Design Method for Low Specific Speed Axial Flow Pump for High-Speed Undersea Vehicles

-

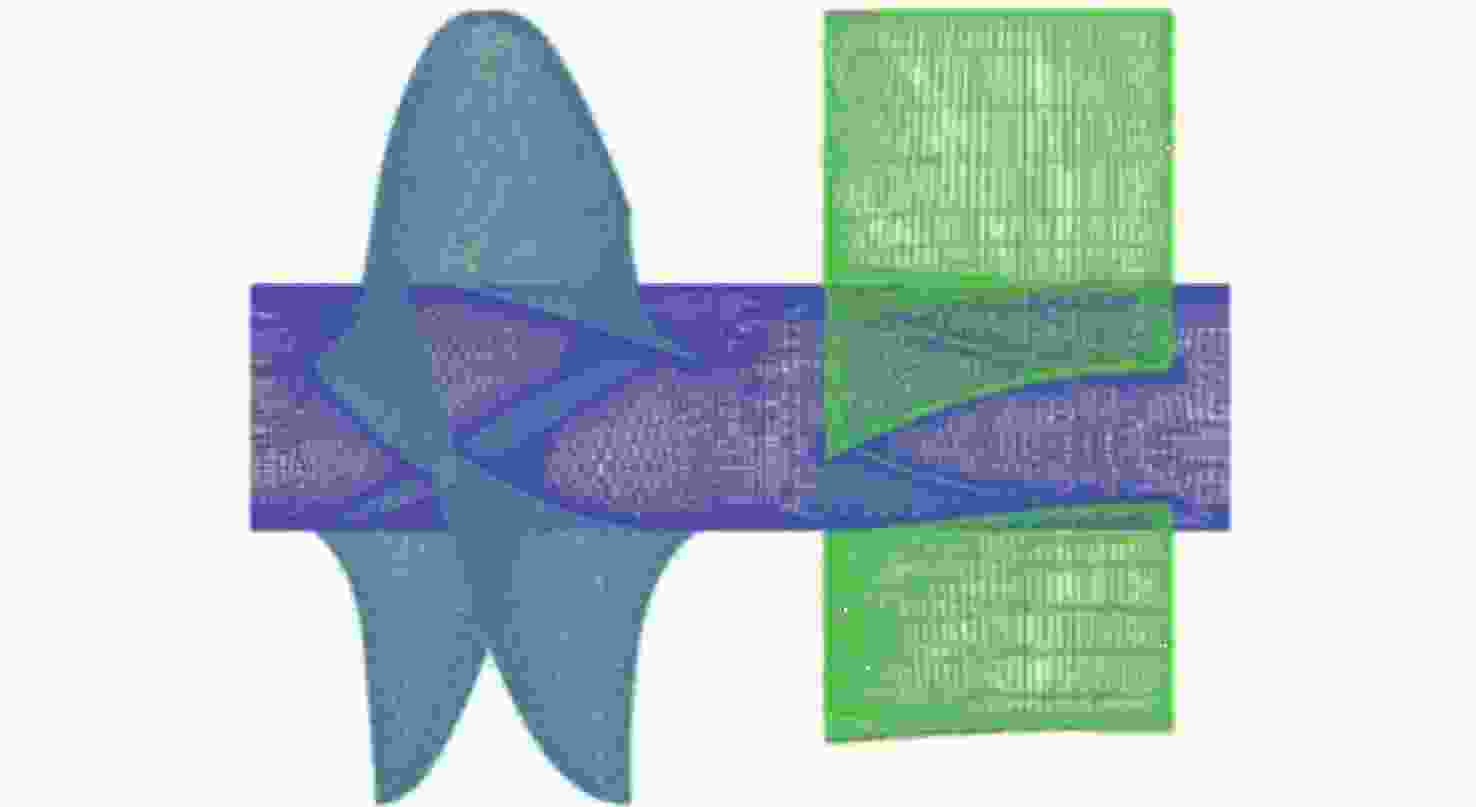

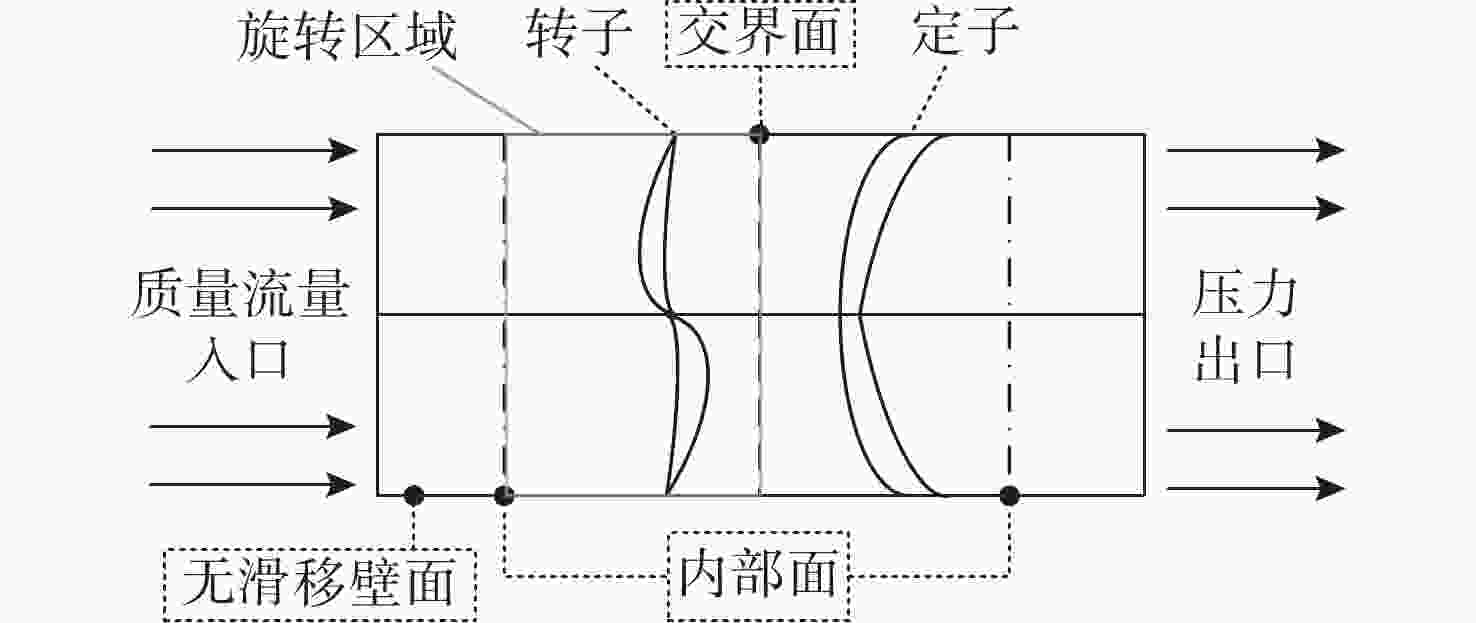

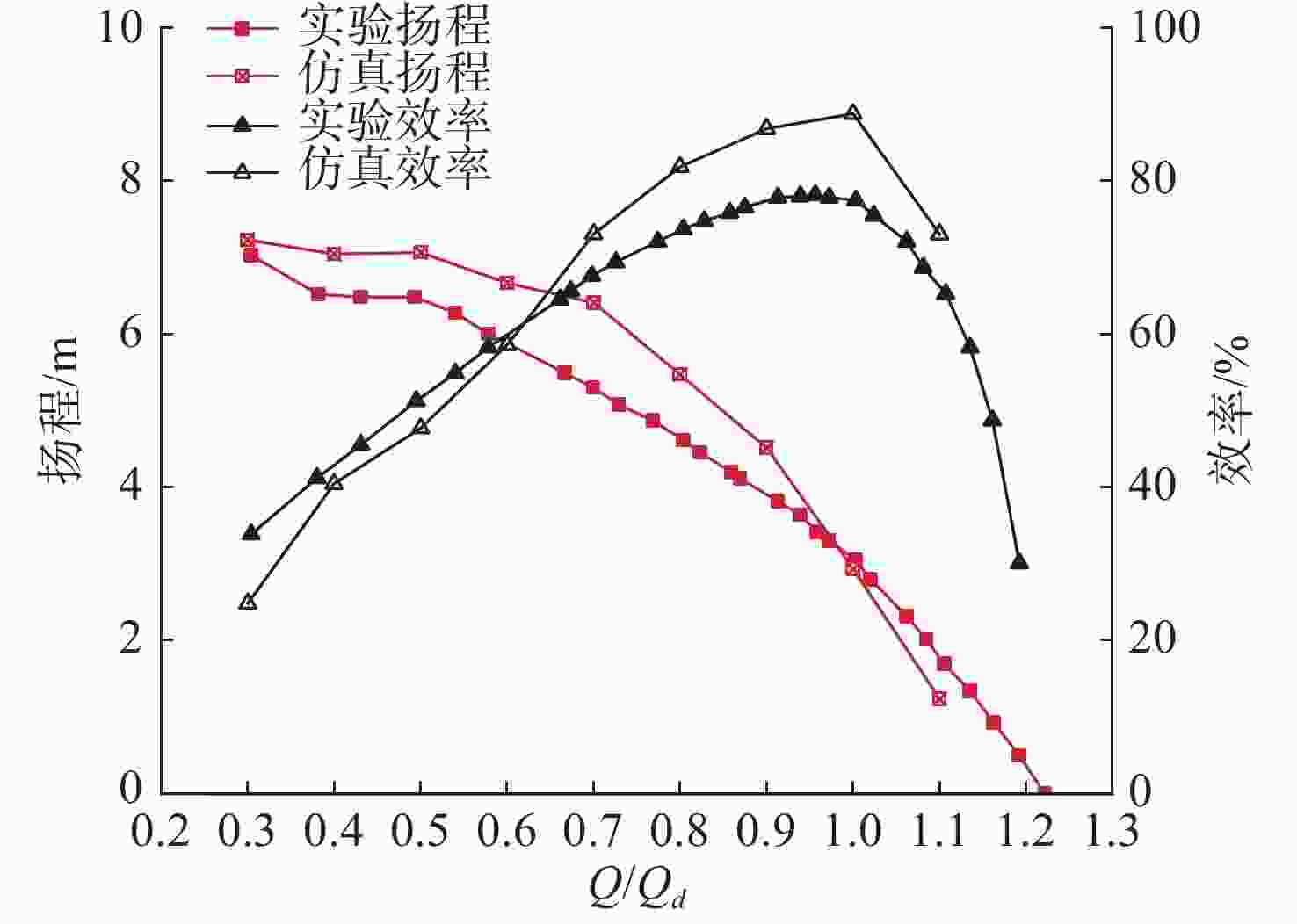

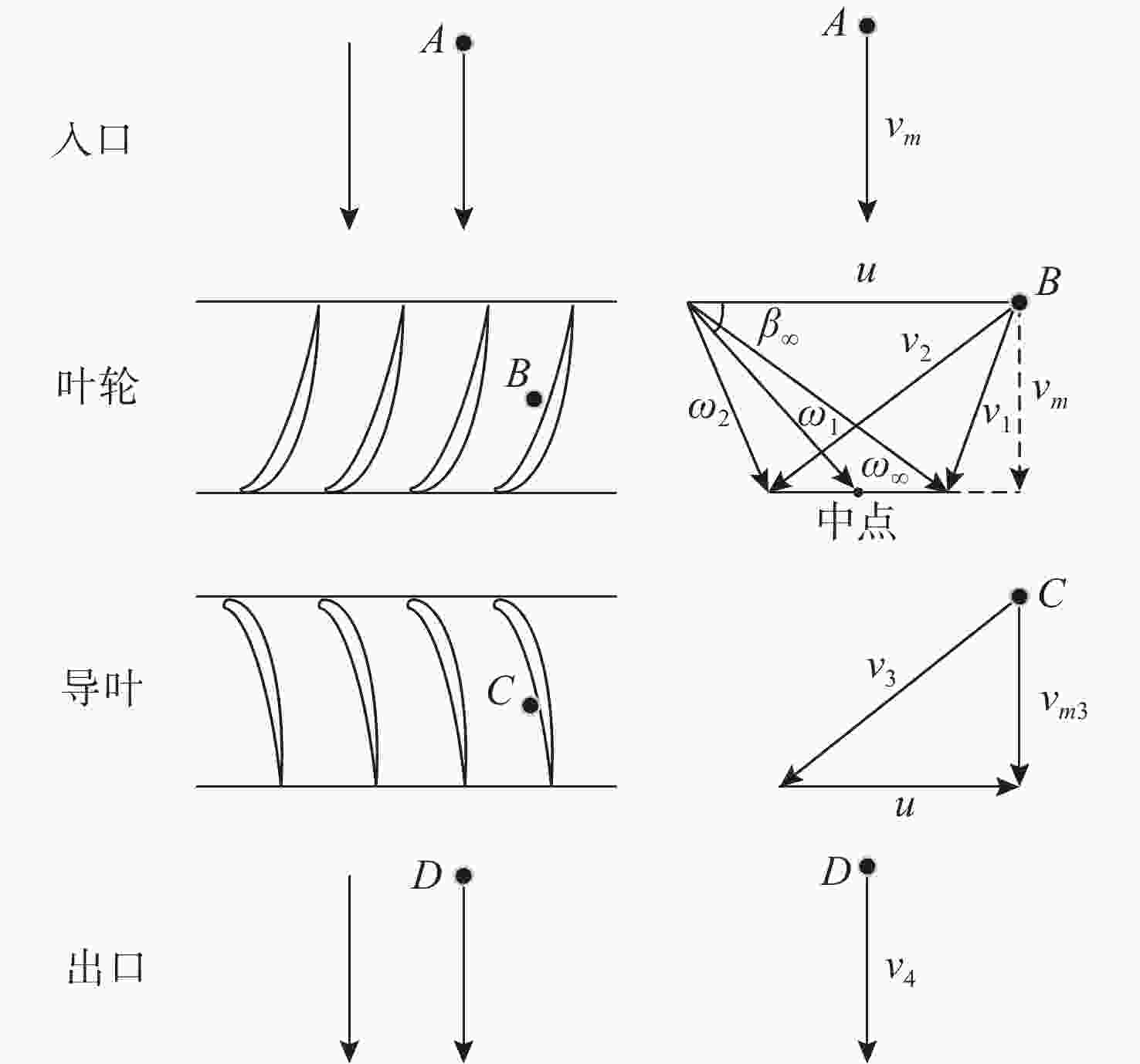

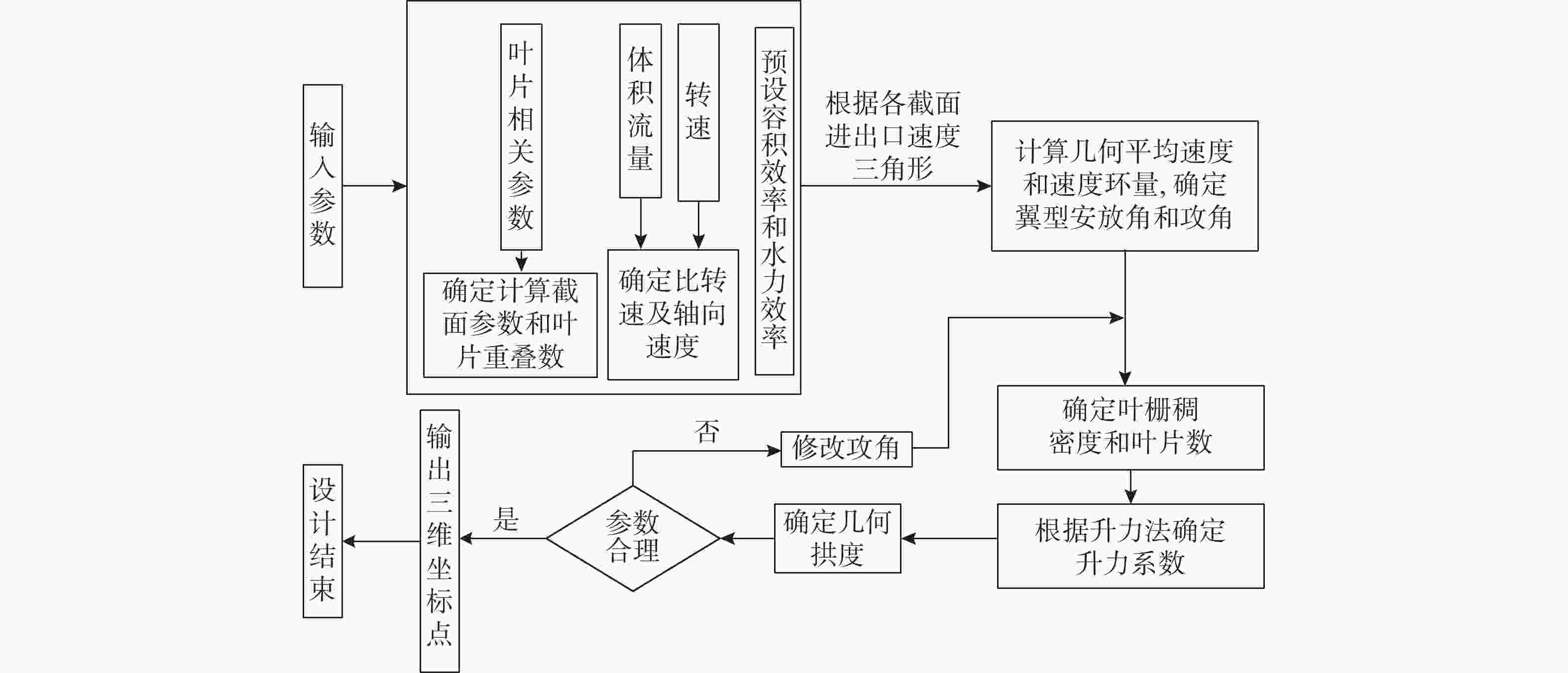

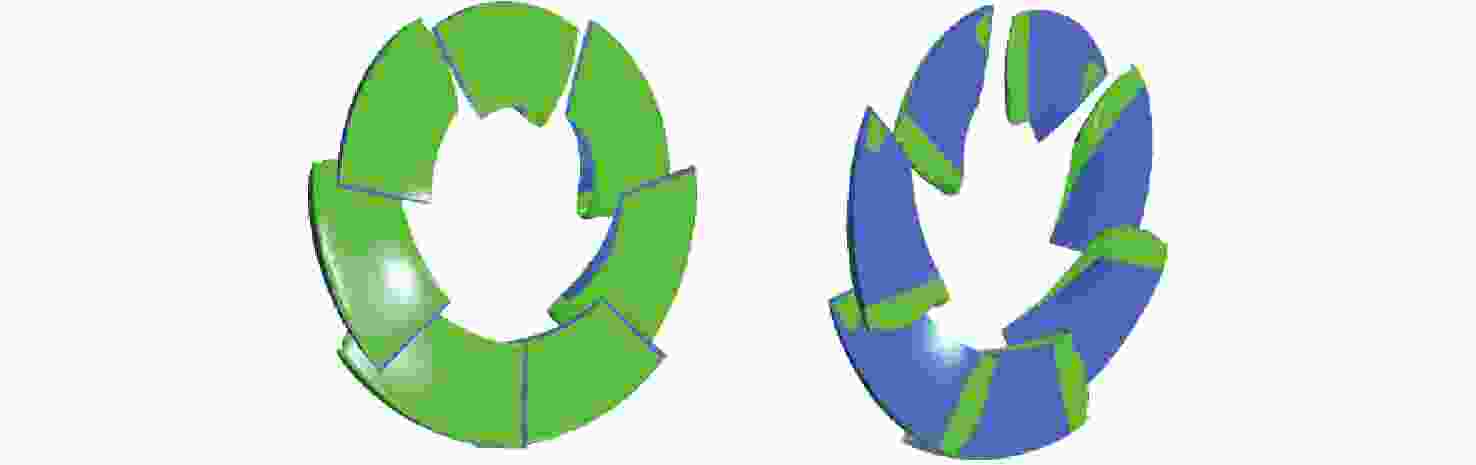

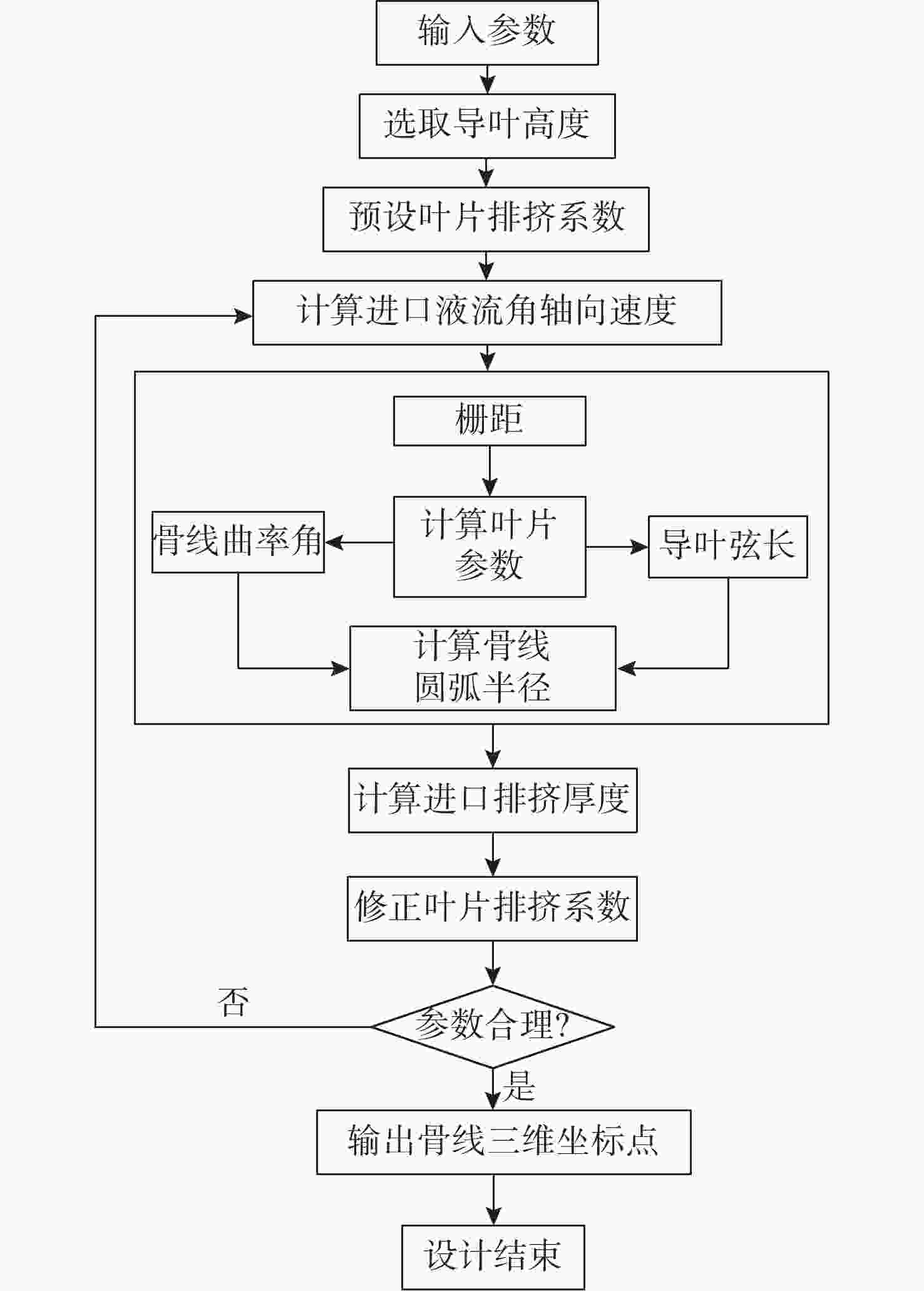

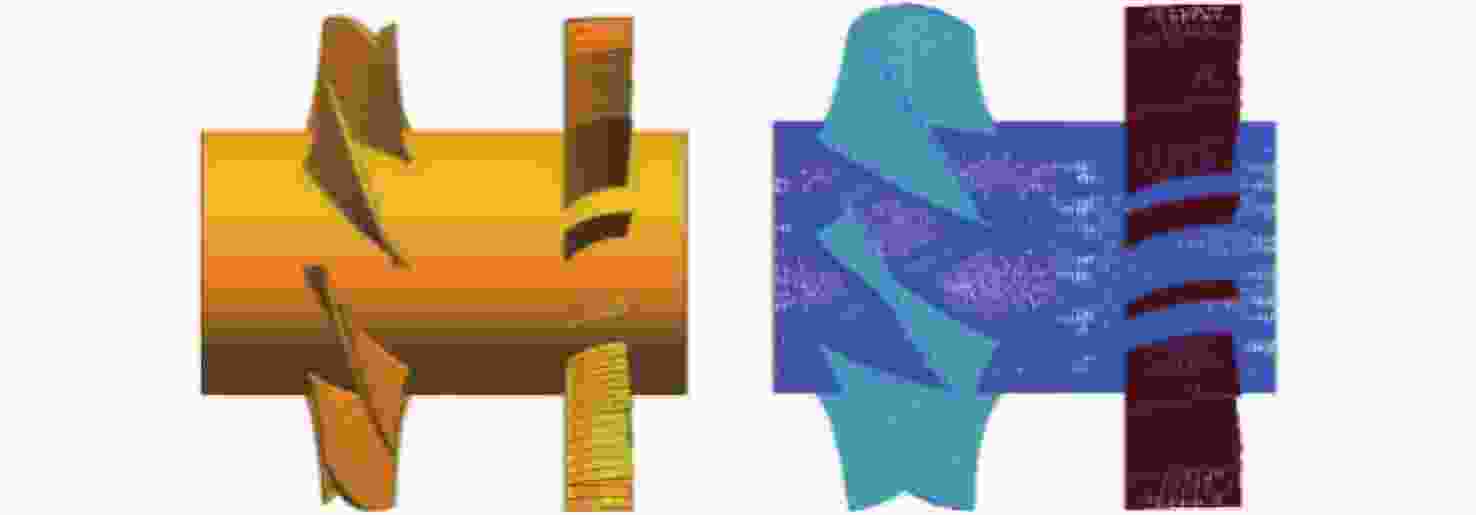

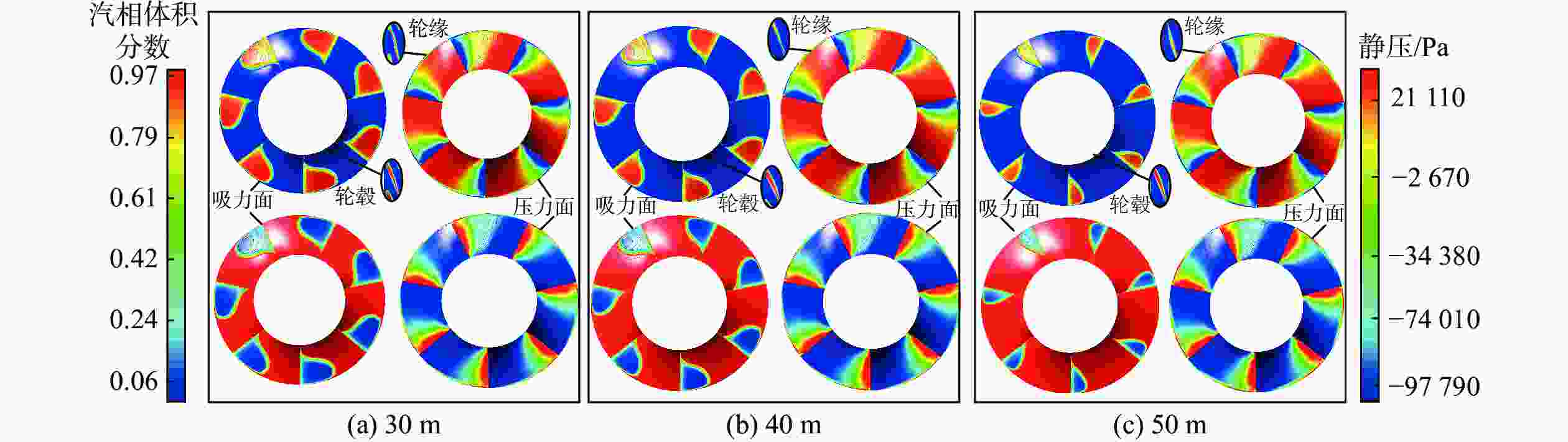

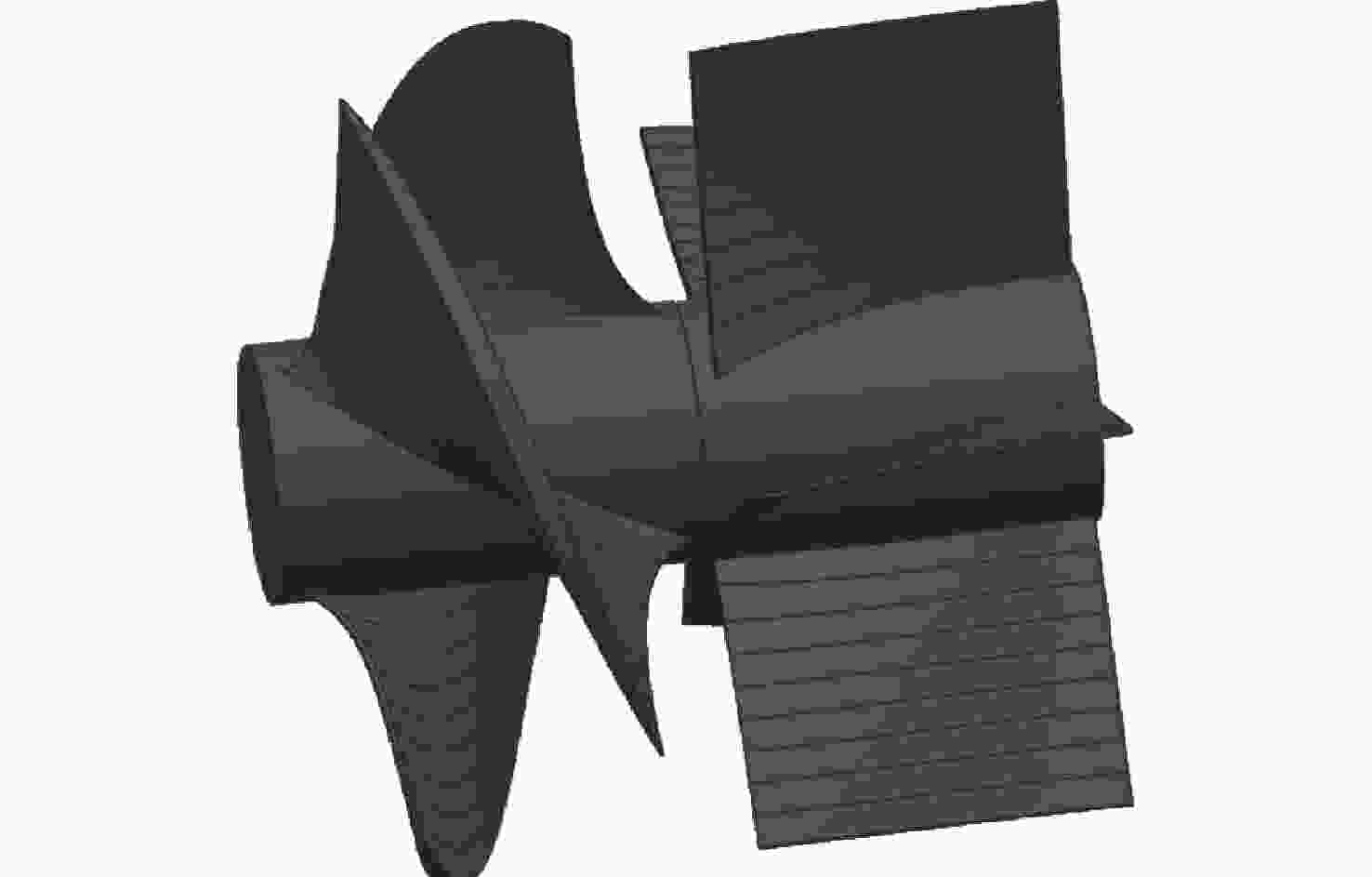

摘要: 对于水下航行器轴流泵喷水推进系统, 现有升力法设计的高比转速轴流泵无法满足在浅水高速工况下正常工作的需求, 为解决这一问题, 提出一种针对低比转速轴流泵的设计方法。考虑所选NACA66a=0.8翼型的叶栅特性, 通过改变攻角和升力系数等参数的设计关系,建立适用于高航速工况的轴流泵模型, 并运用SST k-ω 湍流模型和多重参考系模型对设计泵的流场运动情况进行仿真。结果表明: 设计工况下, 设计泵的扬程和水力效率与设计值误差均控制在8%以内, 同时测试了设计泵在不同水深下的抗空化性能, 进一步探索设计泵工作的最小航深。Abstract: For the axial flow pumps water-jet propulsion system of undersea vehicles, the high specific speed axial flow pump designed by the lift method fails to work under shallow water and high-speed conditions at present. Therefore, this study put forward a method to design a low specific speed axial flow pump. By considering the blade grid characteristics of the NACA66a=0.8 airfoil, the design relationship among the angle of attack, lift coefficient, and other parameters was changed to establish an axial flow pump model suitable for high-speed conditions, and SST k-ω turbulence model and multi-reference frame model were used to simulate the flow field motion of the designed pump. The results show that under the design conditions, for the head and hydraulic efficiency of the designed pump, the error between the design value and the emulation value is controlled within 8%. At the same time, the cavitation resistance of the designed pump at different depths is tested to explore the minimum depth where the designed pump can work.

-

Key words:

- highspeed undersea vehicle /

- axial flow pump /

- shallow water /

- water-jet propulsion

-

表 1 实验泵在标况下的网格无关性验证

Table 1. Verification of grid independence of experimental pumps under standard conditions

工况类型 网格数目 仿真扬程/m Q/Qd=1 $1.0\times {10}^{6}$ 2.96 $ 2.7\times {10}^{6} $ 2.91 $ 4.5\times {10}^{6} $ 3.06 表 2 常规升力法叶轮各截面部分设计参数

Table 2. Design parameters of each section of impeller by the conventional lift method

参数 r1 r2 r3 r4 r5 r6 r7 r8 r9 r10 截面半径/m 0.04 0.04 0.05 0.05 0.06 0.06 0.06 0.07 0.07 0.08 几何平均速度/(m/s) 37.50 42.70 47.90 53.00 58.00 63.00 68.00 72.90 77.80 82.60 翼型安放角/(°) 0.61 0.53 0.47 0.42 0.38 0.34 0.31 0.29 0.27 0.25 叶栅稠密度 1.22 1.16 1.12 1.09 1.08 1.06 1.05 1.04 1.04 1.03 升阻比 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 升力系数 1.17 0.99 0.84 0.72 0.62 0.54 0.47 0.42 0.37 0.33 攻角/(°) 15.90 13.50 11.50 10.00 8.70 7.60 6.80 6.00 5.40 4.90 翼型相对拱度 0.03 0.03 0.02 0.02 0.02 0.01 0.01 0.01 0.01 0.01 水力效率 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 表 3 改进升力法叶轮各截面部分设计参数

Table 3. Design parameters of each section of impeller by the improved conventional lift method

参数 r1 r 2 r 3 r 4 r 5 r 6 r 7 r 8 r 9 r 10 截面半径/m 0.04 0.04 0.05 0.05 0.06 0.06 0.06 0.07 0.07 0.08 几何平均速度/(m/s) 37.50 42.70 47.90 53.00 58.00 63.00 68.00 72.90 77.80 82.60 翼型安放角/(°) 27.10 23.60 20.90 18.80 17.10 15.80 14.60 13.60 12.70 12.00 叶栅稠密度 1.24 1.17 1.13 1.10 1.08 1.06 1.05 1.05 1.04 1.03 升阻比 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 0.04 升力系数 1.15 0.98 0.83 0.71 0.62 0.54 0.47 0.42 0.37 0.33 攻角/(°) 9.32 7.79 6.55 5.56 4.78 4.16 3.67 3.28 2.96 2.71 翼型相对拱度 0.02 0.02 0.02 0.01 0.01 0.01 0.01 0.01 0.01 0.01 水力效率 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 表 4 导叶各截面部分设计参数

Table 4. Design parameters of each section of the guide vane

参数 r1 r2 r3 r4 r5 r6 r7 r8 r9 r10 截面半径/m 0.04 0.04 0.05 0.05 0.06 0.06 0.06 0.07 0.07 0.08 导叶弦长/m 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 进口液流角/(°) 32.8 35.20 37.50 39.70 41.70 43.60 45.40 47.10 48.70 50.20 骨线圆弧半径/m 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 0.02 流道扩散角/(°) 29.00 29.40 29.60 29.50 29.30 29.00 28.60 28.10 27.50 26.90 表 5 低比转速设计泵设计值和仿真值对比表

Table 5. Comparison of low specific speed designed pump design value and simulation value

设计值 仿真值 相对误差 扬程 128 m 125 m 2.34% 效率 88.3% 81.53% 7.66% 表 6 轴流泵空化面积量化表

Table 6. Cavitation area quantification table of axial flow pump

水深/m 叶轮面积/m2 叶轮空化面积/m2 面积占比 30 0.028 0.005 0.193 40 0.028 0.005 0.183 50 0.028 0.004 0.148 -

[1] 杨卫国, 汲国瑞, 蔡佑林. 前置导叶喷水推进轴流泵设计方法[J]. 舰船科学技术, 2020, 42(6): 44-49.Yang Weiguo, Ji Guorui, Cai Youlin. Research on design method of water jet propulsion axial-flow pump with front guide vane[J]. Ship Science and Technology, 2020, 42(6): 44-49. [2] 苑龙飞, 罗凯, 蒋彬, 等. 喷水推进系统在浅水高速工况下适应性问题的数值分析[J]. 水动力学研究与进展A辑, 2016, 31(2): 225-231.Yuan Longfei, Luo Kai, Jiang Bin, et al. Numerical analysis of a waterjet propulsion systerm’s adaptability on the condition of shallow water[J]. Chinese Journal of Hydrodynamics, 2016, 31(2): 225-231. [3] Zhang R, Chen H X. Numerical analysis of cavitation within slanted axial-flow pump[J]. Journal of Hydrodynamics, 2013, 25(5): 663-672. doi: 10.1016/S1001-6058(13)60411-4 [4] 曹玉良, 王永生, 靳栓宝. 喷水推进轴流泵三元水力设计[J]. 交通运输工程学报, 2015, 15(2): 42-49. doi: 10.3969/j.issn.1671-1637.2015.02.007Cao Yuliang, Wang Yongsheng, Jin Shuanbao. Three-dimensional hydraulic design of axial waterjet pump[J]. Hournal of Traffic and Transportation Engineering, 2015, 15(2): 42-49. doi: 10.3969/j.issn.1671-1637.2015.02.007 [5] Shi L, Zhu J, Tang F, et al. Multi-disciplinary optimization design of axial-flow pump impellers based on the approximation model[J]. Energies, 2020, 13(4): 779. doi: 10.3390/en13040779 [6] 曹卫东, 张骞, 徐玉敏. 高速潜水轴流泵大流量工况的空化特性[J]. 水利水电科技进展, 2021, 41(1): 55-61,79. doi: 10.3880/j.issn.1006-7647.2021.01.009Cao Weidong, Zhang Qian, Xu Yumin. Cavitation characteristics of high-speed submersible axial-flow pump in high flow condition[J]. Advances in Science and Technology of Water Resources, 2021, 41(1): 55-61,79. doi: 10.3880/j.issn.1006-7647.2021.01.009 [7] 彭凯. 轴流泵顶隙涡的数值模拟研究[J]. 水动力学研究与进展A辑, 2018, 33(6): 685-688.Peng Kai. Numerical investigation of tip leakage vortex in axial-flow pump[J]. Chinese Journal of Hydrodynamics, 2018, 33(6): 685-688. [8] 袁建平, 范猛, Pace G, 等. 高比转速轴流泵正交优化设计研究[J]. 振动与冲击, 2018, 37(22): 115-121.Yuan Jianping, Fan Meng, Pace G, et al. Orthogonal optimum design method for high specific-speed axial-flow pumps[J]. Journal of Vibration and Shock, 2018, 37(22): 115-121. [9] Gerakopulos R, Boutilier M, Yarusevych S. Aerodynamic characterization of a NACA 0018 airfoil at low reynolds numbers[C]//Fluid Dynamics and Co-located Conference. Reston: American Institute of Aeronautics and Astronautics, 2010. [10] 关醒凡. 现代泵理论与设计[M]. 北京: 中国宇航出版社, 2010. [11] 杨从新, 王玲, 杨焘. 导叶叶片厚度对核主泵性能的影响[J]. 兰州理工大学学报, 2019, 45(2): 45-50. doi: 10.3969/j.issn.1673-5196.2019.02.008Yang Congxin, Wang Ling, Yang Tao. Effect of guide vane thickness on performance of nuclear mean pump[J]. Journal of Lanzhou University of Technology, 2019, 45(2): 45-50. doi: 10.3969/j.issn.1673-5196.2019.02.008 [12] 李忠, 杨敏官, 姬凯, 等. 轴流泵叶顶间隙空化流可视化实验研究[J]. 工程热物理学报, 2011, 32(8): 1315-1318.Li Zhong, Yang Minguan, Ji Kai, et al. Visualization research on cavitating flow in tip clearance of axial-flow pump[J]. Journal of Engineering Thermophysics, 2011, 32(8): 1315-1318. [13] 吴子娟, 侯聪, 梁武科, 等. 叶片安装角对轴流泵空化性能的影响[J]. 水动力学研究与进展A辑, 2020, 35(3): 277-284.Wu Zijuan, Hou Cong, Liang Wuke, et al. Effect of blade installation angle on cavitation performance of axial flow pump[J]. Chinese Journal of Hydrodynamics, 2020, 35(3): 277-284. -

下载:

下载: