行器尾端形成封闭空泡, 在泡内出现绕流, 泡内为低压区, 此时航行器的升力为负值, 待滑行速度提高, 空泡溃灭与大气连通, 升力值明显提高; 在航行器以不同速度进行水面滑行的过程中, 流场明显不同, 导致升力系数和阻力系数差异较大, 升力甚至出现负值, 其主要与不同速度下航行器尾端空化效果不同, 导致沾湿及航行器表面压力分布存在差异有关。研究结果可为航行器水面滑行工程应用提供理论参考。Abstract: This study employed the shear stress transport(SST) k-ω turbulence model and used the volume of fluid(VOF) wave and the multiple reference frame(MRF) model motion reference system to construct a numerical simulation model of vehicle planing implemented in STAR-CCM+ numerical simulation software, whereby its feasibility was verified. This model was then used to numerically simulate the planing conditions of a vehicle at different speeds and to study its flow field and hydrodynamic characteristics. The simulation results show that when the planing speed of the vehicle was higher than 30 m/s, cavitation occurs at the tail end of the vehicle. This results in the pressure inside the cavity being lower than the pressure on the wetted surface of the tail, causing the cavity to deform and the liquid level to curl up towards the tail, resulting in splashes. Subsequently, a closed cavity is formed at the tail, and there is an inner flow around the cavity, within which there is a low-pressure area. At this time, the lift on the vehicle is negative. When the speed increases, the cavity collapses and joins the atmosphere, and the lift is significantly increased. When the vehicle planes at different speeds, the flow field is obviously different, so are the lift coefficient and the drag coefficient; the lift even turns negative. This is mainly due to the difference in the wetting distribution and surface pressure distribution of the vehicle, caused by different cavitation effects at the tail of the vehicle at different speeds. The results can provide a theoretical reference for engineering applications of vehicle planing.

-

Key words:

- planing /

- flow field characteristics /

- hydrodynamic characteristics

-

表 1 不同网格数量下水面滑行流体动力特性

Table 1. Hydrodynamic characteristics of the vehicle planing under different mesh numbers

网格数量 FD/N FL/N CD CL 237万 47 688 143 076 0.052 9 0.158 344万 38 092 120 589 0.042 2 0.134 496万 35 476 112 354 0.039 3 0.125 581万 33 264 108 836 0.036 9 0.121 674万 32 908 108 698 0.036 5 0.121 表 2 不同速度下航行器水面滑行流体动力特性

Table 2. Hydrodynamic characteristics of the vehicle planing at different speeds

v/(m·s−1) FD/N FL /N CD CL 10 560 900 0.050 0.081 20 4 600 −2 400 0.103 −0.054 30 10 956 −6 754 0.109 −0.067 40 15 580 −13 740 0.087 −0.077 50 21 400 −1 200 0.077 −0.004 60 16 000 24 780 0.040 0.062 70 20 908 48 436 0.038 0.089 80 26 954 76 666 0.038 0.107 90 33 264 108 836 0.037 0.121 -

[1] 茹呈瑶. 现代鱼雷、水雷技术发展研究[J]. 舰船科学技术, 2003, 25(4): 42-43.Ru Cheng-yao. Modern Torpedo and Mine Technology Research[J]. Ship Science and Technology, 2003, 25(4): 42-43. [2] 张宝华, 杜选民. 水面舰艇鱼雷防御系统综述[J]. 船舶工程, 2003, 25(4): 17-19. doi: 10.3969/j.issn.1000-6982.2003.04.004Zhang Bao-hua, Du Xuan-min. A Review of Surface Warship Torpedo Defence System[J]. Ship Engineering, 2003, 25(4): 17-19. doi: 10.3969/j.issn.1000-6982.2003.04.004 [3] 徐国亮, 张逊, 王勇. 高速机动反舰导弹防御技术[J]. 指挥控制与仿真, 2011, 33(1): 7-11. doi: 10.3969/j.issn.1673-3819.2011.01.001Xu Guo-liang, Zhang Xun, Wang Yong. Analysis of the High Speed and High Maneuvering Antiship Missiles Defense System[J]. Command Control and Simulation, 2011, 33(1): 7-11. doi: 10.3969/j.issn.1673-3819.2011.01.001 [4] 樊会涛, 崔颢, 天光. 空空导弹70年发展综述[J]. 航空兵器, 2016(1): 3-12. doi: 10.19297/j.cnki.41-1228/tj.2016.01.001Fan Hui-tao, Cui Hao, Tian Guang. A Review on the 70-year Development of Air-to-air Missiles[J]. Aero Weaponry, 2016(1): 3-12. doi: 10.19297/j.cnki.41-1228/tj.2016.01.001 [5] 张考. “飞鱼”一类导弹隐身突防性能的分析[J]. 航空学报, 1988, 9(6): 217-225. doi: 10.3321/j.issn:1000-6893.1988.06.002Zhang Kao. Stealthy Penetrating Performance Analysis of the “Exocetlike” Missiles[J]. Acta Aeronautica et Astronautica Sinica, 1988, 9(6): 217-225. doi: 10.3321/j.issn:1000-6893.1988.06.002 [6] 关皓, 梅华, 闻斌, 等. 复杂海况下飞行器掠海飞行击水概率的模拟研究[J]. 海洋预报, 2015, 32(4): 95-103. doi: 10.11737/j.issn.1003-0239.2015.04.012Guan Hao, Mei Hua, Wen Bin, et al. A Simulation Study of Ditching Probability for Sea-skimming Flight on Complicated Sea Surface Statue[J]. Marine Forecasts, 2015, 32(4): 95-103. doi: 10.11737/j.issn.1003-0239.2015.04.012 [7] Moctar O E, Shiqunov V, Zorn T. Duisburg Test Case: Post-panamax Container Ship for Benchmarking[J]. Ship Technology Research, 2012, 59(3): 50-64. doi: 10.1179/str.2012.59.3.004 [8] De M A, Mancini S, Miranda S, et al. Experimental and Numerical Hydrodynamic Analysis of a Stepped Planing Hull[J]. Applied Ocean Research, 2017, 64: 135-154. doi: 10.1016/j.apor.2017.02.004 [9] Timothy Y, Michael M, Len I, et al. Investigation of Cylinder Planing on a Flat Free Surface[C]//11th International Conference on Fast Sea Transportation Fast. Honolulu, Hawaii, USA: FAST, 2011. [10] 张珂, 孙士明, 颜开, 等. 超空泡航行器尾部滑行流场特性数值仿真与试验[J]. 水下无人系统学报, 2020, 28(2): 126-130.Zhang Ke, Sun Shi-ming, Yan Kai, et al. Numerical Simulation and Experiment on Fluid Field Characteristic of Planing for Supercavity Vehicle Tail[J]. Journal of Unmanned Undersea Systems, 2020, 28(2): 126-130. [11] 张新彬. 基于表面张力的仿水黾机器人研究[D]. 哈尔滨: 哈尔滨工业大学, 2016. [12] 刘富强, 罗凯, 梁红阁, 等. 回转体滑水航行流体动力特性研究[J]. 西北工业大学学报, 2021, 39(1): 101-110. doi: 10.3969/j.issn.1000-2758.2021.01.013Liu Fu-qiang, Luo Kai, Liang Hong-ge, et al. Research on Hydrodynamic Characteristics of Cylinder Planning[J]. Journal of Northwestern Polytechnical University, 2021, 39(1): 101-110. doi: 10.3969/j.issn.1000-2758.2021.01.013 [13] Roohi E, Pendar M, Rahimi A. Simulation of Three-dimensional Cavitation Behind a Disk using Various Turbulence and Mass Transfer Models[J]. Applied Mathematical Modelling, 2016, 40(1): 542-564. doi: 10.1016/j.apm.2015.06.002 [14] 黄闯. 跨声速超空泡射弹的弹道特性研究[D]. 西安: 西北工业大学, 2017. [15] Menter F R. Two-equation Eddy-viscosity Turbulence Models for Engineering Applications[J]. AIAA Journal, 1994, 32(8): 1598-1605. doi: 10.2514/3.12149 [16] Schnerr G H, Sauer J. Physical and Numerical Modeling of Unsteady Cavitation Dynamics[C]//4th International Conference on Multiphase Flow. New Orleans, USA: ICMF, 2001. [17] Zhou J J, Yu K P, Zhang G. Numerical Simulation on the Process of Supercavity Development and the Planing State of Supercavitating Vehicle[J]. Journal of Ship Mechanics, 2011, 15(3): 199-206. [18] Issa R, Luo J Y, Gosman D. Prediction of Impeller Induced Flows in Mixing Vessels Using Multiple Frames of Reference[C]//4th European Conference on Mixing. Cambridge, UK: IMECHE, 1994. [19] 魏海鹏, 符松. 不同多相流模型在航行体出水流场数值模拟中的应用[J]. 振动与冲击, 2015, 34(4): 48-52. doi: 10.13465/j.cnki.jvs.2015.04.009Wei Hai-peng, Fu Song. Multiphase Models for Flow Field Numerical Simulation of a Vehicle Rising from Water[J]. Journal of Vibration and Shock, 2015, 34(4): 48-52. doi: 10.13465/j.cnki.jvs.2015.04.009 [20] 严卫生. 鱼雷航行力学[M]. 西安: 西北工业大学出版社, 2005: 239-240. -

下载:

下载: