Research on the Establishment Time of Underwater Inflatable Positive Buoyancy for Vehicle

-

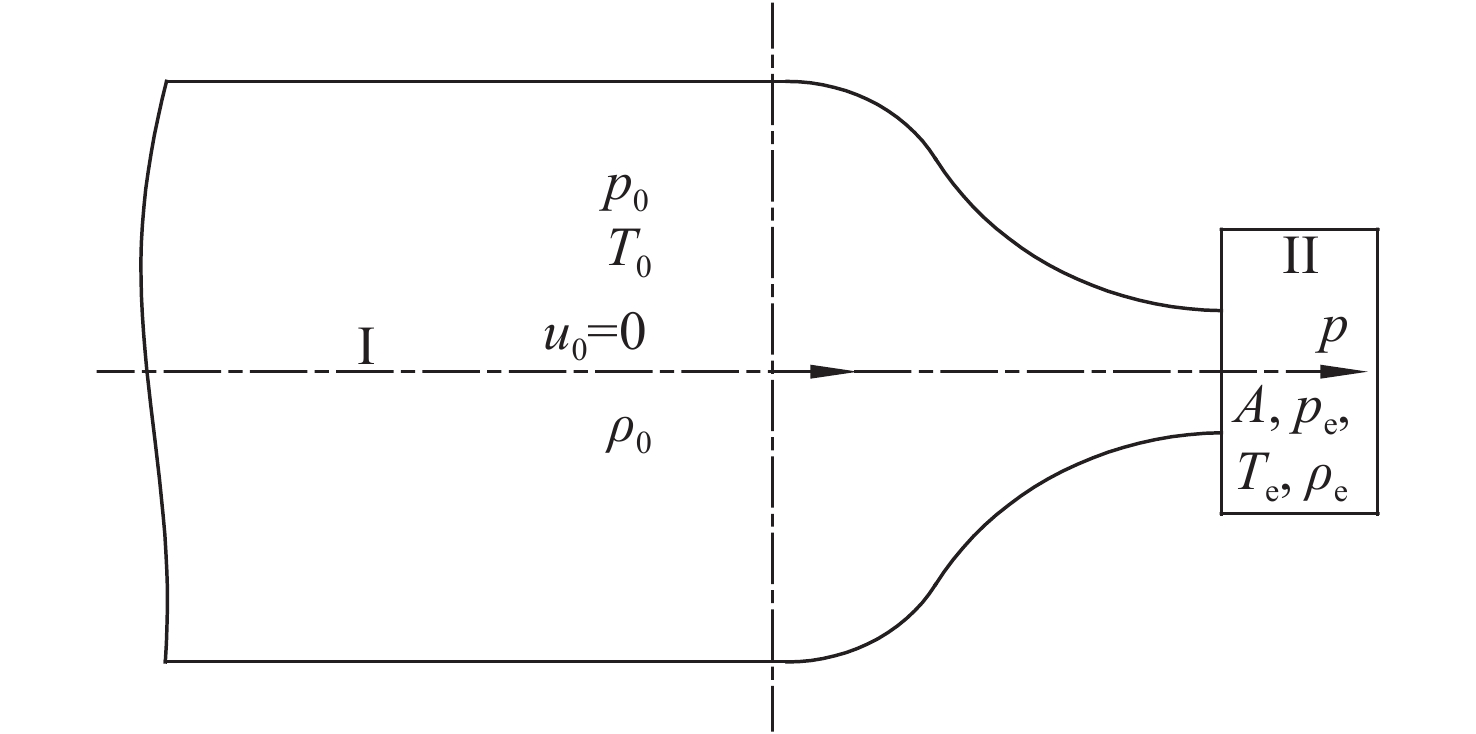

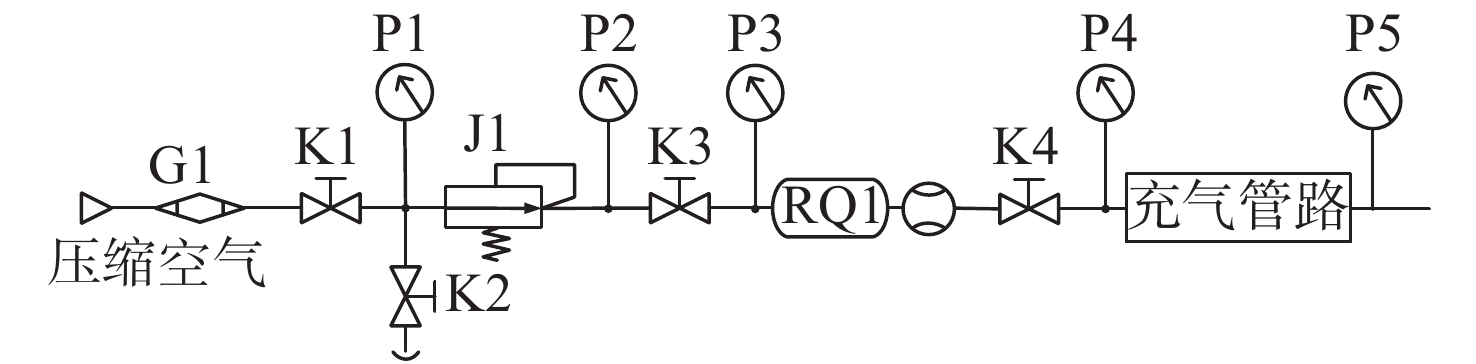

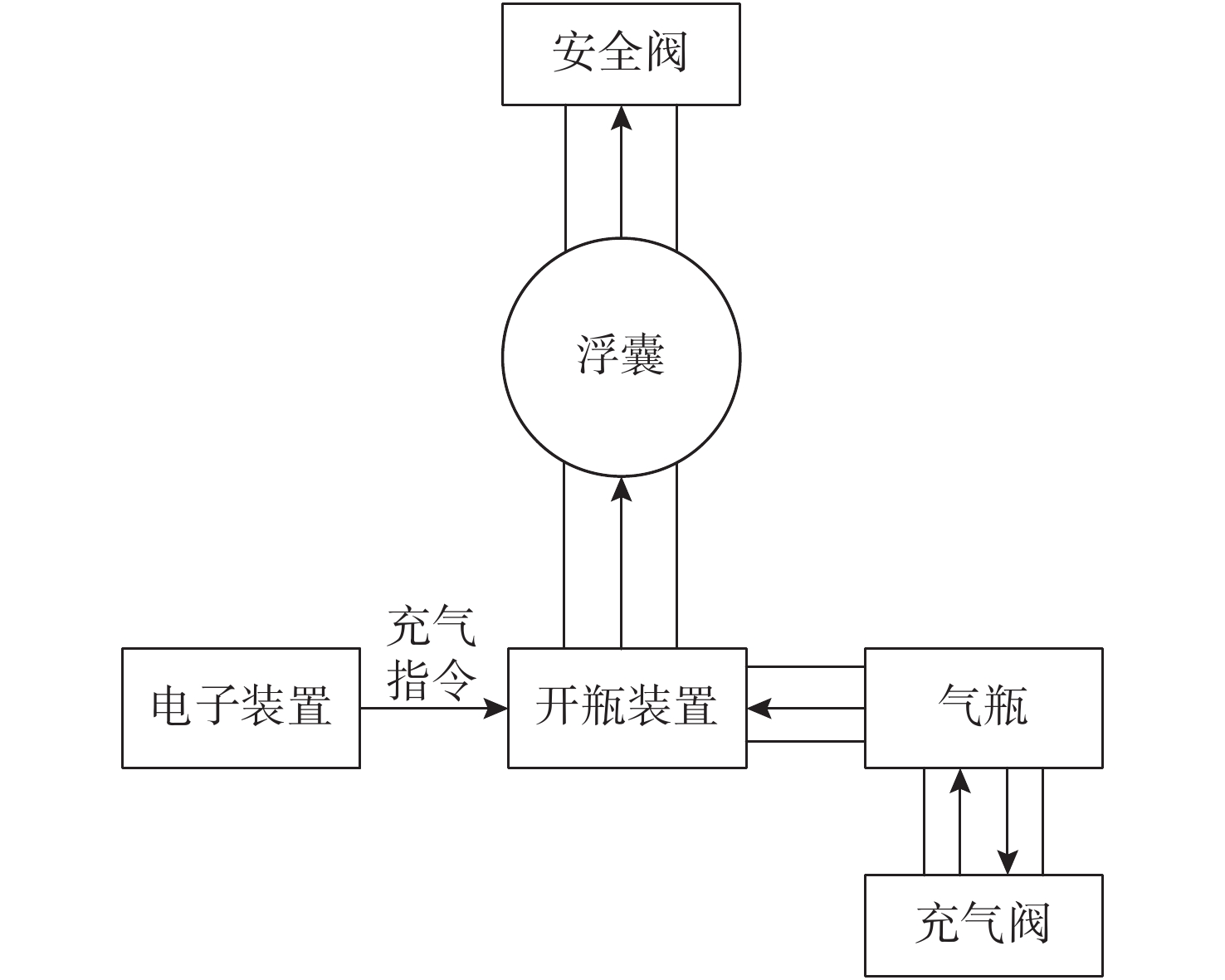

摘要: 为了提高航行器水下回收的安全性, 航行器设计停车深度需与上浮装置充气时间相匹配。目前针对航行器上浮装置水下充气时间的研究成果不具有普遍性,不适用于不同结构形式的浮囊与充气管路。由于上浮装置充气管路不适合采用传统方法测试管路流量系数, 文中重新设计了管路流量系数测试方法,测得充气管路的流量系数, 并采用定积绝热放气条件下充气时间计算模型计算上浮装置充气时间,计算结果与试验数据吻合较好。研究结果可为航行器航深设计及停车流程提供参考。Abstract: To improve the safety of the vehicle underwater recovery, the designed shutdown depth of the vehicle shall match the inflation time of the floating device. At present, the research results on underwater inflation time of vehicle floating device are not universal, and they are not suitable for different structural forms of floatation collar and different structural forms of inflation pipelines. Because the composition of the inflation pipeline of the floating device is not suitable for using the traditional method to test the pipeline flow coefficient, the pipeline flow coefficient test method is redesigned to measure the flow coefficient of the inflation pipeline, and then the inflation time of the floating device is calculated by using the inflation time calculation model under the condition of fixed product adiabatic deflation. The calculation results are in good agreement with the test data, It can provide reference for navigation depth design and shutdown process.

-

Key words:

- undersea vehicle /

- discharge coefficient /

- underwater recovery /

- test method

-

表 1 试验用仪器仪表列表

Table 1. List of test instruments

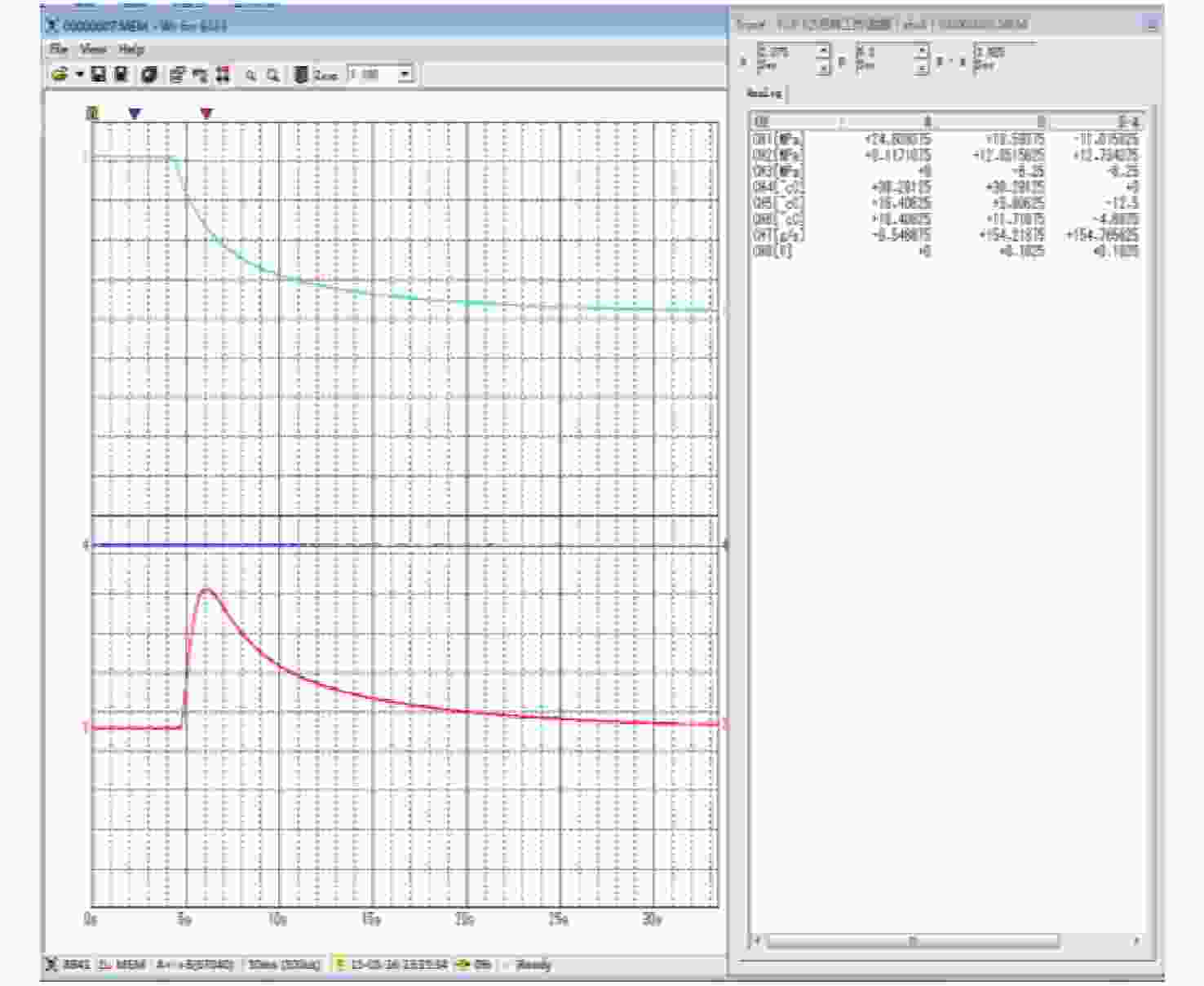

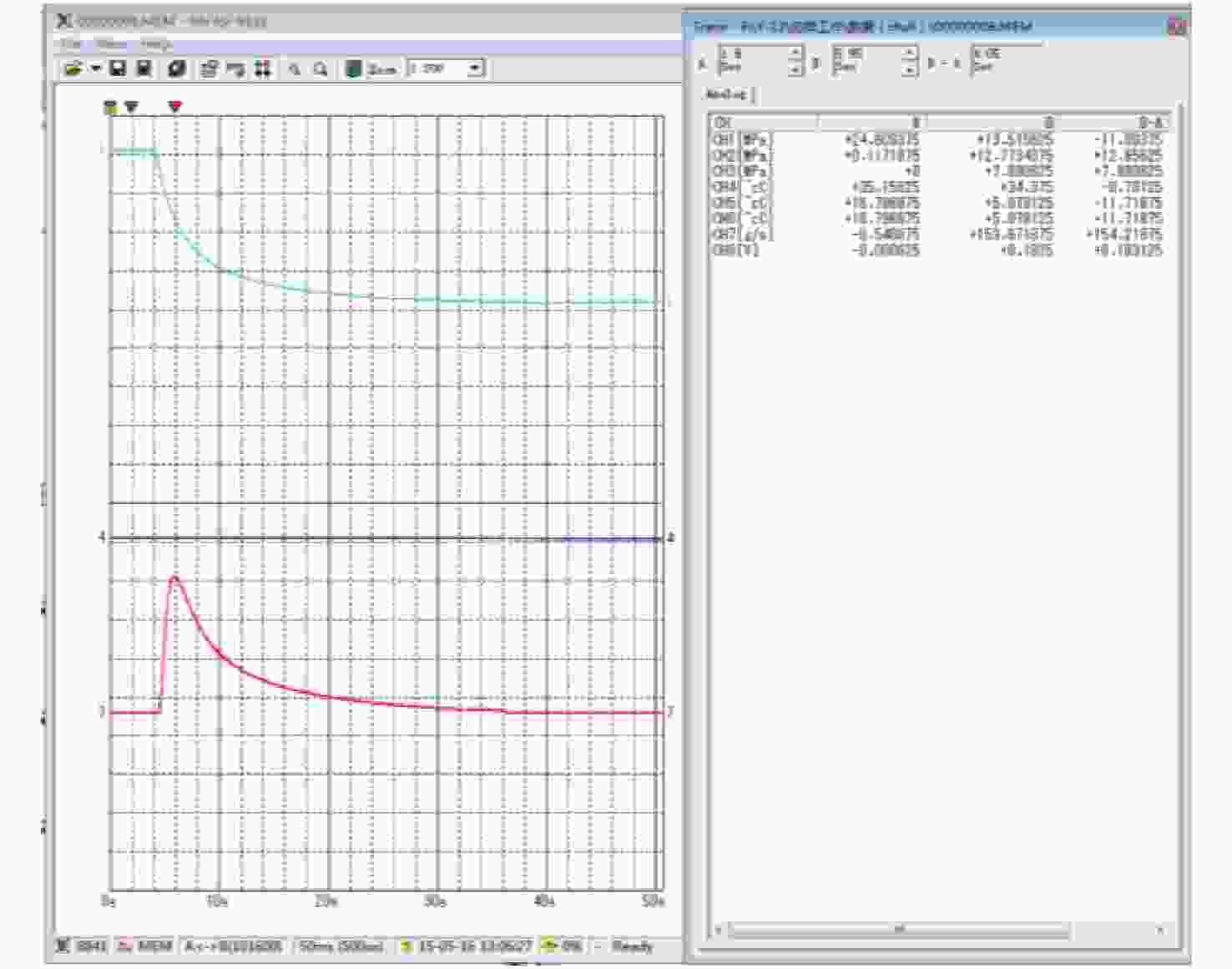

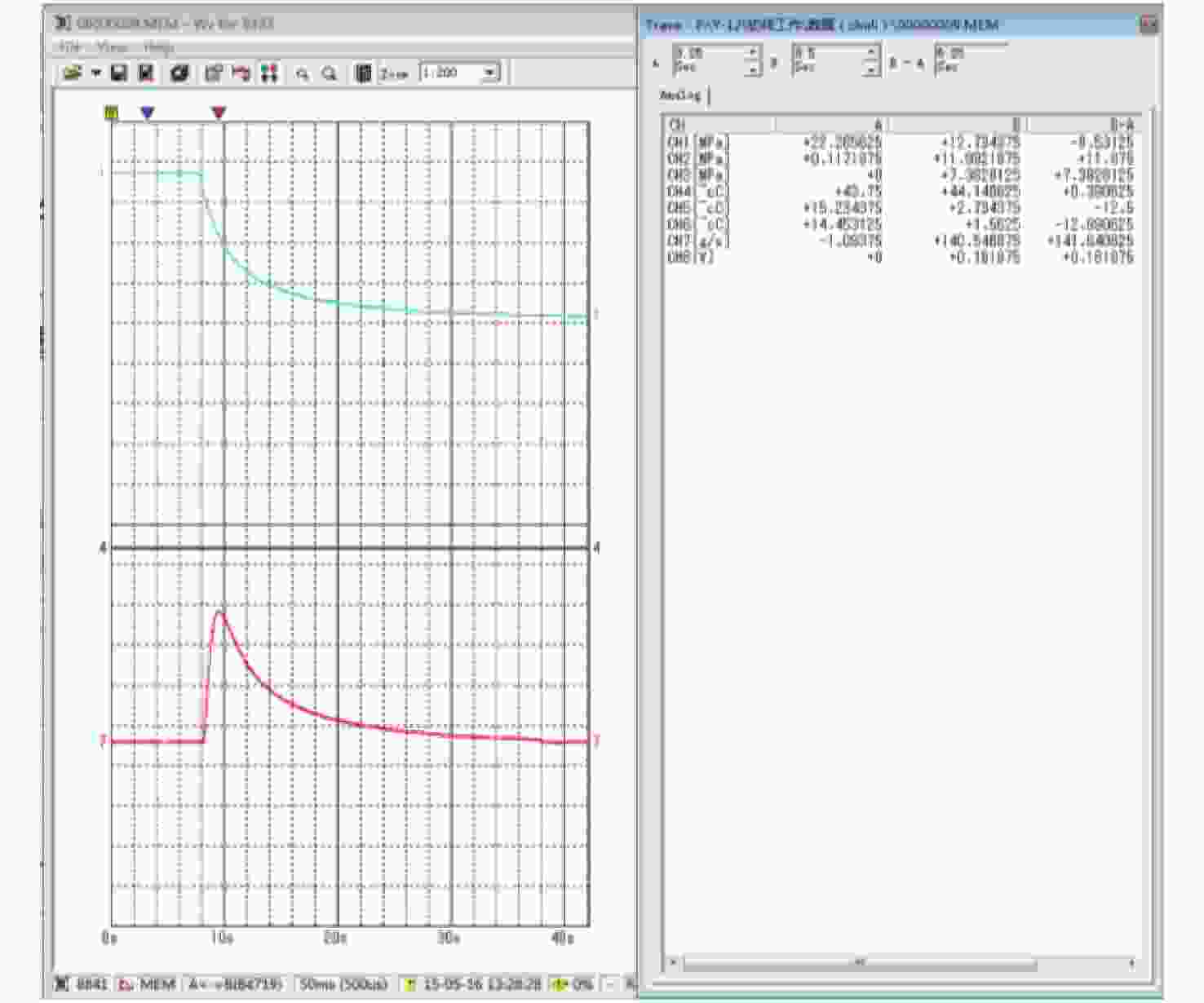

序号 名称 型号 规格 备注 1 压力传感器 DaCY420 0~50 MPa 气瓶压力 2 质量流量计 F050P239C 0~350 g/s 系统流量 3 铂电阻温度

传感器DaCW14-2-07 −50 ℃~200 ℃ 气瓶壁温 4 数据采集系统 CS7-12-6 — 试验数据采集 表 2 充气管路气体流量试验数据文件通道配置表

Table 2. Channel configuration of gas flow test data file for gas filling pipeline

通道序号 测量范围 通道简述 1 0~50 MPa 气瓶压力 4 −50 ℃~200 ℃ 气瓶壁温 7 0~350 g/s 质量流量计 表 4 上浮装置充气管路系数

Table 4. Coefficient of inflation pipeline of floating device

序号 管路系数 管路系数平均值 1 0.2168 0.2201 2 0.2187 3 0.2217 4 0.2231 表 3 试验数据

Table 3. Experimental date

序号 测试项目 测试值 1 气瓶压力/MPa 24.609 气瓶壁温/℃ 35.15 质量流量/(g·s−1) 154.2 2 气瓶压力/MPa 24.609 气瓶壁温/℃ 38.28 质量流量/(g·s−1) 154.76 3 气瓶压力/MPa 22.031 气瓶壁温 40.625 质量流量/(g·s−1) 140 4 气瓶压力/MPa 22.26 气瓶壁温/℃ 43.75 质量流量/(g·s−1) 141.64 表 5 上浮装置充气时间理论计算值与实测值对比

Table 5. Comparison between theoretical calculated value and measured value of inflation time of floating device

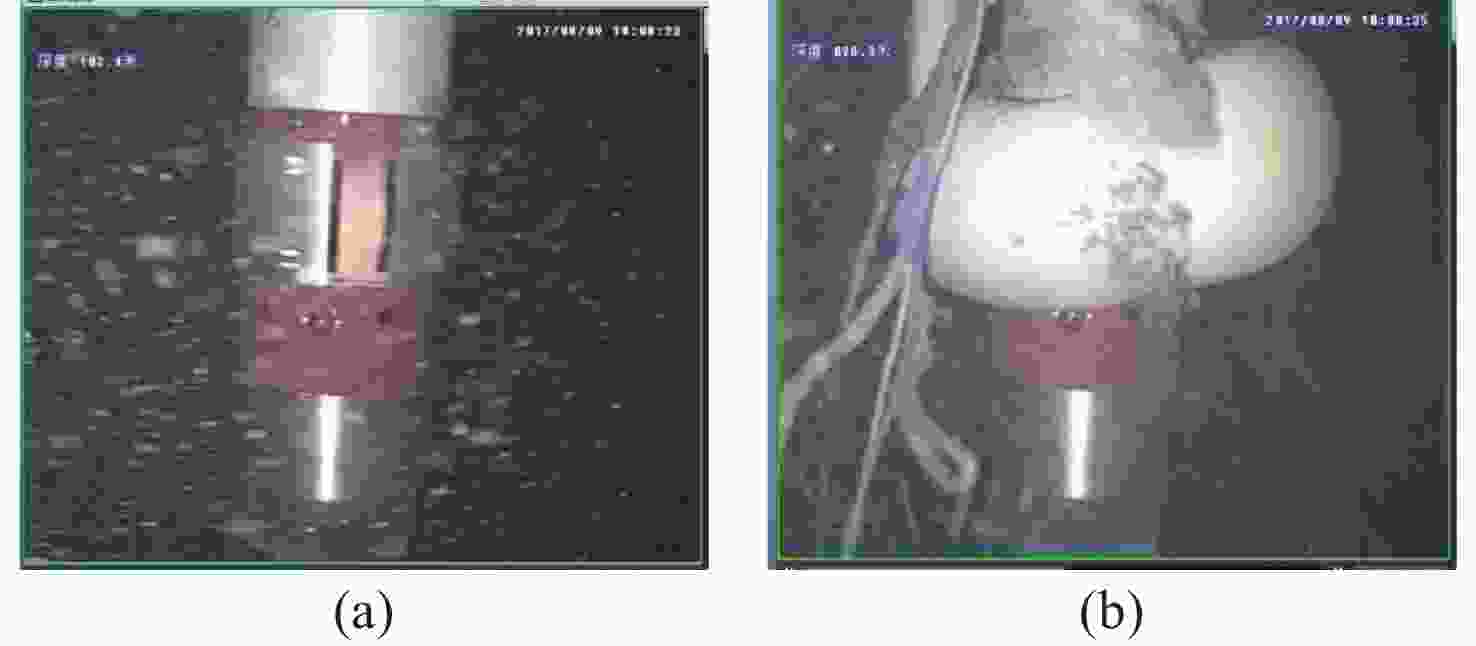

序号 气瓶充气

压力/MPa充气

深度/m充气指令

发出时刻浮囊充满

时刻实测

时间/s理论计算

时间/s1 23.51 102 10 : 08 : 23 10 : 08 : 35 12 11.3 2 23.90 145 14 : 31 : 57 14 : 32 : 38 41 42.3 -

[1] 茹呈瑶. 现代鱼雷、水雷技术发展研究[J]. 舰船科学技术, 2003, 25(4): 42-43.Ru Cheng-yao. Modern Torpedo and Mine Technology Research[J]. Ship Science and Technology, 2003, 25(4): 42-43. [2] 黄震中. 鱼雷总体设计[M]. 西安: 西北工业大学出版社, 1987. [3] 张宇文. 鱼雷总体设计原理与方法[M]. 西安: 西北工业大学出版社, 1998. [4] 尹韶平, 杨芸. 鱼雷总体技术的发展与展望[J]. 鱼雷技术, 2005, 13(3): 1-5.Yin Shao-ping, Yang Yun. A Summary of Development in Torpedo Overall Design Technologies[J]. Torpedo Technology, 2005, 13(3): 1-5. [5] 吕汝信. 鱼雷上浮装置研究[J]. 鱼雷技术, 2000, 8(2): 8-11.Lü Ru-xin. Study of Floating Device of the Training Torpedo[J]. Torpedo Technology, 2000, 8(2): 8-11. [6] 程文鑫, 蔡卫军, 杨春武, 等. 鱼雷浮囊充气过程建模与仿真[J]. 鱼雷技术, 2014, 22(2): 87-90.Cheng Wen-xin, Cai Wei-jun, Yang Chun-wu, et al. Modeling and Simulation of Inflation Process for Torpedo Inflatable Collar[J]. Torpedo Technology, 2014, 22(2): 87-90. [7] 张晓光, 李斌, 党会学, 等. 水下航行体充气上浮仿真方法研究[J]. 兵工学报, 2020, 41(7): 1249-1261. doi: 10.3969/j.issn.1000-1093.2020.07.001Zhang Xiao-guang, Li Bin, Dang Hui-xue, et al. A Simulation Method for Inflatable Floating of Underwater Vehicle[J]. Acta Armamentarii, 2020, 41(7): 1249-1261. doi: 10.3969/j.issn.1000-1093.2020.07.001 [8] 孙潘, 李斌, 温金鹏, 等. 水下无人航行器折叠气囊充气展开特性模拟[J]. 兵工学报, 2020, 41(12): 2540-2549. doi: 10.3969/j.issn.1000-1093.2020.12.020Sun Pan, Li Bin, Wen Jin-peng, et al. Simulation of Inflatable Deployment Characteristics of Folding Airbags for Underwater Unmanned Vehicle[J]. Acta Armamentarii, 2020, 41(12): 2540-2549. doi: 10.3969/j.issn.1000-1093.2020.12.020 [9] 甄文强, 杨奇, 温金鹏, 等. 环形气囊地面及水下充气试验及仿真分析[J]. 工程设计学报, 2020, 27(2): 263-268. doi: 10.3785/j.issn.1006-754X.2020.00.029Zhen Wen-qiang, Yang Qi, Wen Jin-peng, et al. Test and Simulation Analysis of Inflation Process of Annular Collar on the Ground and Underwater[J]. Chinese Journal of Engineering Design, 2020, 27(2): 263-268. doi: 10.3785/j.issn.1006-754X.2020.00.029 -

下载:

下载: